Cohesive-soil strain-control-type I-type fracture toughness tester and testing method

A technology of strain control and fracture toughness, applied in the preparation of test samples, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as fracture, achieve unique structure, convenient cost, and improve test accuracy and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

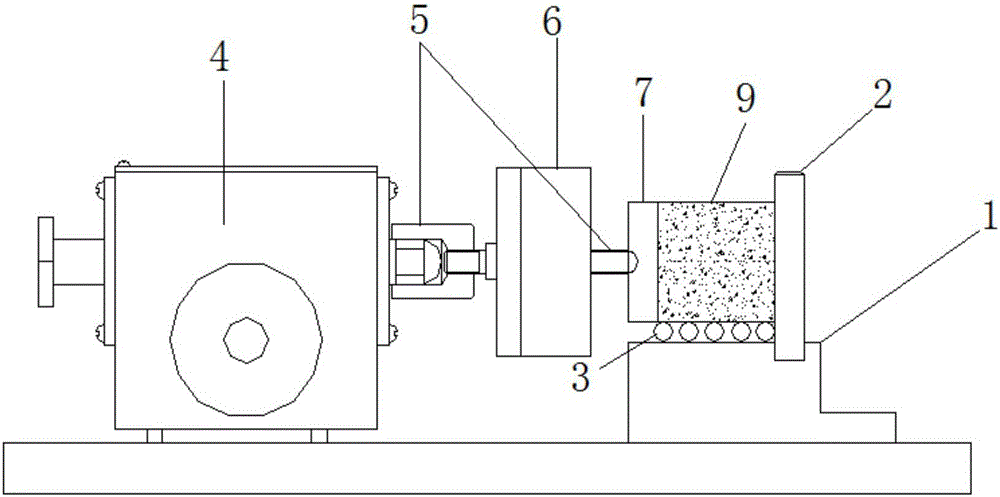

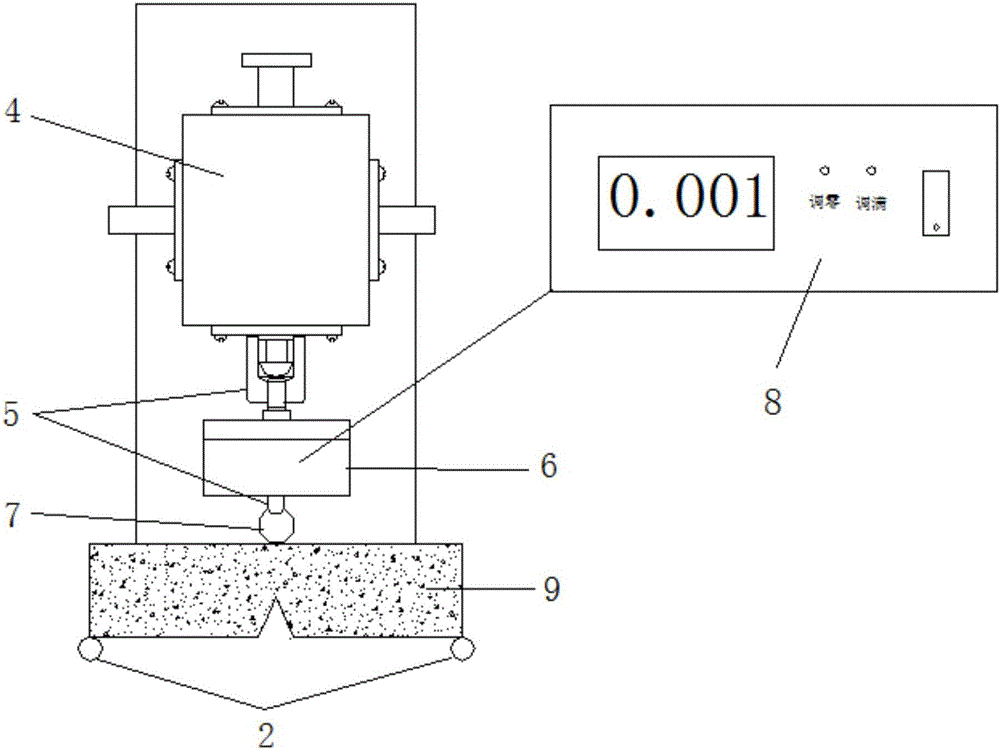

[0023] like figure 1 and figure 2 As shown, a strain-controlled type I fracture toughness tester for cohesive soil of the present invention includes a platform for placing samples, a loading force system and a load-displacement measurement system for causing the samples to fracture, and a place for placing samples The platform includes a base 1, a stop bar 2 and a slide rail 3; the loading force system includes a motor 4, a telescopic connecting rod 5, a sensor 6 is connected to the front end of the connecting rod, and a push rod 7 is connected to the front of the sensor; the measuring system includes a sensor 6 and a The digital display 8 displays the thrust borne by the tested sample 9 through the digital display, and the base and the motor are installed on the mounting table. In the present invention, the expansion and contraction rate of the connecting rod can be controlled, and different expansion and contraction rates can be selected within a wide range.

[0024] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com