A construction test method for improving the slag soil of shield tunneling with water-rich sand layer

A technology for soil improvement and water-rich sand layer, which is used in earth-moving drilling, mining equipment, tunnels, etc., and can solve the problem of unreasonable modifier parameters and driving parameters, poor soil improvement effect, and increased shield machine wear. and other problems, to achieve the effect of solving the phenomenon of sand gushing and water gushing, good flow plasticity and earth pressure balance, and preventing slag from forming cakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

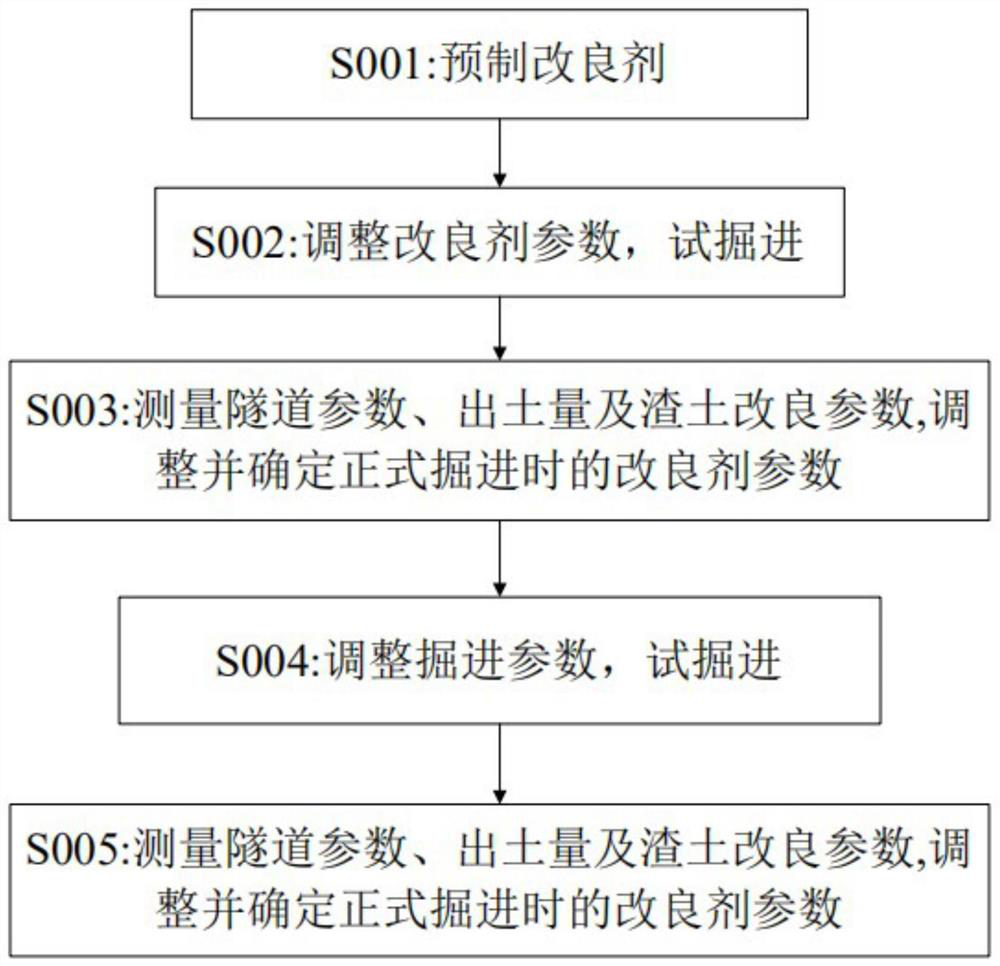

[0041] Specific embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0042] The so-called slag improvement is to inject the modifier through the modifier injection port configured in the shield machine cutter head, soil bin and screw conveyor, and use the cutter head, soil silo stirring wings or screw conveyor to rotate and stir the additive and soil slag. The main purpose of mixing is to make the slag cut by the shield have good fluidity, suitable consistency, lower water permeability and lower frictional resistance, that is, the plastic fluidization transformation of the excavated soil, so as to meet the needs of Under different geological conditions, the ideal working state can be achieved when different excavation modes are adopted.

[0043] The improved slag has better earth pressure balance effect, which is conducive to stabilizing the excavation surface and controlling the surface settlement. The slag has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com