Machining method of high-abrasion resistance valve core

A processing method and high wear resistance technology, applied in the field of mechanical processing, can solve the problems of high performance of control valves and failure of normal operation of control valves, etc., and achieve the effect of stable quality and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

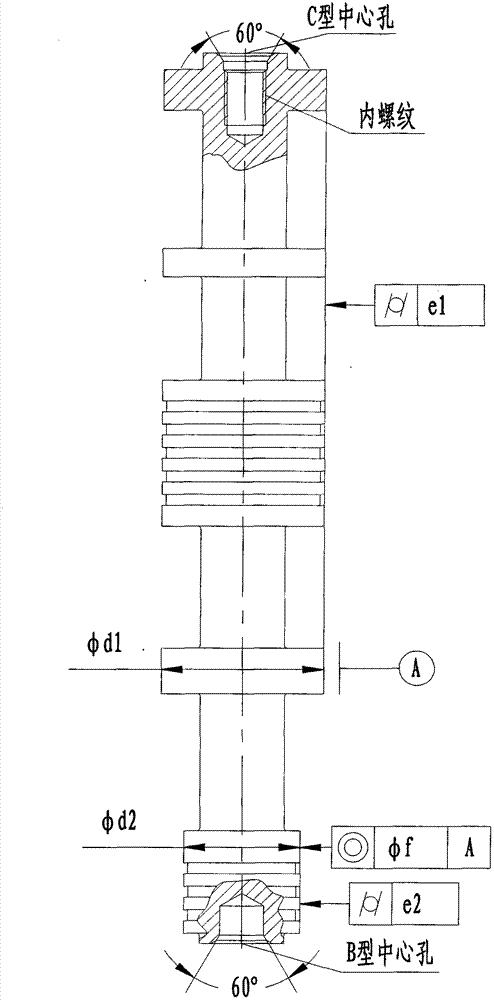

[0016] Embodiments of the present invention: with figure 1 Take this as an example.

[0017] 1. Material preparation: choose 6A02-T6GB / T3191-1998 aluminum alloy bar.

[0018] 2. Turning processing:

[0019] (1) The outer circle φd2 end of the hard three-jaw clamp, turn one end face, drill, turn the center hole and the threaded hole, the tailstock thimble presses against the center hole, rough turn the outer circle φd1, and leave a margin.

[0020] (2) The outer circle of the soft three-jaw clamp is φd1 at the end of the car, and the center hole is drilled at the other end of the car, the tailstock thimble is pressed against the center hole, and the outer circle of the rough car is φd2, leaving a margin.

[0021] (3) The soft three-claw clamps the outer circle φd1, the tailstock thimble pushes against the center hole, semi-finishes the outer circle φd2, leaves the margin for finishing turning on the outer circle, and turns the ring groove of the φd2 section to the requirement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com