Molecular adhesive used for TPZ waterproof rolls and preparation method of molecular adhesive

A waterproof membrane and adhesive technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the failure of waterproof layer wet laying seal, wet laying seal failure, seal adhesion failure, etc. Problems, achieve good bonding and sealing safety, good sealing and waterproof performance, and improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

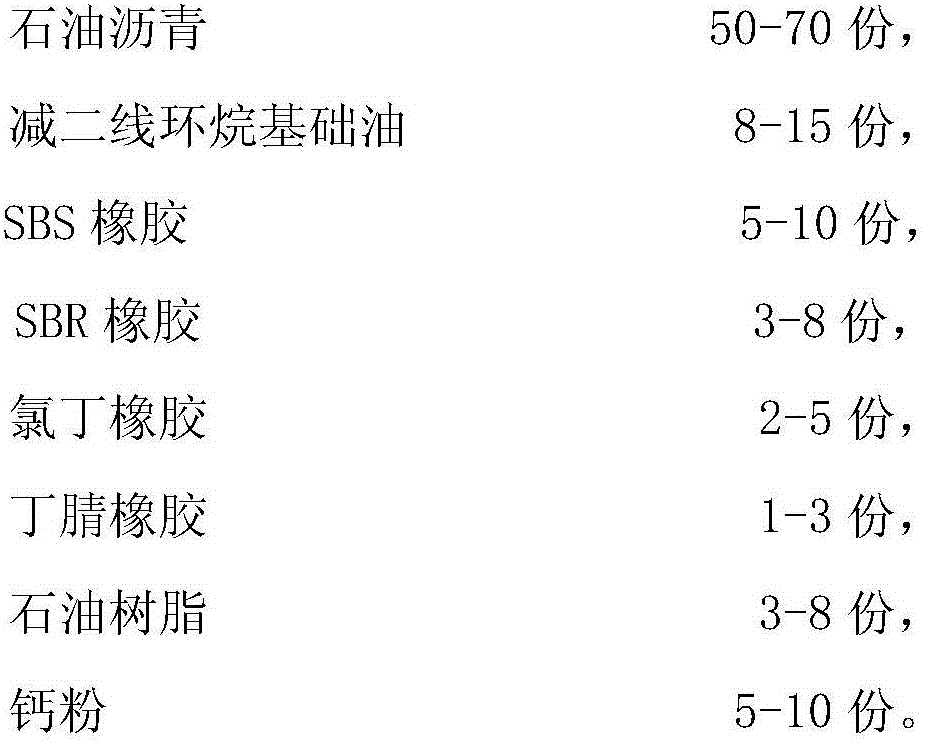

[0044] A molecular adhesive for TPZ waterproof membrane, comprising the following components in parts by weight:

[0045]

[0046]

[0047] Wherein, the petroleum resin is an aliphatic resin, which is obtained by modification with maleic anhydride: it is modified by adding maleic anhydride with an initiator at 175°C.

[0048] The particle size of the heavy calcium powder is 500-600 mesh, which is modified by silane coupling agent and sodium lauryl sulfate at 75°C.

[0049] According to the proportioning of above-mentioned adhesive, make following preparation:

[0050](1) Open the heat transfer oil valve of the reactor, pour in petroleum asphalt and second-line naphthenic base oil, and stir at a speed of 15-20 rpm;

[0051] (2) When the temperature reaches 130-150°C, add SBR rubber, chloroprene rubber and nitrile rubber, mix and stir, and stir at 190-200°C for 1.2 hours until the mixture is completely melted to obtain mixture A;

[0052] (3) Add SBS rubber to mixture A,...

Embodiment 2

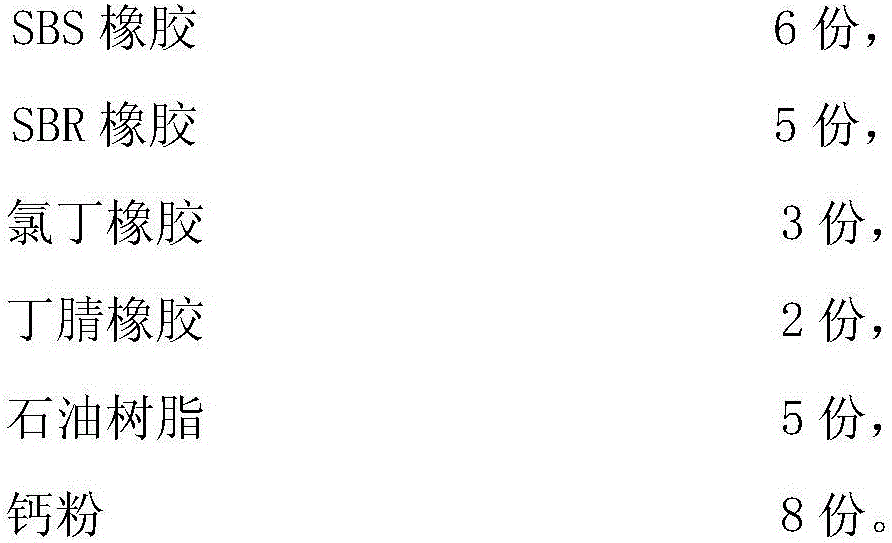

[0056] A molecular adhesive for TPZ waterproof membrane, comprising the following components in parts by weight:

[0057]

[0058] Wherein, the petroleum resin is an aliphatic resin, which is obtained by modification with maleic anhydride: it is formed by modifying the initiator by adding maleic anhydride at 165°C.

[0059] The particle size of the heavy calcium powder is 500-600 mesh, which is modified by silane coupling agent and sodium lauryl sulfate at 65°C.

[0060] According to the proportioning of above-mentioned adhesive, make following preparation:

[0061] (1) Open the heat transfer oil valve of the reactor, pour in petroleum asphalt and second-line naphthenic base oil, and stir at a speed of 15-20 rpm;

[0062] (2) When the temperature reaches 130-150°C, add SBR rubber, neoprene rubber and nitrile rubber, mix and stir, and stir at 190-200°C for 1.0h until it melts completely to obtain mixture A;

[0063] (3) Add SBS rubber to mixture A, keep the temperature at ...

Embodiment 3

[0067] A molecular adhesive for TPZ waterproof membrane, comprising the following components in parts by weight:

[0068]

[0069] Wherein, the petroleum resin is an aliphatic resin, which is obtained by modification with maleic anhydride: it is formed by modifying the initiator by adding maleic anhydride at 180°C.

[0070] The particle size of the heavy calcium powder is 500-600 mesh, which is modified by silane coupling agent and sodium lauryl sulfate at 70°C.

[0071] According to the proportioning of above-mentioned adhesive, make following preparation:

[0072] (1) Open the heat transfer oil valve of the reactor, pour in petroleum asphalt and second-line naphthenic base oil, and stir at a speed of 15-20 rpm;

[0073] (2) When the temperature reaches 130-150°C, add SBR rubber, chloroprene rubber and nitrile rubber, mix and stir, and stir at 190-200°C for 1.5 hours until the mixture is completely melted to obtain mixture A;

[0074] (3) Add SBS rubber to mixture A, kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com