Method for repairing wear of inner wall of intermediate casing of engine

A wear repair and engine technology, applied in the direction of coating, metal material coating process, etc., to achieve the effect of satisfying the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

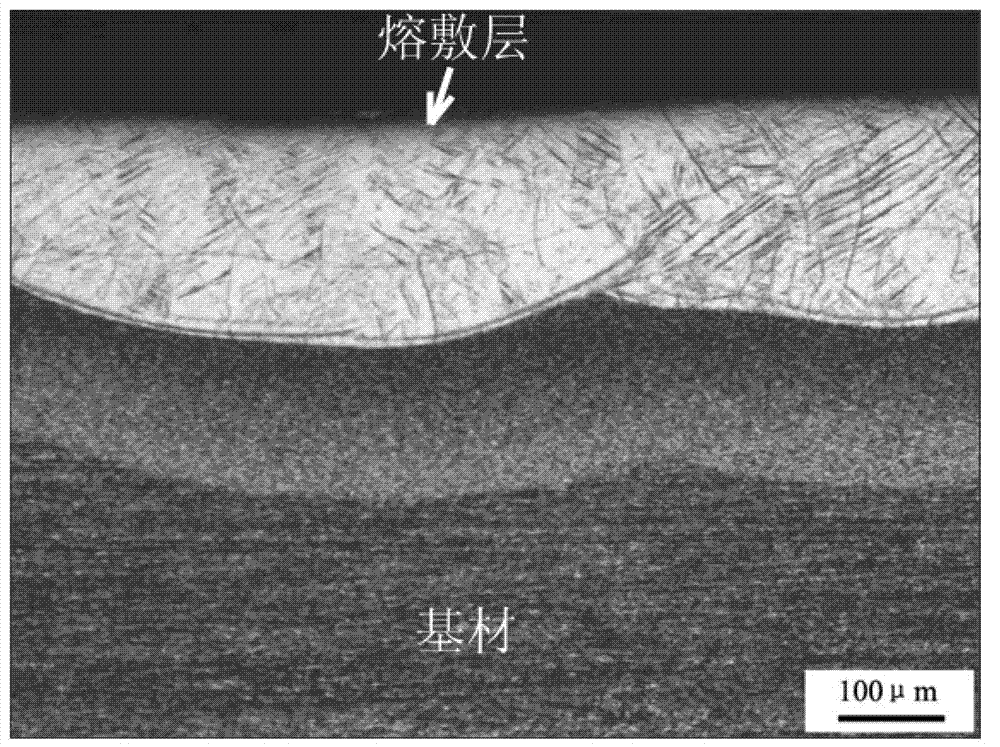

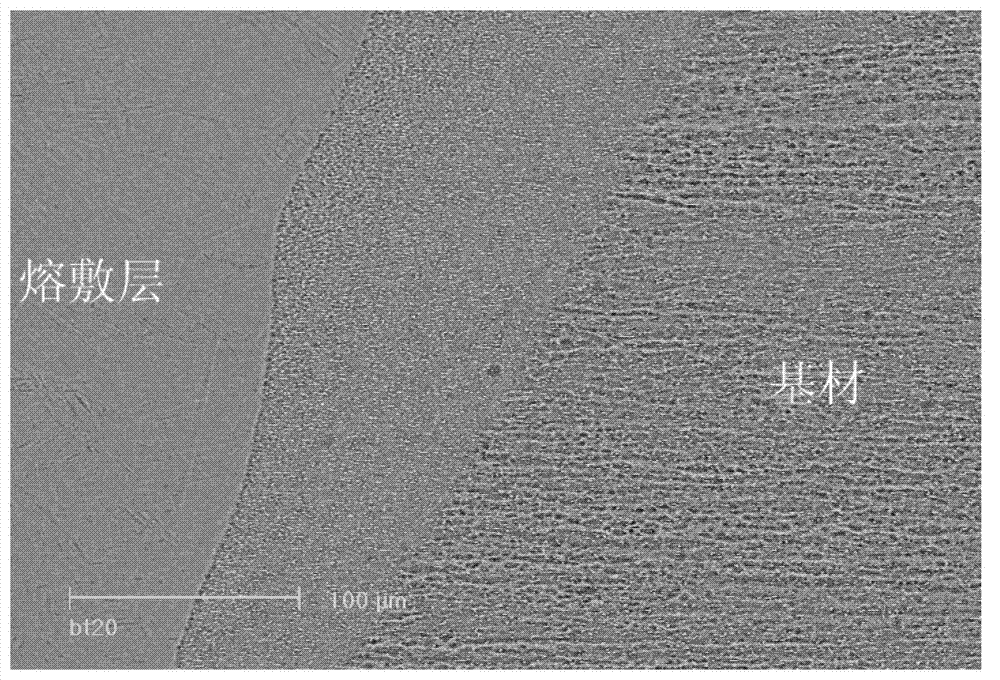

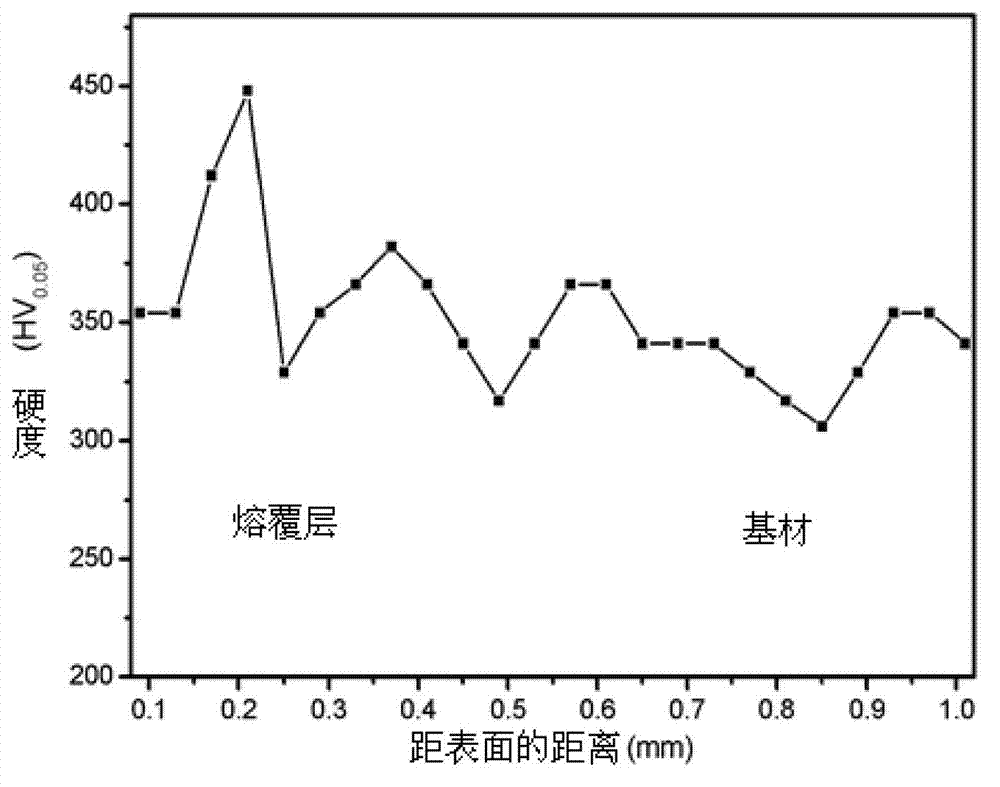

[0018] The material of the intermediate casing is BT20 titanium alloy, and its chemical composition is shown in Table 1. This alloy is a near-α-type titanium alloy with high Al equivalent, the strength level exceeds 930MPa, and the working temperature can reach 500°C. Up to 800°C, and when working at 450°C, the life span can reach 6000h.

[0019] Table 1 Chemical composition of BT20 titanium alloy (wt%)

[0020] Al

Zr

Mo

V

Ti

5.5~7.5

1.5~2.5

0.5~2.0

0.8~1.8

the remaining

[0021] Specific process steps:

[0022] 1) Fault inspection: carry out fault inspection on the intermediate casing, and measure the wear depth (generally, the depth is 0.04-0.1, and 10 places are evenly distributed along the circumference).

[0023] 2) Cleaning before welding: polish the worn parts with emery cloth.

[0024] 3) Make the welding test piece: measure the size of the worn part, select the welding test piece with a thickness of 0.2mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com