Full-metal seal dual-pipe steam injection well head device used for inclined shaft

A technology of double-pipe steam injection and wellhead device, which is applied in the directions of sealing/isolation, wellbore/well components, production fluid, etc. Safe and reliable, improve installation accuracy and sealing reliability, and ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

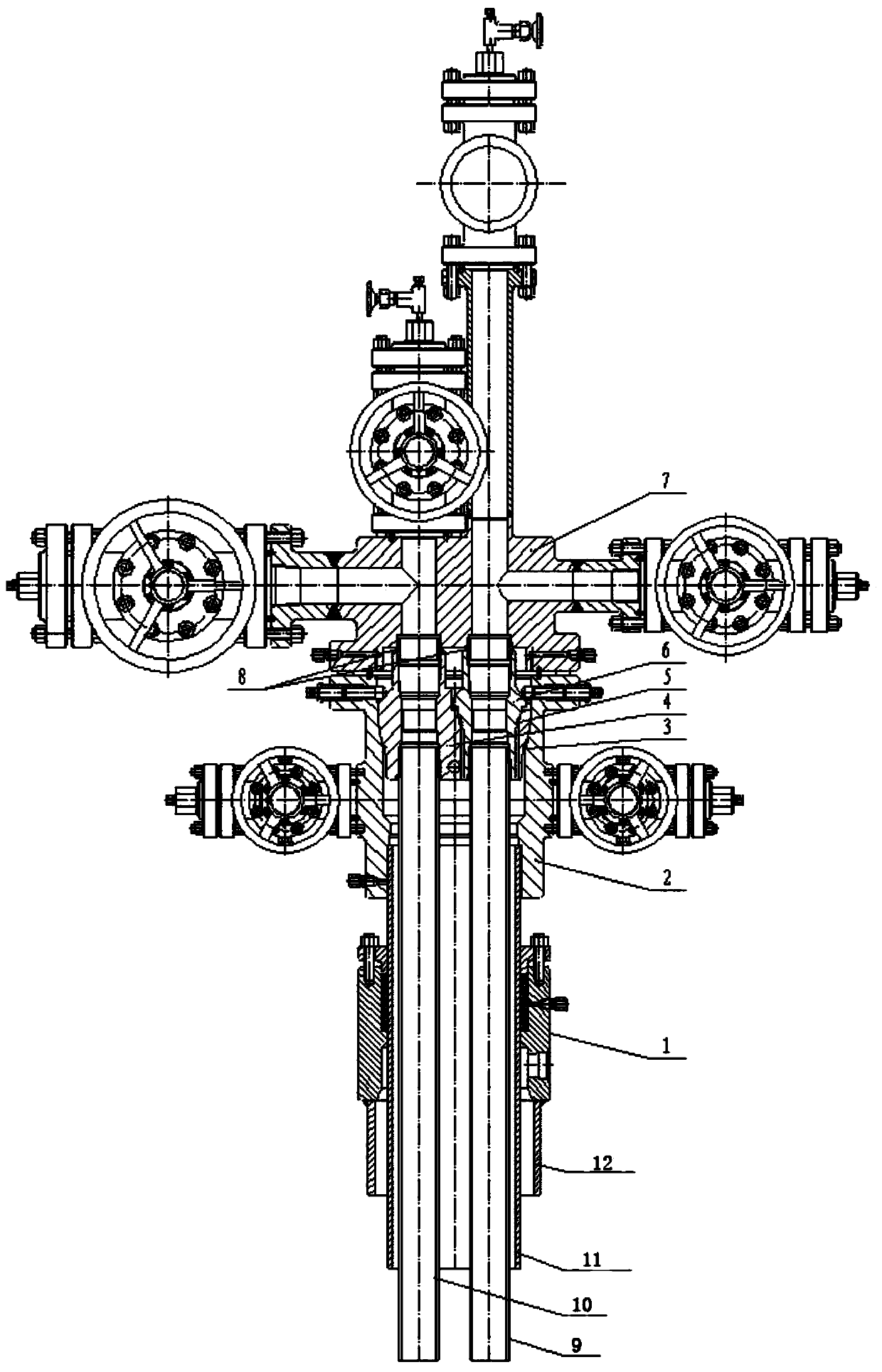

[0018] This embodiment provides an all-metal-sealed double-tube steam injection wellhead device that can be used in inclined wells. The structure is as follows figure 1 As shown, the surface casing 12 is sleeved outside the production casing 11. A simple casing head assembly 1 is welded on the top of the surface casing 12, a sealing packing is arranged inside the simple casing head assembly 1, and a packing gland sealing surface layer is arranged on the top. Socket 12. The top of the production casing 11 is welded with the tubing head cross assembly 2; the tubing head cross assembly 2 has a female hanger 4 and a female suspension metal seal assembly 3 in its four-way cavity, and the mother hanger 4 has a sub-hanger in its cavity 6 and the child suspension metal sealing assembly 5, the mother suspension metal sealing assembly 3 and the child suspension metal sealing assembly 5 have a reduced diameter structure. The tubing 9 and the parent hanger 4 are connected to the four-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com