A kind of easily degradable environment-friendly dispersing foam agent for mudstone geological shield and preparation method

An easily degradable and environmentally friendly technology, applied in chemical instruments and methods, applications, building structures, etc., can solve the problems of poor environmental degradation performance, poor environmental microbial degradation performance, and no mention of foam agent dispersion performance, etc., to achieve Improve flow plastic properties, good clay dispersion function, environmental protection and social benefits are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

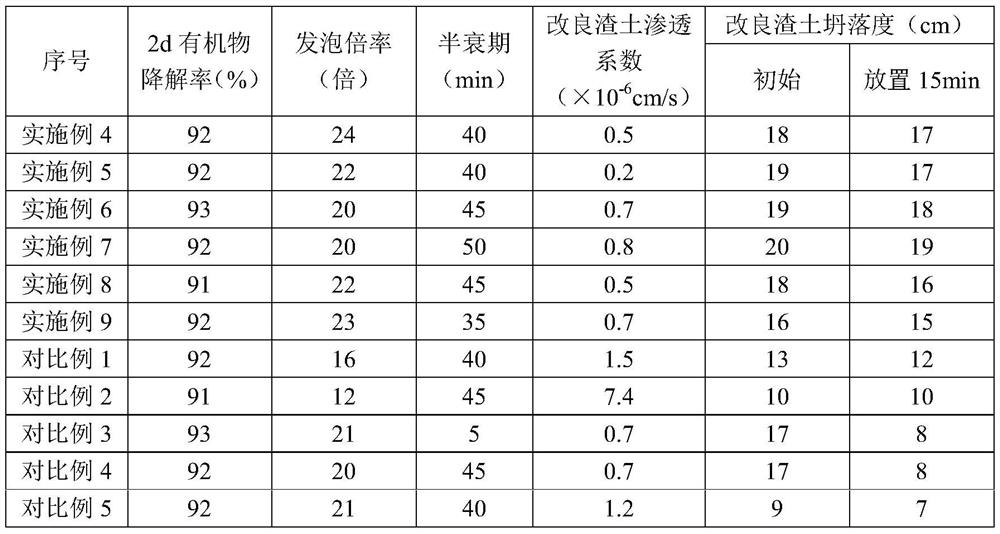

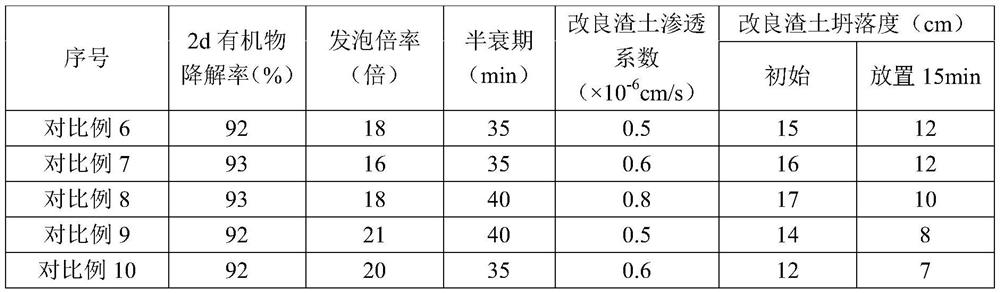

Examples

Embodiment 1

[0028] The easily degradable and environmentally friendly dispersing foaming agent for mudstone geological shield in the present embodiment is composed of the following raw materials by weight percentage: 10% of alkyl ethyl sulfonate, 3% of rhamnolipid, 2% of sodium lactate %, carrageenan 0.8%, citric acid 2%, potassium tannin 1.2%, chitosan 0.5%, and the balance is water; wherein, the straight-chain alkyl carbon number of alkyl ethyl sulfonate is 14; Liglycolipid is obtained by fermentation of Pseudomonas aeruginosa, and its critical micelle concentration CMC is 22.5mg / L, which can reduce the water surface tension to 31.5mN / m; carrageenan is K-type, I-type and λ-type The mixture of carrageenan, wherein the total mass proportion of K-type and I-type carrageenan is 90%; the deacetylation degree of chitosan is 80%.

[0029] The preparation method of the easily degradable environment-friendly dispersed foaming agent for mudstone geological shield of the present embodiment compris...

Embodiment 2

[0035]The easily degradable and environmentally friendly dispersing foaming agent for mudstone geological shield in the present embodiment is composed of the following raw materials by weight: 5% of alkyl ethyl sulfonate, 2% of rhamnolipid, potassium lactate 1%, carrageenan 0.5%, citric acid 1%, potassium tannin 0.5%, chitosan 0.2%, and the balance is water; wherein, the straight-chain alkyl carbon number of the alkyl ethyl sulfonate is 10; Rhamnolipid is obtained by fermentation of Pseudomonas aeruginosa, and its critical micelle concentration CMC is 22.1mg / L, which can reduce the water surface tension to 31.1mN / m; carrageenan is K-type, I-type and λ-type The mixture of type carrageenan, in which the total mass of K-type and I-type carrageenan accounts for 92%; the deacetylation degree of chitosan is 70%.

[0036] The preparation method of the easily degradable environment-friendly dispersed foaming agent for mudstone geological shield of the present embodiment comprises the ...

Embodiment 3

[0042] The easily degradable and environmentally friendly dispersing foaming agent for mudstone geological shield in the present embodiment is composed of the following raw materials by weight percentage: 15% of alkyl ethyl sulfonate, 5% of rhamnolipid, 3% of sodium lactate %, carrageenan 1%, citric acid 3%, potassium tannin 2%, chitosan 0.7%, and the balance is water; wherein, the straight-chain alkyl carbon number of alkyl ethyl sulfonate is 12; Liglycolipids are obtained by fermentation of Pseudomonas aeruginosa, and the critical micelle concentration CMC is 22.3 mg / L, which can reduce the water surface tension to 31.2 mN / m; carrageenan is K-type, I-type and λ-type The mixture of carrageenan, in which the total mass of K-type and I-type carrageenan accounts for 95%; the deacetylation degree of chitosan is 85%.

[0043] The preparation method of the easily degradable environment-friendly dispersed foaming agent for mudstone geological shield of the present embodiment compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com