Patents

Literature

56 results about "Active mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

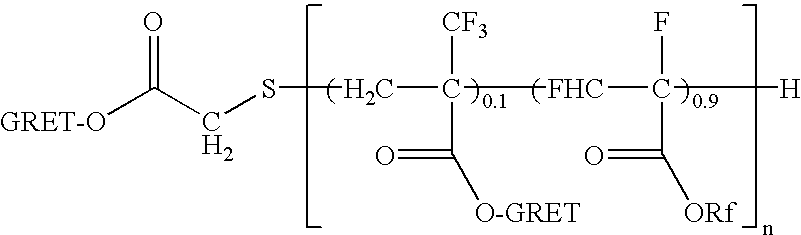

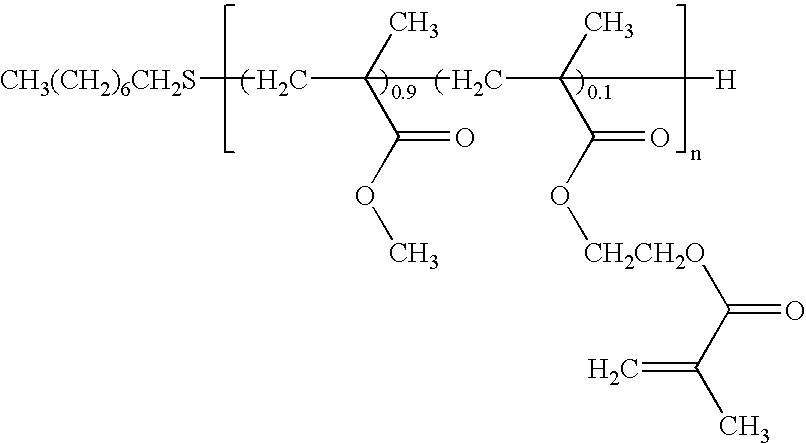

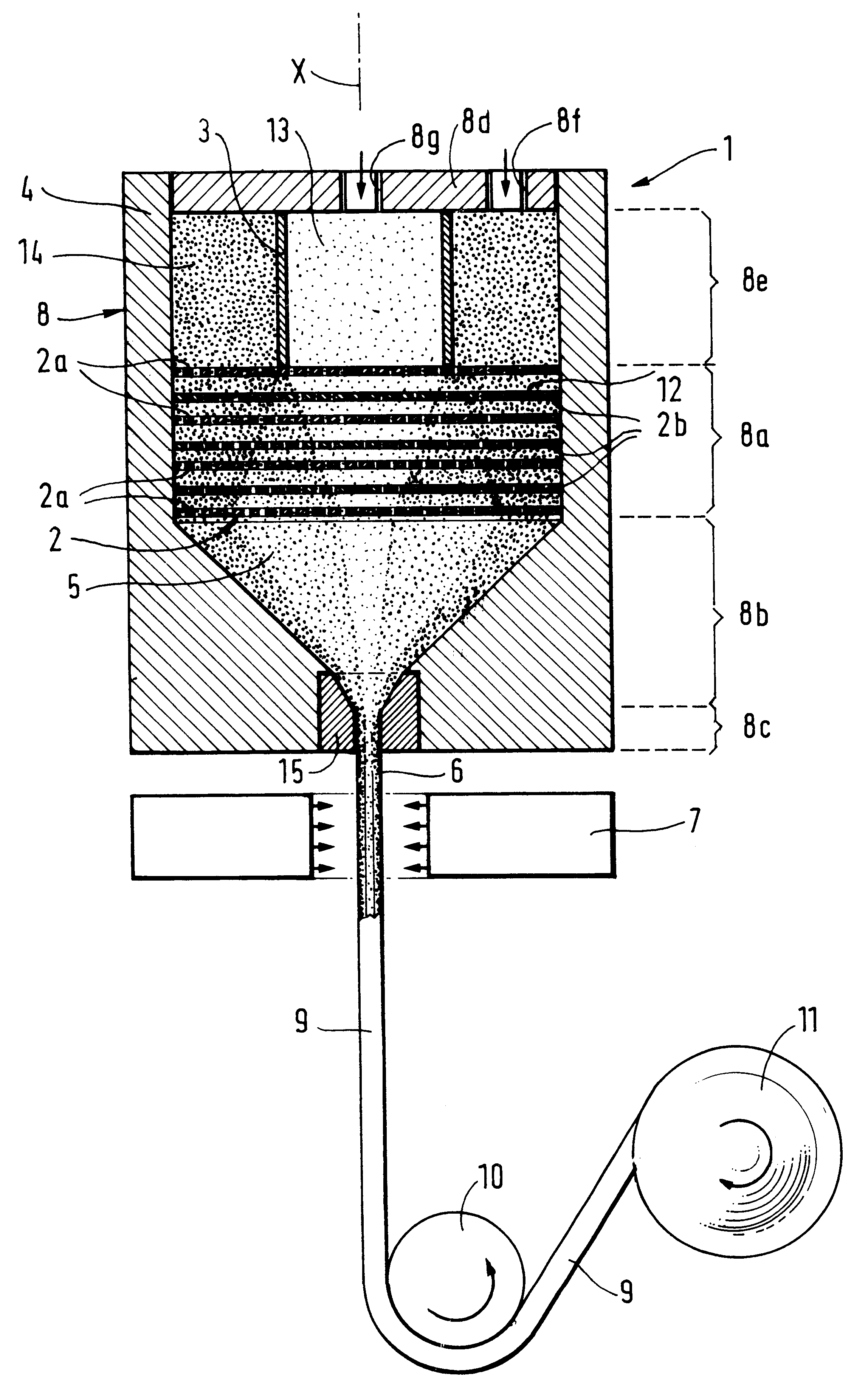

Method of manufacturing a graded-index plastics optical fiber

InactiveUS6576166B1Efficient preparationEasy to placeOptical fibre with graded refractive index core/claddingFlow mixersFiberPolymer science

A method and apparatus for manufacturing a graded-index plastics optical fiber of continuously varying index profile, starting from a particular polymer P and a particular compound M1, the method including the steps of: preparing two compositions of different refractive index, allowing the compositions to diffuse one into the other, and spinning the compositions so as to obtain the fiber, wherein, prior to extrusion, the two compositions are subjected to active mixing, and extrusion of the fiber is followed by curing.

Owner:NEXANS

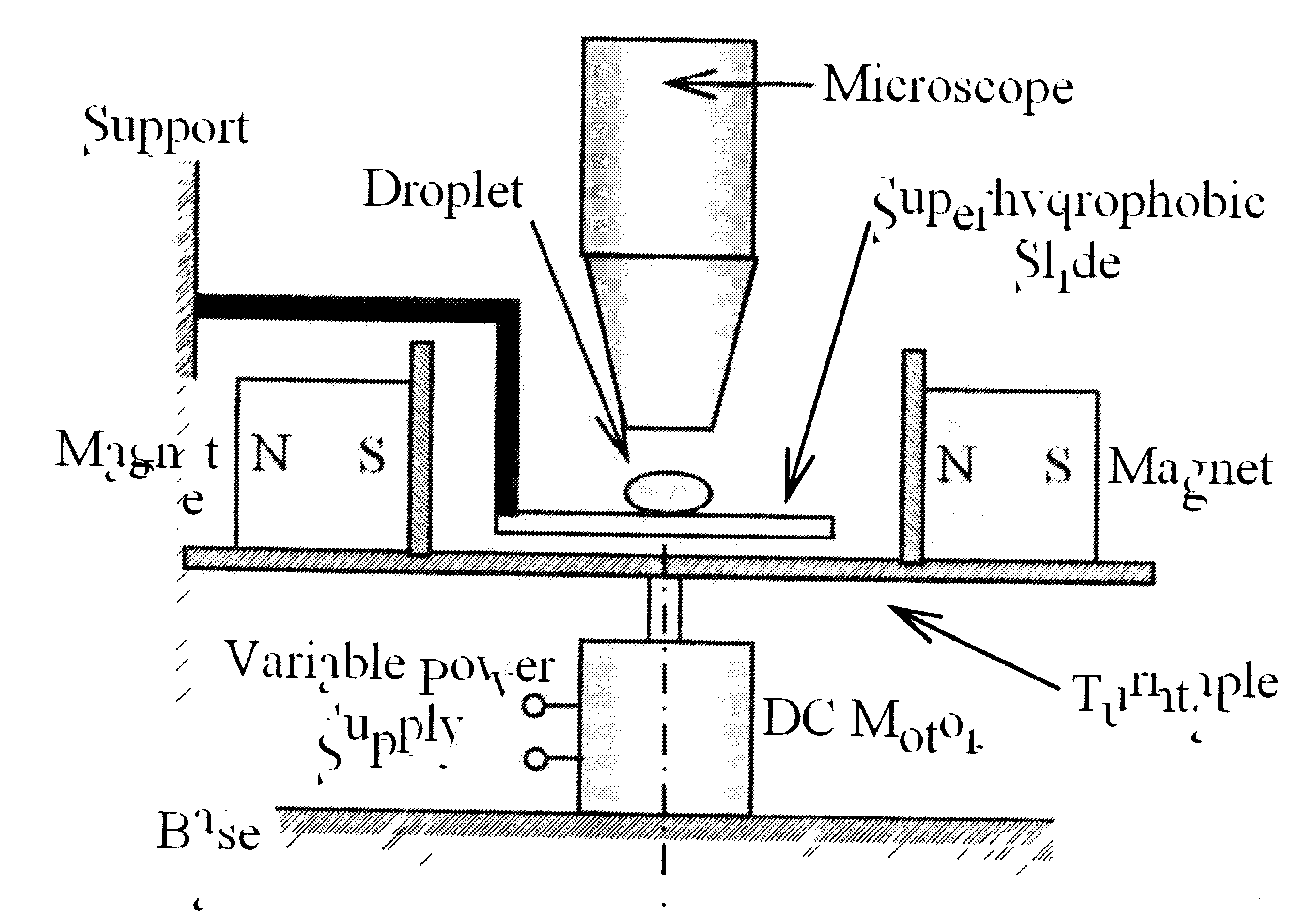

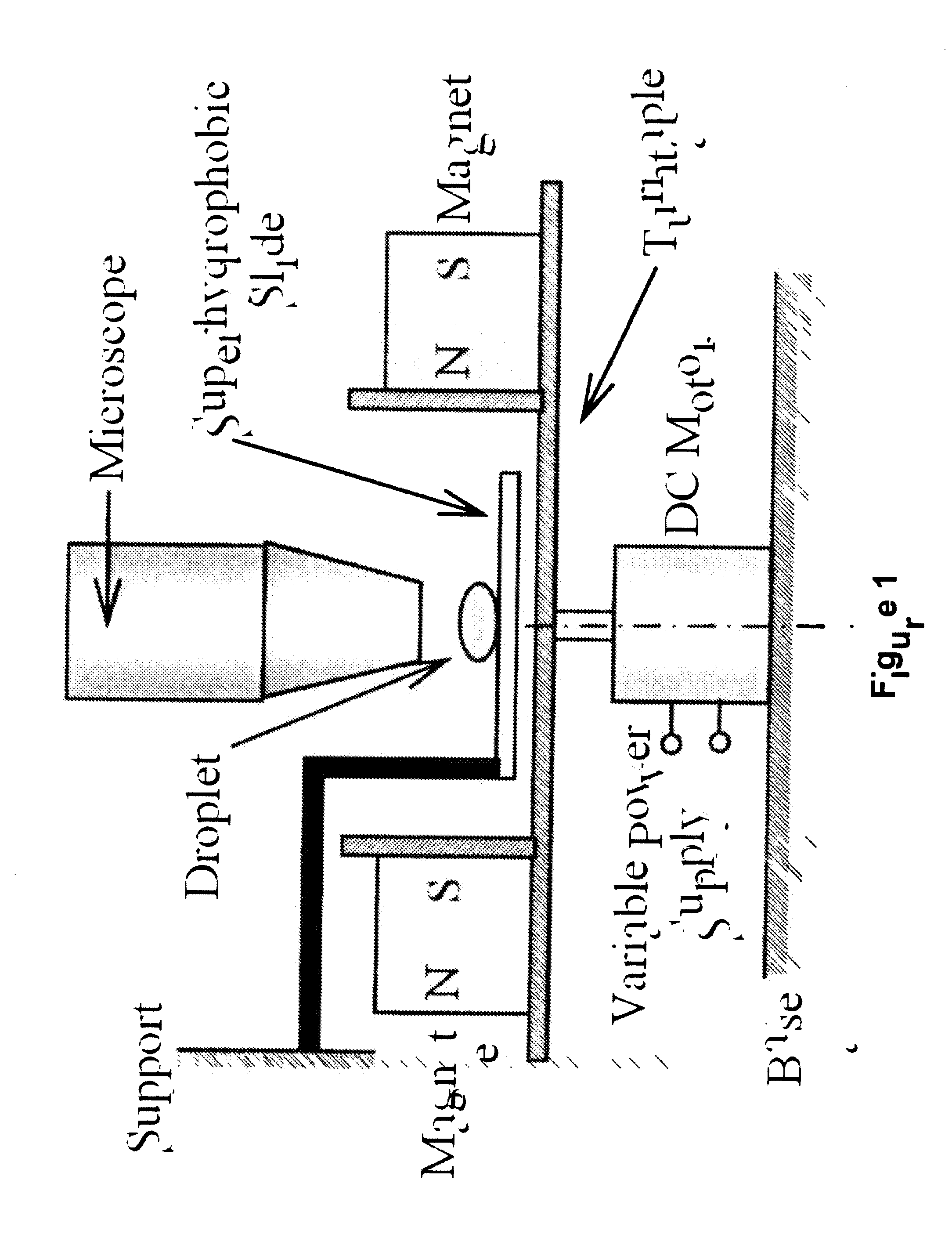

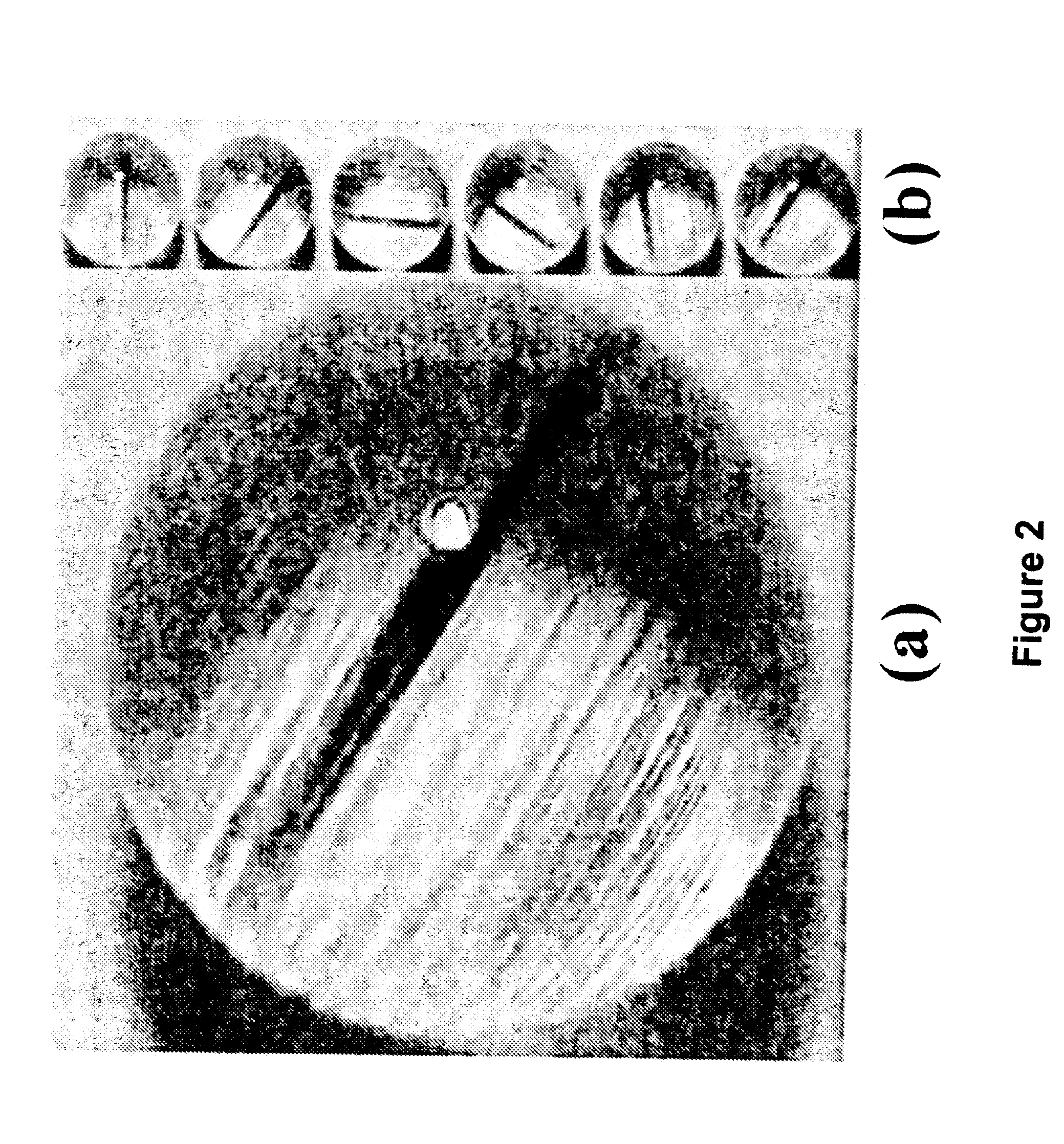

Method and apparatus for magnetic mixing in micron size droplets

InactiveUS20070207272A1Increase fluid-particle interactionEfficient productionMixersPretreated surfacesDiffusionMicrosphere

Active mixing by magnetic stirring is demonstrated inside a picoliter-size liquid droplet. Magnetic microspheres are added to the droplet, which form aligned chains under the influence of a homogeneous magnetic field. When the magnetic field is rotated, the chains also rotate synchronously. Viscous interaction between the particle-chains and the liquid induces advective motion inside the droplet thereby enhancing mixing which is otherwise diffusion-limited. The concept can be effectively used to create a lab-in-a-droplet for MEMS (Micro-Electrical-Mechanical Systems) and Bio-MEMS applications.

Owner:VIRGINIA TECH INTPROP INC

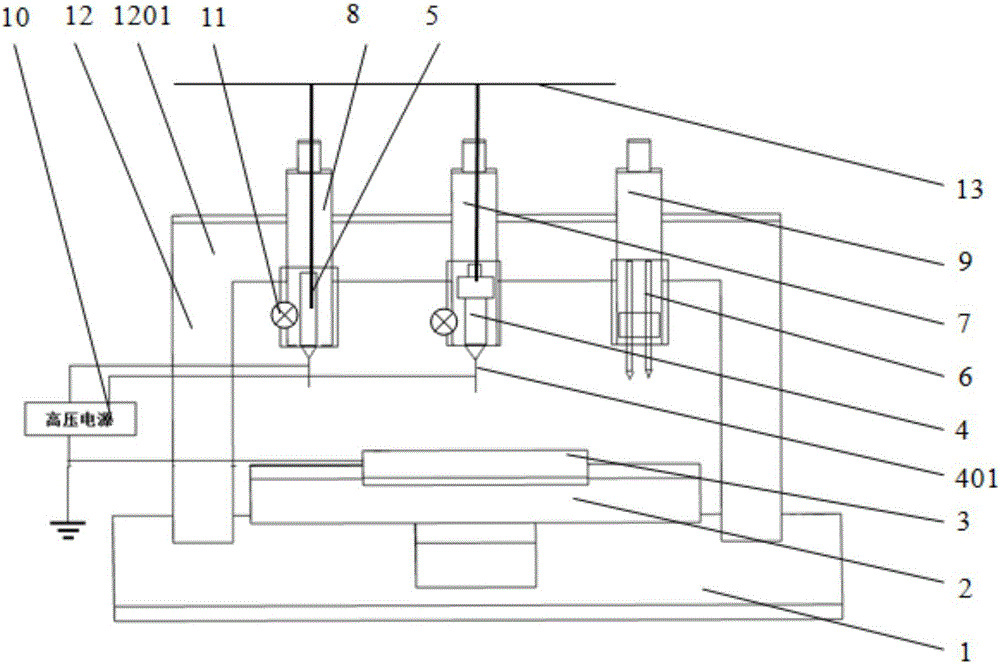

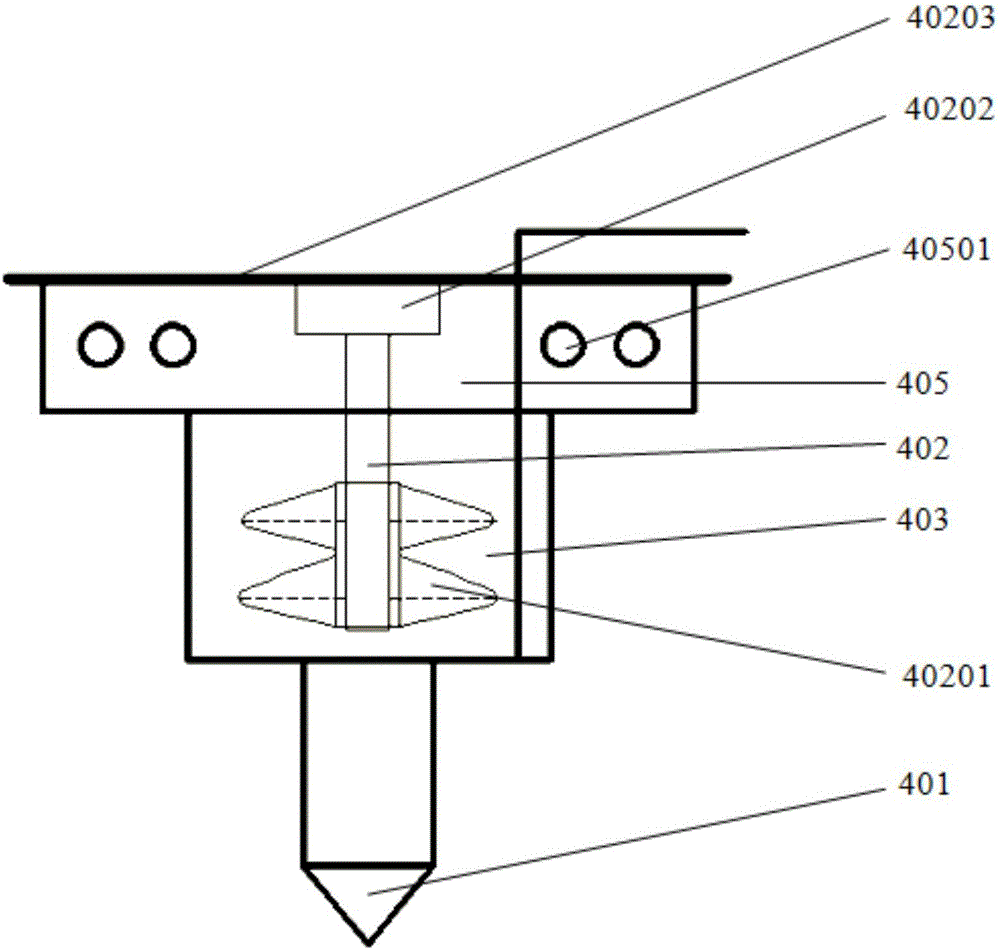

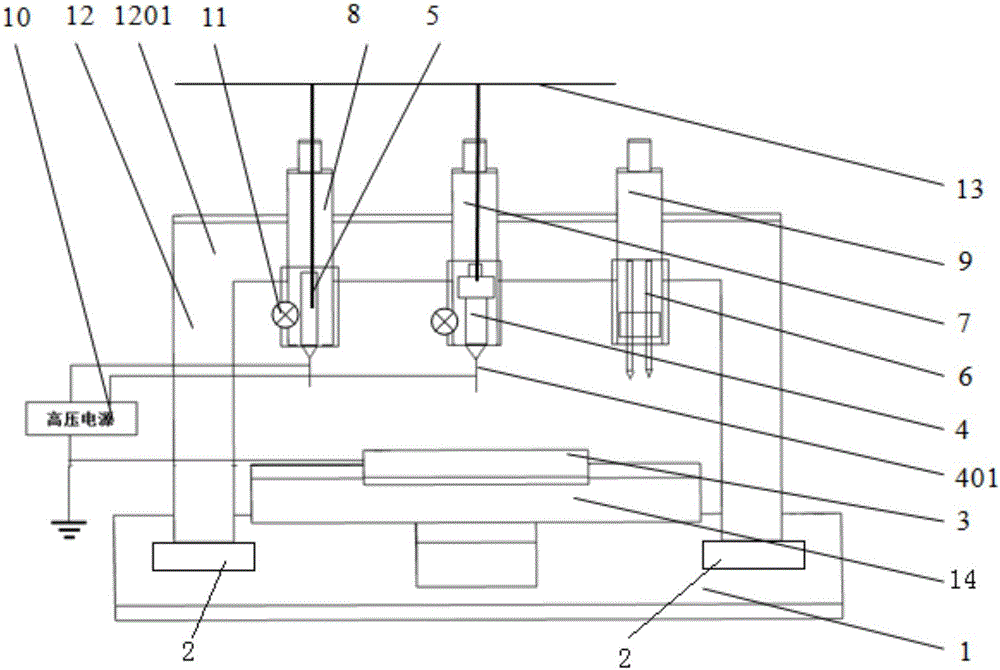

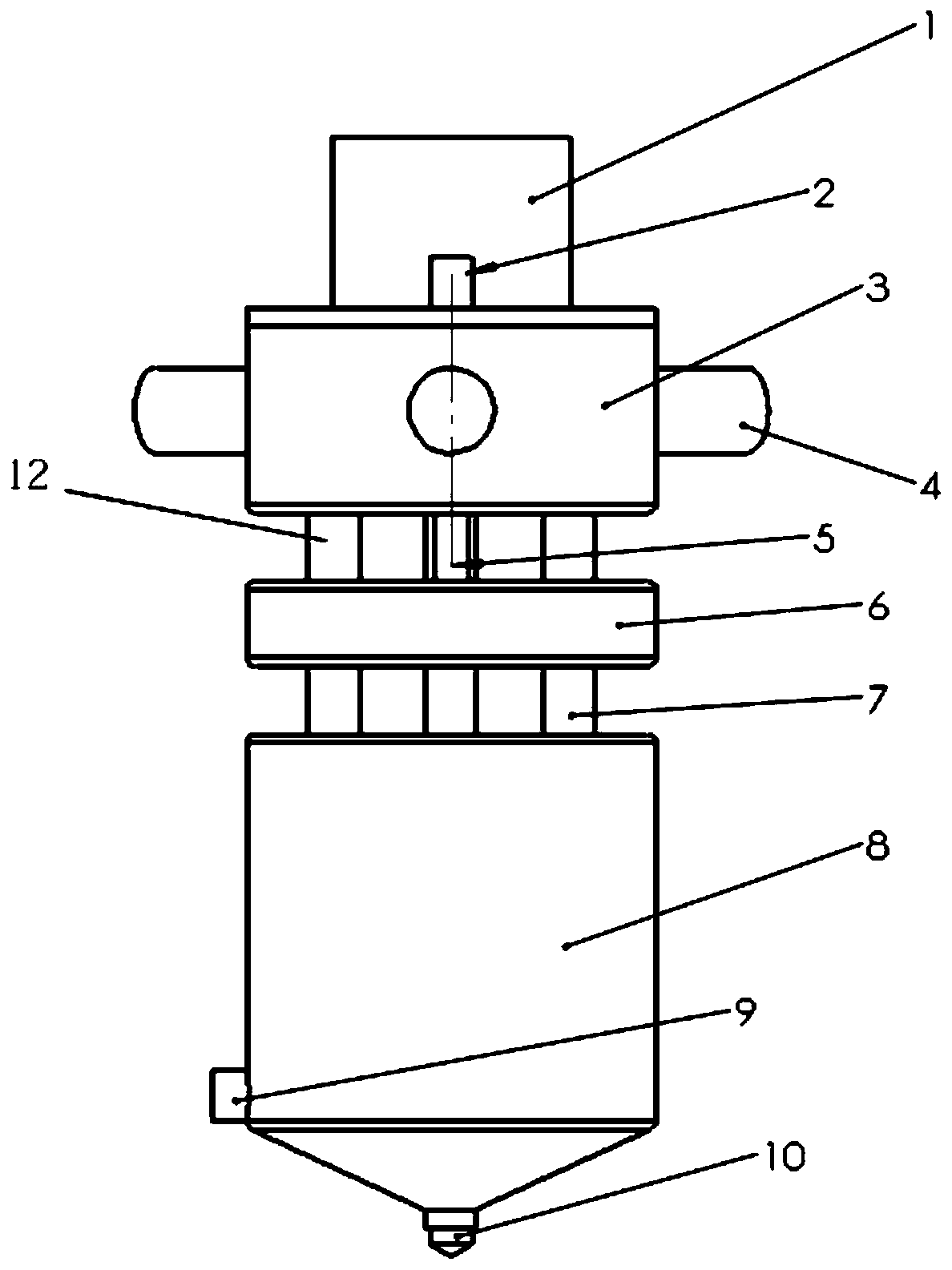

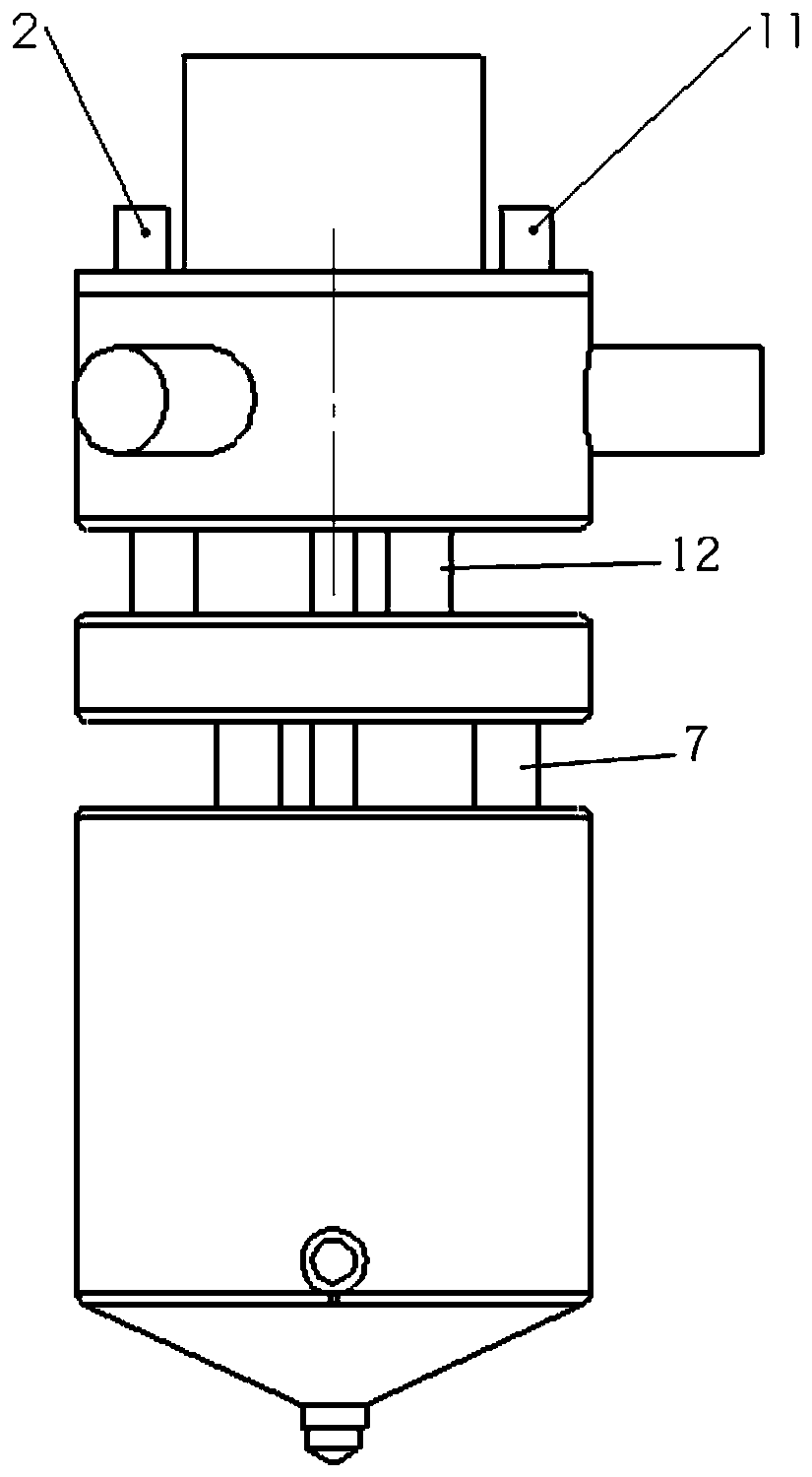

Multi-material composite 3D printer and working method and application of multi-material composite 3D printer

ActiveCN106273497ASolve the costSolve the problem of precise regulationAdditive manufacturing apparatusMulti materialSpray nozzle

The invention discloses a multi-material composite 3D printer and a working method and application of the multi-material composite 3D printer. The multi-material composite 3D printer comprises a base which is provided with a working table and a rack, the working table is provided with a printing bed for supporting a printed object, the rack is at least fixedly provided with a first spray head, a second spray head and a third spray head, and the first spray head, the second spray head and the third spray head are all located above the printed object; the first spray head is a multi-material active mixing spray head, the second spray head comprises a micro injector material barrel and an electric conduction spray nozzle arranged at the lower portion of the micro injector material barrel, and the third spray head at least comprises two fusion deposition spray heads, wherein one fusion deposition spray head is used for printing structural materials, and the other fusion deposition spray head is used for printing supporting materials; and electric conduction spray nozzles of the first spray head and the second spray head are both connected with the positive pole of a power source, and the printing bed is connected with the negative pole of the power source. Multi-material and multi-scale complex structure integrated manufacturing is achieved, the structural materials and functional materials are integrally printed, and the technical bottleneck for limiting integrated manufacturing of materials, structures and devices is broken through.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

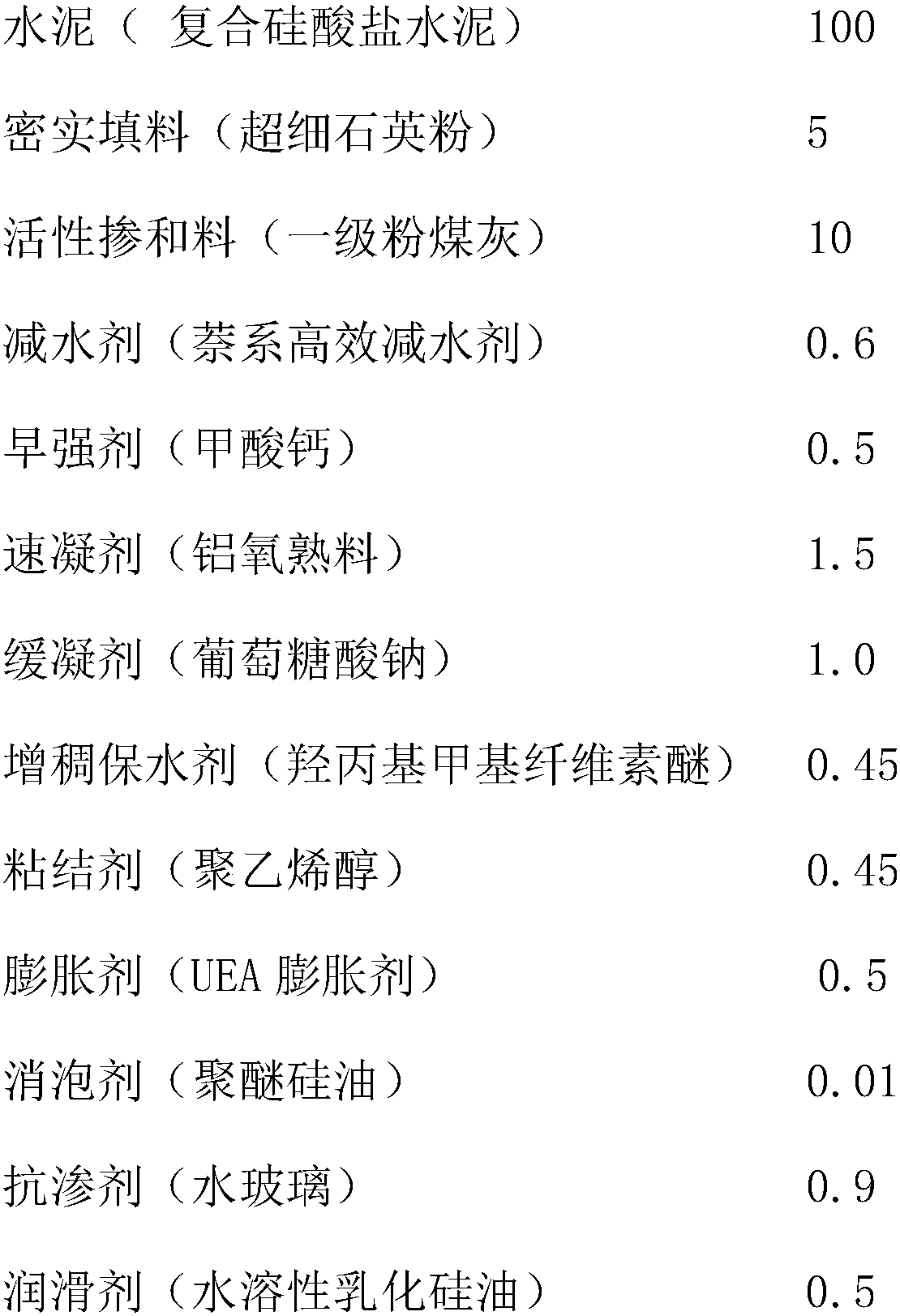

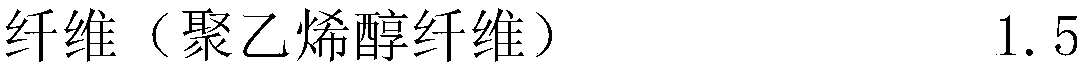

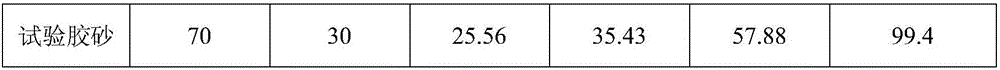

3D printing based cement based inorganic gelling material and preparation method thereof

InactiveCN108484041AWide variety of sourcesLow costAdditive manufacturing apparatusFiberFoaming agent

The invention provides a 3D printing based cement based inorganic gelling material and a preparation method thereof, and relates to a 3D printing material. In order to solve the problems of poorer printing precision and high-precision building component printing incapability of the existing gelling material for printing, the invention provides the 3D printing based cement based inorganic gelling material with the following technical scheme that the 3D printing based cement based inorganic gelling material is prepared from the following ingredients of cement, compaction filling materials, active mixing materials, water reducing agents, earth strength agents, accelerators, retarders, thickening water preservation agents, bonding agents, expansion agents, anti-foaming agents, anti-seepage agents, lubricating agents and fiber. The 3D printing based cement based inorganic gelling material has the beneficial effects that the preparation is simple and convenient; good continuous extrusion performance is realized; good overlapped layer building performance is realized; excellent waterproof, anti-seepage function and good anti-cracking performance are realized.

Owner:深圳市明远建筑科技有限公司

Ultra low density thermally clad microspheres and method of making same

ActiveUS20050282014A1Low densitySynthetic resin layered productsCellulosic plastic layered productsMicrosphereVolumetric Mass Density

Microsphere beads are mixed with a surface barrier solid, liquid or mixture of such a liquid with a solid effective to prevent agglomeration and surface bonding of the microspheres; by the control of the application of heat and balancing temperature and active mixing, removal of water from and expansion of the microsphere is achieved. Microsphere densities of as low as 0.005 to less than 0.015 g / cm3 are realized. The surface barrier solid, liquid or mixture of such a liquid with a solid in the present invention is any one of a wide diversity of materials which meet the requirements of the intended function, i.e., to prevent the agglomeration of the microspheres during the process. Suitable materials include, by way of example, fillers, pigments, plasticizers, diluents, extenders, monomers and oligomers and the like.

Owner:HENKEL IP & HOLDING GMBH

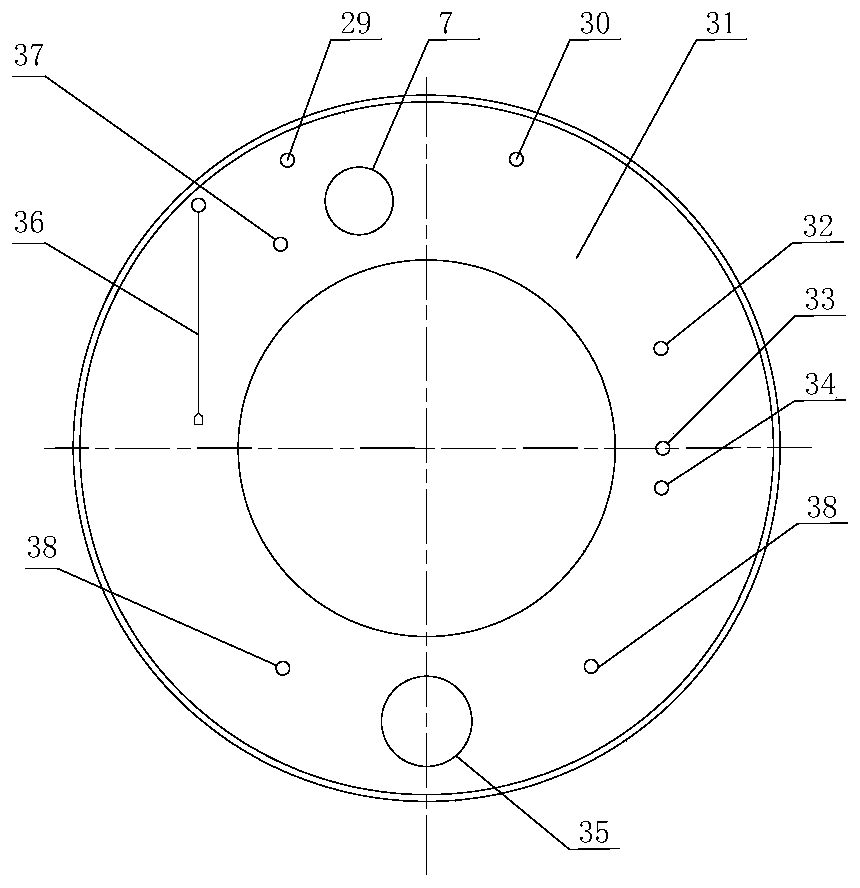

Membrane apparatus with enhanced mass transfer, heat transfer and pumping capabilities via active mixing

InactiveUS7122151B2Increase surface areaReduce deliveryTransportation and packagingRotary stirring mixersEngineeringDistributor

A combination mass transfer and pump apparatus, which in a single step actively mixes a first mass and a second mass and simultaneously pumps one of the first mass and the second mass through the apparatus. The combination mass transfer and pump apparatus substantially comprises a housing and at least one distributor element having a plurality of selectively fluid-permeable membrane elements wherein the at least one distributor element is agitated within the second mass such that the first mass diffuses across the selectively fluid-permeable membrane elements, mixing with the second mass, and in the same step the second mass is pumped through the housing.

Owner:UNIVERSITY OF PITTSBURGH

Ultra low density thermally clad microspheres and method of making same

ActiveUS7368167B2Low densitySynthetic resin layered productsCellulosic plastic layered productsMicrosphereSurface barrier

Microsphere beads are mixed with a surface barrier solid, liquid or mixture of such a liquid with a solid effective to prevent agglomeration and surface bonding of the microspheres; by the control of the application of heat and balancing temperature and active mixing, removal of water from and expansion of the microsphere is achieved. Microsphere densities of as low as 0.005 to less than 0.015 g / cm3 are realized. The surface barrier solid, liquid or mixture of such a liquid with a solid in the present invention is any one of a wide diversity of materials which meet the requirements of the intended function, i.e., to prevent the agglomeration of the microspheres during the process. Suitable materials include, by way of example, fillers, pigments, plasticizers, diluents, extenders, monomers and oligomers and the like.

Owner:HENKEL IP & HOLDING GMBH

Active bauxite dressing tailing micro-powder, and preparation method thereof

ActiveCN102249582AEasy to prepareSolve the emission problemSolid waste managementPortland cementAlkali activated

The invention discloses an active bauxite dressing tailing micro-powder, a preparation method thereof, and an application thereof. The invention belongs to the field of waste recycling. The active micro-powder is prepared through the steps that: 70 to 98wt% of bauxite dressing tailing and 2 to 30wt% of fly ash are mixed, or 92 to 98 wt% of bauxite dressing tailing and 2 to 8wt% of lime are mixed;the mixture are calcined at a temperature of 700 to 900 DEG C, and is grinded, such that a finished product is obtained. The micro-powder also can be prepared from grinded material of a mixture of calcined bauxite dressing tailing and lime. The micro-powder can be used as a preparation raw material of alkali-activated cement, or high active mixing material of composite portland cement. According to the invention, an activation treatment is carried out upon bauxite dressing tailing, which is presently a waste. The method assists in solving discharging and storing problems of bauxite dressing tailing, and provides a precondition for utilizing the resource in the field of cementing materials.

Owner:CHINA BUILDING MATERIALS ACAD

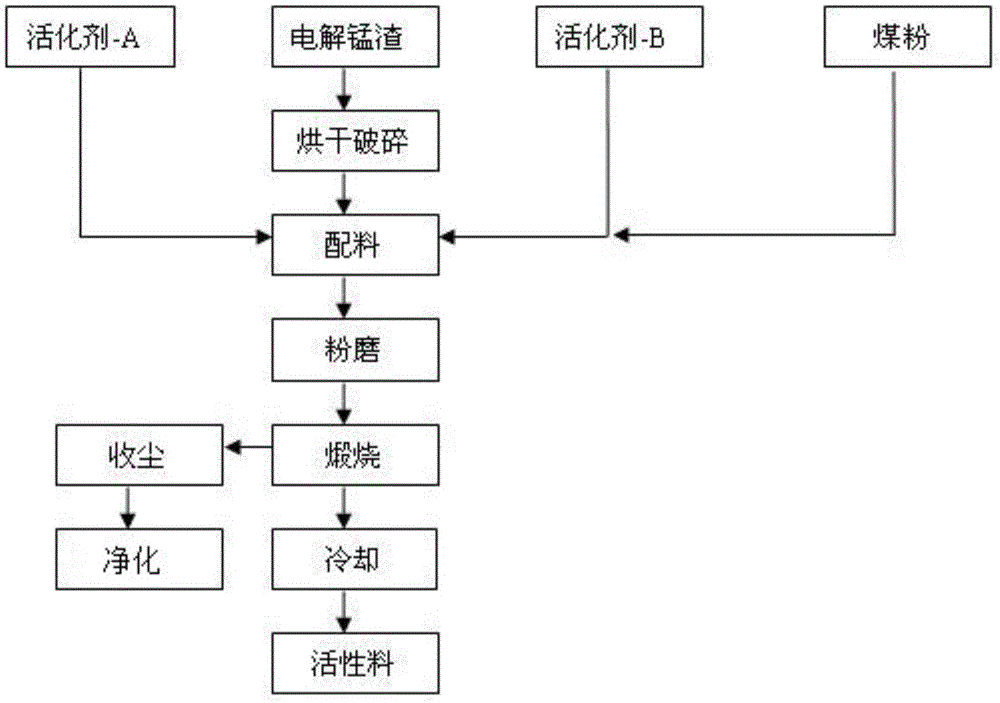

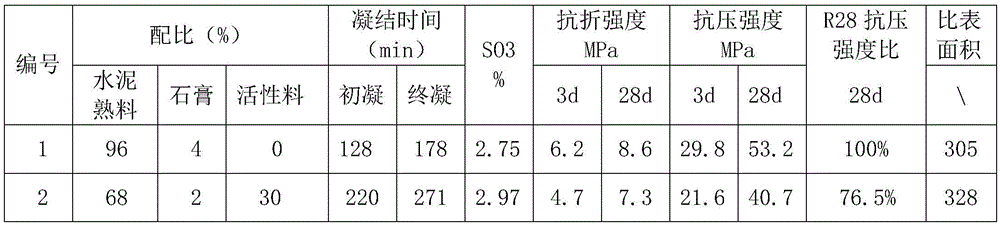

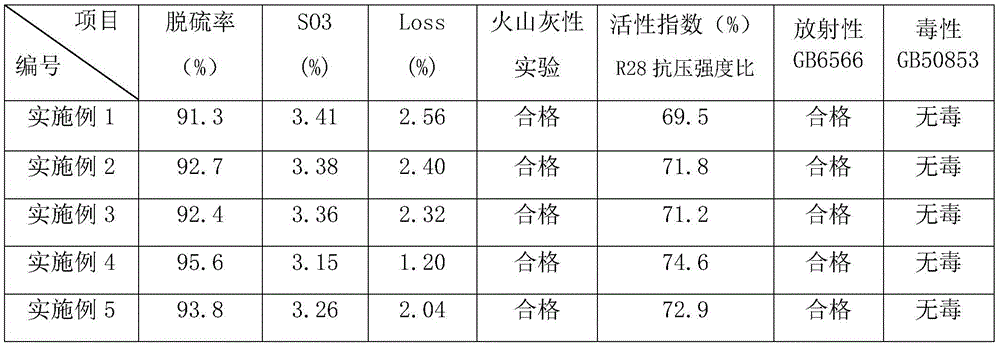

Method using electrolytic manganese slag to manufacture active mixed material

InactiveCN105645793ARemove threatIncrease production capacitySolid waste managementCement productionElectrolysisChemical reaction

The invention discloses a method using electrolytic manganese slag to manufacture an active mixed material. According to the preparation method, an activator and a reducing agent are added into electrolytic manganese slag according to a certain ratio so as to carry out physical and chemical reactions at a high temperature; the reaction products are calcined, and finally the calcined clinker is cooled to obtain the active mixed material. The active mixed material has the properties of volcanic ash, and can be used as the active mixing material in cement industry and composite blending material in commercial concrete industry. A large amount of acid leached slag discharged by electrolytic manganese plants can be used to produce the active mixed material, the environmental pollution generated by harmful components in electrolytic manganese slag is radically eliminated, the clean production of electrolytic manganese can be realized, the pollution is comprehensively controlled, and high economic benefit and environment protection benefit are generated.

Owner:石朝军

Foam concrete capable of pumping and chemically foaming and production method of foam concrete

The invention discloses foam concrete capable of pumping and chemically foaming and an on-site construction production method. The foam concrete comprises the following materials in parts by weight: 75-500 parts of concrete, 20-120 parts of an active mixing material, 40-300 parts of water, 15-50 parts of an adjusting agent, 30-90 parts of a foaming agent and 2-10 parts of a micro foam agent. The volume weight of the prepared foam concrete is 100-600kg / M<3>; the heat conductivity coefficient of the foam concrete is as low as 0.020W / M.DEG C; the strength of the foam concrete can reach 5Mpa. By virtue of the production method, the advantages of cast-in-situ physical foaming and chemical foaming make an organic combination to form a novel construction method; the production method is relatively high in production efficiency, flexible to operate and relatively wide in application; the foam concrete can be made into high-strength product materials with different shapes; the heat-insulating construction of buildings can be effectively completed with high efficiency and low cost.

Owner:河南华泰新材科技股份有限公司

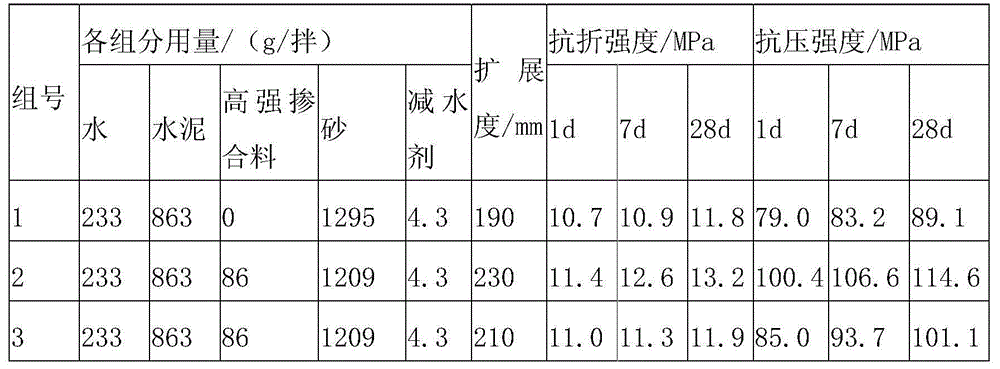

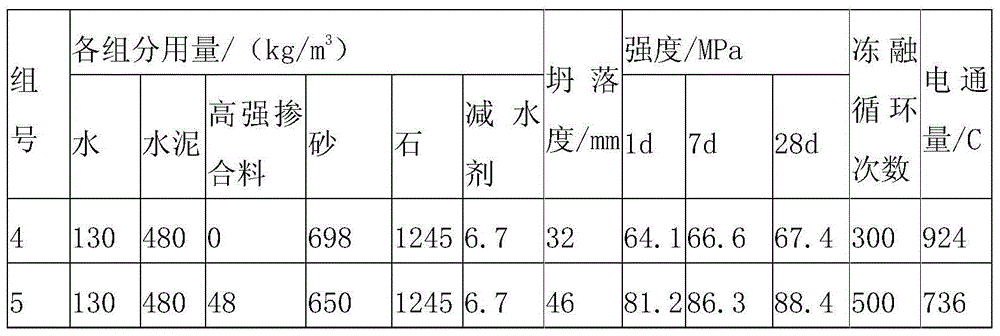

Concrete high-strength admixture, cement mixture and non-autoclaved ultra-high strength concrete product

ActiveCN105819718AImprove early strengthImprove performanceHigh strength concreteUltimate tensile strength

The invention discloses a concrete high-strength admixture, a cement mixture and a non-autoclaved ultra-high strength concrete product. The concrete high-strength admixture comprises the following raw materials by weight percentage: 20-80% of gypsum, 10-78% of an active mixing material, and 0.1-30% of an inorganic exciting agent. The concrete high-strength admixture has the advantage that high strength of the concrete product can be achieved by normal-pressure maintenance.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

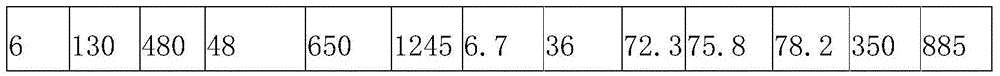

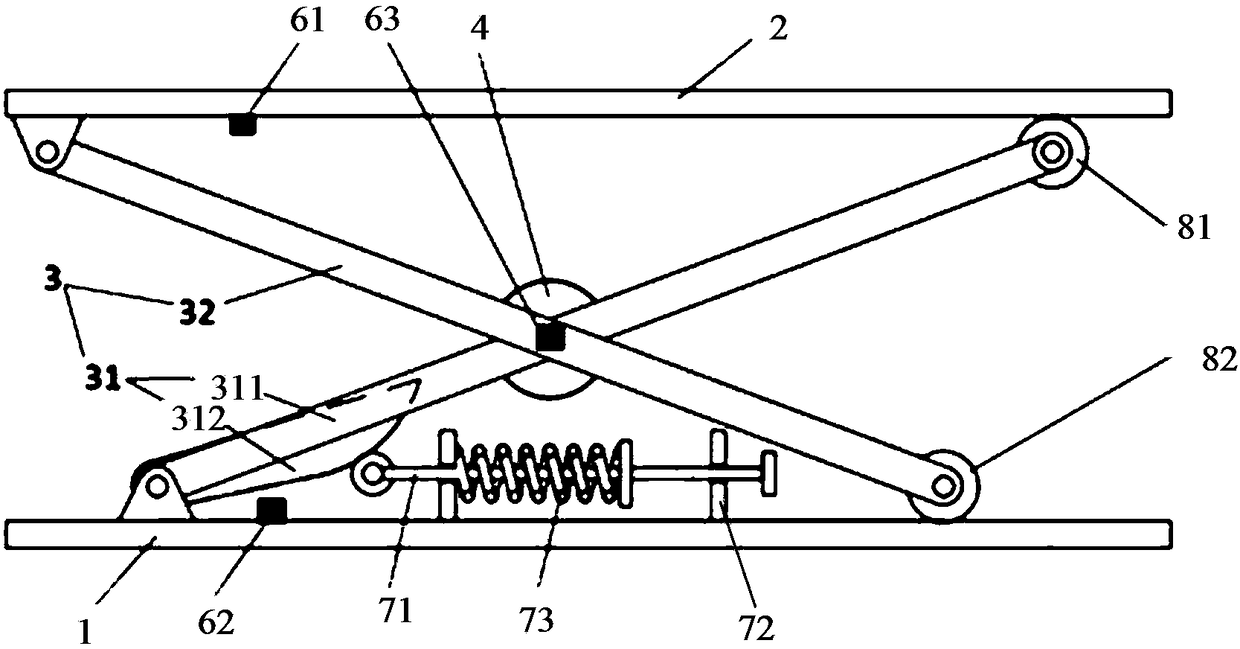

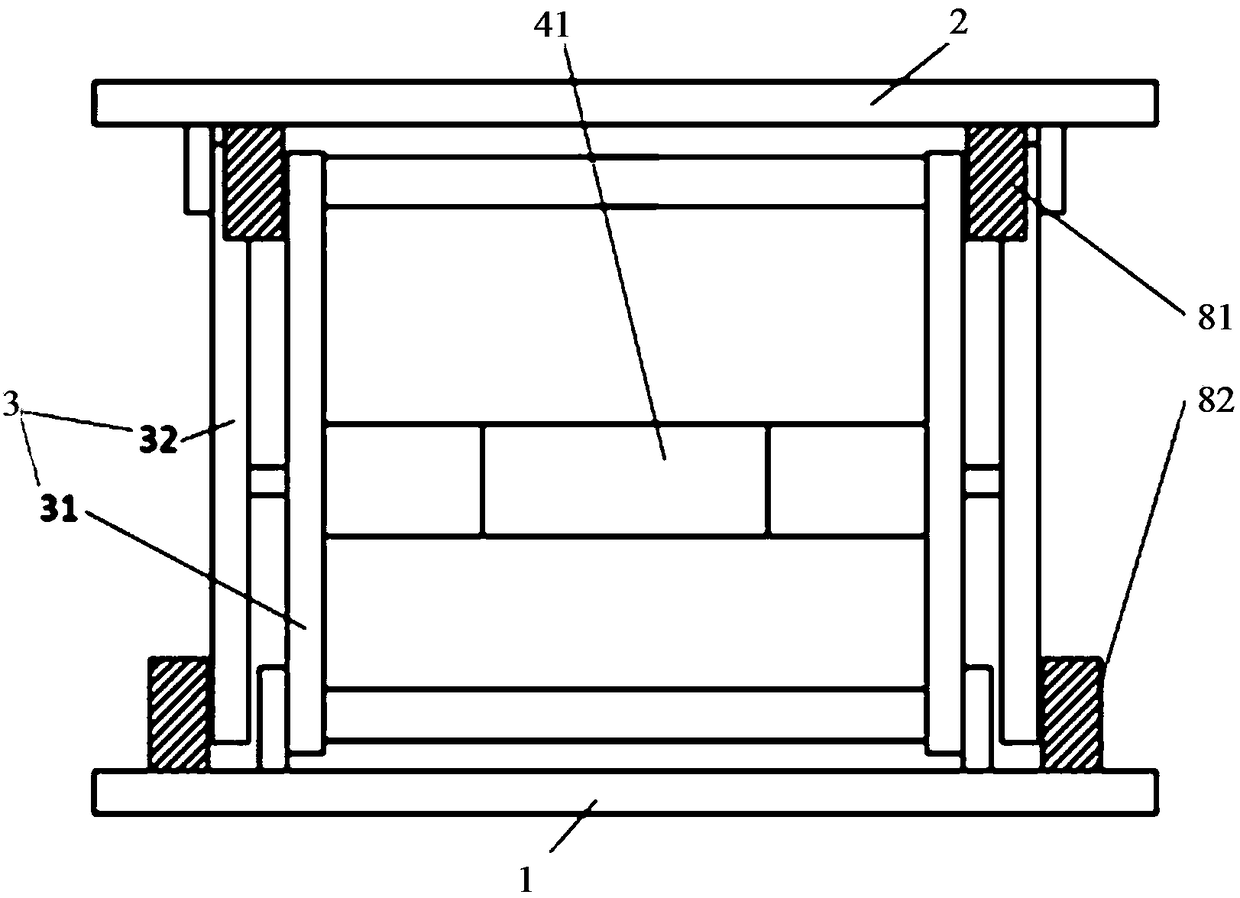

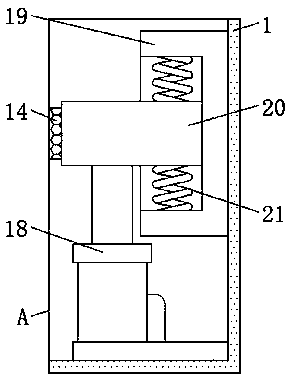

Vehicle and seat suspension based on active and semi-active mixed control

InactiveCN108482199AReduce Active Control Energy ConsumptionSeat suspension devicesSemi activeActuator

The invention discloses a vehicle and a seat suspension based on active and semi-active mixed control. The seat suspension comprises a fixing baseplate, a seat mounting plate, a scissor-type support frame, an actuator and a controller. The fixing baseplate is arranged on a vehicle chassis. A vehicle seat is mounted on the seat mounting plate. The scissor-type support frame is arranged between thefixing baseplate and the seat mounting plate. After the fixing baseplate is vibrated and / or the vehicle seat is loaded with mass, the scissor-type support frame can extend and retract to change the vertical distance between the fixing baseplate and the seat mounting plate. The actuator is used for driving the scissor-type support frame to move. The controller is used for controlling the actuator to move through active control or semi-active control so as to damp the vehicle. The seat suspension has the advantages that the scissor-type support frame is arranged between the fixing baseplate andthe seat mounting plate, the actuator is connected with the scissor-type support frame, the controller controls the actuator to move through active control or semi-active control to damp the vehicle,and power consumption of the active control can be reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

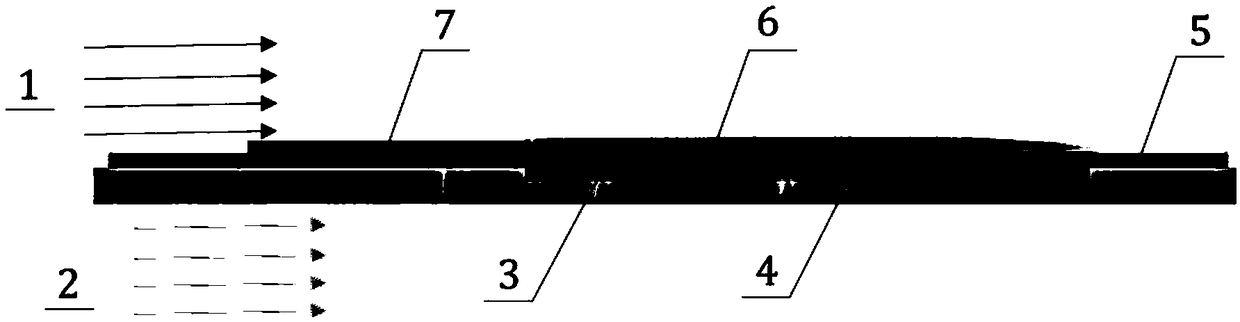

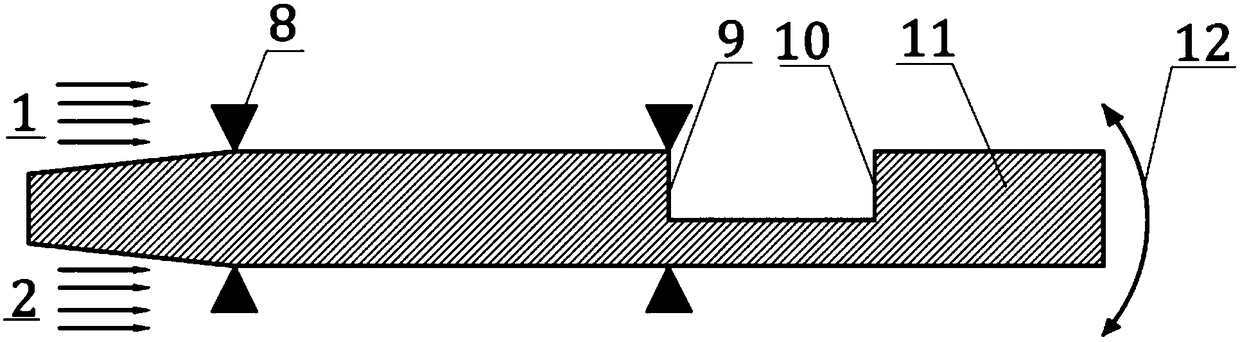

Supersonic mixing reinforcing device

InactiveCN109253470AWell mixedImprove mixing efficiencyContinuous combustion chamberRocket engine plantsEngineeringActive mixing

The invention relates to a supersonic mixing reinforcing device, which comprises a mixing reinforcing plate arranged between the two supersonic flow channels of the two supersonic air flows, wherein the upper side plate surface of the mixing reinforcing plate is provided with a concave cavity recessed from the upper side plate surface to the lower side plate surface; a section of the mixing reinforcing plate after the concave cavity and up to the end of the mixing reinforcing plate is called an oscillation plate; a mixing reinforcing plate, wherein a first supersonic flow channel for flowing afirst supersonic air flow is arranged above the mixing reinforcing plate, and a second supersonic flow channel for passing through a second supersonic air flow is arranged below the mixing reinforcing plate; the first supersonic air flow flows over the mixing reinforcing plate along the length direction of the mixing reinforcing plate to the tail end of the mixing reinforcing plate, and the second supersonic air flow below the mixing reinforcing plate flows along the length direction of the mixing reinforcing plate to the tail end of the mixing reinforcing plate, the first supersonic air flowand the second supersonic air flow realize enhanced mixing outside the tail end of the mixing reinforcing plate. By means of the invention, the energy of the supersonic air flow is utilized to achieve the effect of active mixing enhancement.

Owner:NAT UNIV OF DEFENSE TECH

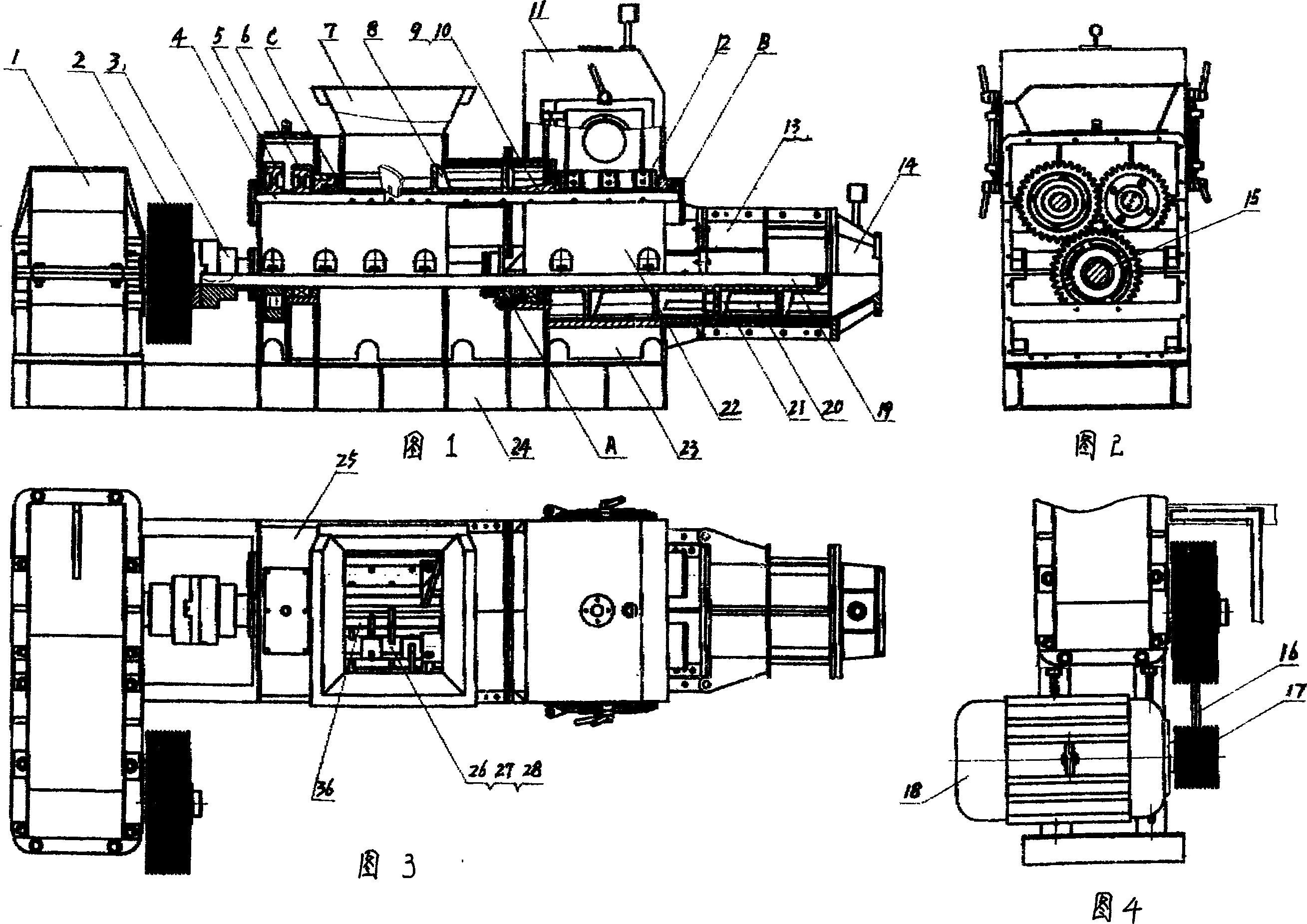

Energy-saving compact type vacuum extrusion machine

InactiveCN1951655AReduce non-functional spaceReduce manufacturing costCeramic shaping apparatusCouplingTransmission belt

The invention relates to an energy-saving compact vacuum extruder, which comprises speed reducer (1), aerated clutch (2), block coupler (3), extruding axle (19), transmission gears (5, 6, 15), mixing axles (4, 26), Haf mixing blade (8), vacuum room (11), compressing plate (12), extruding cylinder (13), head (14), extruding mold (21), upper, middle, and lower boxes (22, 23, 25), machine base (24), and material hopper (7). The invention is characterized in that: the output axle wheel (17) of power machine (18) via transmission belt (16) drives the aerated clutch belt wheel (2) at the input of speed reducer (1); the output of speed reducer via block coupler (3) rotates the extruding axle (19); the active gear (15) at the back extruding axle makes the inactive gear (5) to rotate the active mixing axle (4), and makes the gear (6) axial with active gear (15) to rotate the inactive mixing axle (26). The invention can reduce mechanical friction and save enegy.

Owner:程玉全

New earth pressure balance shield machine and working method thereof

PendingCN110500108AImprove flow plasticityReasonable combinationUnderground chambersTunnel liningSlagAgricultural engineering

The invention discloses a new earth pressure balance shield machine and a working method thereof. The shield machine comprises a cutter head, a front shield, a middle shield, a miter gate, a tail shield, an assembling machine, a main drive and a screw conveyor. A front shield partition board is arranged between the front shield and the middle shield, front shield space is divided into two parts byinstalling a middle partition board in the front shield, the front is a mud chamber, and the rear is an air cushion chamber; the lower part of the middle partition board is not closed; the cutter head is connected with a big gear ring of the main drive by a support arm; a first gate, an air inlet and an overflow port are arranged on the front shield diaphragm board, and a second gate is arrangedon the miter gate; a passage gate and a passive mixing rod are arranged on the middle partition board; an active mixing rod is installed behind the cutter head; the first gate is arranged on the upperpart of the front shield partition board, and the lower part of the front shield partition board is provided with a slag conveying port. The new earth pressure balance shield machine is provided withthe mud chamber and the air cushion chamber, and a mud water balance shield play to the advantage. The shield machine further provides mixing rods, residual soil entering the mud chamber of the shield machine is stirred through the mixing rods, and flow plasticity of the residual soil is further increased.

Owner:POWERCHINA RAILWAY CONSTR +2

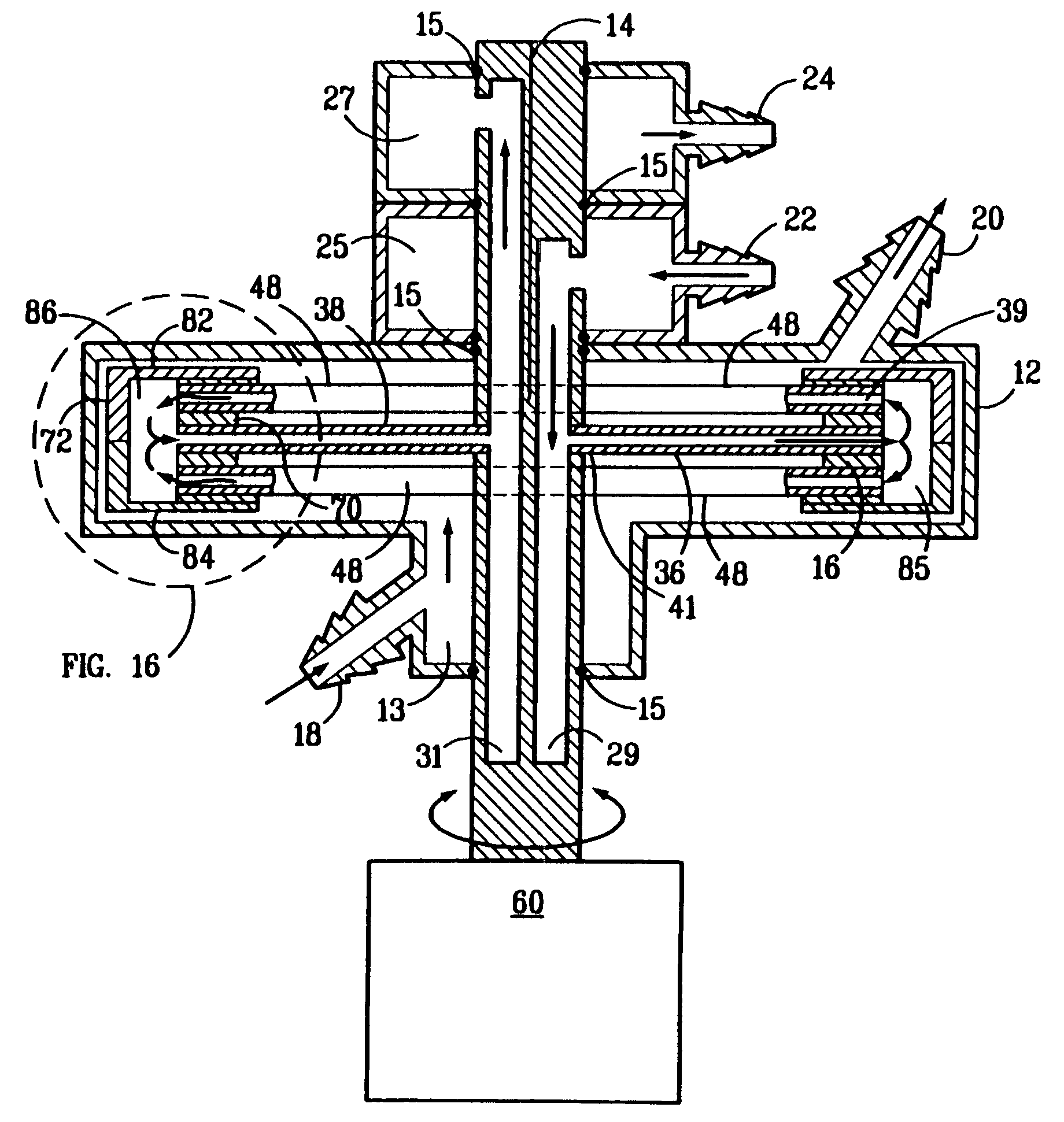

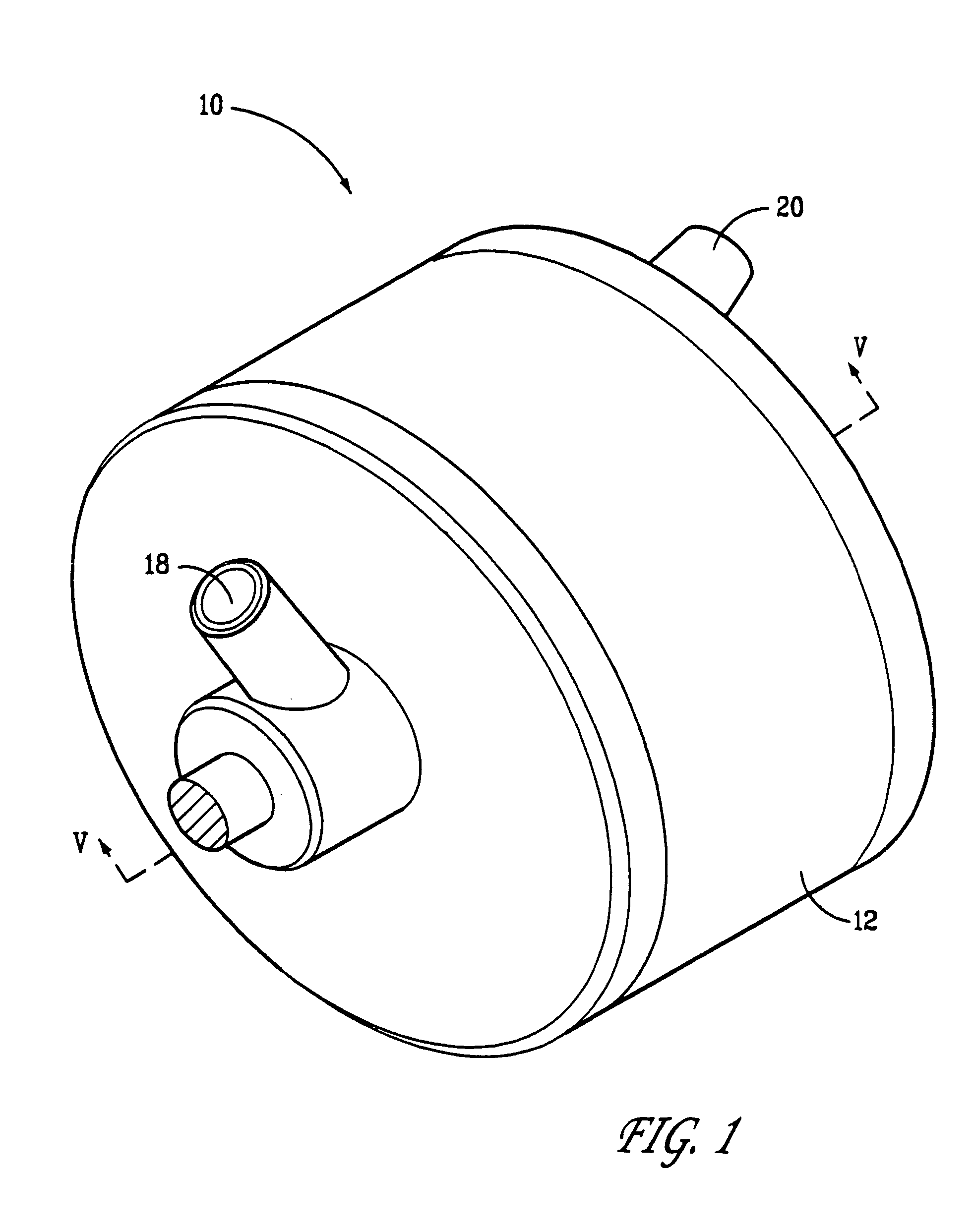

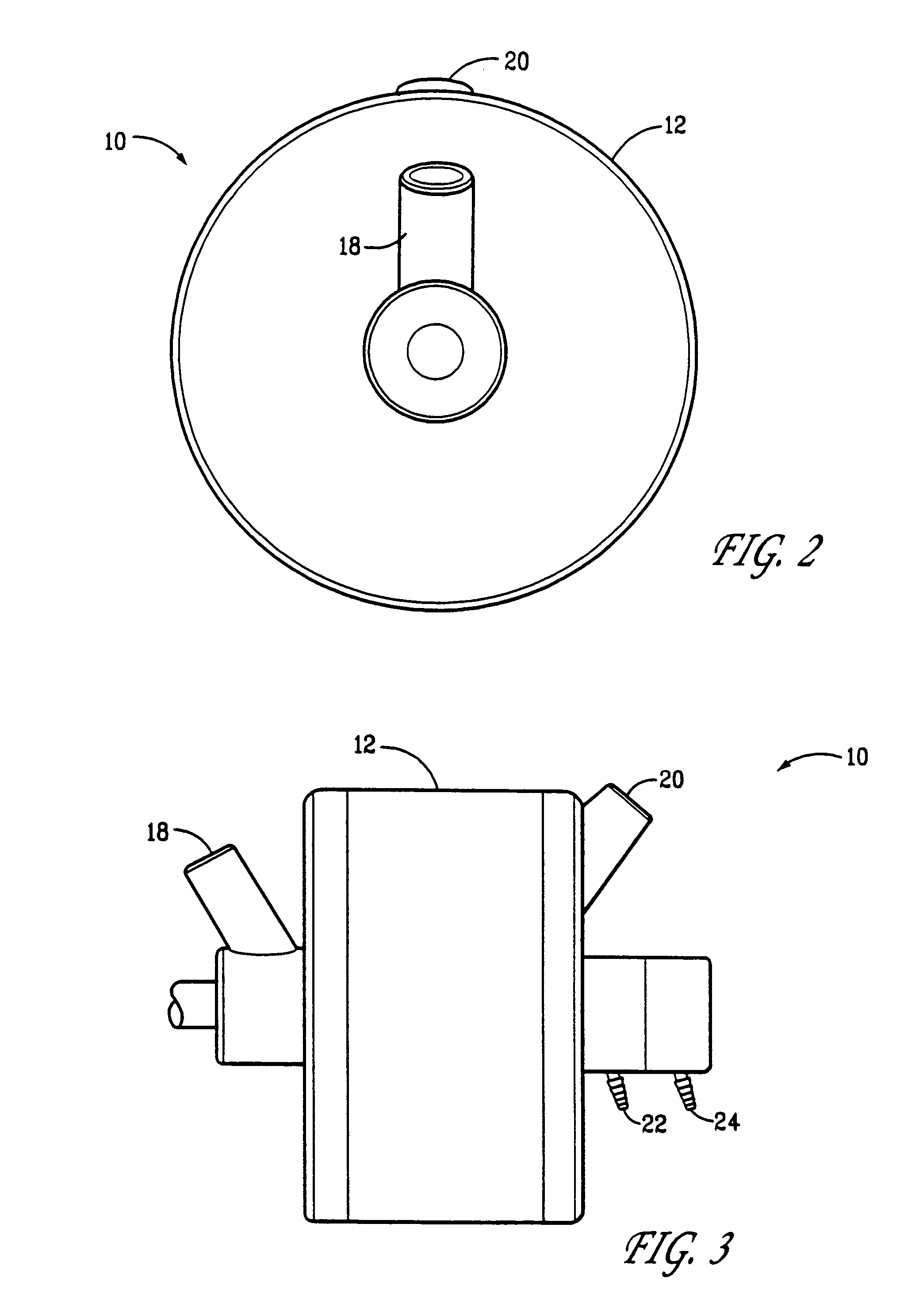

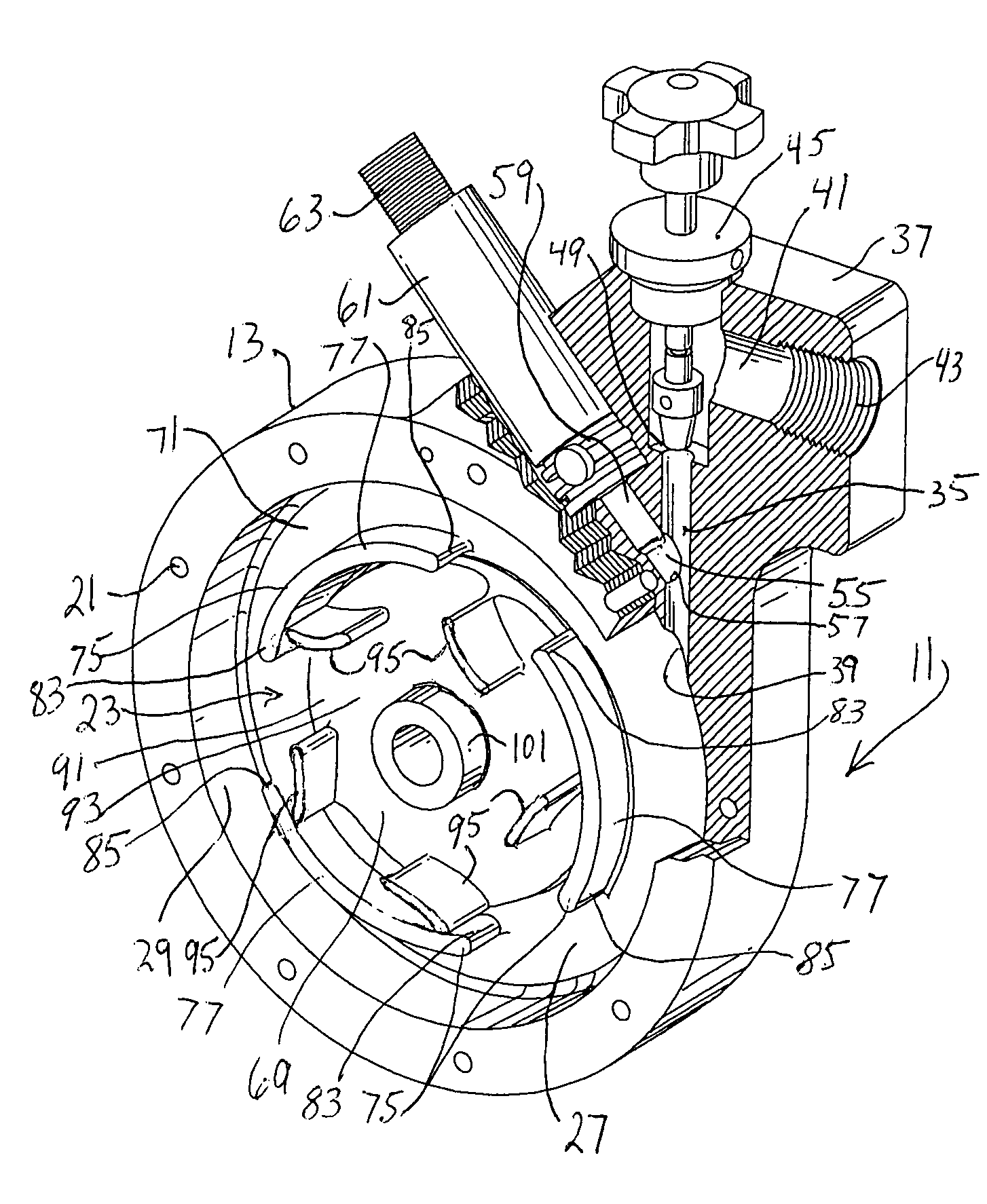

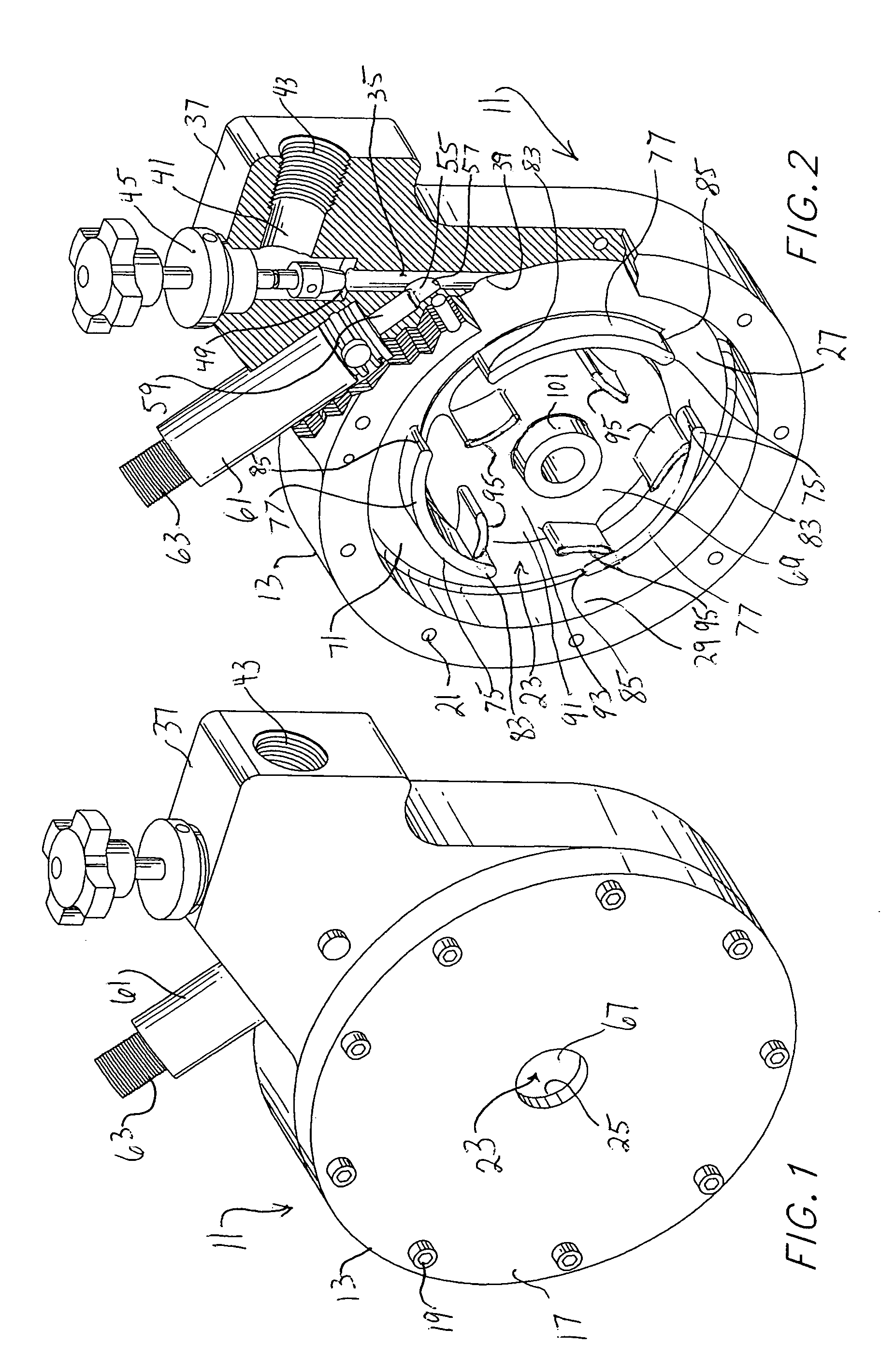

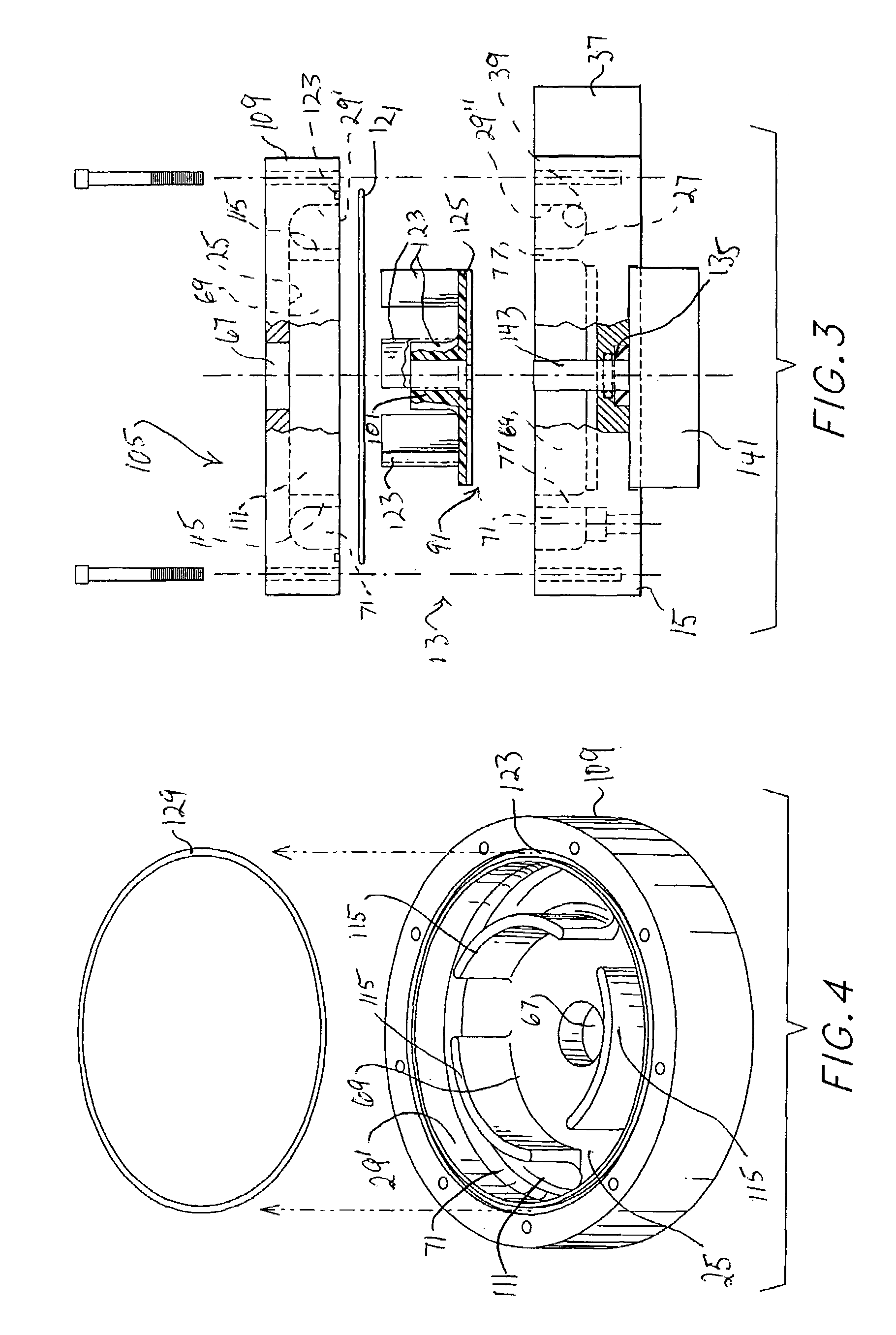

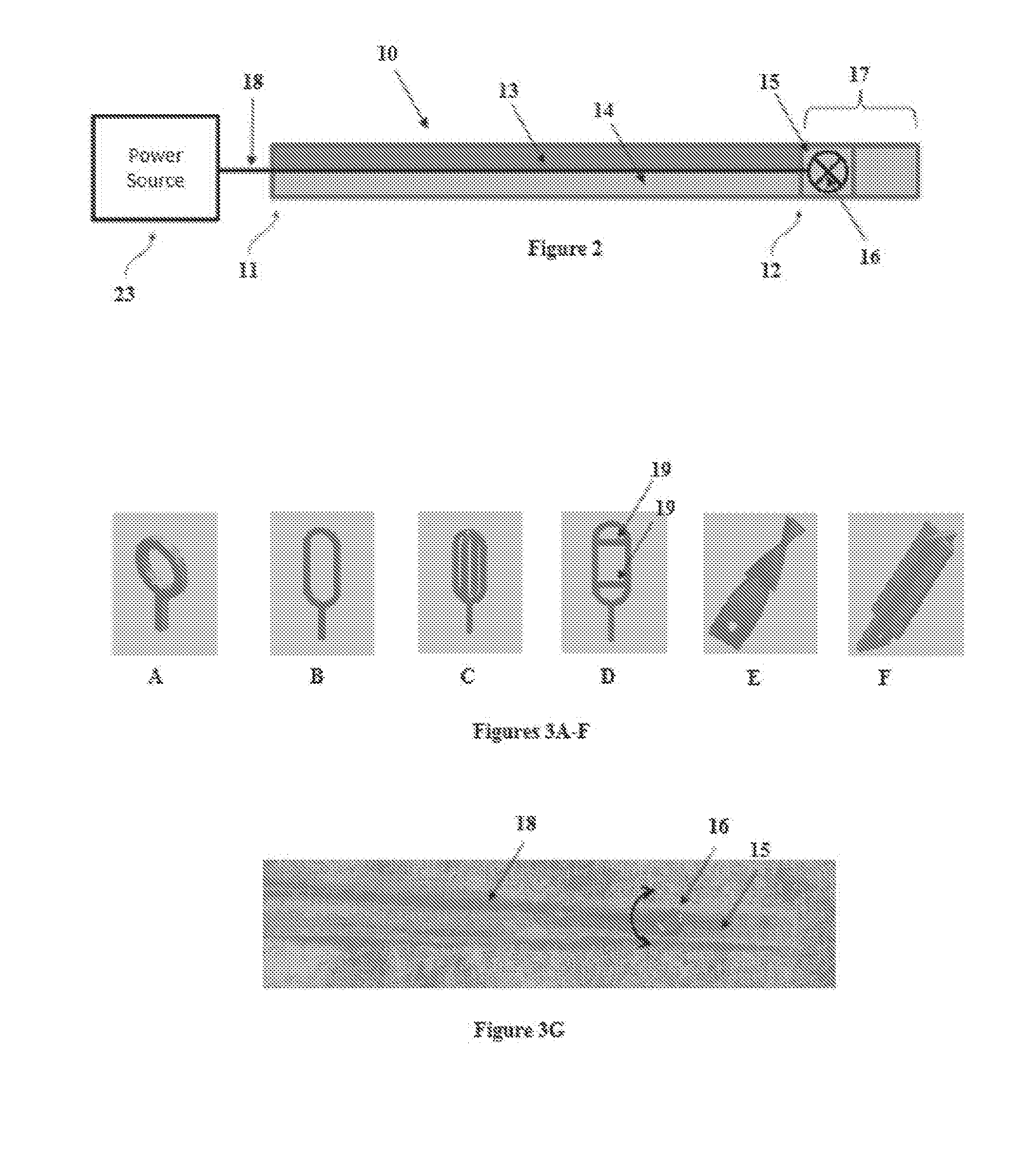

Fluid blending utilizing either or both passive and active mixing

ActiveUS7267477B1Reduce the likelihood of damageSimple methodFlow mixersRotary stirring mixersImpellerInlet channel

Fluid blenders and blending methods are provided, the blending apparatus including components accommodating both passive and / or active mixing. The apparatus includes a main body and closure connectable to define a chamber having a fluid outlet. A valved fluid inlet channel opens into the chamber and is tangentially oriented relative to a peripheral wall thereof so that fluid entering the chamber has a primary vortical flow circulation direction. A fluid injection channel opens to the inlet channel at an acute angle relative to direction of fluid flow through the inlet channel. A plurality of barriers are arrayed in the chamber to define interconnected inner and outer chamber portions. An impeller is rotatably mounted at the inner chamber portion and includes a plurality of blades oriented to urge flow from the inner chamber portion to the outer chamber portion.

Owner:VELOCITY DYNAMICS

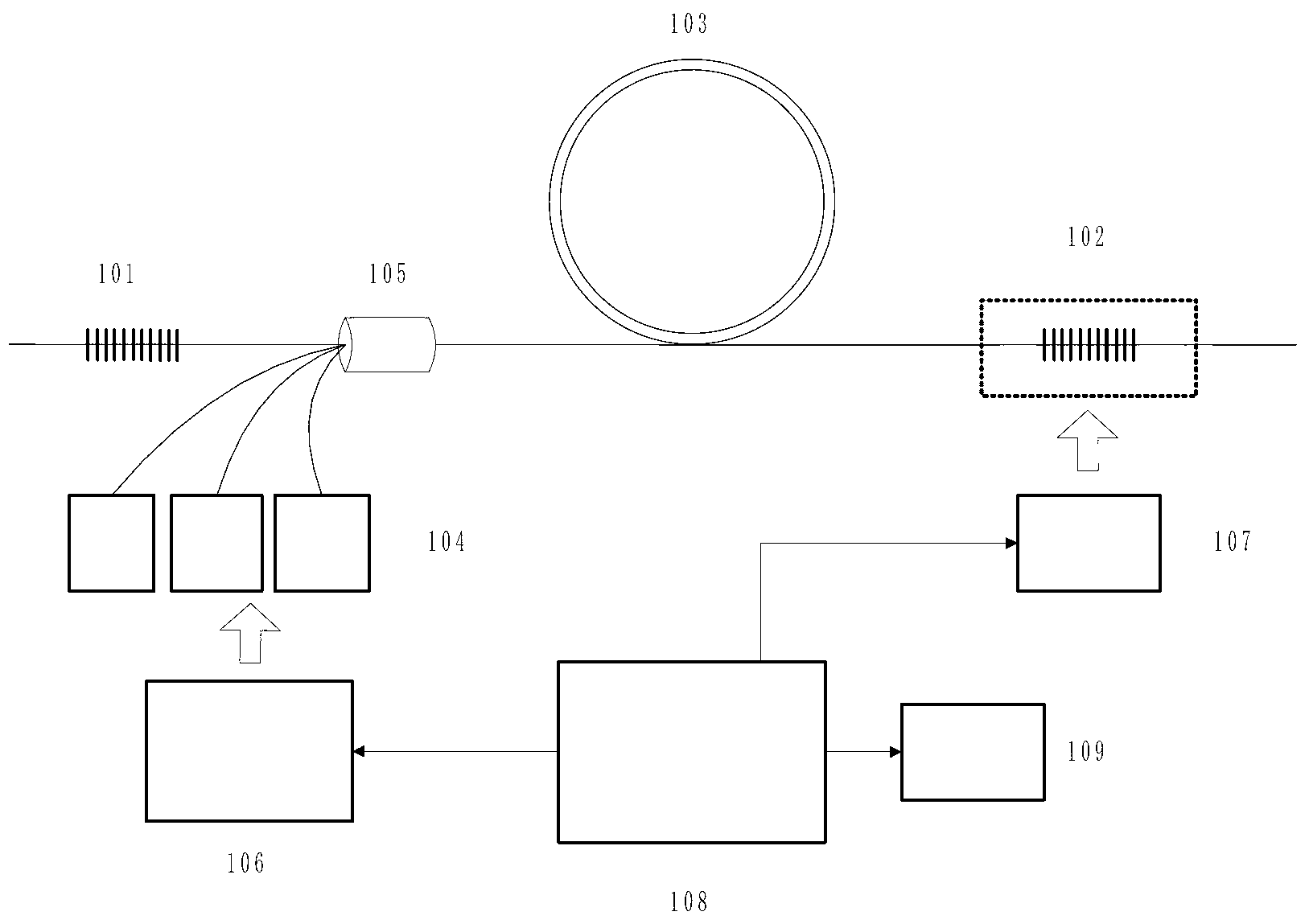

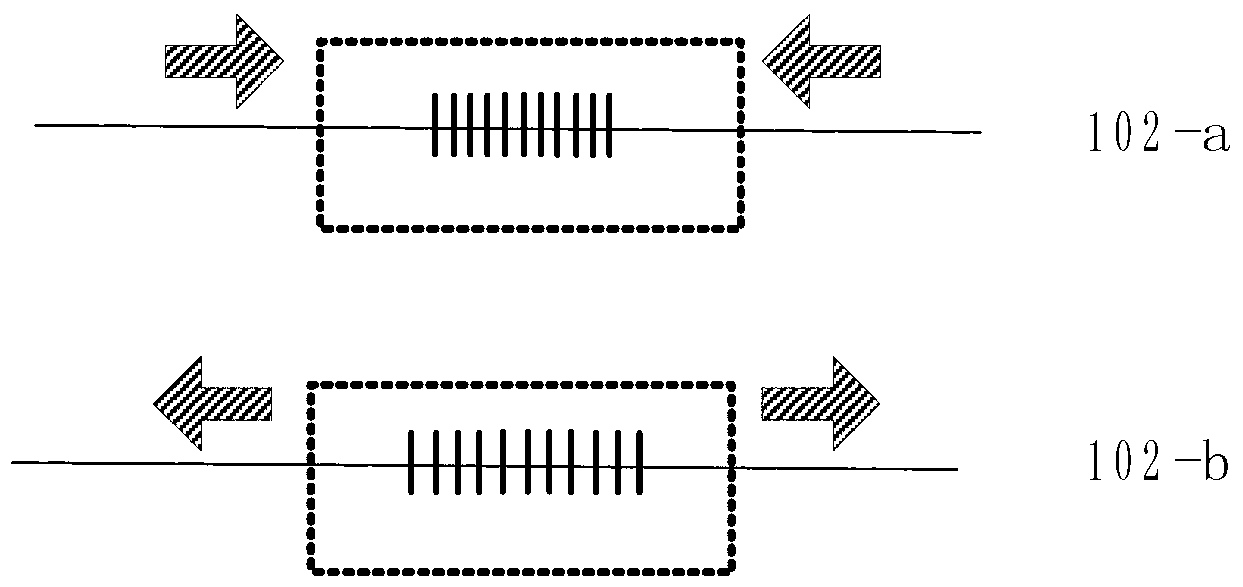

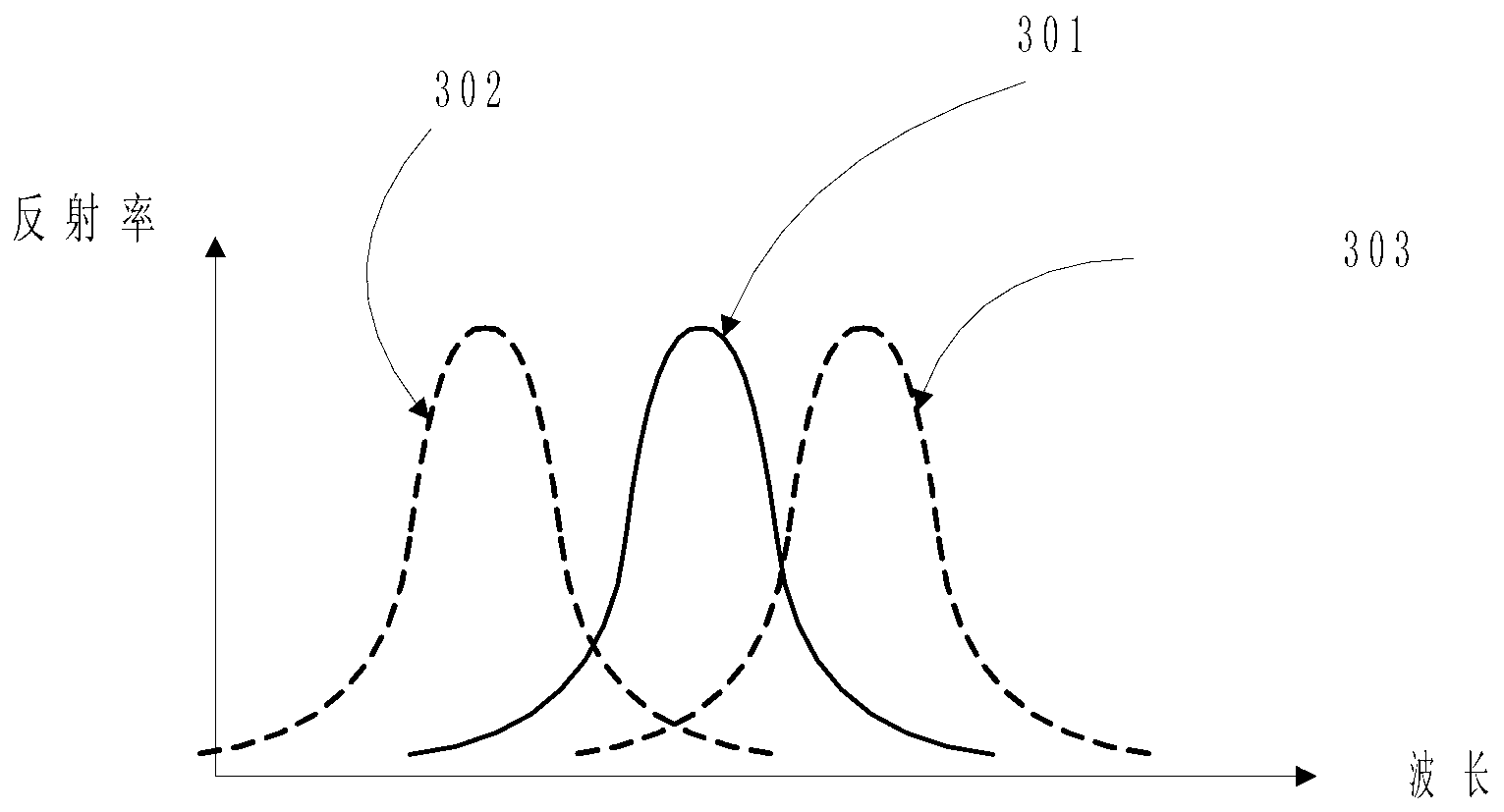

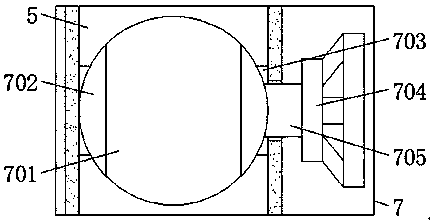

Pulse fiber laser of fiber bragg grating modulation Q

InactiveCN103219639ARealize full one-dimensional optical fiberUp to laser outputActive medium shape and constructionCoupling lossGrating

The invention discloses a pulse fiber laser of fiber bragg grating modulation Q. The pulse fiber laser comprises a fixed wavelength fiber bragg grating (101), a tunable fiber bragg grating (102), an active mixing double-clad fiber (103), a pumping semiconductor laser (104), a fiber pumping photosynthetic bundle device (105), a pumping drive circuit (106), a piezoelectric ceramic or magnetostriction drive circuit (107), a main control circuit (108) and an interface circuit (109), and is characterized in that the tunable fiber bragg grating (102) is connected with the external drive circuit (107), the tunable fiber bragg grating (102) is compressed or stretched so as to change a reflection central wavelength under the action the external drive circuit (107), and the reflection central wavelength of the tunable fiber bragg grating (102) and the wavelength of the other fixed wavelength fiber bragg grating (101) are overlapped and mismatched, thus the pulse fiber laser sends out periodic pulse laser output. The pulse fiber laser provided by the invention has the advantages that the full one-dimensional fiber of an optical element is realized, the coupling loss is reduced, and the system stability is improved.

Owner:JIANGSU SKYERALASER TECH

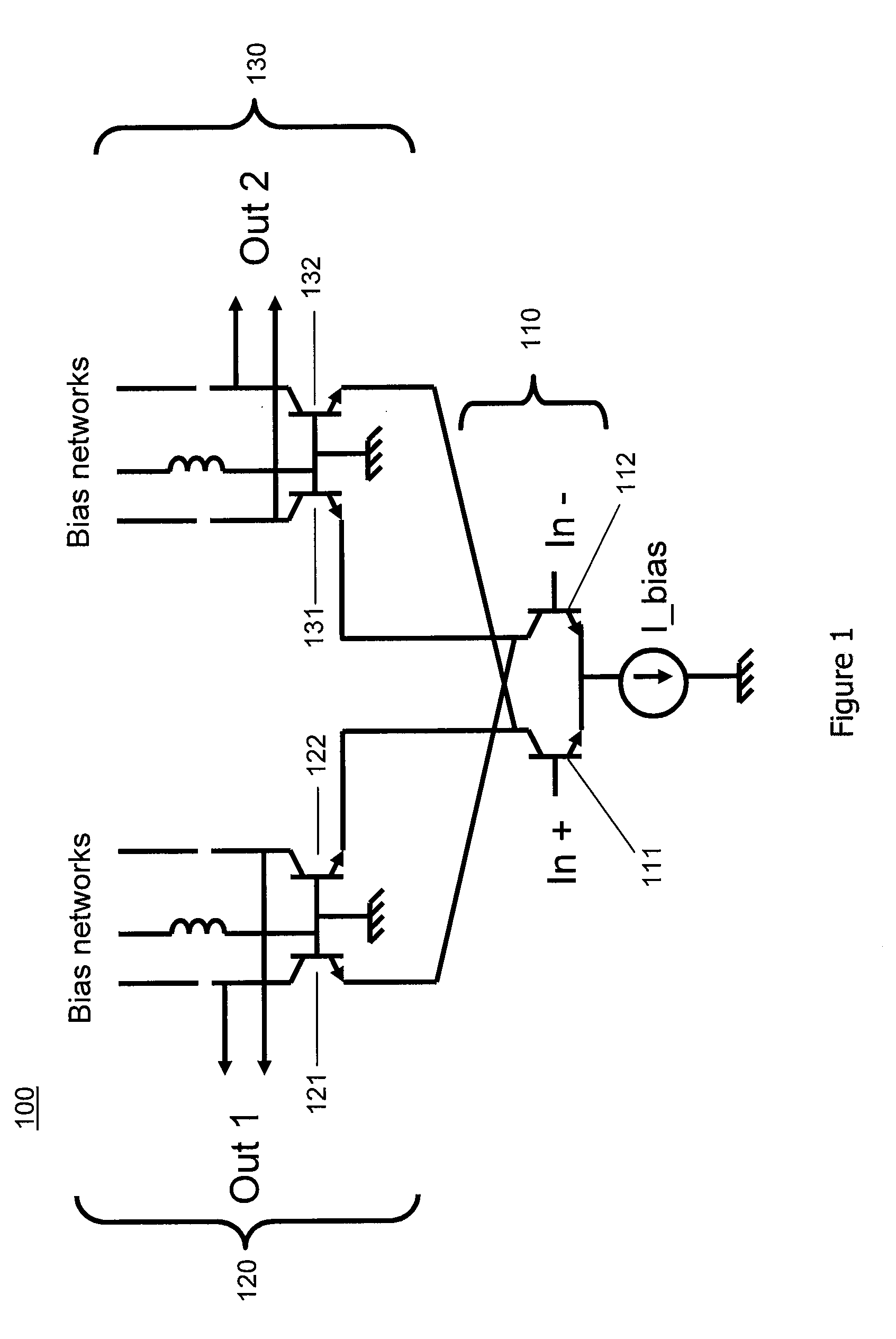

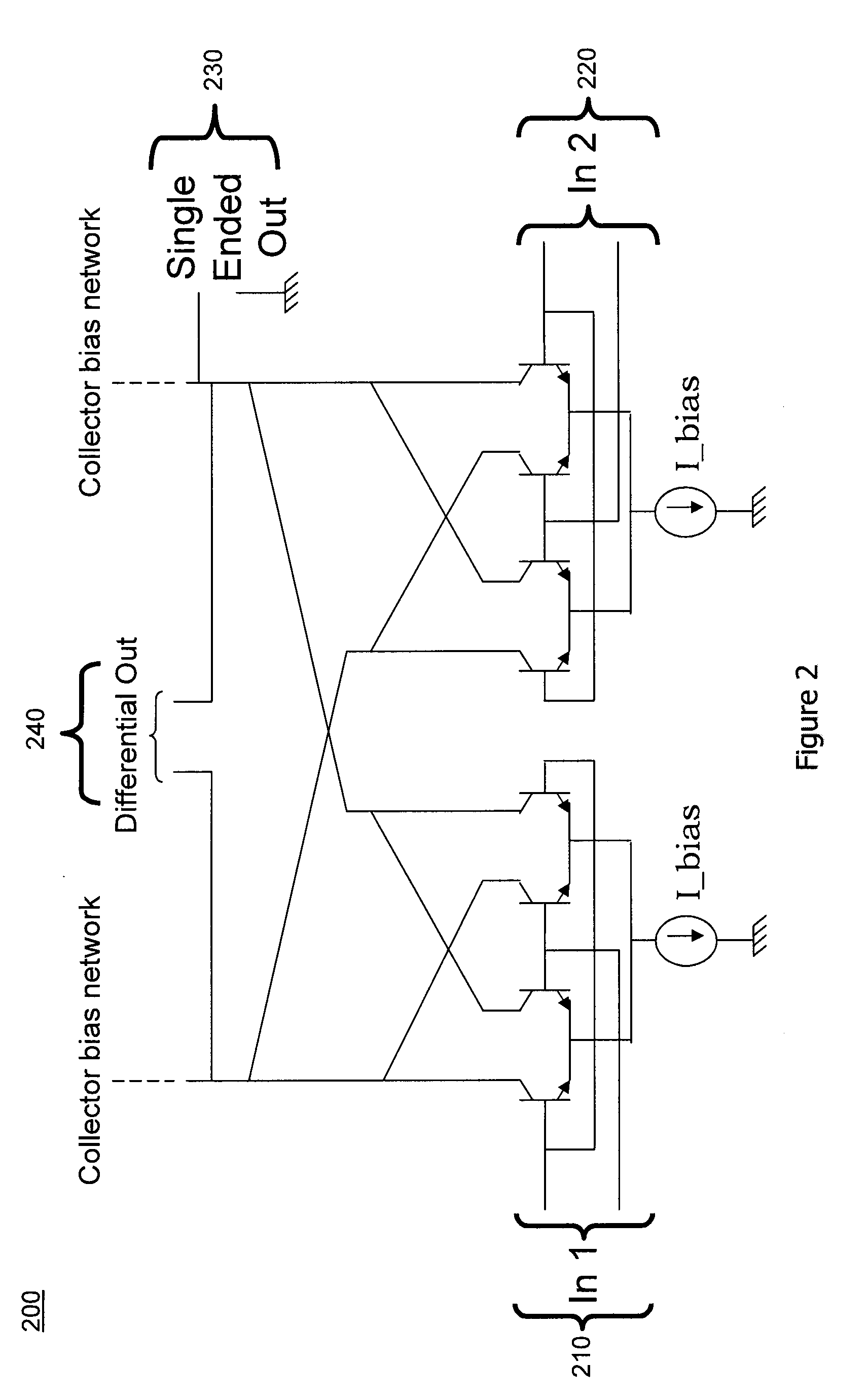

Active hybrids for antenna systems

ActiveUS20100259339A1Low costSmall volumeActive element networkComputing operation arrangementsPower combinerBroadband

In an exemplary embodiment, a fully monolithic active hybrid architecture can be configured to replace a ring hybrid, magic tee, branchline coupler, or 180° hybrid by providing similar functionality in an integrated monolithic solution. Exemplary embodiments of the active hybrids combine active implementations of power splitters, power combiners, and phase shifting elements in a novel fashion allowing for ultra-compact size and broadband performance. In an exemplary embodiment, the active hybrid replaces the typical hybrid couplers with active splitters and active combiners. Similarly, the delay lines and amplitude adjustment elements are replaced by active vector generators. Vector generators are magnitude and phase control circuits. The active hybrid results in certain advantages including being size independent of the operating frequency, wide frequency range of operation, and RF signals undergo a neutral or slight positive power gain, rather than power losses that occur in the passive prior art systems.

Owner:VIASAT INC

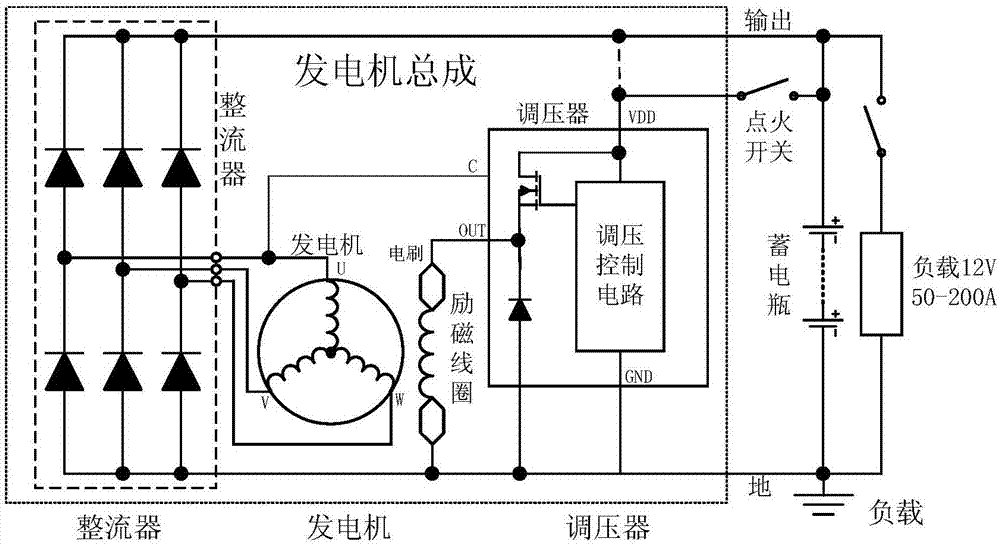

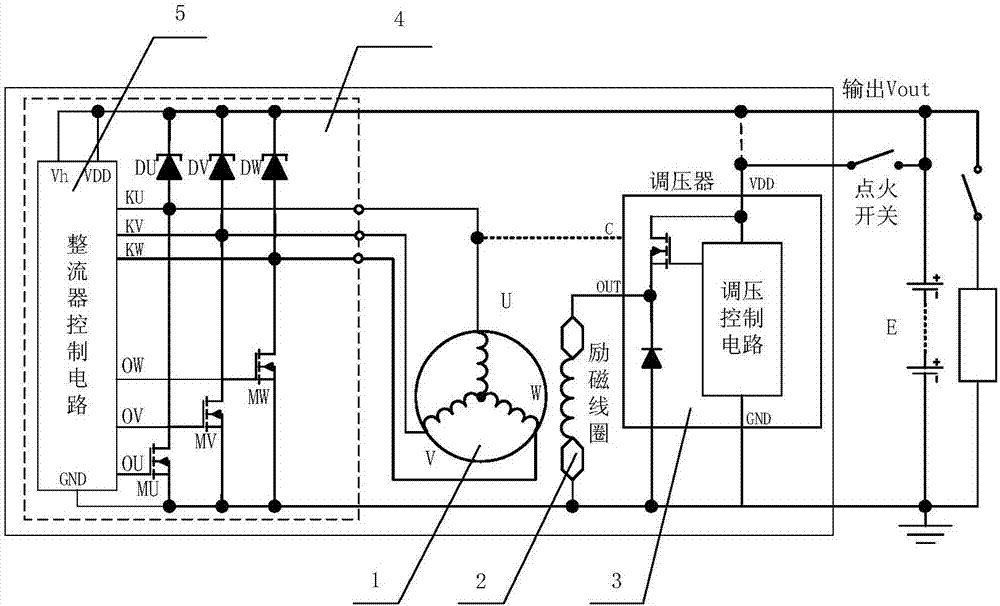

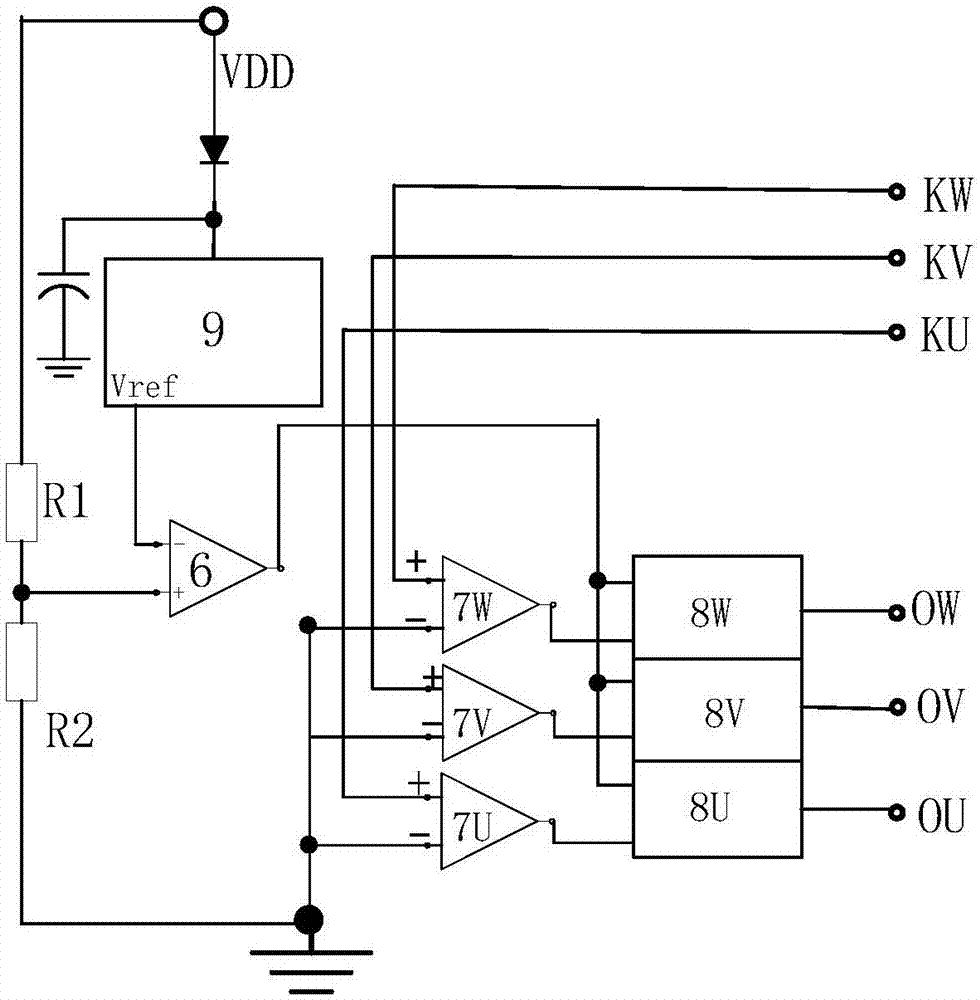

Vehicle applied power supply system and active mixing rectifier and control method

ActiveCN106877478ASolve the problem of dumpingImprove rectification efficiencyBatteries circuit arrangementsAc-dc conversionMOSFETGrating

The invention discloses a vehicle applied power supply system and an active mixing rectifier and a control method. The vehicle applied power supply system comprises a motor, excitation coils, a voltage regulator and a rectifier. The rectifier is an active mixing rectifier which consists of a three-phase bridge type rectifier and a rectifier control circuit. The upper bridge arm of the three-phase type rectifier adopts diodes to rectify while the lower bridge arm adopts a MOSFET tube to rectify. When a certain phase voltage of the motor is greater than the voltage outputted by the rectifier, the rectification diode corresponding to the phase turns on; when a certain phase voltage of the motor is smaller than the voltage outputted by the rectifier, the rectification diode corresponding to the phase turns off. The rectifier control circuit receives the signal outputted from the phase wires of the motor and serves as the driving signal provided to the grating electrode of the MOSFET tube. When a certain phase voltage of the motor is smaller than the ground voltage, the rectifier control circuit provides a control signal to control the MOSFET tube corresponding to the phase to be on; otherwise, the MOSFET tube corresponding to the phase is off. The invention can be applied to a variety of vehicle applied power supply systems.

Owner:CHONGQING SANXIN ELECTRONICS

Preparation process of high-compression-resistance light weight foam concrete

InactiveCN104803708AGood sound and heat insulationUniform textureCeramicwareFoam concretePolymer science

The invention discloses a preparation process of high-compression-resistance light weight foam concrete. The preparation process comprises the following steps: preparing active mixing materials: uniformly mixing river sand, glass fiber, a naphthalenesulfonate water reducing agent and active silica; preparing slurry: controlling by an automatic foamed cement equipment mainframe, and respectively injecting water, cement, an active mixing material and a propylene organic thickener according to the proportion through a water pump and a material injector in a double-shaft mixer in a mixing state, wherein the water adding frequency, the material injecting frequency and the power input frequency of a stirring engine are controlled within the range of 0-70 HZ; preparing foam with a foaming agent; controlling by the automatic foamed cement equipment mainframe, and preparing foam with the foaming agent through a plunger pump and an air compressor; mixing and pouring the prepared mixed slurry in a moulding die. Concrete prepared by the preparation process has the advantages of being better in sound insulation and heat insulation effects, and excellent in compression resistance and the like.

Owner:SICHUAN YAHAO REAL ESTATE DEV

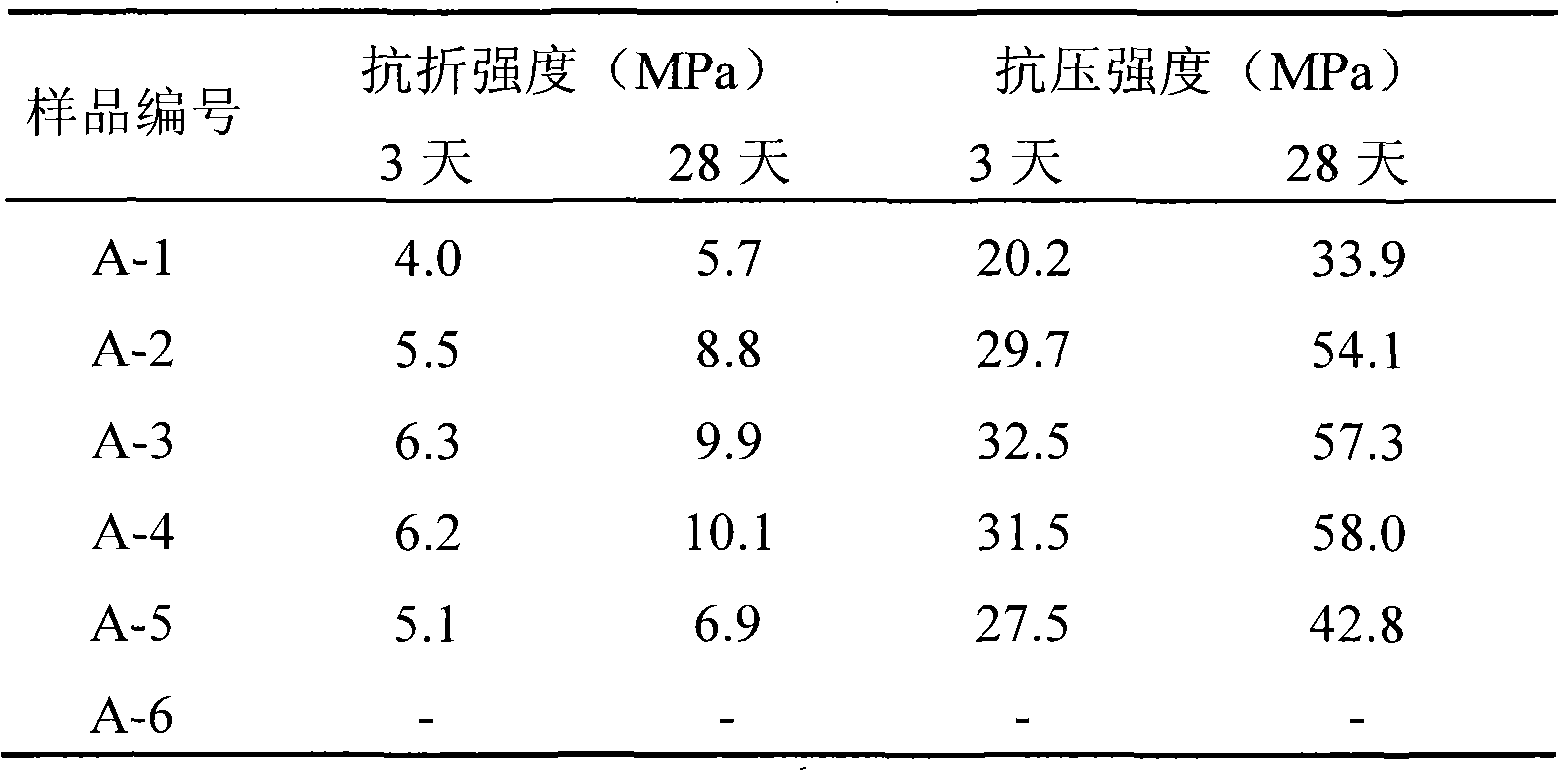

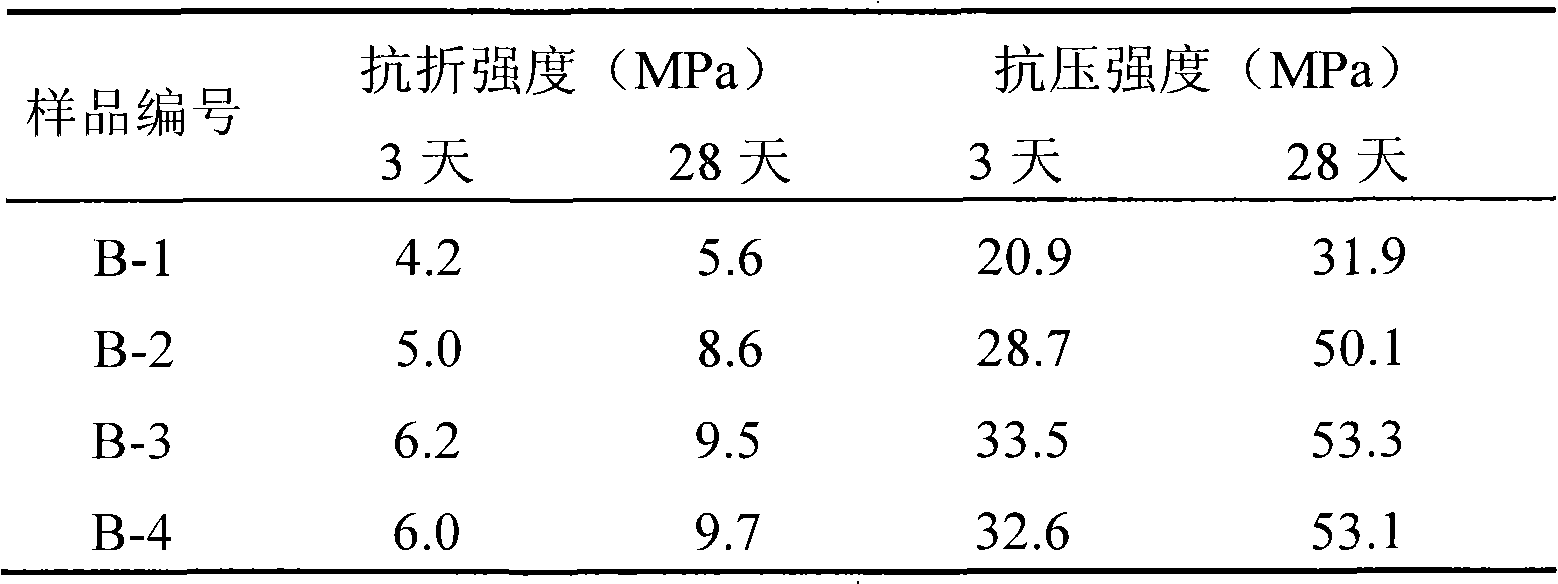

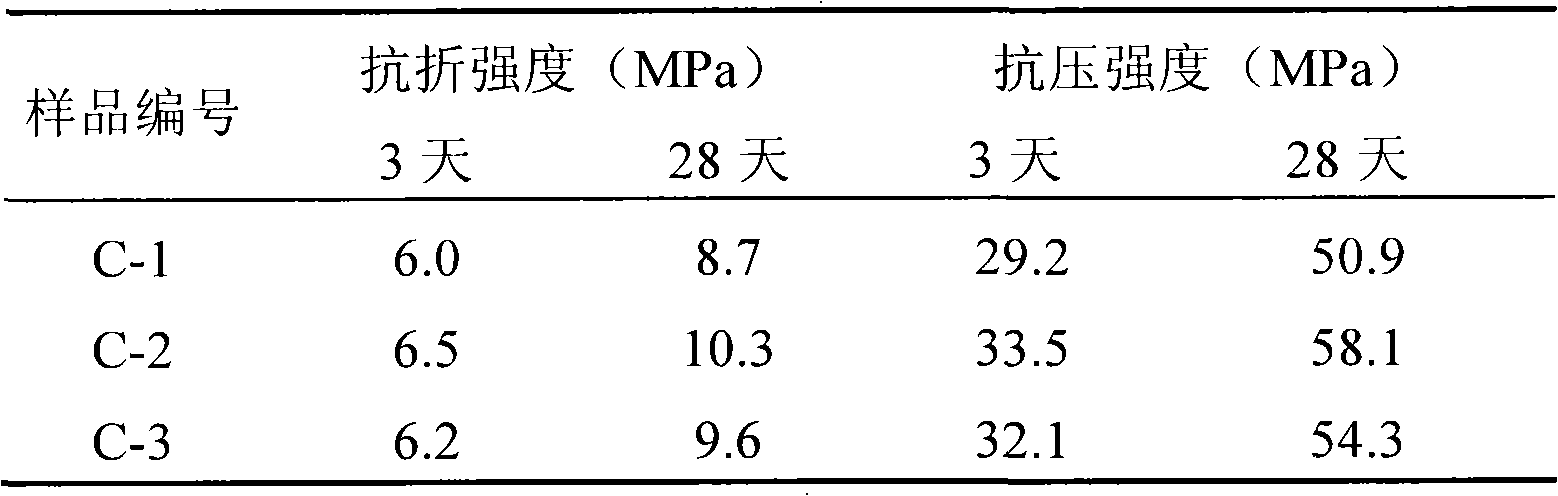

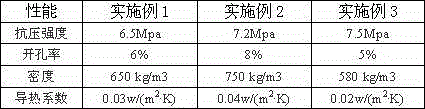

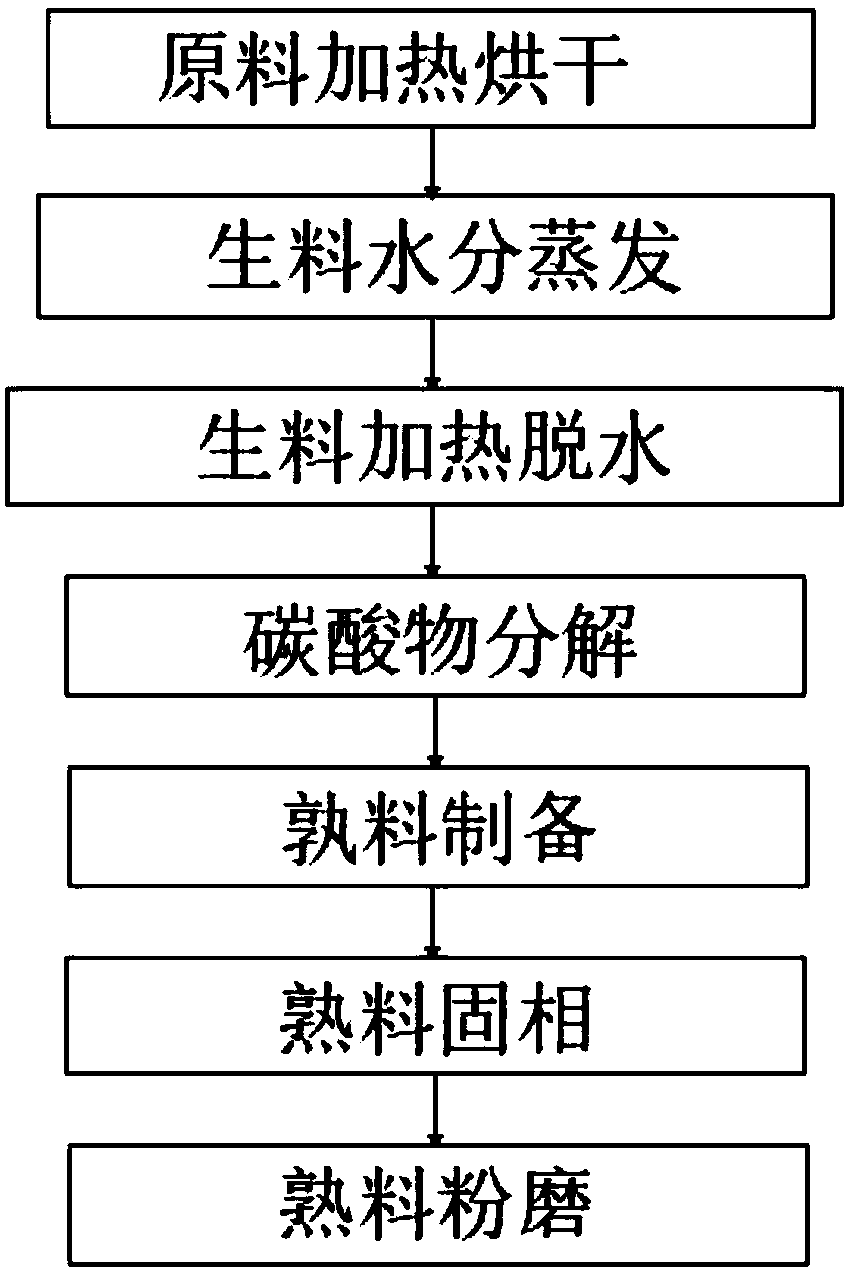

Novel cement with high breakage resistance value and preparation method of novel cement

InactiveCN109354426AChange the breaking resistance valueImprove flexural strengthCement productionBreaking strengthWater soluble

The invention discloses novel cement with high breakage resistance value and a preparation method of the novel cement, and belongs to the technical field of production of cement. According to the novel cement with the high breakage resistance value and the preparation method of the novel cement, the cement comprises the following components in percentages by weight: 50% of limestone, 5% of a clawraw material, 3.5-30% of flyash, 9-30% of a non-active mixing material, 3.5-6% of gypsum, 2% of water-soluble resin and 1.5-30% of an active mixing material. The preparation method comprises the following steps: heating and drying raw materials, evaporating water of the raw materials, heating and dehydrating the raw materials, decomposing carbonate, preparing clinker, solidifying the clinker and grinding the clinker. The breakage resistance value of the cement can be changed, the breaking strength of the cement is greatly enhanced, thus, the cement has certain resistance on stress breakage dueto strength fatigue, creep breakage at a high temperature and breakage affected by an environment acting force, and the breakage resistance of a concrete building blended with cement is improved.

Owner:柏焕玉

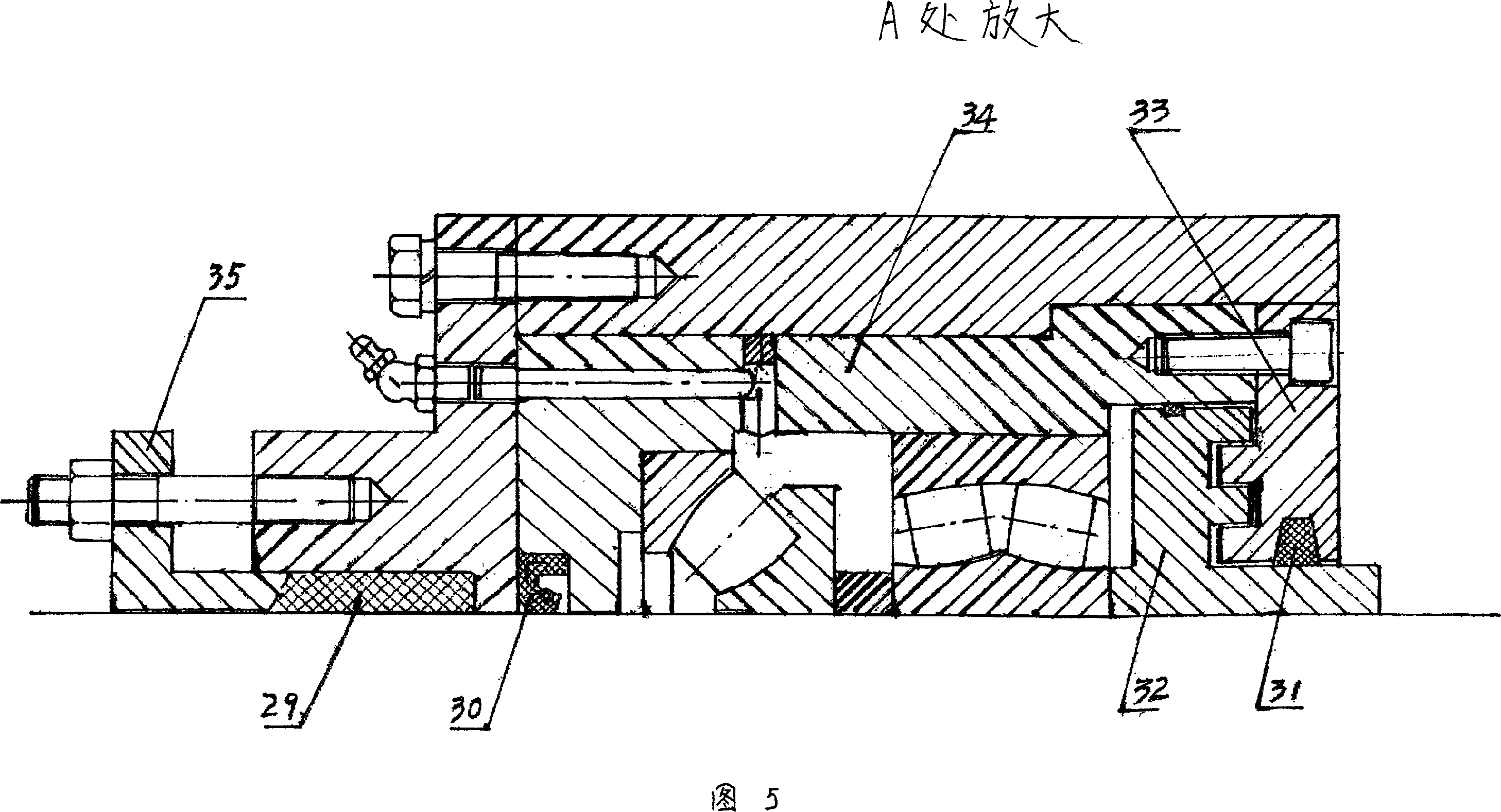

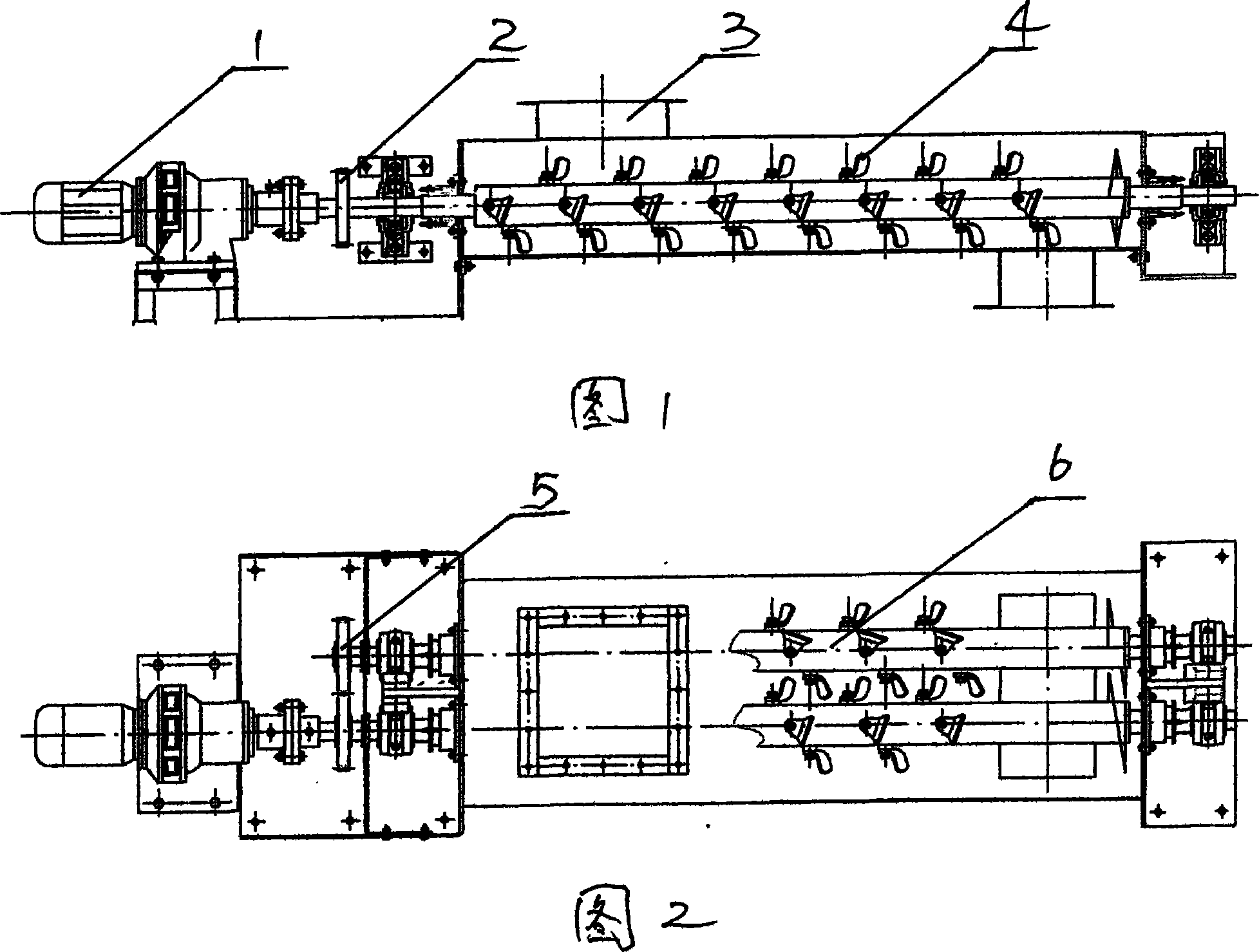

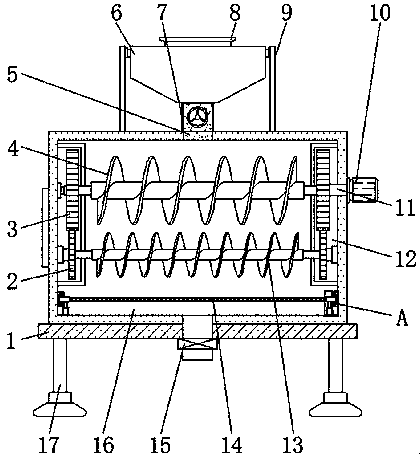

Multi-spire stirring machine

The invention provides a multispiral mixer, which comprises a drive motor, a rotating axle and a mixing blade. The invention adopts two mixing axles, the active mixing axle is driven by the motor, the passive mixing axle is connected with the active mixing axle by a gear plate to rotate reversely, a plurality of helix mixing blades are arranged on two rotating axles, adopts two axles which moves reversely and the helix mixing blade in this way, therefore breaking global harden material in high efficiency.

Owner:吴江粮食机械有限公司

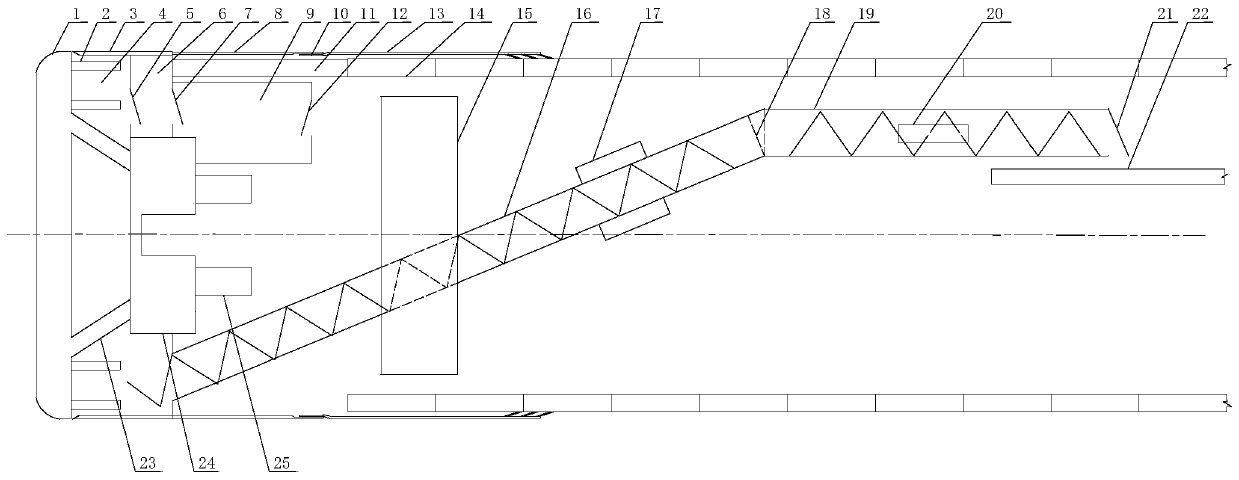

Double-shaft paddle mixer for feed production

InactiveCN110694506AImprove the mixing effectImprove convenienceFeeding-stuffRotary stirring mixersGear wheelEngineering

The invention discloses a double-shaft paddle mixer for feed production, which comprises a base, a driving mixing paddle, a material injection through groove, a mixing chamber and a control panel, wherein the mixing chamber is fixed at the central position of the top end of the base; the two inner side walls of the mixing chamber are both provided with a linking chamber; the bottom end inside thelinking chamber is hinged with a driven gear; the inside of the linking chamber above the driven gear is hinged with a driving gear; the driving gear and the driven gear are meshed with each other; one end inside the mixing chamber is provided with the driving mixing paddle, both ends of the driving mixing paddle are fixedly connected with the outer wall of the driving gear through a connecting rod, and a driven mixing paddle is arranged inside the mixing chamber below the driving mixing paddle, and both ends of the driven mixing paddle are fixedly connected with the outer wall of the driven gear through the connecting rod. The double-shaft paddle mixer not only improves the mixing effect when the mixer is used, avoids the precipitation phenomenon at the bottom of the mixing chamber when the mixer is used, but also improves the convenience when the mixer is used.

Owner:陈耀东

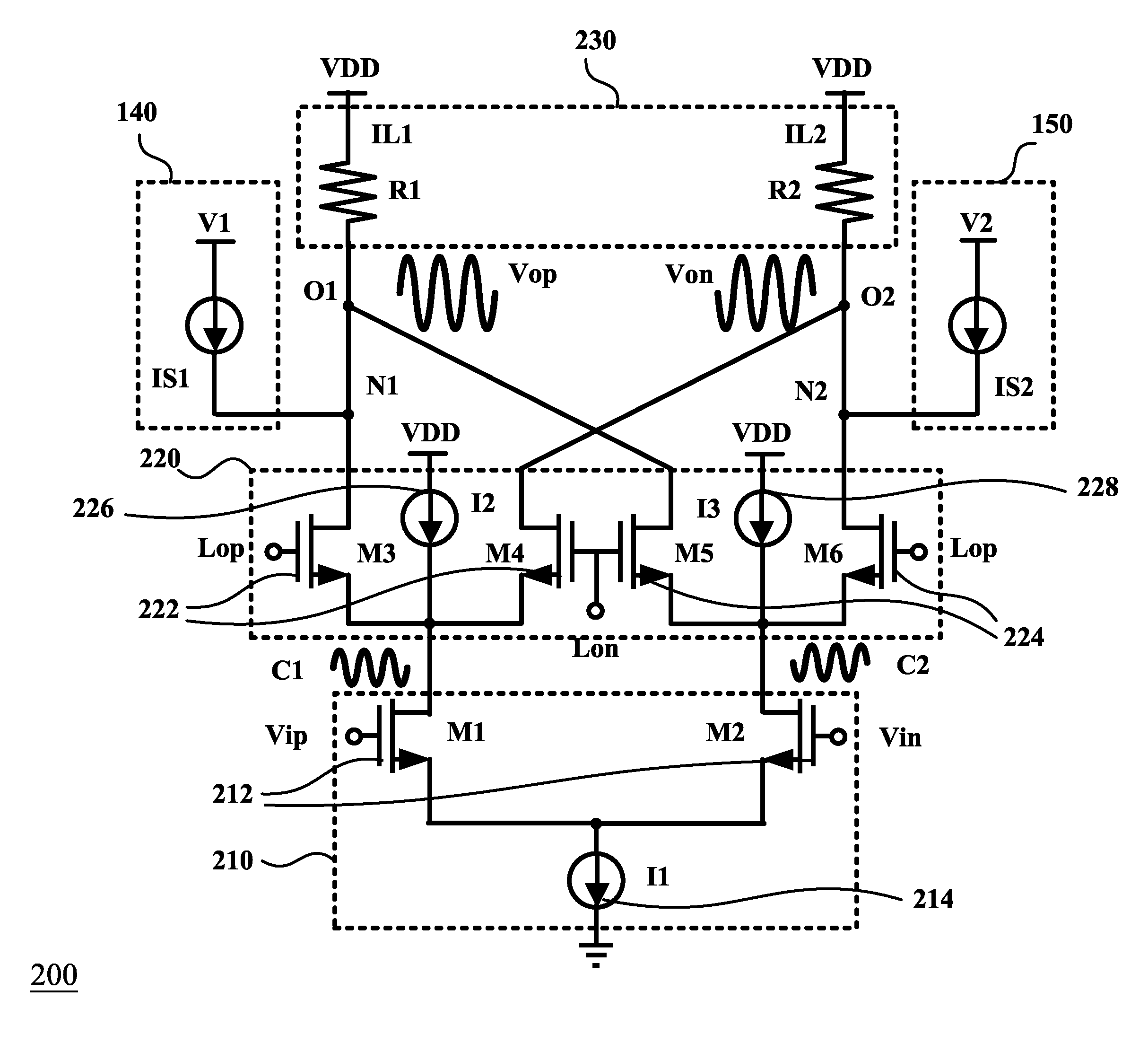

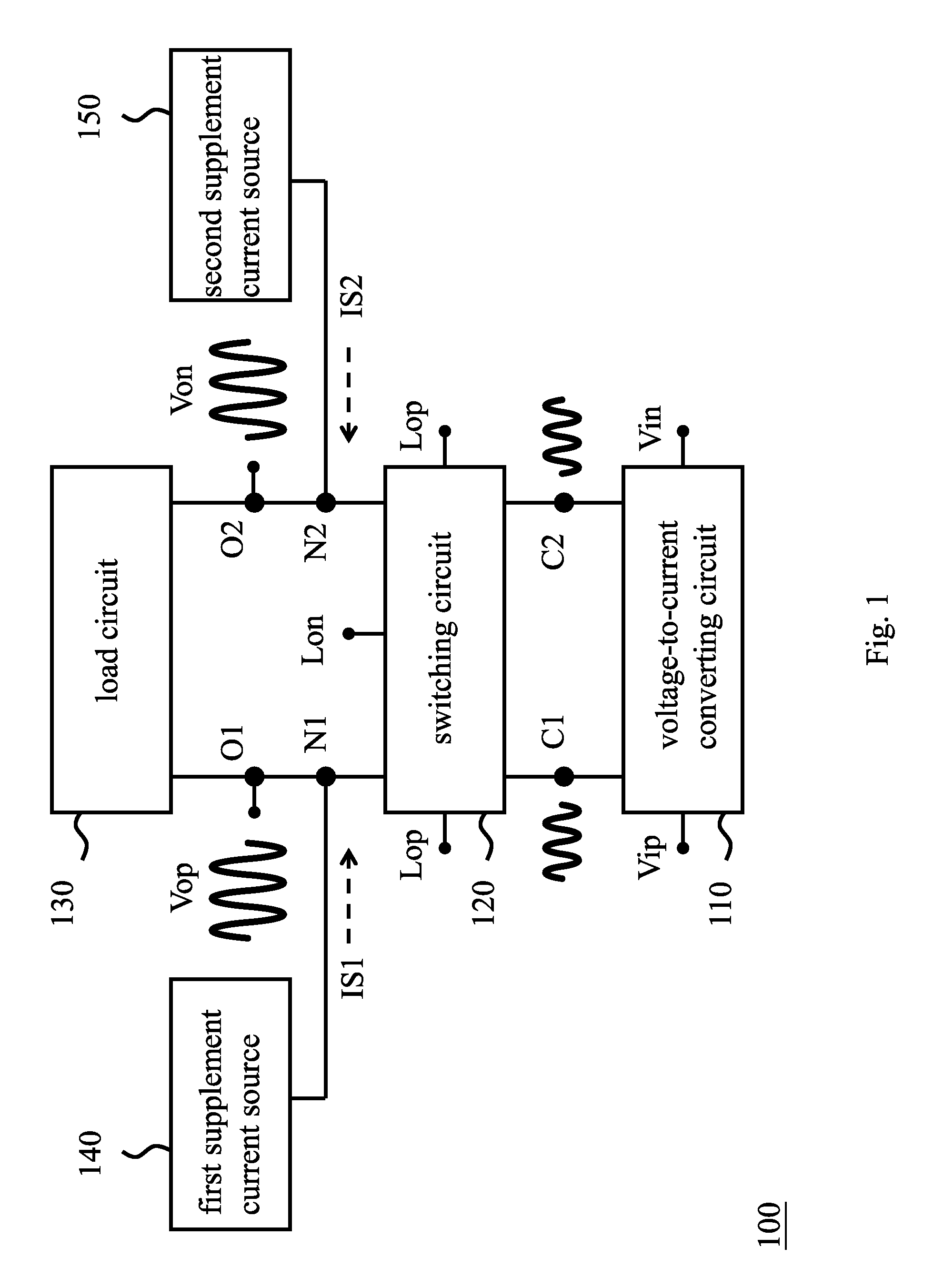

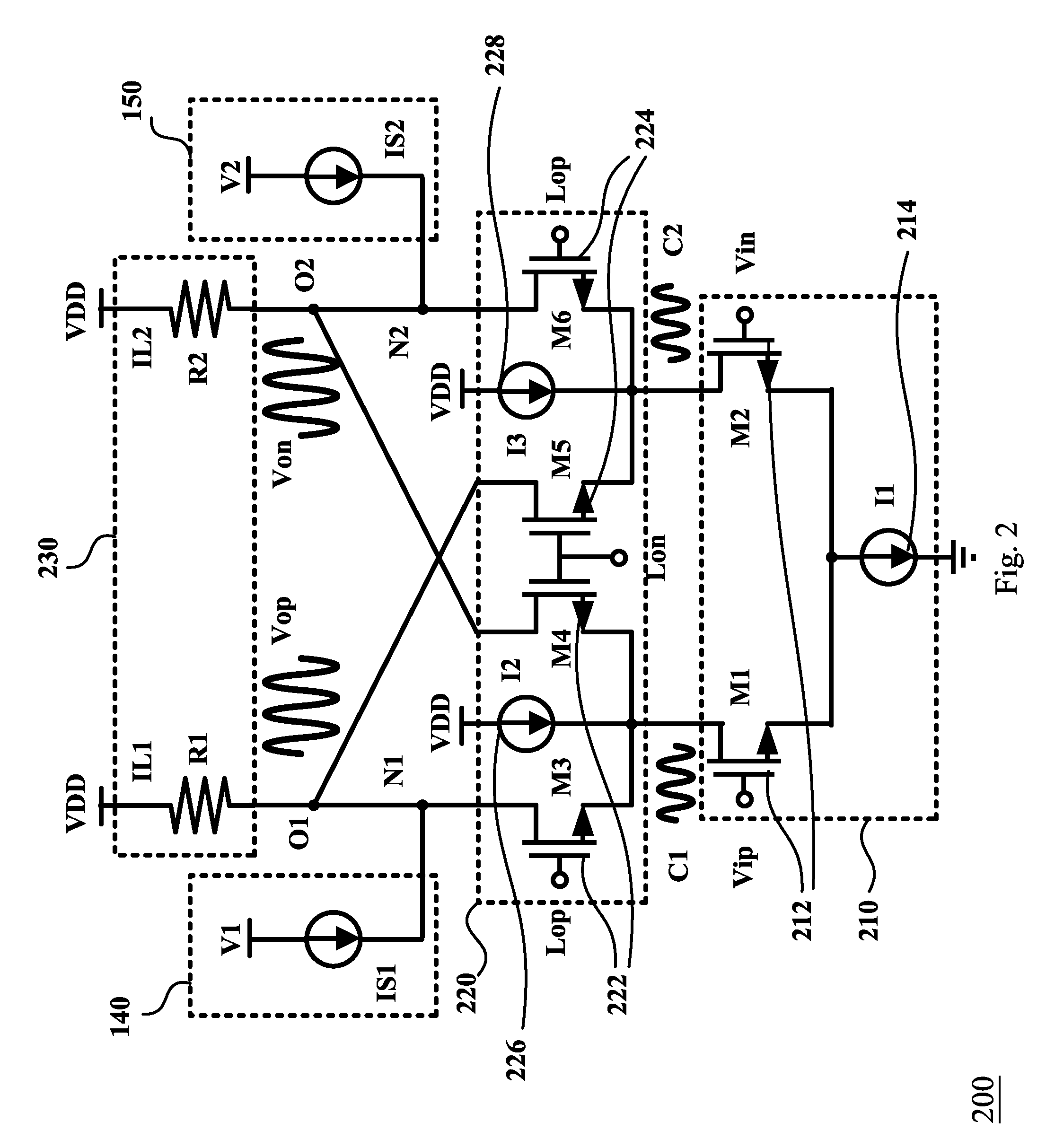

Active mixer and active mixing method

ActiveUS9350297B2Modulation transference balanced arrangementsComputing operation arrangementsLoad circuitElectricity

Owner:REALTEK SEMICON CORP

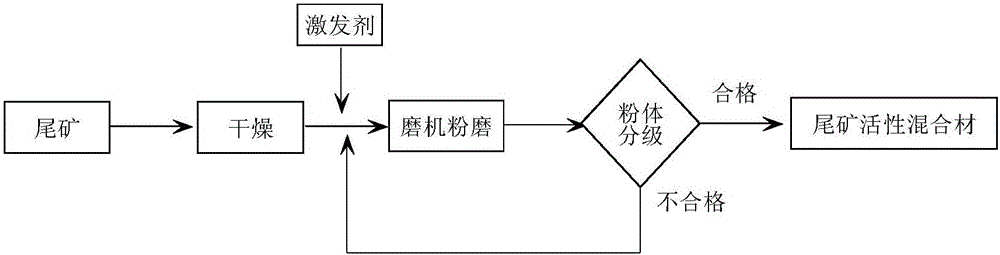

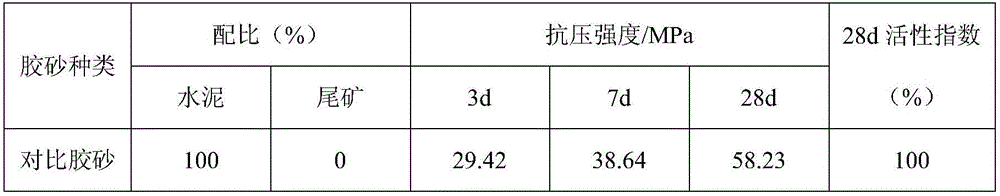

Method for preparing active mixing material by mine tailing

ActiveCN106082741AReduce energy consumptionIncrease profitSolid waste managementSoluble glassSodium silicate

The invention discloses a method for preparing an active mixing material by mine tailing. The method comprises the following steps: 1) uniformly mixing mine tailing, controlling the dried mine tailing at 1% and below; 2) preparing an exciting agent to a solution with certain concentration by deionized water; wherein the exciting agent is poly(alcohol amine) macromolecule and organic ethylene glycol and soluble glass or sodium silicate; mass percentage concentration of the poly(alcohol amine) macromolecule is 5-20%, the mass percentage concentration of ethylene glycol is 5-20%, and the mass percentage concentration of soluble glass or sodium silicate is 20-60%; and 3) weighing a certain amount of mine tailing, by taking the mass of the mine tailing as a reference, the addition amount of the exciting agent comprises: 0.01-0.06% of poly(alcohol amine) macromolecule, 0.005-0.02% of organic ethylene glycol, and 0.2-0.5% of soluble glass or sodium silicate, and employing a grinding machine for grinding mine tailing to obtain the mine tailing active mixing material.

Owner:JIANGXI UNIV OF SCI & TECH

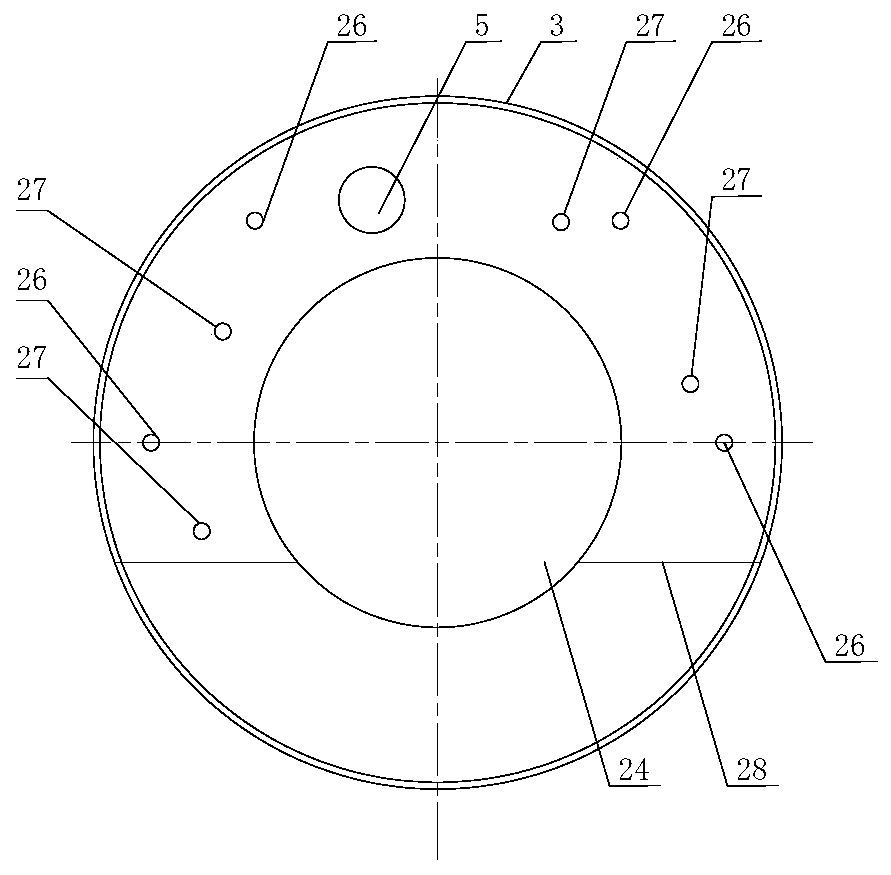

Normal-temperature automatic mixing device for high-viscosity liquid

InactiveCN111214991AIncrease contact areaFlexible control over the degree of mixingTransportation and packagingMixersEngineeringViscosity

The invention relates to a normal-temperature automatic mixing device for high-viscosity liquid, and belongs to the technical field of micro-fluidic control. The automatic mixing device comprises a sample feeding channel, a sample discharging channel, a fixing screw, an upper cover plate, a lower cover plate, a sealing gasket, a sample feeding transverse channel, a sample discharging transverse channel, a cavity and a magnetic body. After entering the closed cavity at a constant flow rate, various high-viscosity liquids are quickly stirred and mixed into a mixed solution under the action of the magnetic body rotating at a high speed, and the mixed solution is automatically discharged out of the cavity under the extrusion of the liquid in the cavity. According to the device, through an active mixing mode, a solution containing the magnetic body generates a bent motion trail under the action of magnetic field force, so that the contact area of the solution containing the magnetic body and another solution is increased, and the two solutions with relatively high viscosity are rapidly and uniformly mixed; the device is sealed through screws and can be flexibly disassembled, so that theuse cost of the device is reduced; and a plurality of devices can be connected in series to achieve an ideal mixing degree.

Owner:TSINGHUA UNIV

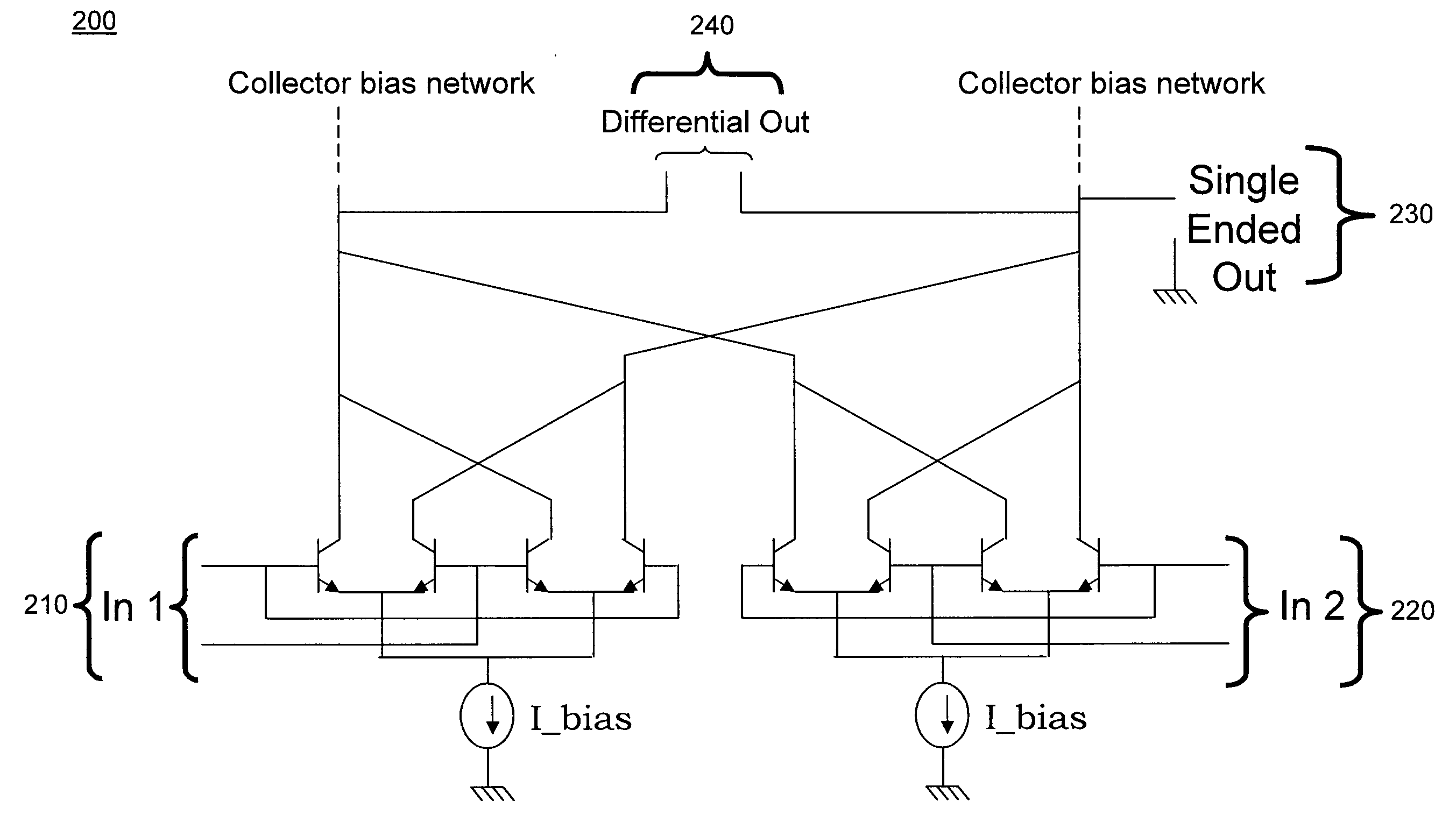

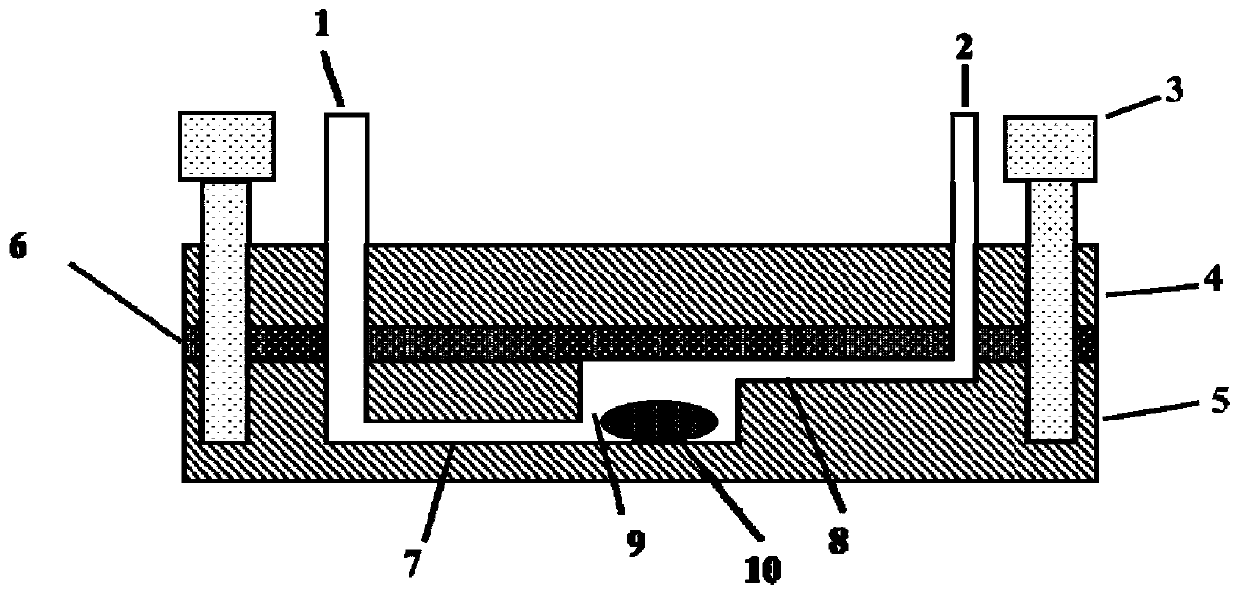

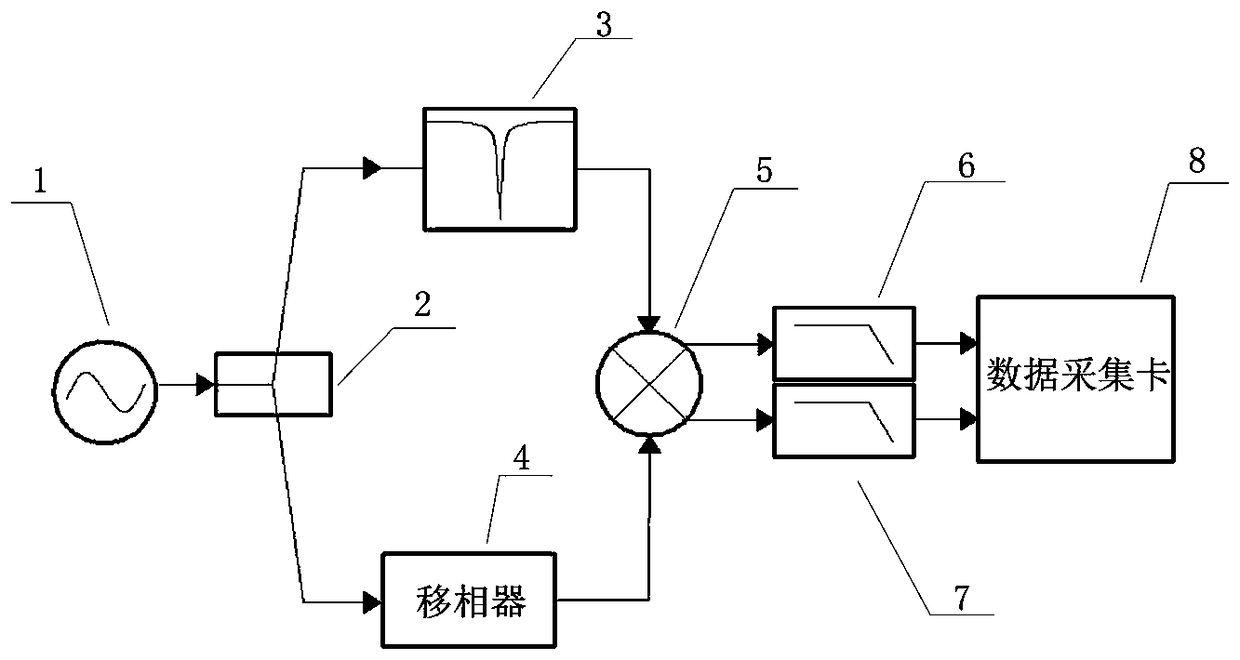

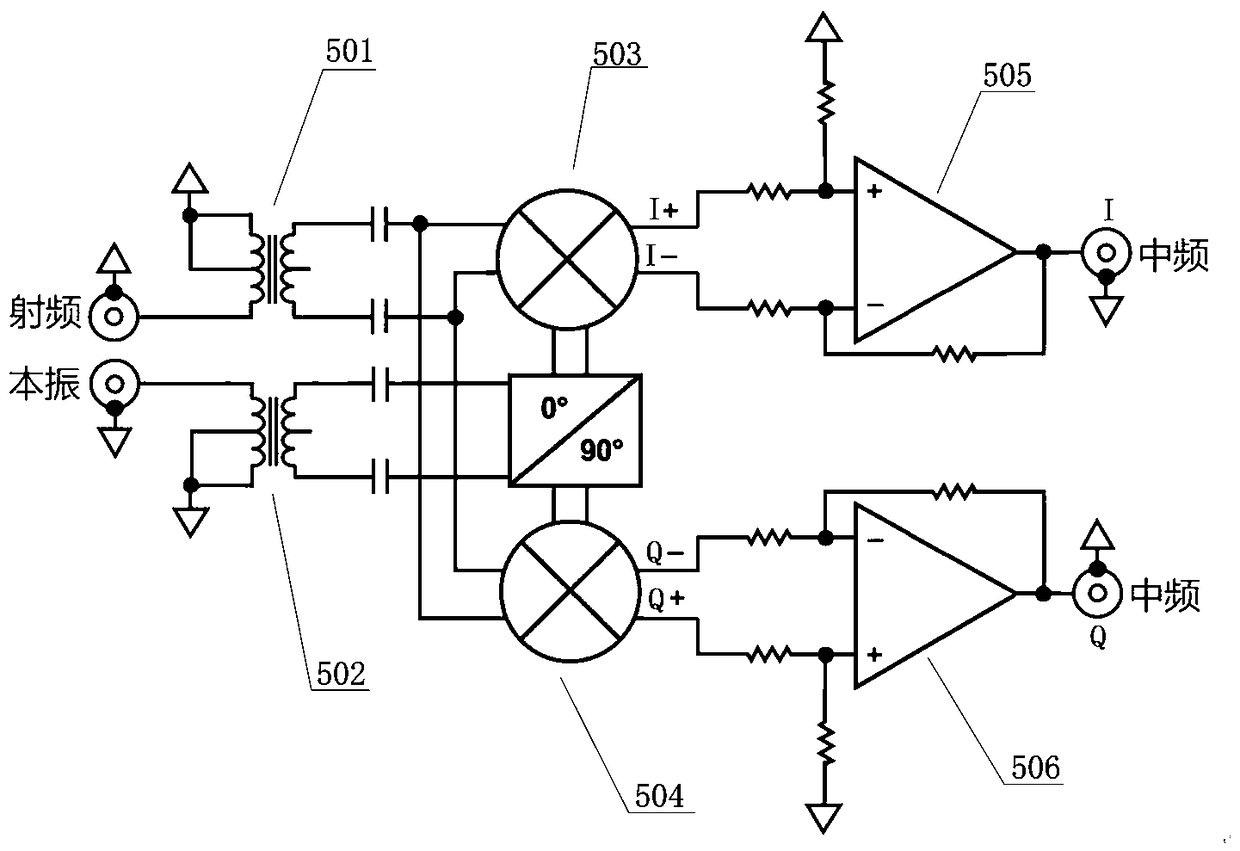

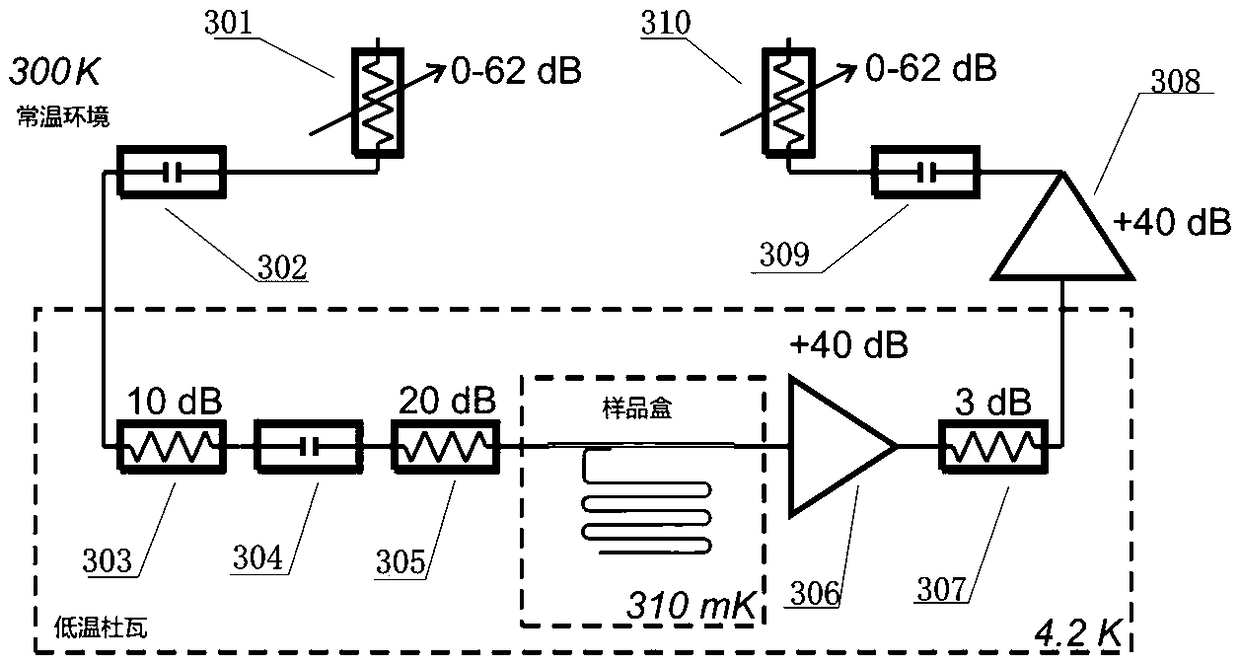

KIDs detector noise test circuit based on active quadrature mixer and test method thereof

ActiveCN109470936AReduce noise interferenceOptimization rangeNoise figure or signal-to-noise ratio measurementIntermediate frequencyPhase balancing

The invention provides a KIDs detector noise test circuit based on an active quadrature mixer and a test method thereof. The test circuit is characterized in that the test circuit comprises a frequency synthesis source, a directional coupler, a KIDs detector readout circuit module, an adjustable phase shifter, an active mixing circuit module, a filter circuit module, a data acquisition card, a control computer and the like. The test circuit takes a broadband Gilbert double-balance active quadrature mixer circuit structure as a core module, can complete noise test work on KIDs detector chips, and has excellent amplitude / phase balance degree and port isolation degree. The parasitic direct current bias voltage generated by a frequency output port is weak, the measurement is accurate, the mixer does not need to be separately calibrated, the measurement process is simplified, and the power level of the frequency synthesis source is reduced at the same time.

Owner:ZIJINSHAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

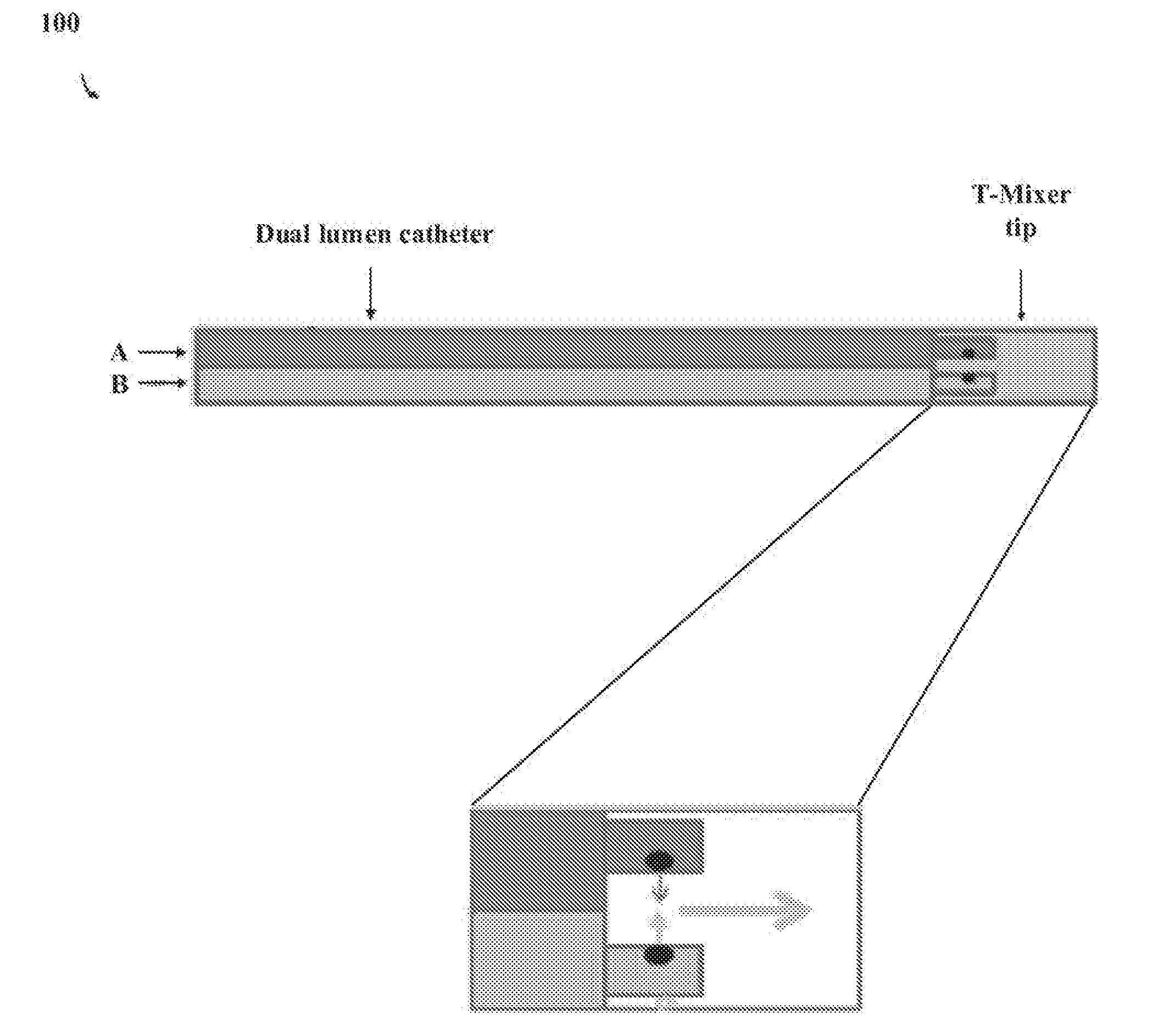

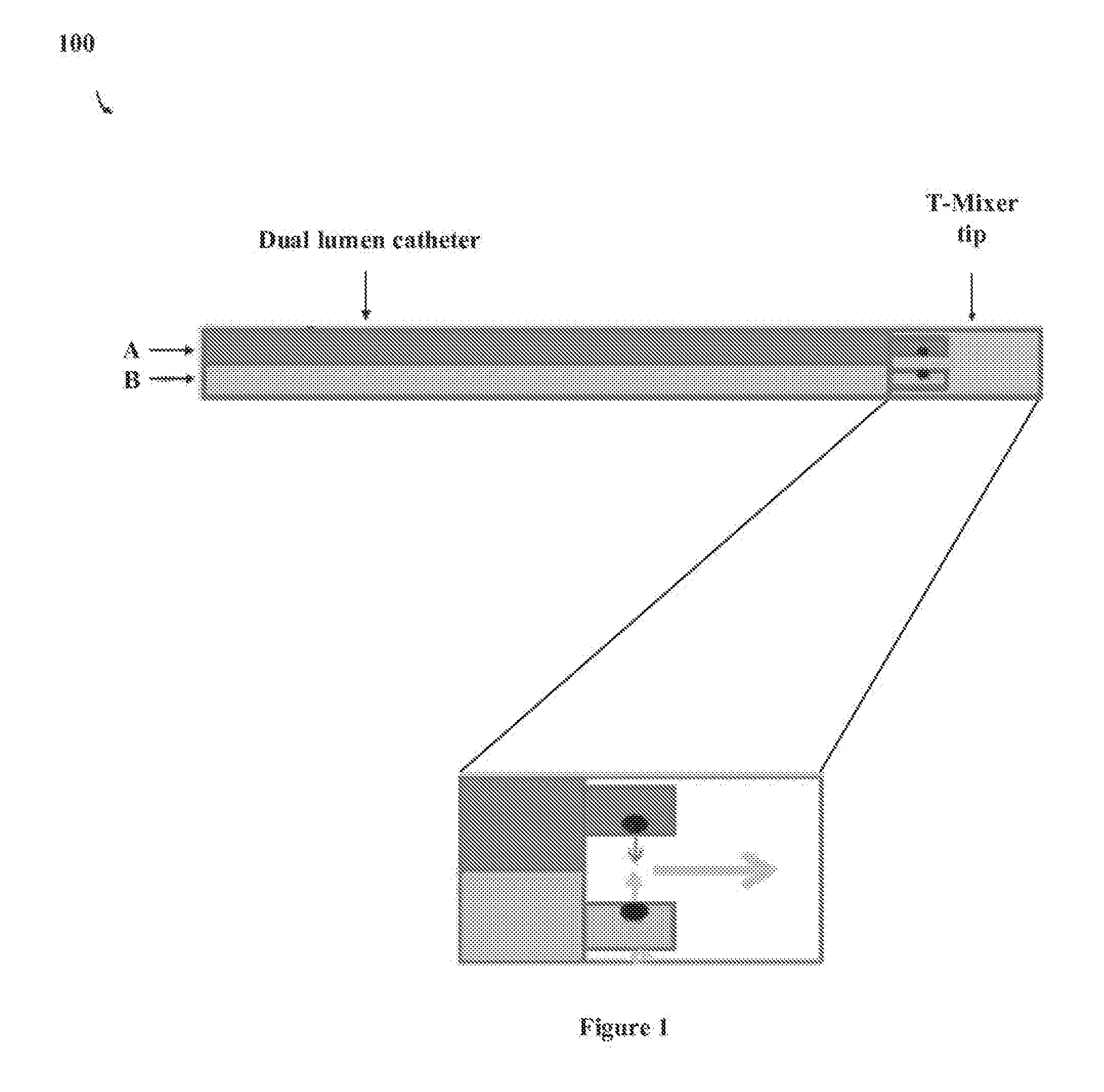

Mixing catheter for two-part system

InactiveUS20160296723A1Eliminate curingReduce the impactMulti-lumen catheterOcculdersRelative viscosityBiomedical engineering

Dual-lumen catheters for actively mixing two or more fluid components such that they react to form a more viscous pre-polymer formulation at or near the distal tip of the catheter are describe herein. The mixing dynamics within the dual-lumen catheter may be varied depending on the relative viscosity of each individual fluid component, as well as the viscosity of the resulting pre-polymer formulation.

Owner:BUSOLD RANY +4

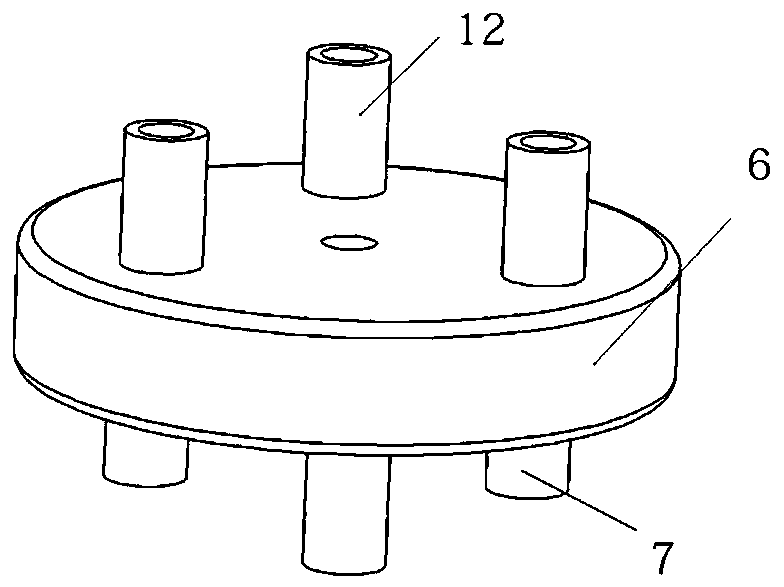

Active mixing and passive mixing 3D printing nozzle

InactiveCN110861303AAvoid easy cloggingHigh precision3D object support structuresApplying layer meansElectric machineryAgitator

The invention provides an active mixing and passive mixing 3D printing nozzle. The active mixing and passive mixing 3D printing nozzle comprises a feeding chamber, a mixing chamber, a stirring chamberand a nozzle, wherein the feeding chamber, the mixing chamber, the stirring chamber and the nozzle are sequentially arranged from top to bottom. The feeding chamber is in communication with the mixing chamber through three upper pipelines. The mixing chamber communicates with the stirring chamber through three lower pipelines. The nozzle communicates with the bottom of the stirring chamber. A stirrer is arranged in the stirring chamber. The stirrer is driven to rotate by a motor fixed above the feeding chamber. The three upper pipelines and the three lower pipelines are arranged in a staggered mode. Three feeding ports are uniformly arranged on the side wall of the feeding chamber. A compressed air inlet is formed in the upper portion of the feeding chamber. Compressed air enters the feeding chamber from the compressed air inlet, so that a printing material in the feeding chamber sequentially enters the mixing chamber and the stirring chamber. By means of the active mixing and passivemixing 3D printing nozzle, single-nozzle multi-material printing can be achieved, and active mixing and passive mixing are combined, so that the purposes of reducing the cost, saving the volume and improving the printing quality and the printing precision are achieved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

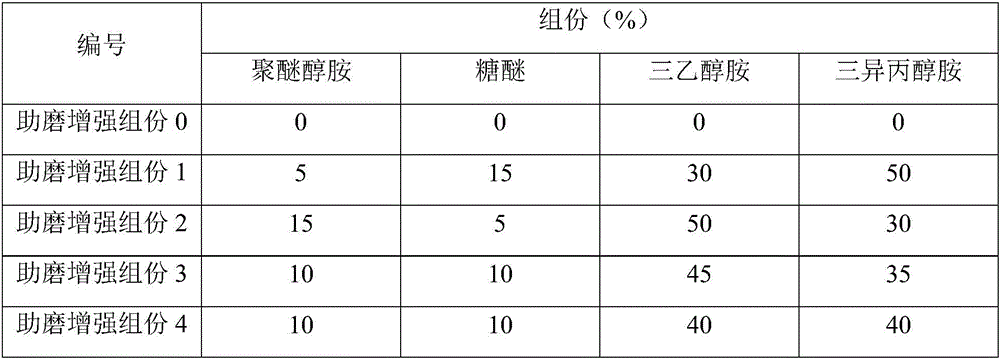

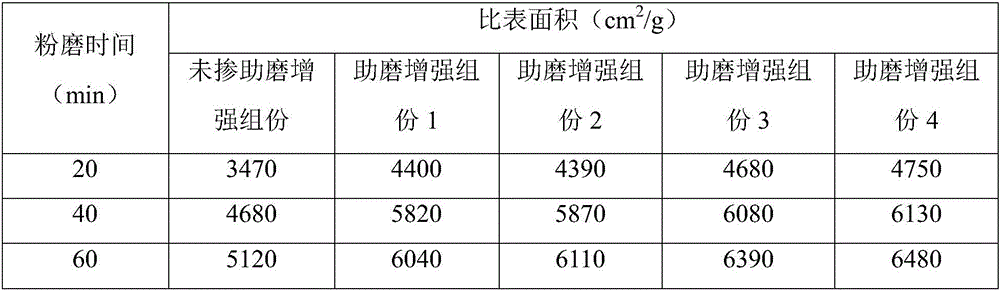

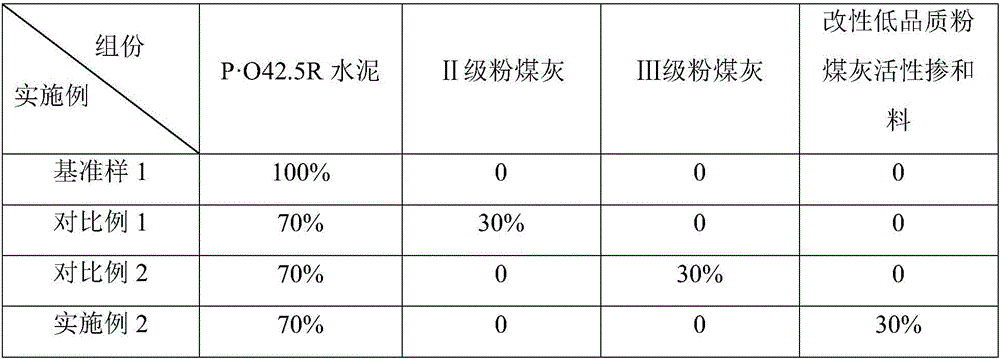

Fly ash modification agent and modified low-quality fly ash active mixing material thereof

ActiveCN106431065AImprovement not available for C30High strengthSolid waste managementReinforced concreteSlag

The invention relates to a fly ash modification agent and a modified low-quality fly ash active mixing material thereof. Firstly, 75 to 80 parts of red mud, 20 to 25 parts of phosphogypsum and 0.1 to 0.3 part of grinding aiding enhancing ingredients are uniformly mixed; then, grinding is performed until the surface area is not smaller than 6000 cm<2> / g to obtain the fly ash modification agent; the obtained fly ash modification agent is sufficiently and uniformly mixed with grade III fly ash; then, the modified low-quality fly ash active mixing material is obtained. Through being metered in parts by mass of all raw materials, the stage III fly ash accounts for 75 to 81 parts, and the fly ash modification agent accounts for 19 to 25 parts. The fly ash modification agent and the modified low-quality fly ash active mixing material solve the problem of application of low-quality stage III fly ash to C30 or higher premixed reinforced concrete. In addition, the industrial waste slag of the red mud, the phosphogypsum and the like can be consumed; 100 weight percent of stage II fly ash can be replaced in an equal mass in concrete; the workability of the concrete and the anti-seeping performance of the concrete can be improved.

Owner:中建西部建设西南有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com