Preparation method of pure-phase Li2Si2O5 rodlike crystal

A lithium disilicate, rod-shaped technology, applied in the field of preparation of pure-phase lithium disilicate rod-shaped crystals, can solve the problems of low chemical potential, unfavorable anisotropic growth of target products, non-compliance with stoichiometric ratio, and insufficient reaction kinetics, etc., to achieve Wide range of solid content and hydrothermal filling degree, convenient for industrial application, and good for dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

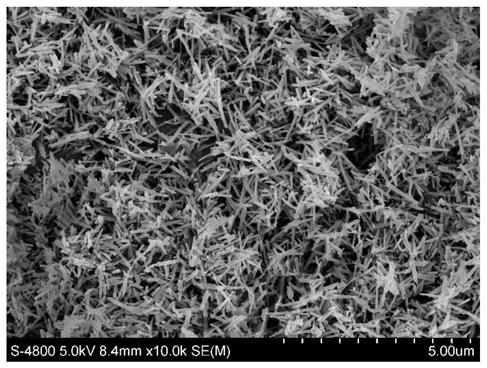

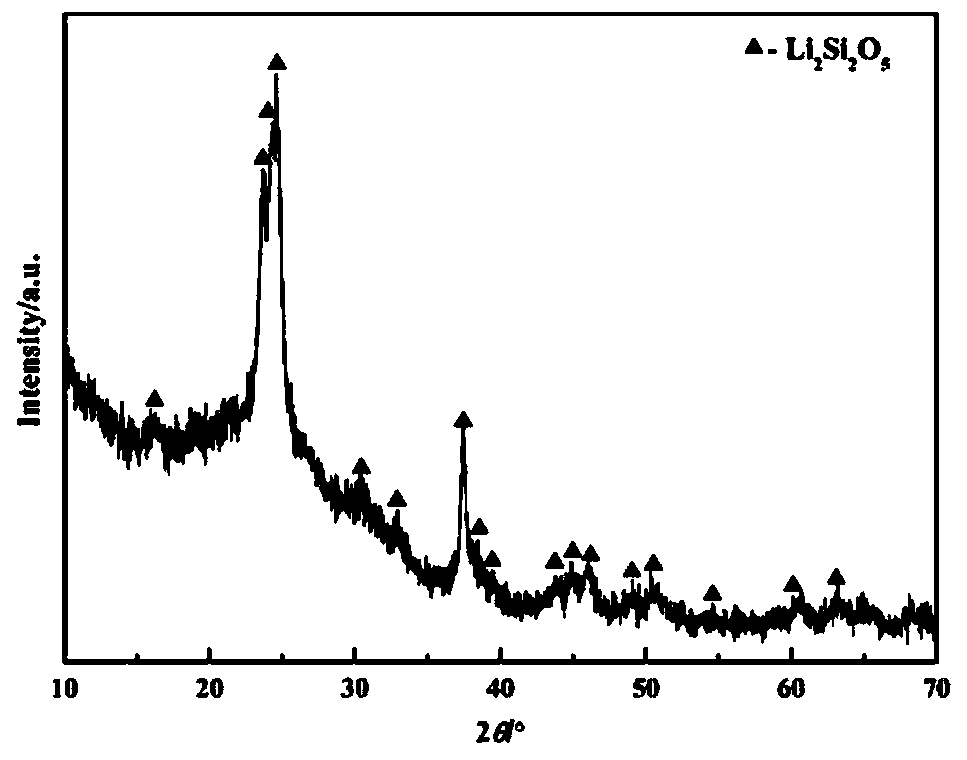

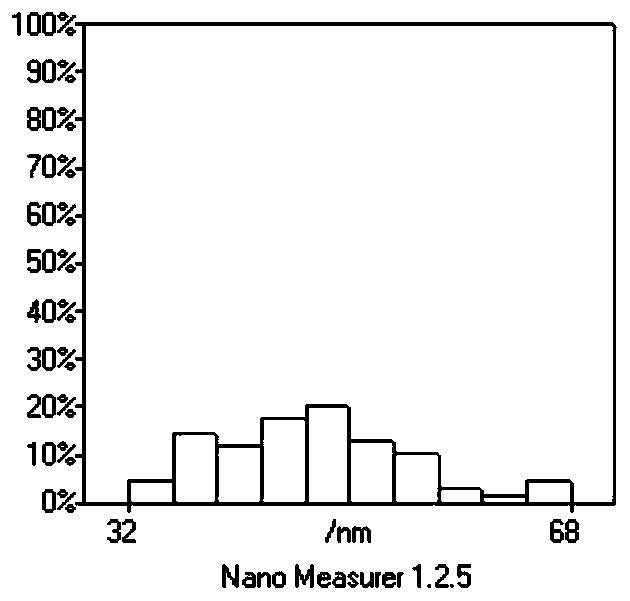

[0030] A method for preparing a pure-phase lithium disilicate rod-shaped crystal of the present invention comprises the following steps:

[0031] S1, LiOH·H 2 Add O into distilled water, stir magnetically for 5 to 10 minutes, and rotate at a speed of 800 to 1500 r / min to fully dissolve to obtain a transparent solution;

[0032] S2. Weigh tetraethyl orthosilicate, and add it dropwise to the transparent solution prepared in step S1 within 10 to 15 minutes, so that the Li / Si molar ratio is 1, and continue magnetic stirring after the addition is completed to obtain a uniform mixed solution;

[0033] Among them, the magnetic stirring time is 30-45min, and the rotating speed is 800-1500r / min;

[0034] S3. Pour the mixed solution obtained in step S2 into a polytetrafluoroethylene liner, control the volume filling degree to 60% to 80%, react at 180°C for 24 to 48 hours, and the solid content of raw materials in the reaction solution is 200 to 500g / L , to obtain a white precipitate; ...

Embodiment 1

[0042] S1, LiOH·H 2 O was added to distilled water, magnetically stirred for 5min, and the rotating speed was 800r / min to fully dissolve it to obtain a transparent solution;

[0043] S2. Weigh tetraethyl orthosilicate and add it dropwise to the transparent solution prepared in step S1 within 10 minutes, so that the Li / Si molar ratio is 1. After the addition is completed, control the speed of 800r / min and continue magnetic stirring for 30 minutes to obtain a uniform solution. the mixture;

[0044] S3. Pour the mixed solution obtained in step S2 into a hydrothermal liner, control the volume filling degree to 60%, and react at 180° C. for 24 hours. The solid content of the raw material in the reaction solution is 200 g / L, and a white precipitate is obtained;

[0045] S4, wash with alcohol and distilled water 3 times respectively, remove impurity, obtain filter cake;

[0046] S5. Dry the filter cake obtained in step S4 at 60° C. for 12 hours to remove alcohol and water, and then...

Embodiment 2

[0050] S1, LiOH·H 2 O was added to distilled water, magnetically stirred for 6 minutes, and the rotating speed was 1200r / min to fully dissolve it, and a transparent solution was obtained;

[0051] S2. Weigh tetraethyl orthosilicate and add it dropwise to the transparent solution prepared in step S1 within 12 minutes, so that the Li / Si molar ratio is 1. After the addition is completed, control the speed of 900r / min and continue magnetic stirring for 35 minutes to obtain a uniform solution. the mixture;

[0052] S3. Pour the mixed solution obtained in step S2 into a hydrothermal liner, control the volume filling degree to 75%, and react at 180° C. for 40 hours. The solid content of the raw material in the reaction solution is 400 g / L, and a white precipitate is obtained;

[0053] S4, wash 4 times with alcohol and distilled water respectively, remove impurity, obtain filter cake;

[0054] S5, drying the filter cake obtained in step S4 at 90° C. for 20 h, removing alcohol and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com