Halogen-free flame-retardant ethylene-propylene-diene monomer rubber for sealing strips, and preparation method thereof

A technology of EPDM rubber and sealing strip, applied in the rubber field, can solve the problems of non-reuse, unfavorable health, strong smell, etc., and achieve the effects of long service life, fast vulcanization speed and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

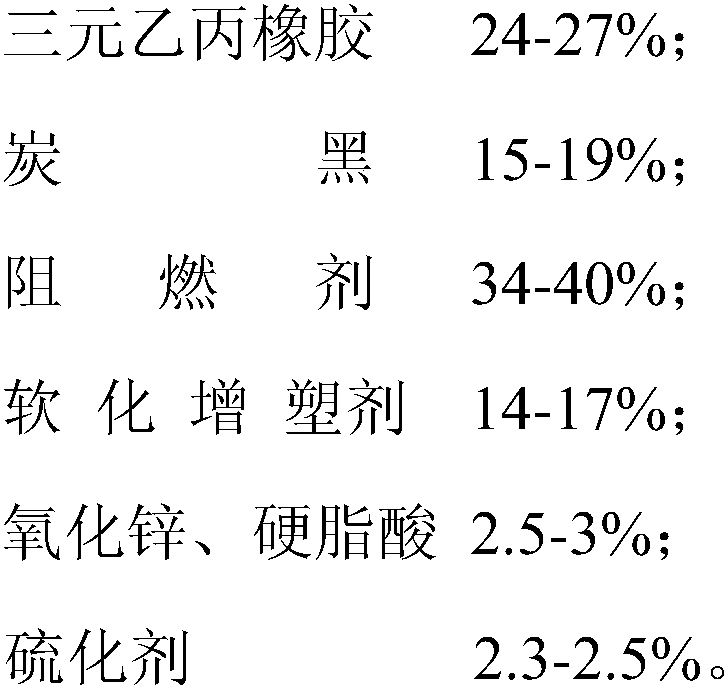

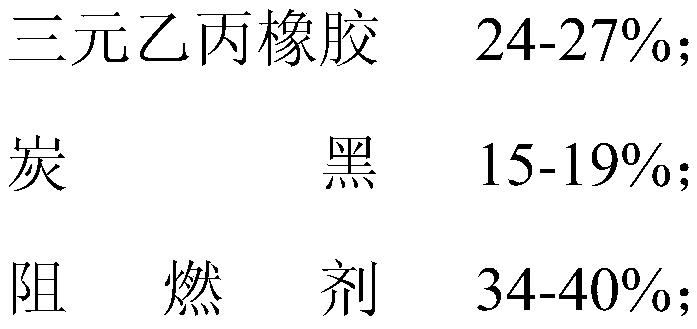

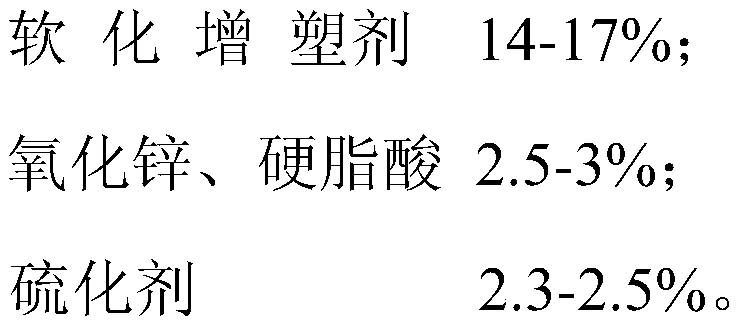

[0029] The production of EPDM rubber for halogen-free flame-retardant sealing strips in Examples 1-7 was carried out according to the composition ratio in Table 1.

[0030] According to the following steps, the EPDM rubber used for the halogen-free flame-retardant sealing strip of the present invention is manufactured:

[0031] (1) Raw material preparation: According to the ingredients and proportions in Table 1, weigh EPDM rubber, carbon black, flame retardant, softening plasticizer, and activator respectively and mix them to form ingredient A, and weigh the vulcanizing agent form ingredient B;

[0032] (2) The first mixing: Put ingredient A into the internal mixer for 60-90 seconds, lift the hammer to clean, then press the hammer to mix for 60-90 seconds, lift the hammer to clean again (temperature 140-150°C), and then press the hammer Mix for 60-80 seconds and unload (temperature 150-170°C) to the cutting machine to discharge the sheet to make the mixed rubber A;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com