Emulsified SBS polymer modified asphalt and preparation method thereof

A technology for modifying asphalt and polymers, applied in building construction, climate change adaptation, building components, etc., can solve the problems of difficult emulsification, difficult product stability, difficult to meet the requirements of road surface temperature, etc. The effect of reducing difficulty, shortening the time to close traffic, and meeting road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The composition of the emulsified SBS polymer modified asphalt of the present invention comprises base asphalt, water, SBS (being butadiene-styrene-butadiene) asphalt modifier, composite asphalt emulsifier, emulsification stabilizer and hydrochloric acid, each composition Weight ratio is: base asphalt: water: SBS asphalt modifier: composite asphalt emulsifier: emulsification stabilizer: hydrochloric acid=48.25%: 47.2%: 1.75%: 2.3%: 0.4%: 0.1%, the consumption purpose of hydrochloric acid is to use Then adjust the pH value of the soap solution to 2.5.

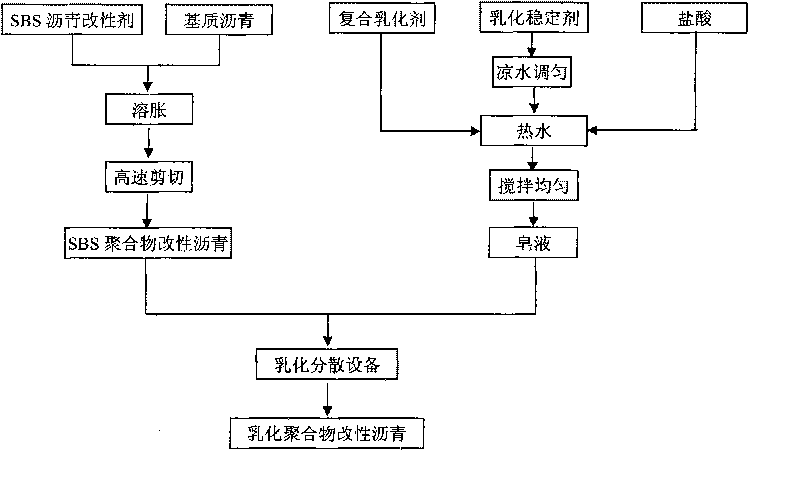

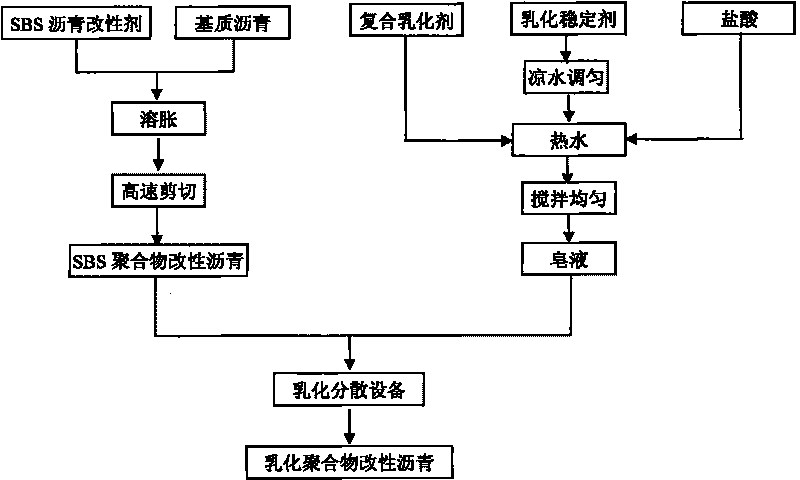

[0013] The preparation method of emulsified SBS polymer modified asphalt of the present invention is:

[0014] A. Preparation of SBS modified asphalt:

[0015] Add 1.75% (according to the mass percentage of emulsified polymer modified asphalt,) of SBS asphalt modifier (Kumho brand SBS asphalt modifier 101) to the base asphalt that has been heated to 170-180°C ( Huanxiling brand heavy traffic No. 90 road asphalt), after ...

Embodiment 2

[0024] The composition of the emulsified SBS polymer modified asphalt of the present invention comprises base asphalt, water, SBS (being butadiene-styrene-butadiene) asphalt modifier, composite asphalt emulsifier, emulsification stabilizer and hydrochloric acid, each composition Weight ratio is: base asphalt: water: SBS asphalt modifier: composite asphalt emulsifier: emulsion stabilizer: hydrochloric acid=52.5%: 42.07%: 2.5%: 2.5%: 0.35%: 0.08%, the consumption purpose of hydrochloric acid is to use Then adjust the pH value of the soap solution to 3.

[0025] The preparation method of emulsified SBS polymer modified asphalt of the present invention is:

[0026] A. Preparation of SBS modified asphalt:

[0027] Add 2.5% (according to the mass percentage of emulsified polymer modified asphalt) of SBS asphalt modifier (SBS asphalt modifier of Korean LG production model 501) to the base asphalt (ESSO Brand Zhongtong Traffic No. 90 road asphalt), after swelling for 20 minutes, it ...

Embodiment 3

[0035] The composition of the emulsified SBS polymer modified asphalt of the present invention comprises base asphalt, water, SBS (being butadiene-styrene-butadiene) asphalt modifier, composite asphalt emulsifier, emulsification stabilizer and hydrochloric acid, each composition Weight ratio is: matrix asphalt: water: SBS asphalt modifier: composite asphalt emulsifier: emulsification stabilizer: hydrochloric acid=60.5%: 33.2%: 2.5%: 3.2%: 0.5%: 0.1%, the consumption purpose of hydrochloric acid is to use Then adjust the pH value of the soap solution to 2.5.

[0036] The preparation method of emulsified SBS polymer modified asphalt of the present invention is:

[0037] A. Preparation of SBS modified asphalt:

[0038] Add 2.5% (according to the mass percentage of base asphalt) of SBS asphalt modifier (the SBS asphalt modifier of Taiwan LCY brand model 3501) to the base asphalt (Tepco brand) that has been heated to 170-180 ° C Heavy traffic No. 90 road asphalt), after swelling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com