Bentonite Slurry Control System for Shield Construction

A control system and bentonite technology, applied in the direction of control devices, etc., can solve the problems of unguaranteed slurry output and unstable slurry quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of Bentonite Pulping Control System for Shield Construction

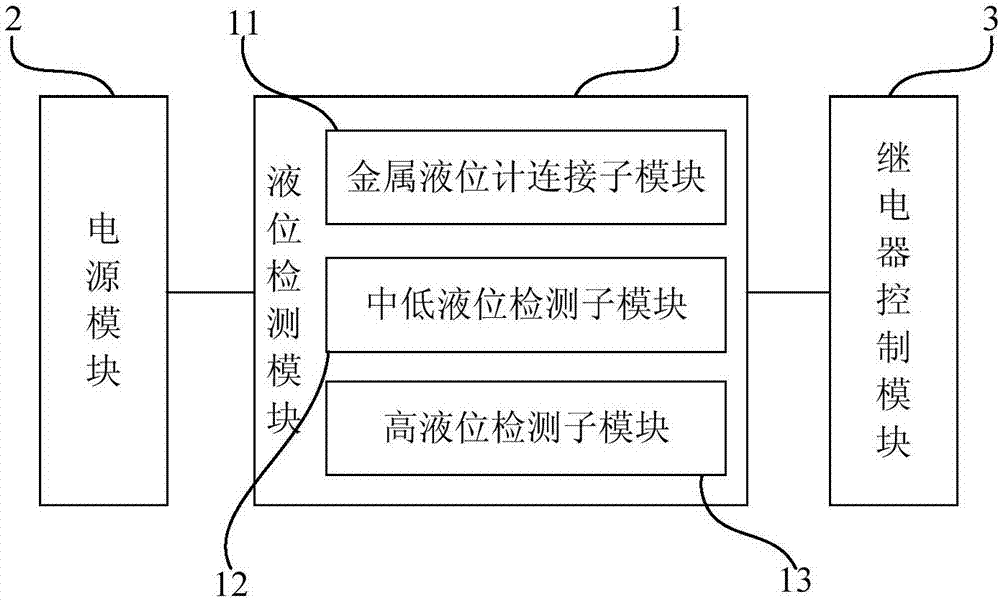

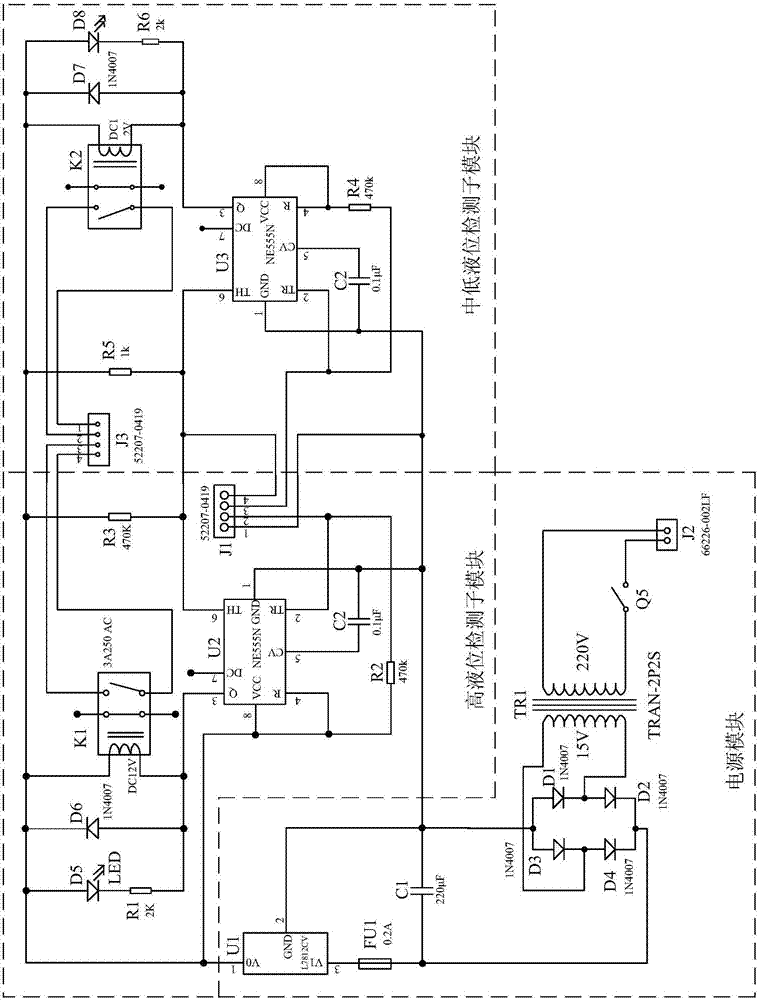

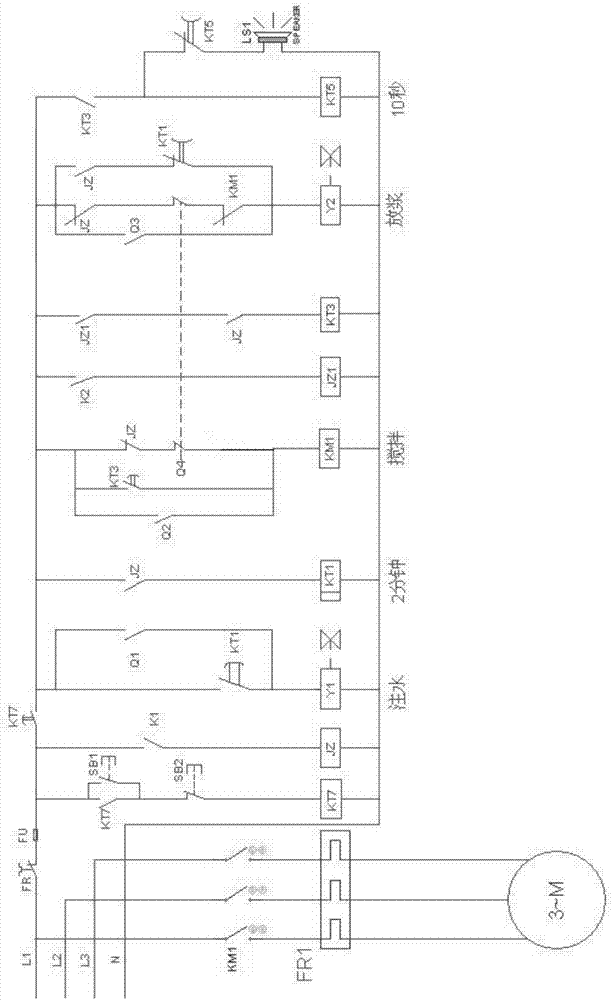

[0025] figure 1 It is a structural schematic diagram of an embodiment of the bentonite pulping control system used for shield construction in the present invention, as figure 1 As shown, it includes a liquid level detection module 1 for detecting the liquid level of the stirring tank 5 and outputting different signals according to the three liquid levels of the stirring tank 5, low, middle and high, a power supply module 2 for supplying power to the liquid level detection module 1, and a user Based on the relay control module 3 that controls the working state of the stirring tank 5 according to the different signals output by the liquid level detection module 1, the liquid level detection module 1 is connected to the relay control module 3, and the liquid level detection module 1 includes a metal liquid level gauge connection sub-module 11 , The middle and low liquid level detection sub-module 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com