Needle tester and needle testing method

A tester and a technology to be tested, applied in the field of needle testing, can solve the problems of unclear needle physical performance indicators, inability to determine the quality of needles, wear life, fracture resistance and resilience, and inability to evaluate physical properties, etc., to achieve force. Simulate Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

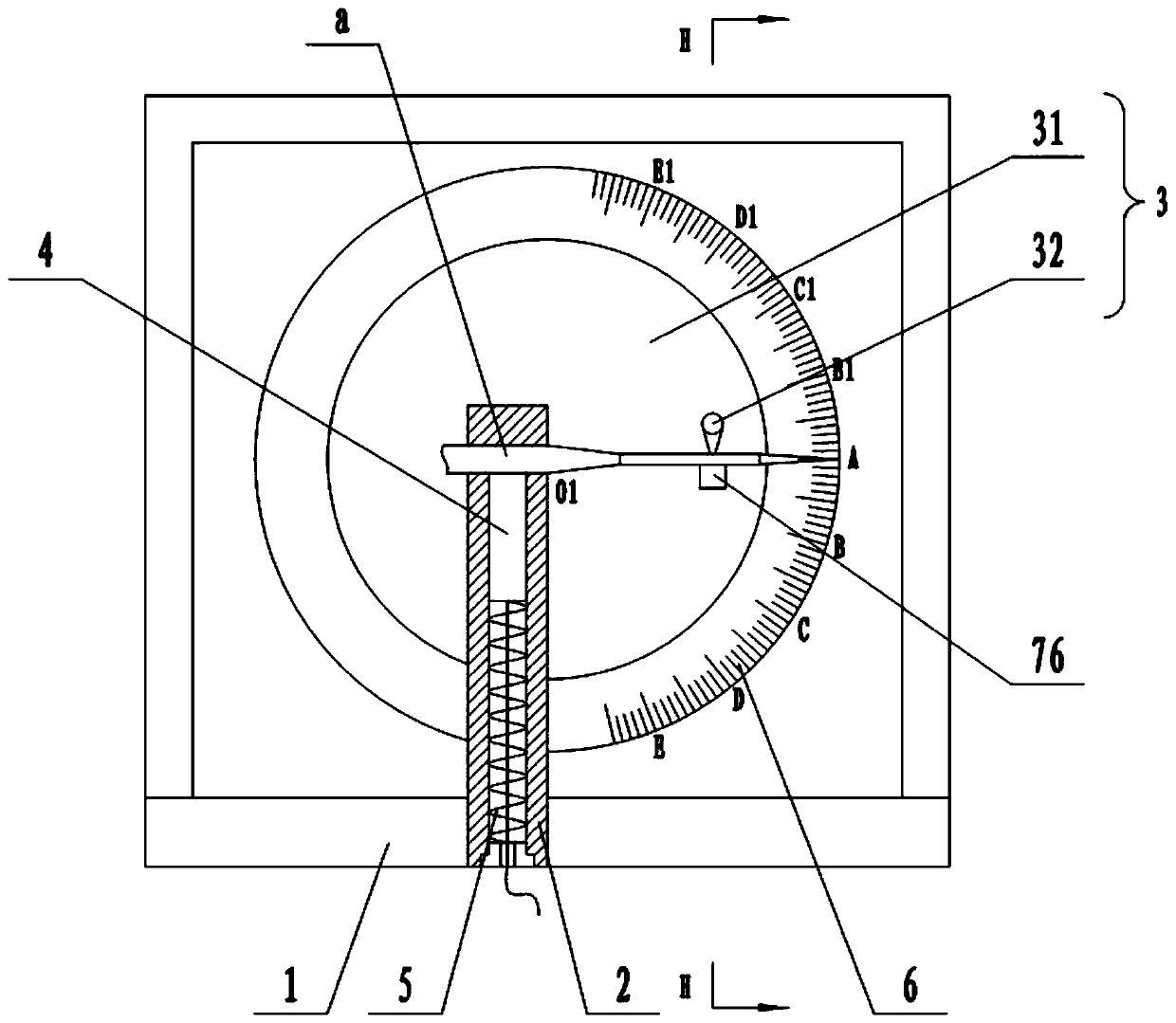

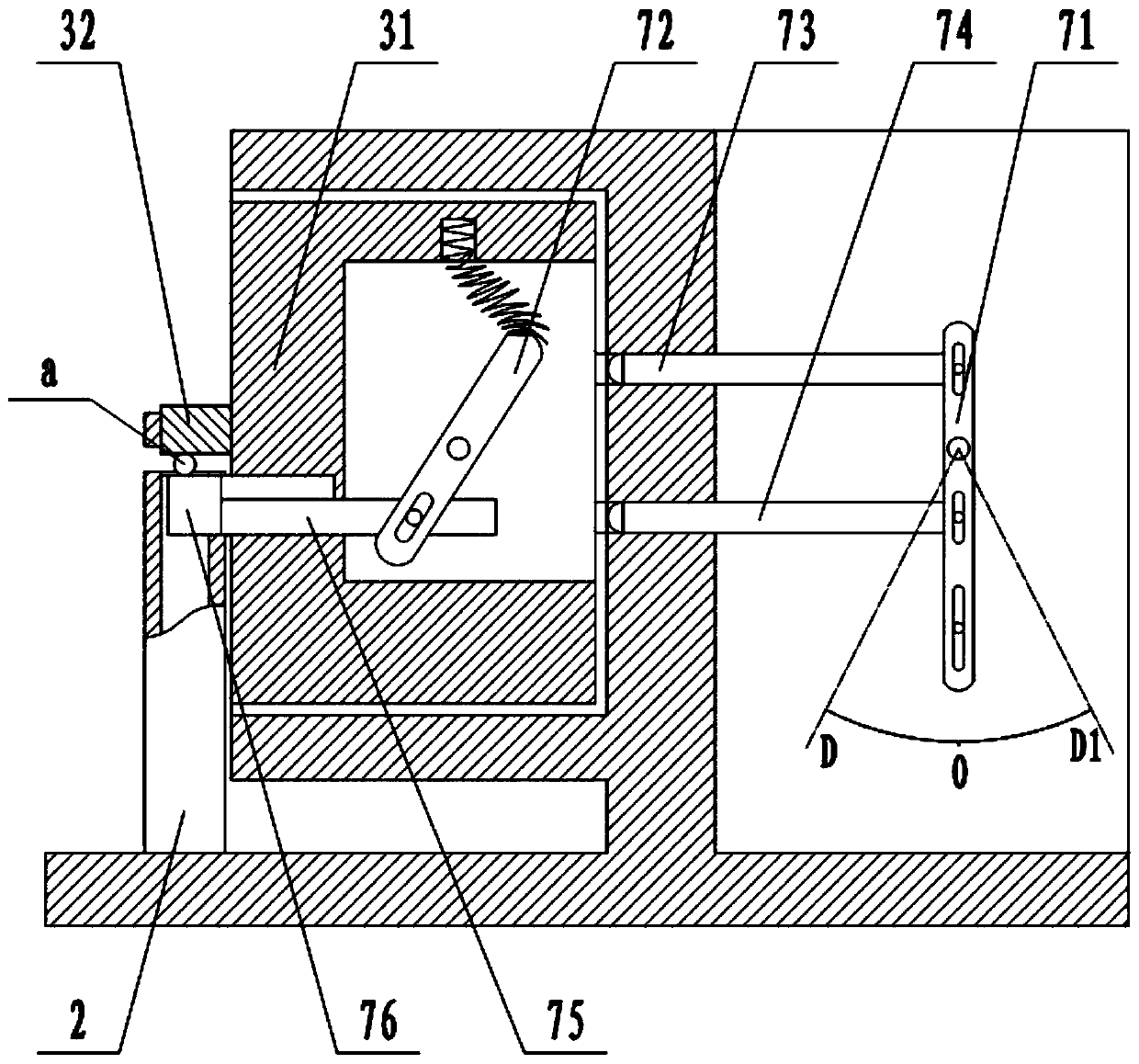

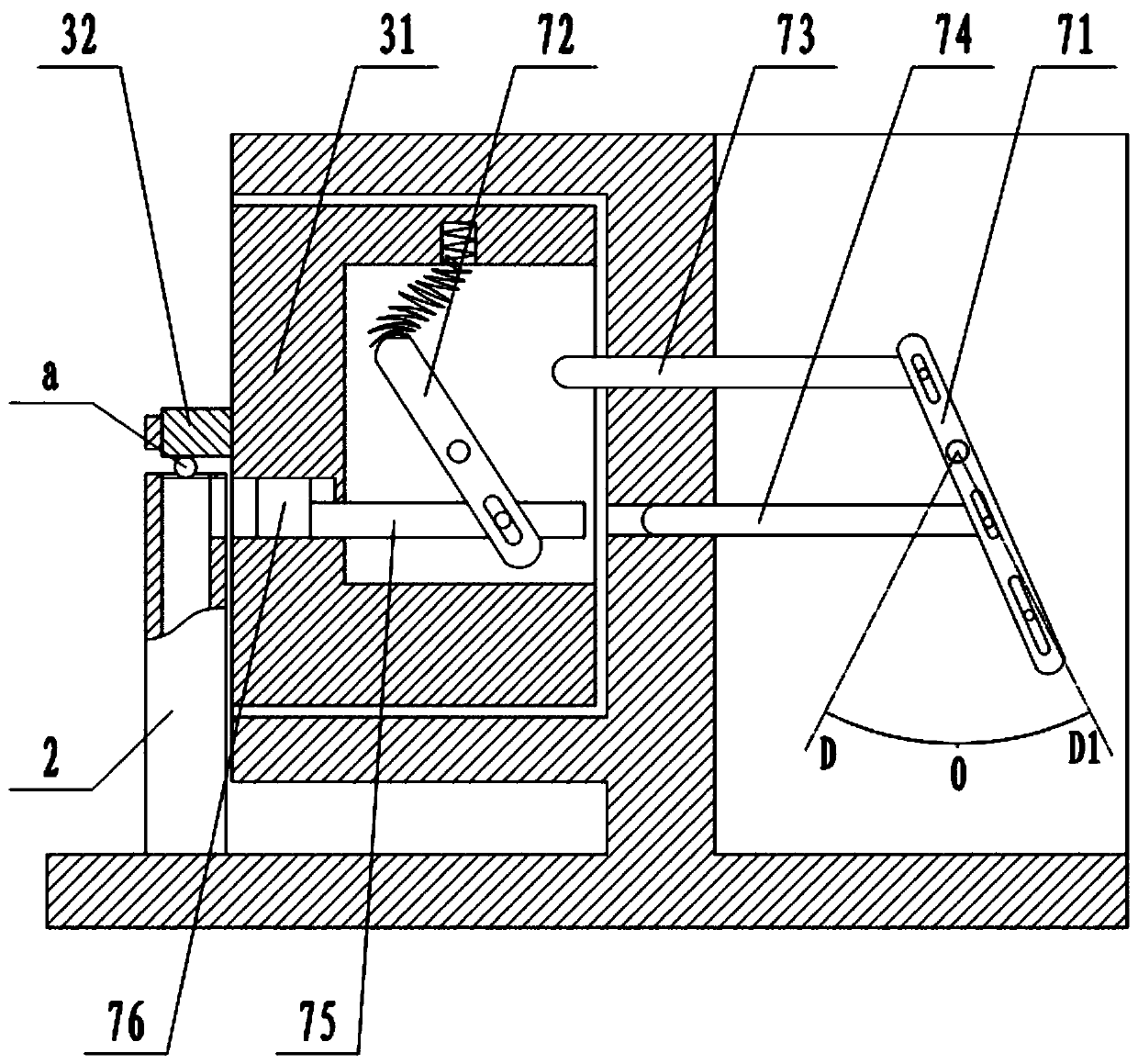

[0033] A needle tester such as Figure 1 to Figure 4 As shown, it includes a bracket 1 , a fixed platform 2 and a rotating assembly 3 .

[0034] Such as figure 1 As shown, the fixed platform 2 is arranged on the bracket 1, and the fixed platform 2 is used to fix the tested needle a. The rotating assembly 3 is arranged on the bracket 1, and when rotating, the rotating assembly 3 provides a swinging arc force for the tested needle a. The arc force has the following effect: even if the tested needle a rotates under the action of the arc force, the action point of the arc force on the tested needle a remains as constant as possible. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com