Fe-Mn-Al-C series high-strength low-density steel and preparation method thereof

A fe-mn-al-c, low-density steel technology, applied in the field of Fe-Mn-Al-C high-strength low-density steel and its preparation, can solve the problems of deteriorated plasticity, reduced formability, difficult springback detection and Control and other issues to achieve the effect of improving strength and elongation and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

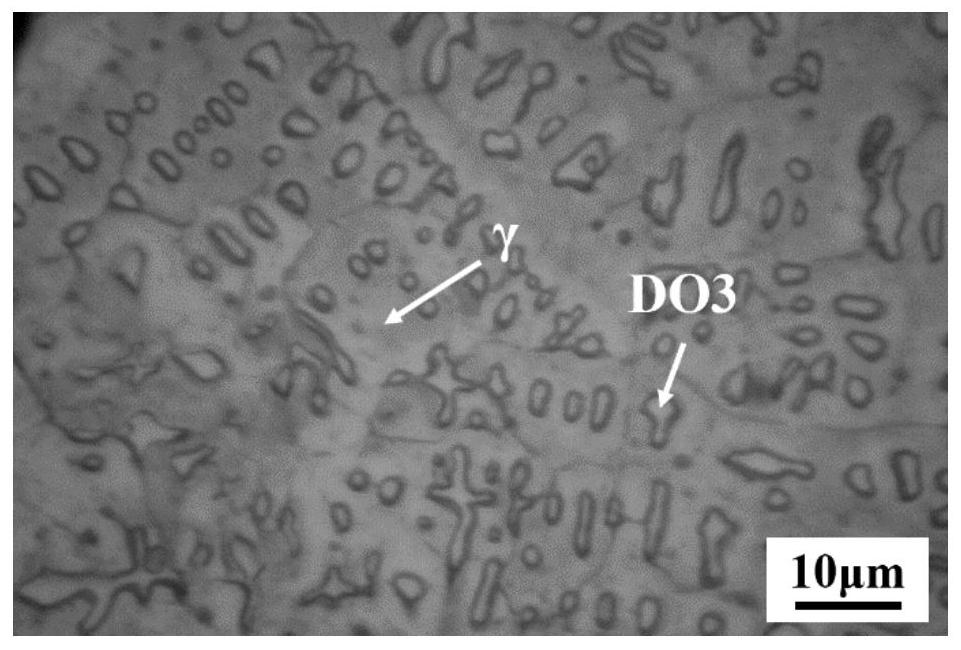

Image

Examples

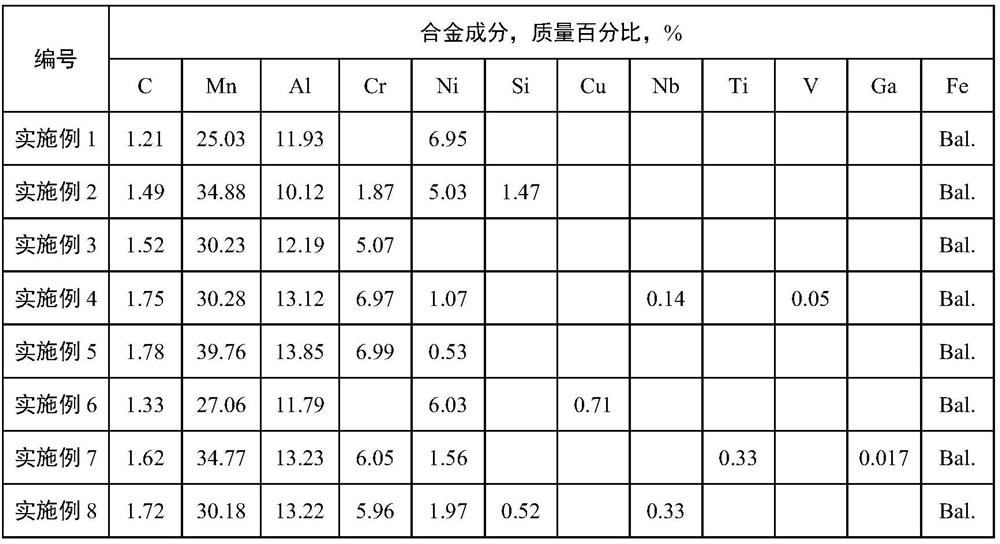

Embodiment 1

[0024] A method for preparing Fe-Mn-Al-C-based high-strength low-density steel in this embodiment, the high-strength low-density steel includes the following elemental components in mass percentages: C 1.21%, Mn 25.03%, Al 11.93 %, Ni 6.95%, and the balance is Fe. Concrete preparation method is as follows:

[0025] (1) Smelting: smelting the raw materials of high-strength low-density steel through induction melting furnace;

[0026] (2) solidification casting: the molten steel obtained in the step (1) is injected into a mould, and an ingot is produced by die casting;

[0027](3) Thermal processing (forging / rolling): the ingot obtained in step (2) is opened and then heated and kept for 1 hour at a temperature of 1050°C. After the heat preservation is over, the ingot is forged with a forging machine. The forging ratio is 2. After the forging is completed, it is air-cooled to room temperature. The forging temperature is always kept within the temperature range of 1000-1100 °C. ...

Embodiment 2

[0030] A method for preparing Fe-Mn-Al-C high-strength low-density steel in this embodiment, the high-strength low-density steel includes the following elemental components in mass percentages: C 1.49%, Mn 34.88%, Al 10.12 %, Ni 5.03%, Cr1.87%, Si 1.47%, and the balance is Fe. The specific preparation method is as follows:

[0031] (1) Smelting: smelting the raw materials of high-strength and low-density steel through a converter;

[0032] (2) solidification casting: the molten steel obtained in the step (1) is injected into the mould, and continuous casting is adopted to produce a slab;

[0033] (3) Hot forging: the cast slab obtained in step (2) is opened and heated for 5 hours, and the heat preservation temperature is 1200°C. After the heat preservation is over, use a forging machine to forge the billet. The forging ratio is 3. After the forging is completed, it is air-cooled to room temperature. The forging temperature is always kept within the temperature range of 1000-1...

Embodiment 3

[0037] A method for preparing Fe-Mn-Al-C high-strength low-density steel in this embodiment, the high-strength low-density steel includes the following elemental components in mass percentages: C 1.52%, Mn 30.23%, Al 12.19 %, Cr 5.07%, and the balance is Fe. The specific preparation method is as follows:

[0038] (1) Smelting: Smelting raw materials of high-strength and low-density steel through an electric furnace;

[0039] (2) solidification casting: the molten steel obtained in the step (1) is injected into a mould, and an ingot is produced by die casting;

[0040] (3) Thermal processing (forging / rolling): the ingot obtained in step (2) was opened and then heated and kept for 8 hours at a temperature of 1150°C. After the heat preservation is over, the ingot is forged with a forging machine. The forging ratio is 2.4. After the forging is completed, it is air-cooled to room temperature. The forging temperature is always kept within the temperature range of 1000-1100 °C. Reh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com