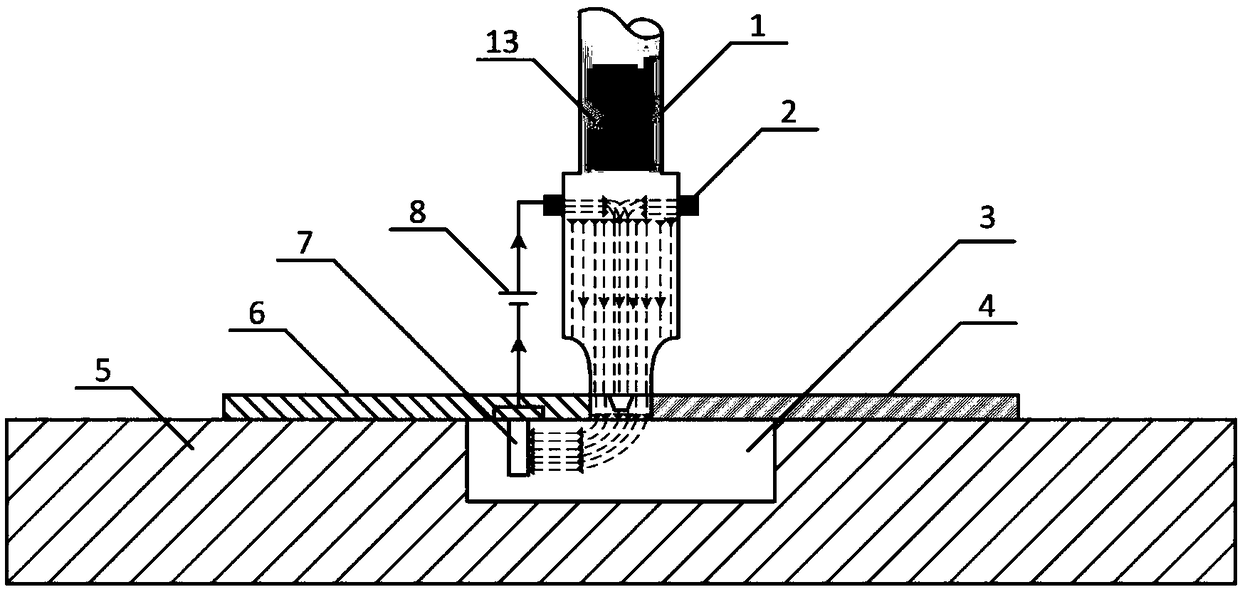

Current-carrying friction stir welding method based on adjustable current distribution

A technology of friction stir and welding methods, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as uneven heat distribution and poor weld performance, so as to improve the surface hardness of the weld, increase heat input, The effect of improving the quality of weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

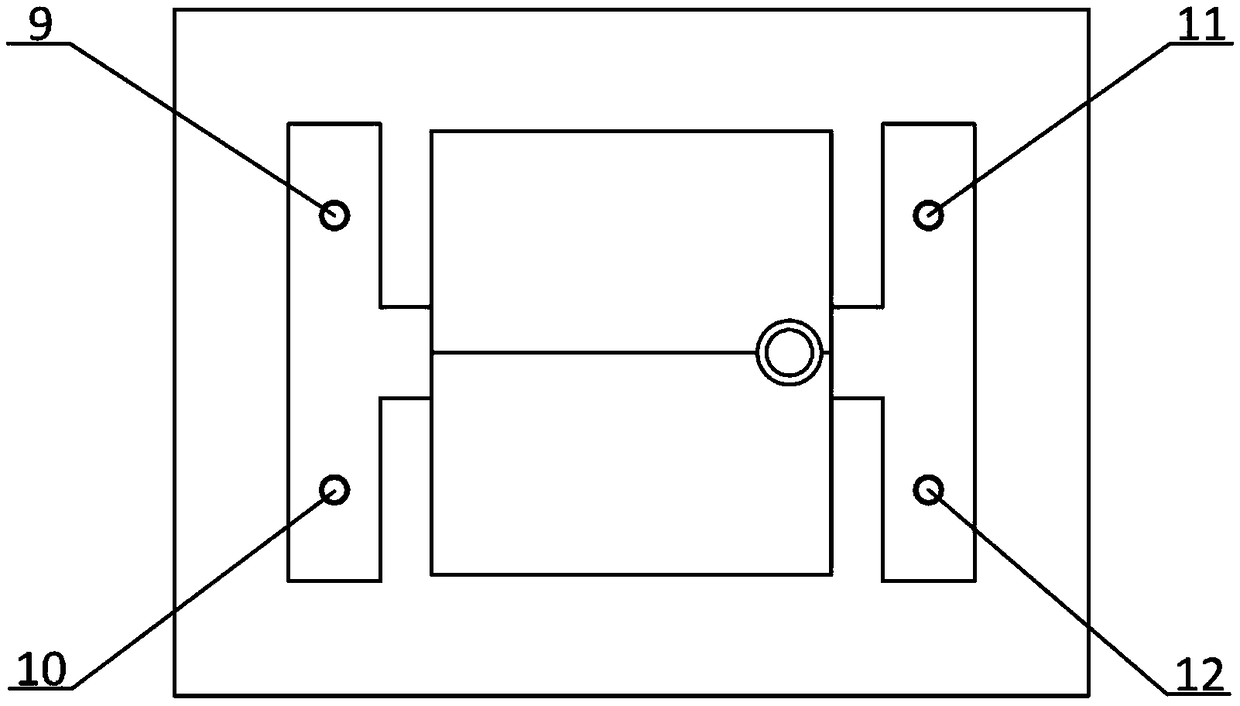

[0028] Example 1: Use this stirring head to conduct current-carrying friction stir welding of 6mm thick 2219 aluminum plate. The welding process parameters are as follows: DC power supply is used to provide current, the DC current is 20-400A, the rotation speed of the stirring needle is 500-1000rmp, and the welding speed is 60- 160mm / min. According to the actual welding objects and materials, the welding process parameters are optimized, and the influence of the auxiliary current on the welding heat input and the influence of the auxiliary current on the small welding process parameters are considered. Among them, the fracture position of the welded joint connected to the preheating forward side port of the deflector changes, and the tensile strength increases by 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com