Red-mud coal ash baking-free brick

A technology for fly ash and non-burning bricks, which is applied in the field of building materials, can solve problems such as environmental pollution, and achieve the effects of obvious economic benefits, improved compressive strength, and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The weight percent of its raw materials and the amount added (all ingredients are the dry material ratio of various raw materials) red mud 40, fly ash 29, aggregate 20, quicklime 10, quick gypsum 1; in the aggregate, coarse sand 10, crushed Gravel 10.

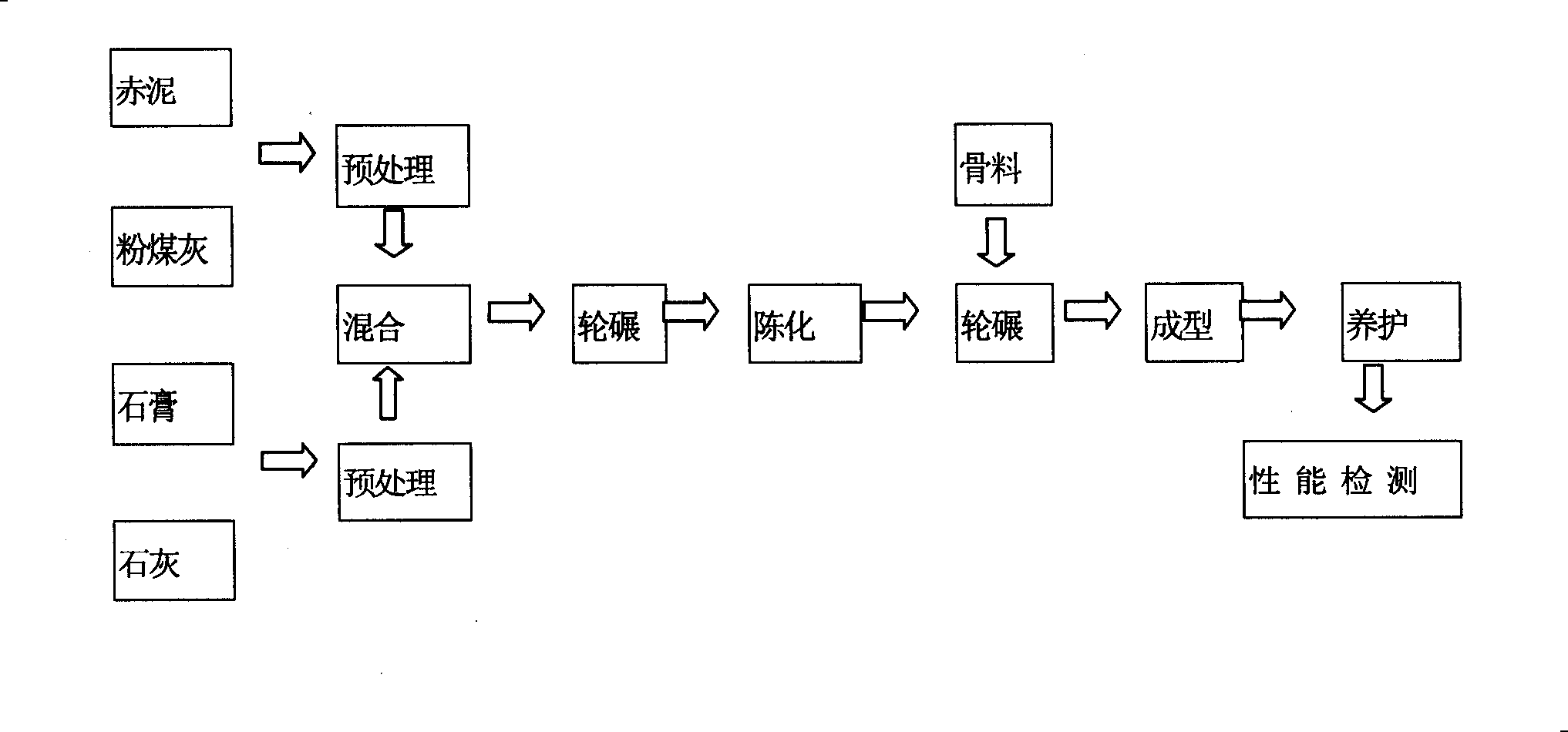

[0024] Its production process is as attached figure 1 Shown: After the above raw materials (except aggregate) are added and mixed in proportion, among them, the red mud is a wet material (about 45% of water content, and the weight is calculated after deducting the water when batching), and the others are dry materials; Chemicalization (cover the uniformly mixed material tightly with plastic cloth and let it stand for a certain period of time), add aggregate, and then roll grinding, molding (the prepared material contains 10-14% water content and is directly pressurized by a brick press), curing , to obtain products, wherein the aging time is controlled at about 24 hours, and the molding pressure is 20Mpa. According to ...

Embodiment 2

[0026] The weight percent of its raw materials and added amount (all ingredients are the dry material ratio of various raw materials) red mud 30, fly ash 20, aggregate 40, quicklime 8, quick gypsum 2; among its aggregates, coarse sand 10, crushed Gravel 30.

[0027] Its production process is the same as that of Example 1. As a result of testing, the 7d strength is 26.68Mpa, and the 28d strength is 28.90Mpa.

Embodiment 3

[0029] The weight percent of its raw materials and addition amount (all ingredients are the dry material ratio of various raw materials) red mud 22, fly ash 33, aggregate 30, quicklime 12, quick gypsum 3. Among its aggregates, there are 5 coarse sand and 25 crushed gravel.

[0030] Its production process is the same as that of Example 1. As a result of testing, the 7d strength is 23.41Mpa, and the 28d strength is 29.50Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com