Large-diameter slurry shield comprehensive tunneling method for strong permeable soil and rock composite stratum

A composite stratum and mud-water shield technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as poor quality of mud film, imperfect control technology, difficulty in entering the warehouse under pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

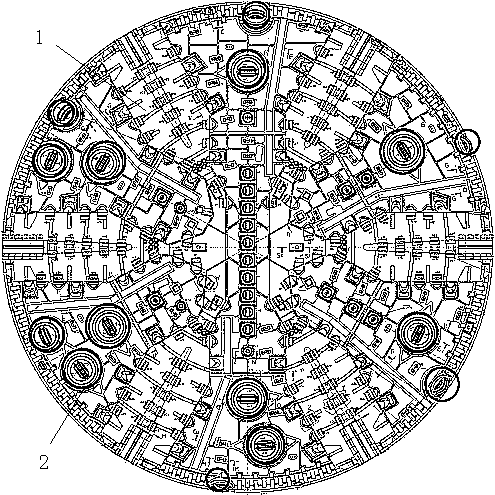

[0039] For the compound stratum with upper soil and lower rock, it is necessary to select the type of cutter head 1 and configure the cutters before the formal tunneling of the shield machine.

[0040] Such as figure 1 , the cutter head 1 innovatively adopts the design form of the composite atmospheric cutter head 1, and the internal design is a hollow structure. There are two types of knife positions arranged on the surface of the cutter head 1: the middle part of the cutter head 1 is a type I knife fixed in the form of a knife position, the outer ring of cutter head 1 is a type II tool position that can realize normal pressure hobbing interchangeability (such as figure 1 The position circled in the middle), the ratio of the two types of cutter positions during the shield tunneling process is determined according to the ratio of the soil mass to the rock mass in the shield tunneling section and the intrusion height of the rock mass, to ensure that the hob in the composite str...

Embodiment 2

[0059] On the basis of Example 1, the prevention and control of the mud cake on cutter head 1 is strengthened.

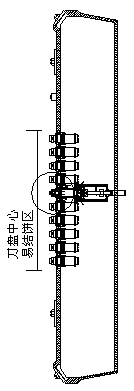

[0060] The prevention and treatment of mud cake in the center body of cutter head 1 includes two technical measures: prevention and treatment. The comprehensive use includes the developed central scour knife with scouring function, mud cake cutting water jet, cutter head 1 temperature real-time monitoring system, mud cake dispersant in the A variety of equipment and materials in the tunnel, supplemented by shield tunneling parameters to jointly prevent and control mud cake.

[0061] The prevention of mud cake on cutter head 1 is to replace the original central flushing knife of cutter head 1 with a central flushing knife with a flushing nozzle and a mud channel, and the rear of the cutter barrel is connected to the rear P 0.1 The pump and the mud pressure are adjusted according to the actual situation. While the shield tunneling is cutting the soil, the mud is spray...

Embodiment 3

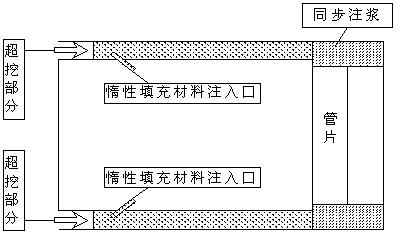

[0065] Since the excavation diameter of the shield machine is slightly larger than the diameter of the shield body, and the diameter of the shield body is slightly larger than the diameter of the shield tail, the excavation diameter of the shield machine is 12.55 meters, while the diameter of the front shield body is 12.51 meters, and the diameter of the middle shield is 12.49 meters. The diameter of the shield tail is 12.47 meters, so the gap between the excavation surface and the shield tail is about 4cm. This space is a tapered space before the segment wall is grouted after the segment comes out of the shield tail. It is to reduce the soil mass. It is set for the extrusion force and friction force of the shield machine, but it may form a space for top settlement during the excavation process.

[0066] In order to reduce the settlement caused by the taper formed between the excavation surface and the shield body, during the advancement of the shield body, an inert material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com