Concrete fracture test system and test method thereof

A testing system and testing method technology, applied in the direction of using stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of less acquisition frequency, difficult double K fracture parameters, rough load-displacement curve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

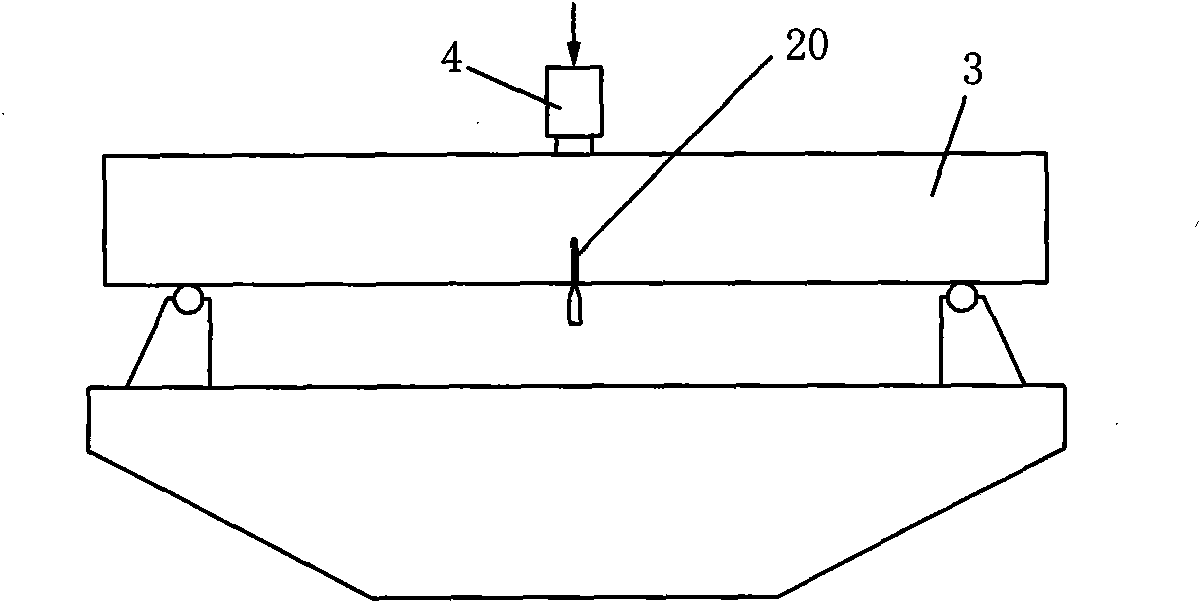

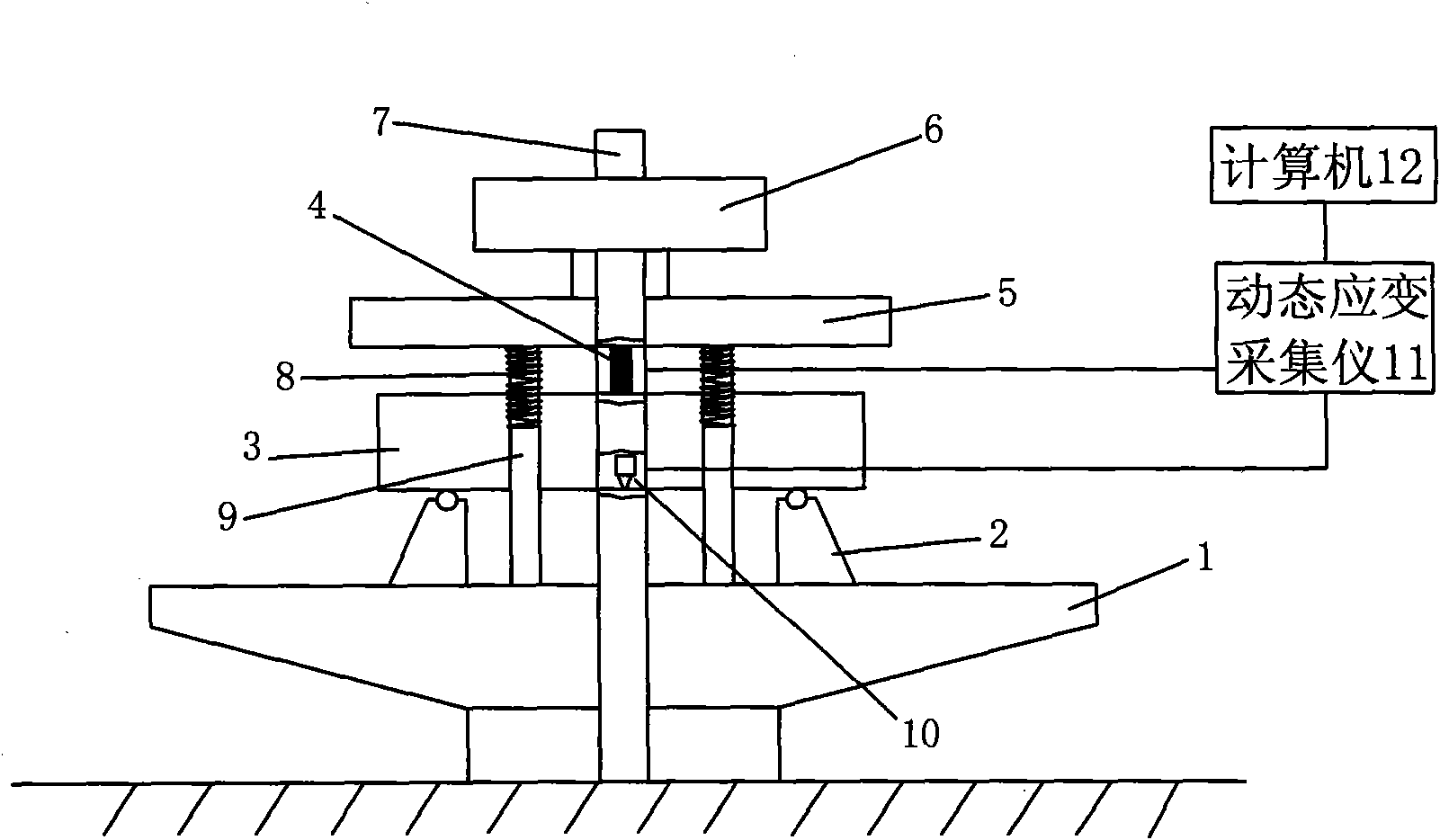

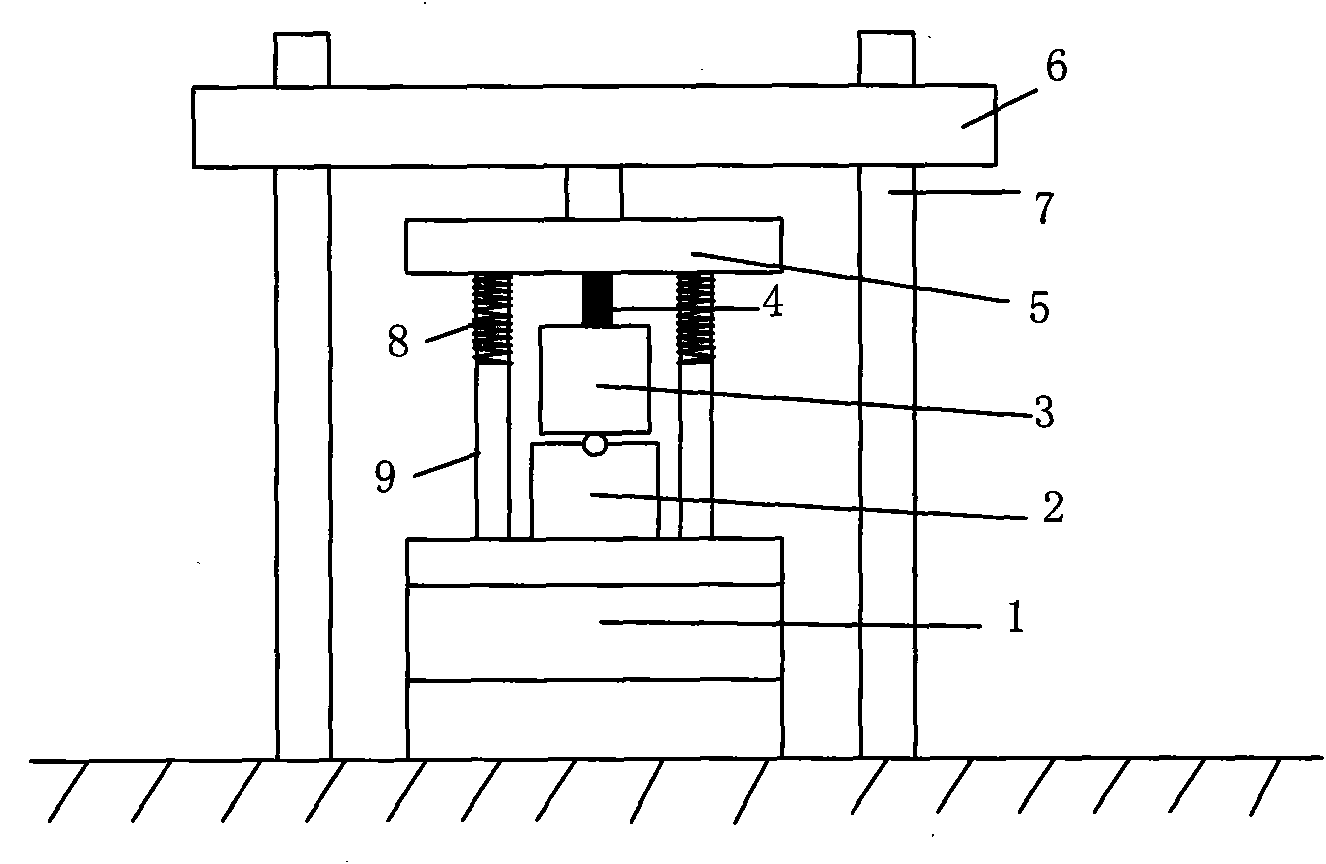

Embodiment 1

[0042] The concrete fracture test system of this embodiment is as follows figure 2 , image 3 As shown, including a measurement system and a data acquisition and processing system, the measurement system includes an existing pressure testing machine, a pressure sensor 4 for placing on the top of the concrete specimen 3 and a clip-type for setting at the prefabricated crack of the concrete specimen 3 Extensometer 10. The pressure testing machine is a 5000kN triaxial hydraulic testing machine produced by Changchun Testing Machine Factory. The driving device (ie the hydraulic cylinder), the upper end of the top plate 5 is fixed on the beam 6 of the testing machine, and the beam 6 of the testing machine is sleeved on the column 7 of the testing machine. The clip-type extensometer adopts the clip-type extensometer produced by Epsilon Company in the United States. The clip-type extensometer 10 is embedded between the thin steel bars (not shown in the figure) pasted on both sides ...

Embodiment 2

[0064] The concrete fracture test system of this embodiment is an improvement on the basis of Embodiment 1, such as Image 6 As shown, the difference from the first embodiment is: ① also includes an acoustic emission meter 13 and an acoustic emission sensor 14 placed on the surface of the concrete specimen 3, the input end and the output end of the acoustic emission instrument 13 are connected to the The emission sensor 14 is connected to the computer 12, and the acoustic emission instrument adopts SAMOSTM acoustic emission instrument produced by PAC Company of each country; ② the thin steel bar at the knife edge is replaced with the bolts embedded on both sides of the crack opening (not shown in the figure).

[0065] The concrete fracture test method of this embodiment is an improvement on the basis of Embodiment 1, and the difference from Embodiment 1 is: ① In step 1), an acoustic emission meter 13 and an acoustic emission sensor 14 are also used, and the Acoustic emission s...

Embodiment 3

[0067] The concrete fracture test system of the present embodiment is an improvement on the basis of the first embodiment, and the difference from the first embodiment is that it also includes a strain gauge (not shown in the figure), and the strain gauge is arranged on the prefabricated crack of the concrete specimen 3 It is connected to the dynamic strain acquisition instrument 11 through the data line.

[0068] The concrete fracture test method of the present embodiment is an improvement on the basis of the first embodiment, and the difference from the first embodiment is: ① in the 3rd) step, a strain gauge is attached to the prefabricated crack of the concrete specimen; ② In step 6), when the loading is continued at a loading rate of 1 N / S, the dynamic strain collecting instrument 11 collects the strain signal of the concrete specimen 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com