Sintered gas-sealed optical fiber socket

An optical fiber socket and hermetic sealing technology, which is applied in the field of sintered air-sealed optical fiber sockets, can solve problems such as cracking, intolerance to harsh environments, and easy aging of elastic seals, and achieve simple structure, good air sealing effect, and good pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

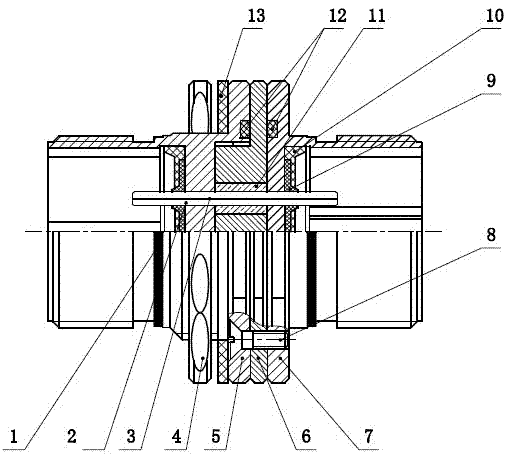

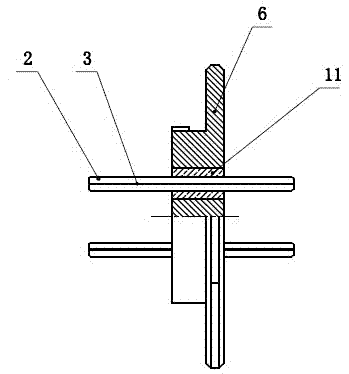

[0009] control attached figure 1 , which is characterized in that the optical fiber ferrule 2 is installed in the middle casing 6, the left casing 5, and the right casing 7, and the middle casing 6, the left casing 5, and the right casing 7 are respectively provided with pin holes, and the middle casing The pin holes provided in the body 6 , the left housing 5 and the right housing 7 are in clearance fit with the optical fiber ferrule 2 . Its structure is that the intermediate housing 6 is provided with a pin hole, the aperture of the pin hole is larger than the optical fiber ferrule 2, and after the optical fiber ferrule 2 is aligned with the axis of the pin hole in the intermediate housing 6, it is filled with glass medium 11, and the glass medium 11 is sintered and solidified to form a sealed whole with the intermediate housing 6 and the optical fiber ferrule 2, so as to realize the airtightness between the optical fiber ferrule and the housing.

[0010] The left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com