Device and method for bituminous concrete hydraulic fracture testing

A technology of asphalt concrete and hydraulic splitting, applied in the direction of material inspection products, etc., can solve the problems of increased water permeability of the core wall, hydraulic splitting of the core wall, etc., and achieve the effect of simple boundary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

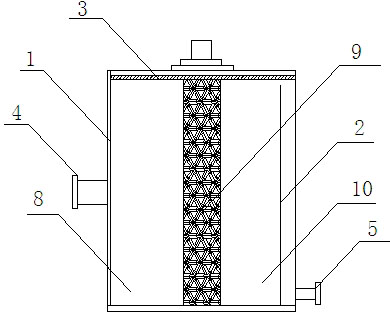

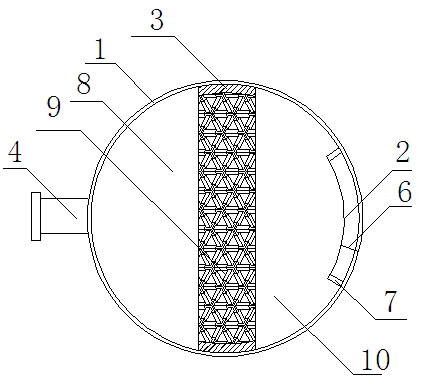

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] As shown in the figure: an asphalt concrete hydraulic splitting test device, including a rigid drum 1, a rigid support 2, a water-stop layer 3, a barrel cover, a pressure water inlet 4, a downstream seepage outlet 5, and telescopic bolts 6, Filling material7.

[0027] The top of the rigid drum 1 is arranged with a bung cover, the outer side wall of the rigid drum 1 is arranged with a pressure water inlet 4, and the outer side of the rigid drum 1 on the other side of the pressure water inlet 4 is arranged with a downstream leakage outlet 5, and the pressure water inlet 4 is high The water outlet 5 is leaked downstream. A sample 9 is placed at the center of the rigid drum 1. The sample 9 is block-shaped and tangent to the inner wall of the rigid drum 1 in the radial direction. An asphalt concrete upstream material is arranged between the sample 9 and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com