Cold spinning belt pulley and fabricating method and fabricating equipment thereof

A manufacturing method and technology of pulleys, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problem that welding filler affects the balance performance of pulleys, affects the stability of use performance, and is difficult to eliminate shrinkage internal stress, etc. problem, to achieve the effect of light weight, beautiful appearance and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

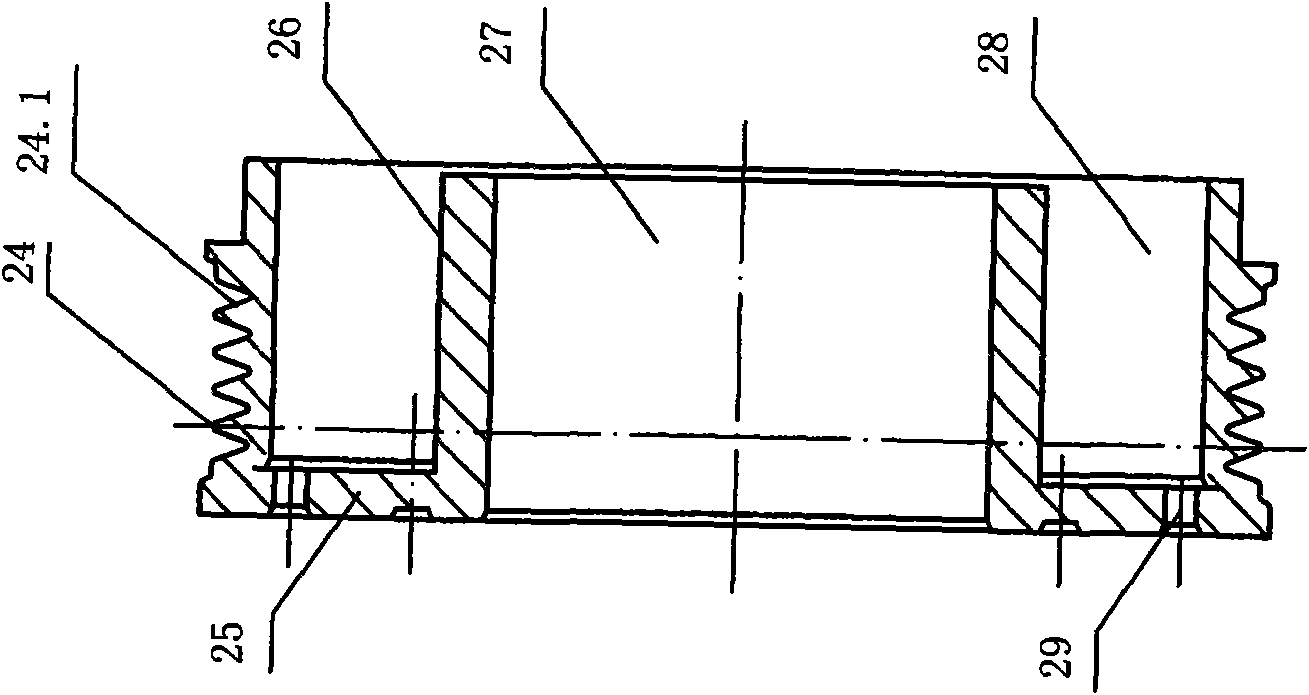

[0015] Such as figure 1 As shown, as an embodiment of the present invention is a single-stage coaxial multi-ribbed pulley, including a wheel rim 24, a wheel spoke 25 and a wheel hub 26, and a plurality of multi-ribbed V-shaped grooves 24.1 are opened on the wheel rim 24, The effective diameter center of each V-shaped groove 24.1 is concentric with the shaft hole 27 center of the wheel hub 26, and each V-shaped groove 24.1 is left-right symmetrical, and its center line is perpendicular to the central axis of the wheel hub 26. The wheel rim 24, the spoke 25 and the wheel hub 26 There is an annular groove 28 between the three, and there are several arc grooves 29 on the spoke 25. The rim 24, the spoke 25 and the hub 26 are integrally formed by cold spinning of steel plates on a spinning machine. In this embodiment, the groove pitch of the V-shaped groove 1.1 is 3.65±0.05mm, and the groove angle is 40°±0.5°.

[0016] The single-stage coaxial multi-ribbed pulley of the above embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com