Fluorescent powder color wheel base plate with demarcation structures and manufacturing method thereof

A fluorescent pink wheel and fluorescent powder technology, which is applied in the direction of optical elements, optics, and lighting device components used to change the spectral characteristics of emitted light. problem, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

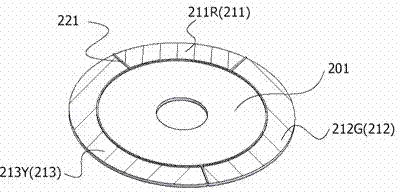

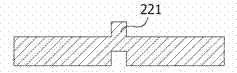

[0036] figure 1Shown is an embodiment of the present invention using a ring-shaped aluminum substrate with a silver-plated film on the surface, and a fluorescent powder layer with a boundary structure fluorescent pink segment boundary structure of the fluorescent pink wheel substrate. By extruding the circular substrate 201 with a diameter of 40 mm, it is separated into a structure with a demarcation effect, and the entire substrate is evenly divided into three independent regions 211 , 212 and 213 . As shown above, the boundary structure 221 is produced by mechanical and chemical methods such as extrusion on the substrate 201, and the width of the sag (ie, the protrusion of the boundary structure 221) in the corresponding phosphor sheet region of the substrate is 0.15mm. The boundary structure 221 The convex cross-section of the substrate is square, with a height of 0.2 mm. The lowest surface of the upper surface of the substrate when placed horizontally is used as a referenc...

Embodiment 2

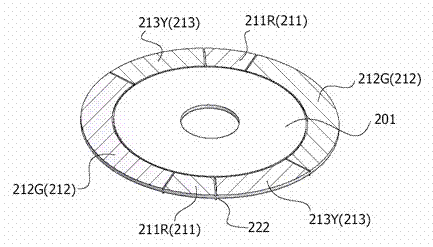

[0039] image 3 Shown is an embodiment of the present invention using a ring-shaped aluminum substrate with a silver-plated film on the surface, and a fluorescent powder layer with a boundary structure fluorescent pink segment boundary structure of the fluorescent pink wheel substrate. By extruding the circular substrate 201 with a diameter of 40 mm, it is separated into a structure with a demarcation effect, and the entire substrate 201 is evenly divided into six independent regions 211 , 212 and 213 and two symmetrical independent regions. As shown above, the boundary structure 222 is produced by mechanical and chemical methods such as extrusion on the substrate 201. The width of the protrusion (that is, the depression of the boundary structure 222) of the phosphor sheet area corresponding to the substrate is 0.2mm, and the boundary structure The concave cross-section of 222 is arc-shaped, with a height of -0.2mm, and the lowest surface of the upper surface of the substrate ...

Embodiment 3

[0042] Figure 5 Shown is an embodiment of the present invention using a ring-shaped aluminum substrate with a silver-plated film on the surface, and a fluorescent powder layer with a boundary structure fluorescent pink segment boundary structure of the fluorescent pink wheel substrate. By extruding the circular substrate 201 with a diameter of 40 mm, it is separated into a structure with a demarcation effect, and the entire substrate 201 is divided into two areas, one of which is concave. For reflective areas of the substrate (ie no machining and fluorescent pink segment coating). As shown above, the boundary structure 222 is produced by mechanical and chemical methods such as extruding the substrate. The concave width of the phosphor layer area corresponding to the substrate is 5 mm, and the concave cross section of the boundary structure 222 is square, and the height is - 0.18mm, taking the lowest surface of the upper surface of the substrate when it is placed horizontally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com