New earth pressure balance shield machine and working method thereof

A technology of earth pressure balance and shield machine, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of not being able to find the construction site of the working well, and achieve the effects of increasing flow plasticity, reasonable combination, and great promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

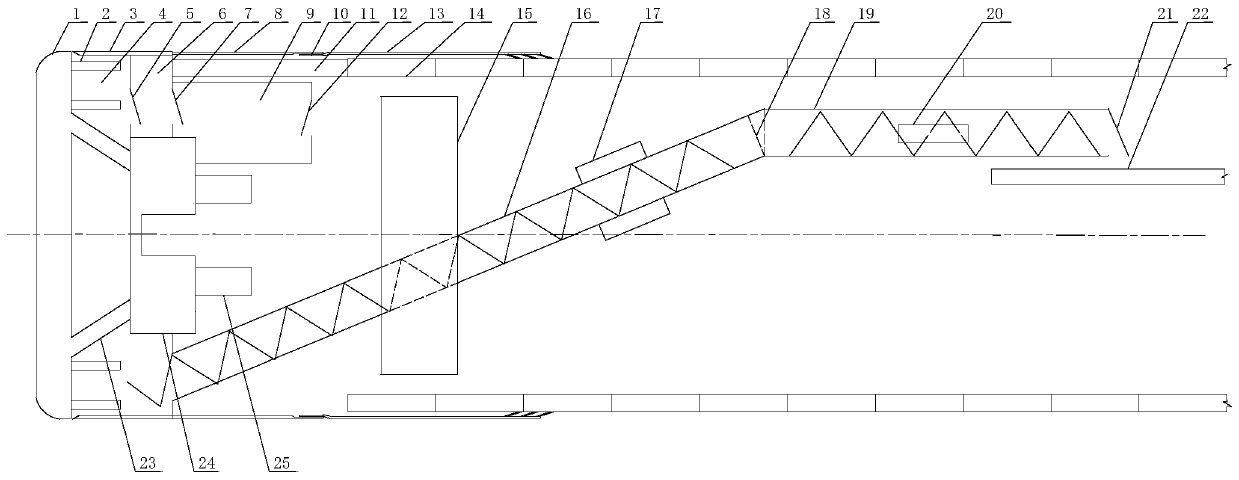

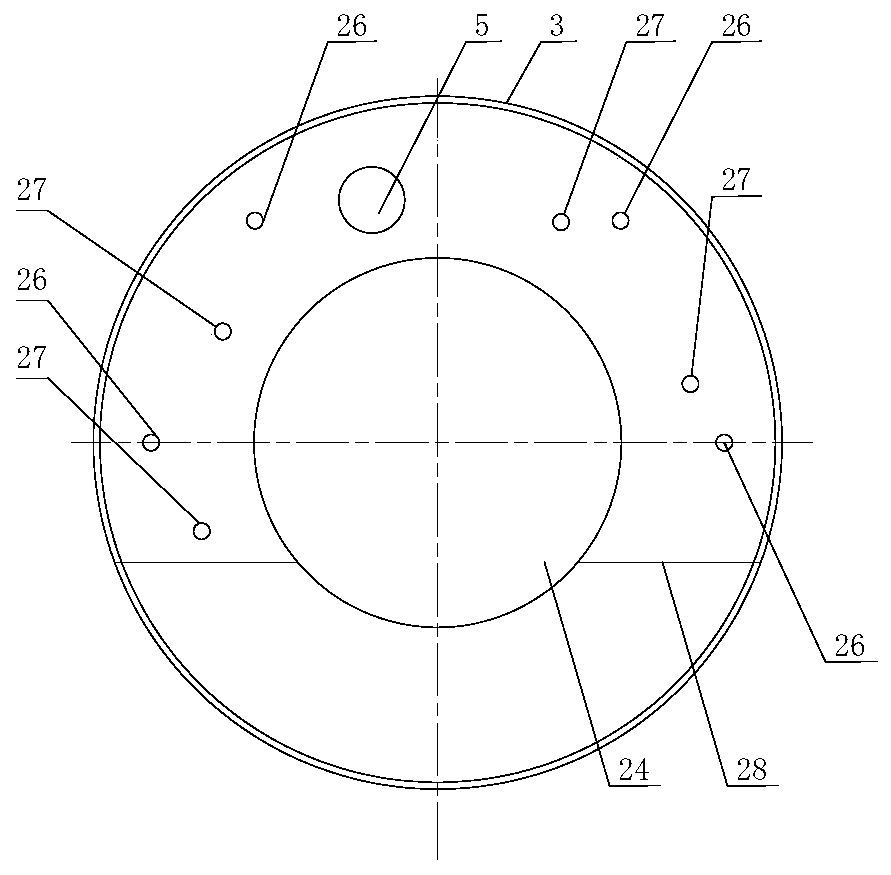

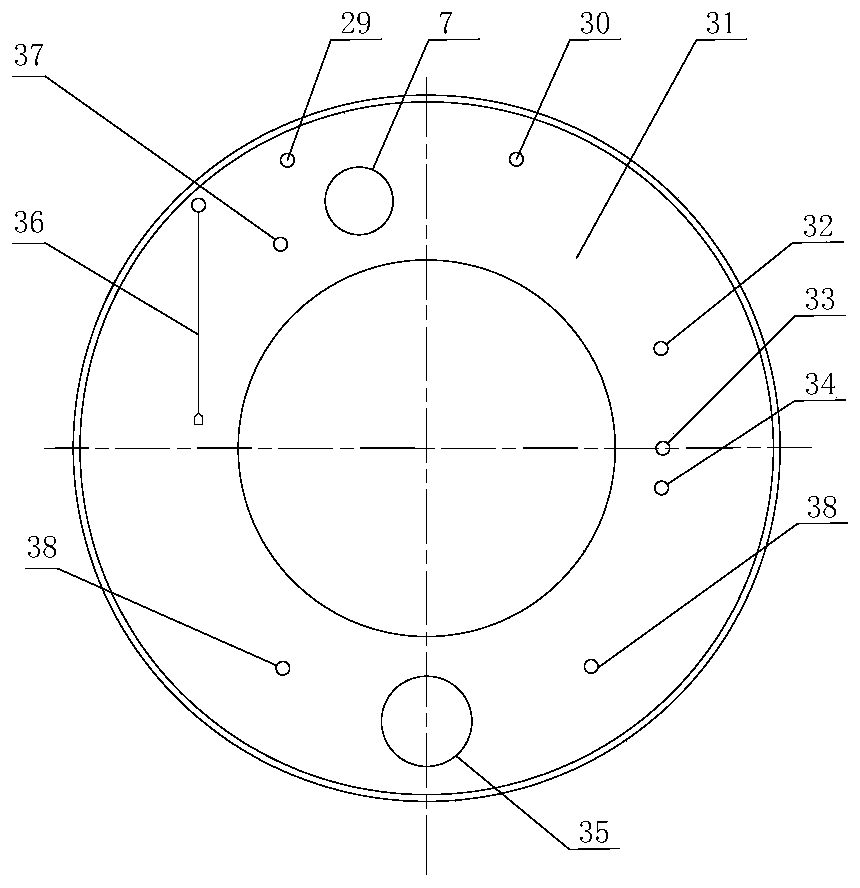

[0032] Such as figure 1 with figure 2 As shown, a new type of earth pressure balance shield machine includes cutter head 1, front shield 3, middle shield 8, man gate 9, shield tail 13, assembly machine 15, main drive 24 and screw conveyor, front shield 3 and A front shield partition 31 is installed between the middle shield 8, and a middle partition 28 is installed in the front shield 3 to divide the space of the front shield 3 into two parts. The front is a soil cabin 4, and the rear is an air cushion cabin 6; Closed; the cutter head 1 is connected with the large gear ring of the main drive 24 through the support arm 23; a hinged seal 10 is provided between the middle shield 3 and the shield tail 13.

[0033] The front shield partition 31 is provided with a first gate 7, an air inlet 30 and an exhaust port 29, a second gate 12 is provided on the access gate 9; an access door 5 is provided on the intermediate partition 28; the first gate 7 is provided in the front The upper part...

Embodiment 2

[0036] This embodiment is similar to the first embodiment, and the difference is that an active stirring rod 2 is installed behind the cutter head 1 and a passive stirring rod 26 is installed on the intermediate partition 28.

[0037] Alternatively, two stirring rods are arranged at the upper part of the rear of the cutter head 1, and two stirring rods are arranged at the lower part of the rear of the cutter head 1; the stirring rods are located on the vertical line of the cutter head 1. As the cutter head 1 rotates, the active stirring rod 2 rotates in the soil chamber 4 to stir the residue in the soil chamber 4, and a good stirring effect can also be achieved.

[0038] Such as figure 1 with figure 2 As shown, the position of the active stirring rod 2 and the position of the passive stirring rod 26 are staggered. Generally speaking, the muck is first stirred by the active stirring rod 2 and then pushed onto the passive stirring rod 26 for stirring. The two cooperate with each oth...

Embodiment 3

[0041] Traditional screw conveyors are often only set at one level, but due to the limited height of the shield machine, the transportation distance is often limited. The invention is equipped with a two-stage screw conveyor, which can transport a longer distance and ensures that the belt 22 can be arranged horizontally.

[0042] The screw conveyor includes two sections, the first section of the screw conveyor 16 and the second section of the screw conveyor 19; the first section of the screw conveyor 16 is arranged obliquely, and the front of the first section of the screw conveyor 16 is located on the front shield partition 31 slag conveying port 35; the second section of screw conveyor 19 is arranged horizontally. The first section of the screw conveyor 16 and the second section of the screw conveyor 19 may be connected by a spherical hinge 18 or a spherical joint, or may be connected by a soft rubber joint.

[0043] For the drive of the screw conveyor, a circular drive can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com