Low temperature resistant daiamid hot melt adhesive with high air tightness and application thereof

A polyamide hot-melt adhesive and hermetic sealing technology, which is applied in the direction of adhesives, etc., can solve the problems of unguaranteed flexibility and gas-holding performance, unsatisfactory low-temperature resistance and gas-holding performance, and poor product stability. Good low temperature resistance, stable product performance, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

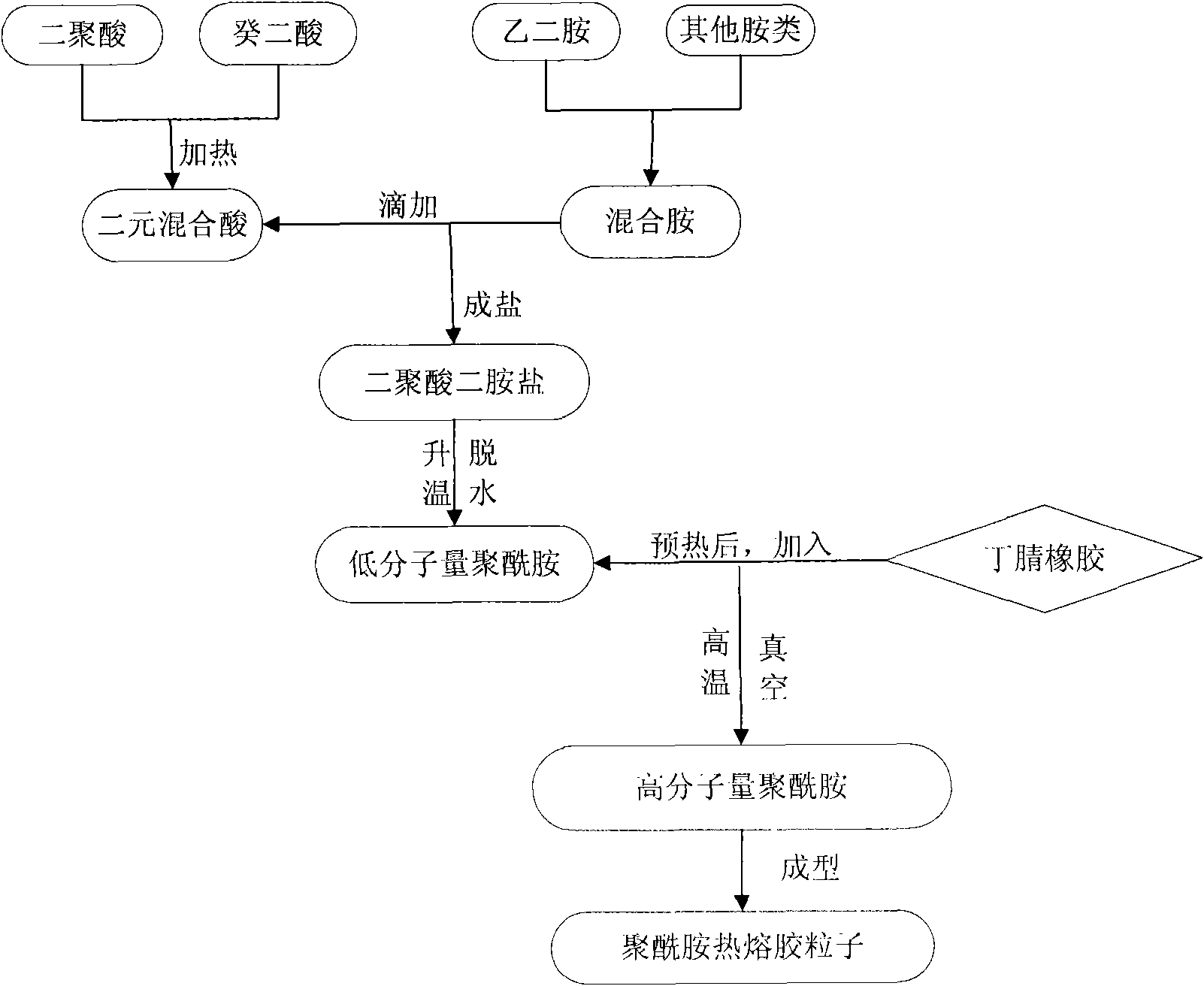

Method used

Image

Examples

Embodiment

[0054] The following examples are used to further illustrate the present invention, but it should be understood that these examples cannot be used to limit the protection scope of the present invention.

[0055] In the following examples, the performance parameters of the polyamide hot-melt adhesive of the present invention were determined as follows.

[0056] Softening point test:

[0057] On the SYP4202-I asphalt softening point tester, the test is carried out according to the standard GB / T 15332-94.

[0058] Melt viscosity test:

[0059] The melt viscosity of the sample was tested by a Brookfield DV-E rotary viscometer, and 8.0g of polyamide hot melt adhesive sample was weighed. During the test, the rotor model S27 was selected, the temperature was controlled at 200 °C, and the rotational speed was constantly adjusted to make it The test value is within the linear range of 10% to 90%, and the measured value is recorded after stabilization.

[0060] Determination of acid ...

Embodiment P1

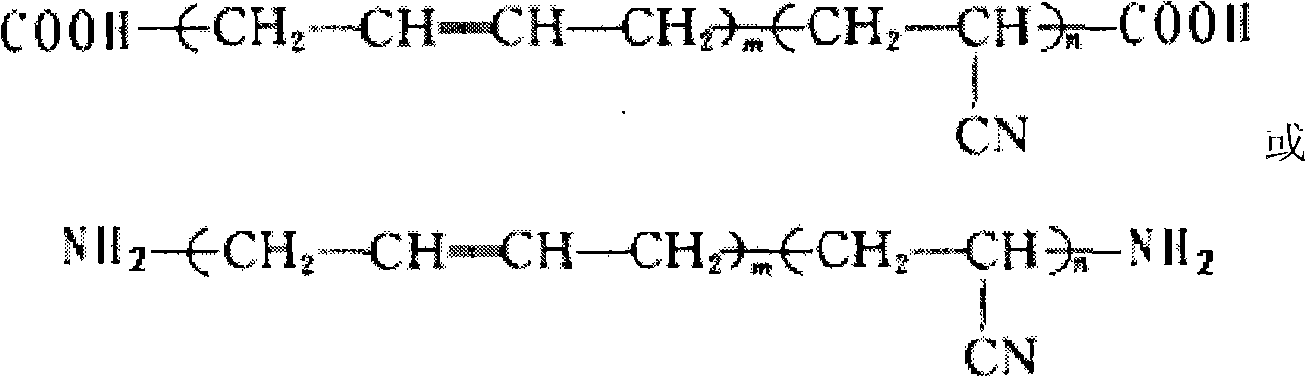

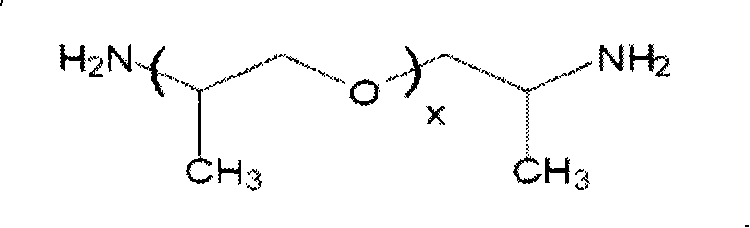

[0090] Add 286.9 grams of dimerized linoleic acid (British Croda Company, Pripol 1013, 95% dimeric acid content) and 6.1 grams of decane in a 1000ml reaction flask with a thermometer, a mechanical stirrer, a condenser tube and a nitrogen inlet tube. Acid; 35.7 grams of ethylenediamine was placed in a 100ml constant pressure dropper; nitrogen gas was introduced, stirred, and heated to raise the temperature. When the temperature in the reaction bottle reached 120-130°C, the mixed amines were added dropwise, and the temperature was controlled at 130-140°C. ℃. After the dropwise addition, add 5 drops of phosphoric acid and 12.1g of stearic acid into the reaction bottle, and start to slowly heat up to about 230-240°C; 204g of liquid nitrile rubber CTBN1300×18 (U.S. Emerald company, Hycar series reaction) was weighed in advance. Type liquid nitrile rubber) and preheat the rubber to 80°C-90°C, and add it into the reaction bottle in a transparent liquid state with good fluidity; at th...

Embodiment P2~P4

[0093] Same as Example P1, except that carboxyl-terminated liquid nitrile rubber (Hycar series liquid rubber, Emerald Company of the United States) of different models and different proportions is used.

[0094] The product obtained from Example P4 has the characteristics of low-temperature resistance of -25°C and excellent air-tight performance that can reach 12 high and low temperature cycles without air leakage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com