Rare earth-magnesium alloy and preparation method thereof

A rare earth magnesium and magnesium alloy technology, applied in the field of metal materials, can solve the problems of inapplicability to large-scale production, alloy ratio, smelting and forming process, etc., and achieve high-temperature mechanical properties, good formability, and thermal conductivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

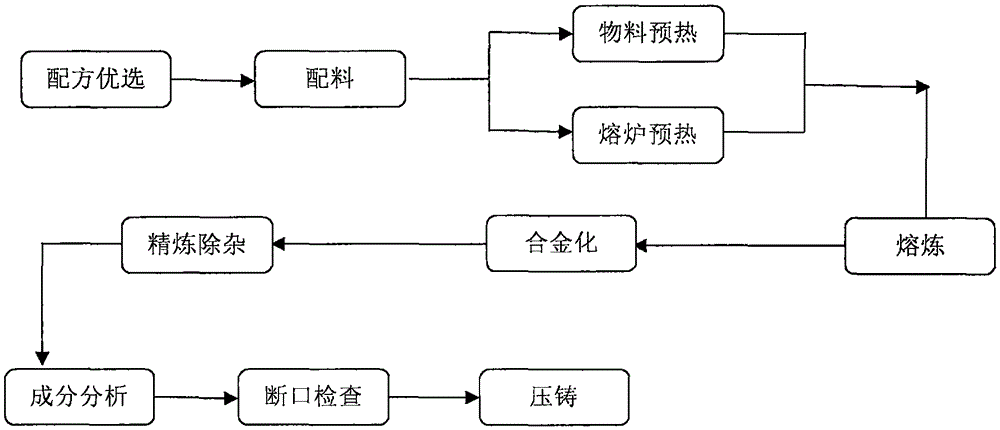

[0038] The present invention also provides a method for preparing the rare earth magnesium alloy described in the above technical solution, comprising the following steps:

[0039] (1) preheating metal Mg and other alloy raw materials;

[0040] (2) smelting the preheated metal Mg to obtain molten magnesium;

[0041] (3) alloying the magnesium liquid obtained in the step (2) to obtain a magnesium alloy liquid;

[0042] (4) leaving the magnesium alloy liquid obtained in the step (3) to stand, then refining and removing slag to obtain pure magnesium alloy liquid;

[0043] (5) Die casting the magnesium alloy liquid obtained in the step (4) to obtain a rare earth magnesium alloy.

[0044]In the present invention, metal Mg and other alloy raw materials are preheated. The present invention has no special limitation on the preheating operation, and the technical scheme of preheating well known to those skilled in the art can be adopted. The present invention is preferably preheate...

Embodiment 1

[0058] (1) Batching: take by weighing metal Mg275kg; Take by weighing Mg-Sm master alloy 100kg by the mass content of 3% and the loss rate of 50%, wherein Sm element accounts for the alloy ratio is 20%; According to the mass content of 0.5% and 50% burning loss rate takes by weighing Mg-Sr master alloy 20kg, wherein the Sr element accounts for 20% of the alloy ratio; according to 0.5% mass content and 10% burning loss rate, take by weighing metal Zn5.5kg, wherein the Zn purity is 98%;

[0059] (2) Preheating: preheat the above materials to 300°C in an oven;

[0060] (3) Melting: Put the preheated metal Mg into a crucible preheated at 400°C, and raise the temperature inside the crucible to 720°C under the protection of nitrogen and sulfur hexafluoride mixed gas, N 2 The flow rate is 1.5L / min, SF 6 The flow rate is 0.27L / min, the metal Mg is melted;

[0061] (4) Alloying: Control the temperature of the magnesium liquid at 660°C, add the preheated Mg-Sm intermediate alloy, Mg-...

Embodiment 2

[0067] (1) batching: take by weighing metal Mg360kg; Take by weighing Mg-Sm master alloy 126kg by the mass content of 3% and 50% burning loss rate, wherein Sm element accounts for alloy proportion and be 20%; According to the mass content of 0.5% and 50% burning loss rate weighs 25.6 kg of Mg-Sr master alloy, wherein Sr element accounts for 20% of the alloy; weighs metal Zn 5.1 kg according to 1.0% mass content and 10% burning loss rate, wherein Zn purity 98%; 20 kg of Mg-Zr master alloy is weighed according to a mass content of 0.2% and a burning loss rate of 75%, wherein the Zr element accounts for an alloy ratio of 25%;

[0068] (2) Preheating: preheat the above materials to 300°C in an oven;

[0069] (3) Melting: Put the preheated metal Mg into a crucible preheated at 400°C, and raise the temperature inside the crucible to 715°C under the protection of nitrogen and sulfur hexafluoride mixed gas, N 2 The flow rate is 1.5L / min, SF 6 The flow rate is 0.27L / min, the metal Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com