Liquid floated gyroscope

A liquid floating gyroscope, integrated technology, applied in the direction of rotating gyroscope, etc., can solve the problems of low reliability, troublesome ground storage and testing, accelerated gas seal leakage, etc., so as to improve reliability, avoid gas leakage, and improve gas leakage. The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

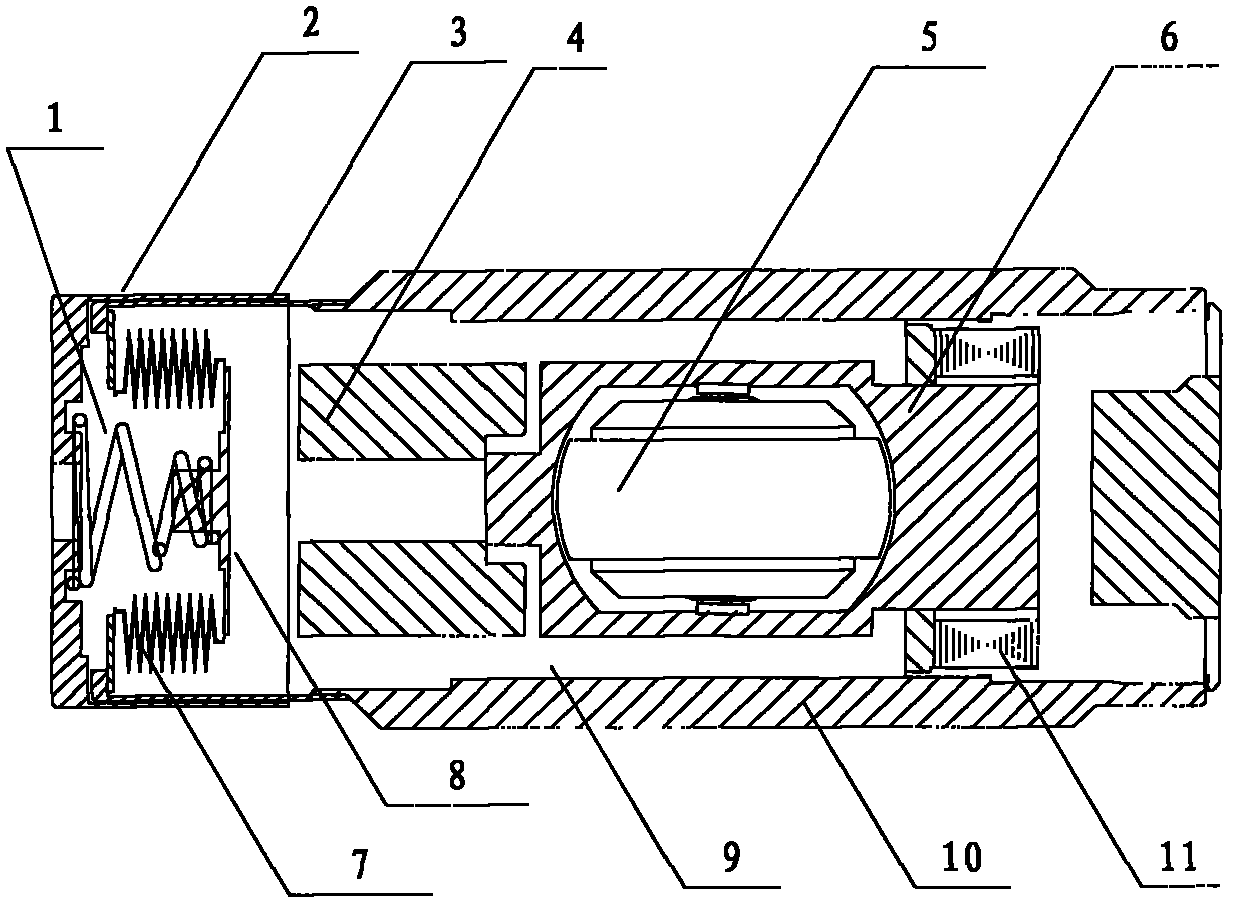

[0016] Such as figure 1 Shown is a schematic structural view of the liquid floating gyroscope of the present invention. The liquid floating gyroscope includes a conical spring 1, a rear cover 2, a rear cover 3, a torque device 4, a motor 5, a buoy 6, a bellows 7, a gasket 8, a floating liquid 9, a housing 10, and a sensor 11. Wherein the bellows 7 and the gasket 8 are welded into one body, a back cover 2 is installed on the outer diameter of the back cover 3 of the housing, and the back cover 2 and the back cover 3 are bonded with glue E-16; the bottom of the inner hole of the back cover 2 There is a groove in the upper processing, and the back cover 2 is made of the same material as the back cover 3, all selecting expansion alloy 4J34 steel for use.

[0017] The large end of the conical spring 1 is placed in the groove at the bottom of the inner hole of the back cover 2 , and the small end is placed on the boss of the gasket 8 . The total number of turns of the conical spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com