Machining method of cylindrical spinning mandrel

A processing method and core pressing technology, applied in the field of mechanical processing, can solve problems such as difficulty in adjusting the margin of machining and heat treatment processes, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

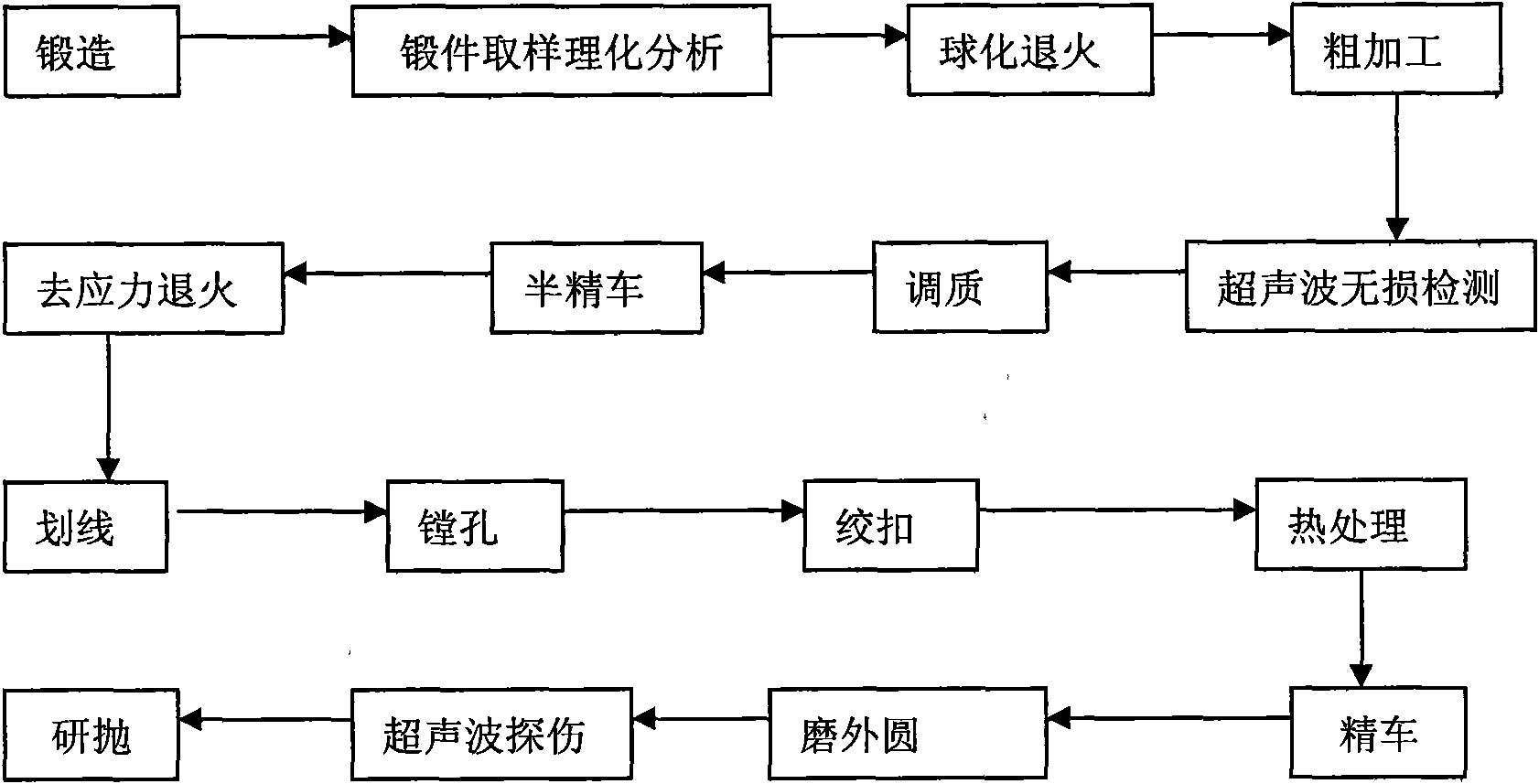

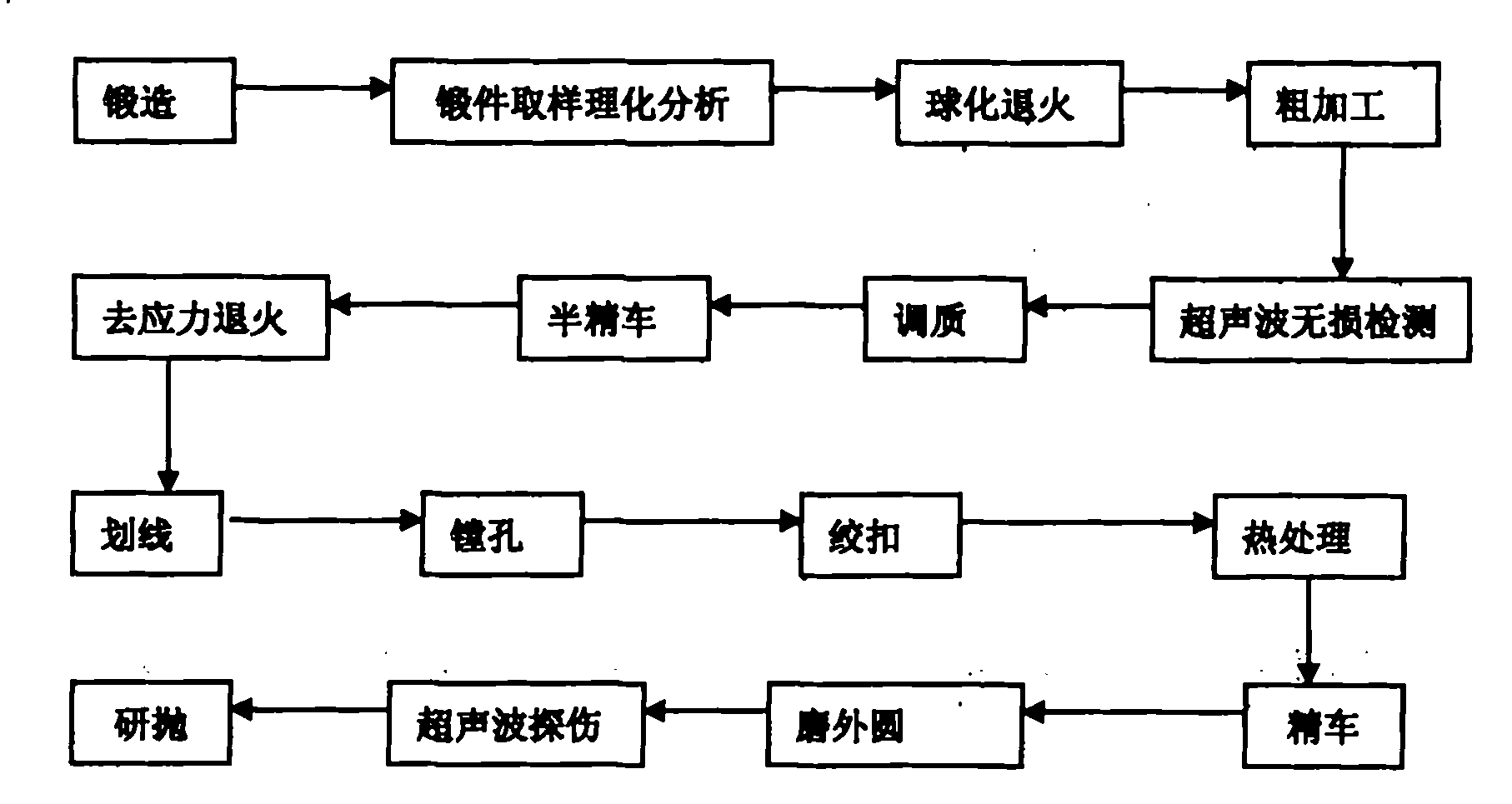

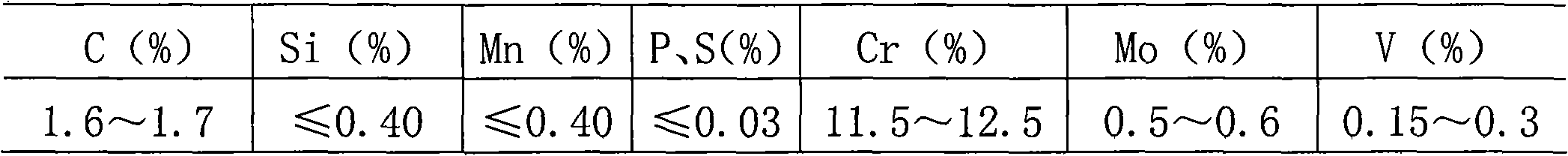

[0027] A processing method for a cylindrical spinning mandrel can be widely used in the manufacture and production of a core component mandrel which is a key equipment mandrel in spinning. Practice has proved that the optimal processing procedure and spheroidizing annealing process can meet the performance requirements of the mandrel and improve the practical life of the product. Best example of the present invention is further described below in conjunction with accompanying drawing:

[0028] The processing process of a cylindrical spinning mandrel is: forging→forging sampling physical and chemical analysis→spheroidizing annealing→rough machining→ultrasonic nondestructive testing→quenching and tempering→semi-finishing turning→stress relief annealing→scribing→boring→reaming Buckle→heat treatment→finish turning→circle grinding→ultrasonic flaw detection→grinding and polishing

[0029] The specific process flow is:

[0030] 1) Forging: The forging blank must be preheated once a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com