Method for repairing high-speed steel cutter by means of laser cladding

A cutting tool and laser cladding technology, which is applied in the field of repairing high-speed steel cutting tools by laser cladding, can solve the problems of difficulty in thread processing, reduce the hardness of the tool body, and the large heat-affected zone of the tool, and achieve the effect of repair and remanufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

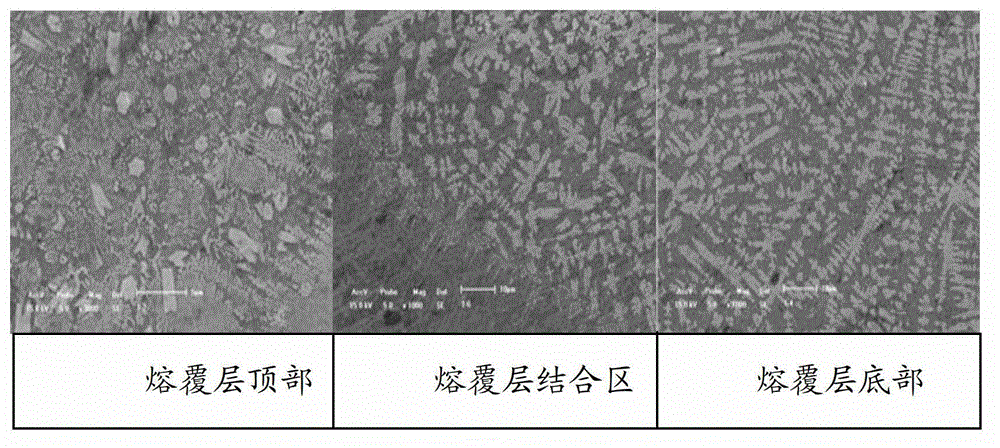

Image

Examples

Embodiment

[0032] The cutting tool is an outer turning tool, and its material is high-speed steel M42. The cladding powder is 325 mesh YG12 cemented carbide powder. The outer turning tool is repaired by laser cladding in a vacuum environment. The implementation steps are as follows:

[0033] 1) Record the original data of the outer circle turning tool, namely: rake angle γ o , relief angle α o , leading angle κ r ;

[0034] 2) Correct the worn part of the tool into a regular geometric shape, remove the oxide layer by grinding, and clean the area to be clad with acetone solution (anhydrous acetone solution, mass fraction ≥ 99.7%);

[0035] 3) Fix the cleaned tool, put it into the vacuum box, and evacuate it. When the vacuum degree is greater than 6×10 -2 Pa filled with argon as protective gas;

[0036] 4) Set the process parameters according to the cladding position (including laser power of 2.2-2.5KW, scanning speed of 2mm / s, spot diameter of 1-3mm, defocus of 20mm;), write the nume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com