An electrode lead-out device for a capacitive liquid level sensor used in a high-pressure storage tank

A technology of electrode extraction and capacitor liquid level, which is applied to liquid level indicators, containers, and large containers for physical variable measurement, can solve the problems of easy failure of sealing, and achieve the effects of improving sealing performance, prolonging life, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

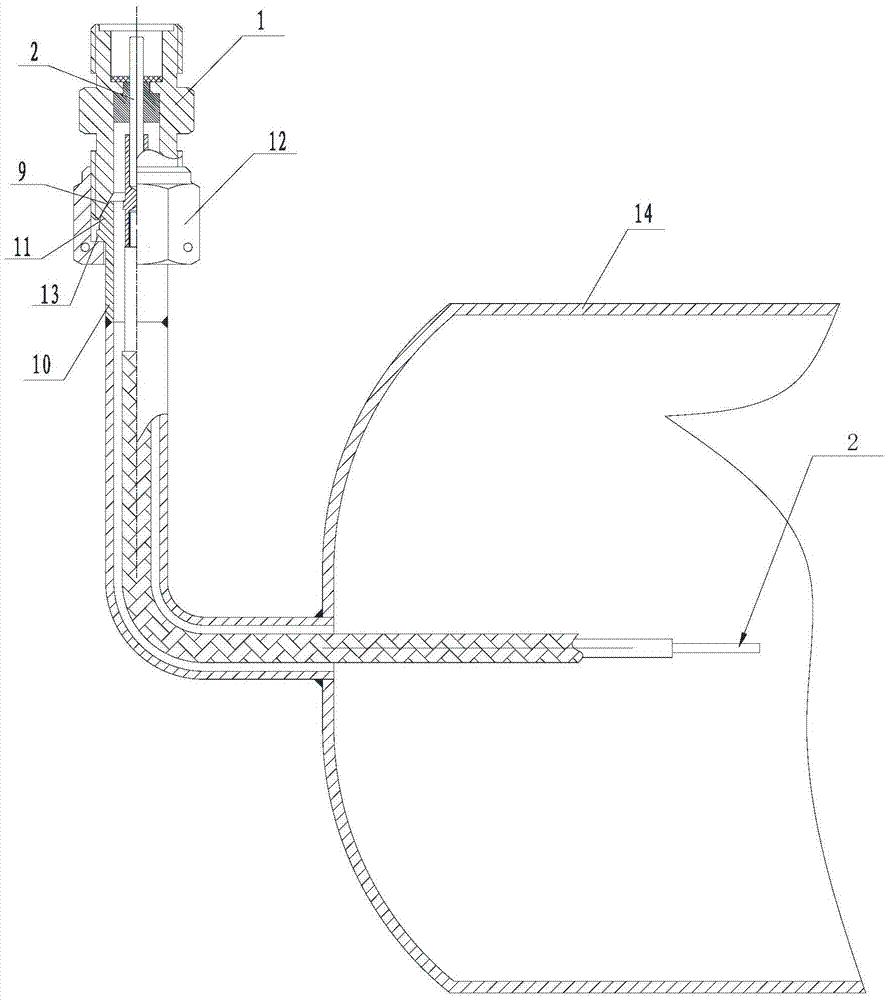

[0019] figure 1 It is a schematic diagram of the structure of the electrode extraction device of the capacitive liquid level sensor for the high-voltage storage tank of the present invention. The probe of the capacitive liquid level sensor is located in the tank 14, and the tank 14 itself is made of conductive metal. The first electrode 2 of the probe is led out through the wall of the tank 14, and the second electrode (not shown in the figure) is electrically connected to the tank 14 and guided through the tank 14.

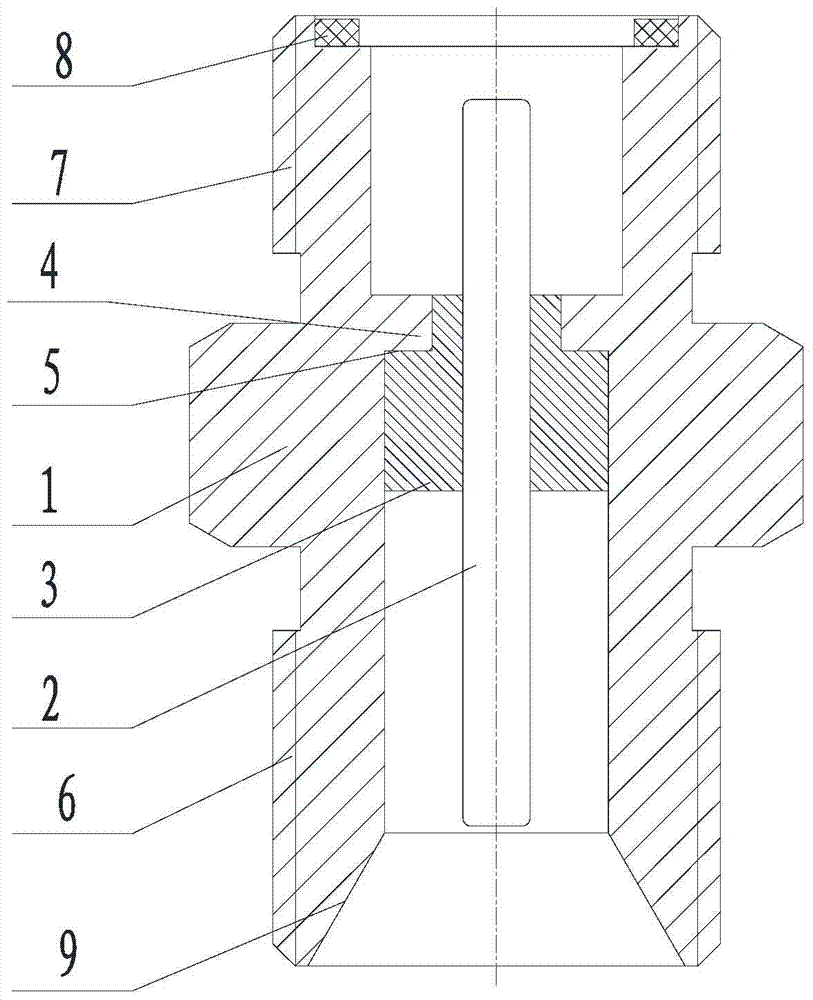

[0020] figure 2 It is an enlarged cross-sectional view of the first lead-out tube of the electrode lead-out device of the capacitive liquid level sensor for a high-voltage storage tank according to an embodiment of the present invention, such as figure 1 with figure 2 As shown, the electrode lead-out device for the capacitive liquid level sensor of the high-pressure storage tank of the present invention includes a first lead-out tube 1 made of conductive metal, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com