An intelligent multi-color screen printing machine

A technology of screen printing machines and manipulators, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of inability to print 360-degree oval products, low degree of automation, and complicated manual operations, and achieve reduction The effect of additional resource waste and capital investment, high degree of automation, and small workstations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

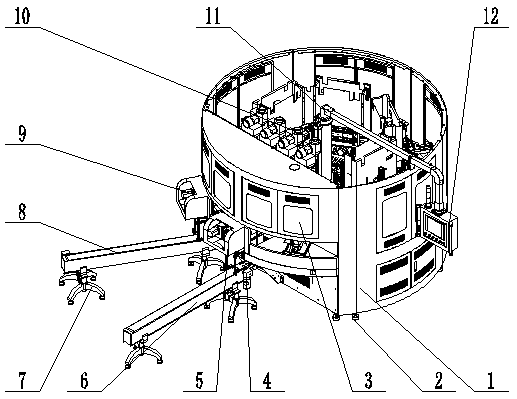

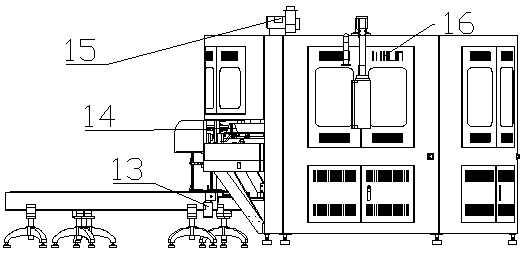

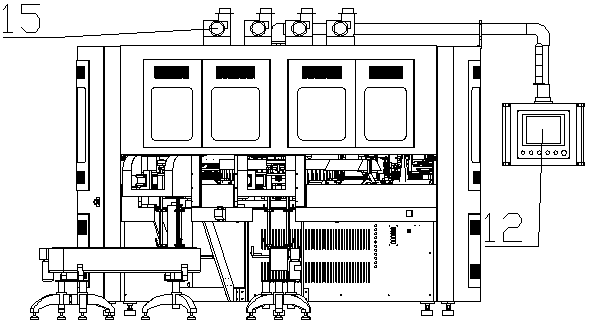

[0022] Such as Figure 1-Figure 8 As shown, an intelligent multi-color screen printing machine includes a device housing 1, feet 2, a visualization window 3, and a turntable screen printing machine 10. The bottom of the device housing 1 is provided with the feet 2, and the device The side of the upper part of the housing 1 is provided with the visualization window 3, the top and bottom sides are provided with exhaust holes 16, and the side entrance of the equipment housing 1 is provided with a feeding conveyor belt 6. A product positioner 4 is installed on the edge of the support of the conveyor belt 6, a feeding manipulator 5 is arranged above the feeding conveyor belt 6, a blanking conveyor belt 8 is arranged at the exit of the equipment housing 1, and the blanking conveyor belt 8 The top is provided with blanking manipulator 9, and the end portion of the support of described loading conveyor belt 6 and described blanking conveyor belt 8 is all provided with conveyor belt mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com