Sludge baking-free brick and preparation method thereof

A technology of avoiding burning bricks and silt, which is applied in the field of environmental engineering and geotechnical engineering, can solve the problems of high energy consumption in the production of solid clay bricks, can not reflect the superiority, and poor thermal insulation performance, so as to save earth and stone resources and highlight environmental benefits , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A non-burning silt brick, including the following components and the mass percentage content of each component: dredged silt (deducting moisture): 28%; fly ash: 45%; quicklime: 18%; raw gypsum: 8%; Ammonium nitrate: 0.3%; zinc chloride: 0.4%; sodium silicate: 0.15%; chlorine salt series antifreeze: 0.15%.

[0030] The water content of the dredged sludge is 80%. When weighing the dredged sludge, the corresponding water must be deducted. The added amount of antifreeze is suitable for use in winter in cold areas.

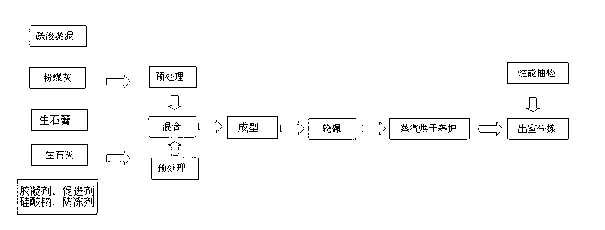

[0031] figure 1 It is a flow chart of the method for preparing silt-free burnt bricks according to the present invention.

[0032] Such as figure 1 As shown, a method for preparing silt-free burnt bricks is carried out as follows:

[0033] (1) According to the raw materials of the dredged silt free-burning brick according to claim 1, each component is weighed, stirred until the mixture is uniform, and rolled.

[0034] (2) Feed the raw materials crushed by the wheel to t...

Embodiment 2

[0040] A non-burning silt brick includes the following components and the mass percentages of each component: dredged silt (deducted moisture): 34%; fly ash: 40%; quicklime: 20%; raw gypsum: 5%; Ammonium nitrate: 0.35%; zinc chloride: 0.3%; sodium silicate: 0.1%.

[0041] The water content of the dredged sludge is 80%. When weighing the dredged sludge, the corresponding water must be deducted.

[0042] The preparation method of the dredged silt-free brick in Example 2 is the same as that in Example 1.

Embodiment 3

[0044] A non-burning silt brick, including the following components and the mass percentages of each component: dredged silt (deducted moisture): 40%; fly ash: 35%; quicklime: 16%; raw gypsum: 6.5%; Zinc nitrate: 0.45%; zinc chloride: 0.2%; sodium silicate: 0.1%; chlorine salt series antifreeze: 0.2%.

[0045] The water content of the dredged sludge is 80%. When weighing the dredged sludge, the corresponding water must be deducted. The added amount of antifreeze is suitable for use in winter in cold areas.

[0046] The preparation method of the dredged silt-free brick in Example 3 is the same as the preparation method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com