Concrete high-strength admixture, cement mixture and non-autoclaved ultra-high strength concrete product

A concrete and admixture technology, applied in the field of concrete, can solve the problems of shortened service life of pipe piles, personal casualties, property, and high prices, and achieve the effects of simplifying the production process, eliminating potential safety hazards, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] The difference between this embodiment and embodiment 1 is that the gypsum used in the high-strength concrete admixture is desulfurized gypsum.

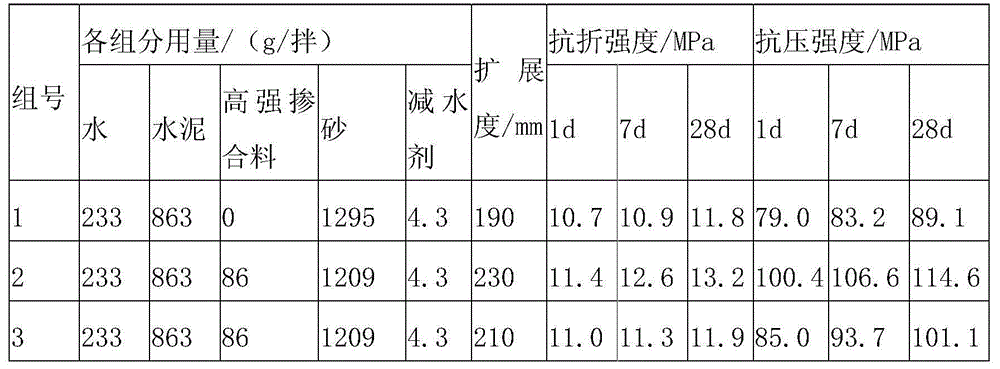

[0029] Comparative experiment 1

[0030] The mortar (group No. 1) that does not use the concrete high-strength admixture of the embodiment of the present invention is molded and cured. The high-strength cement mixture of the above-mentioned embodiment 1 is used to configure mortar (group No. 2), and molded and maintained. The mortar (group number 3) of the concrete comparison admixture in Example 2 of the present invention was adopted for molding maintenance. Carry out relevant performance tests on molded products of group numbers 1, 2, and 3. The components, proportions and performance parameters of the concrete mortar with group number 1, group number 2 and group number 3 are shown in Table 1. It should be noted that: the high-strength concrete admixture and the comparison admixture are externally mixed, and the same amou...

Embodiment 3

[0046] The high-strength concrete admixture differs from the high-strength admixture in Example 1 only in that the components and weight percentages are: 30% ground type II anhydrite, 50% silica fume, and 12% superfine Fly ash, 6.5% quicklime and 1.5% sodium sulfate.

[0047] A high-strength cement mixture, the above-mentioned high-strength concrete admixture and general-purpose portland cement are used to form a high-strength cement mixture, wherein the weight percentage of the high-strength concrete admixture is 16.7%, and the weight percentage of the general-purpose Portland cement is 83.3%.

Embodiment 4

[0049] The difference between this embodiment and embodiment 3 is that desulfurized gypsum is used as the gypsum in the high-strength concrete admixture.

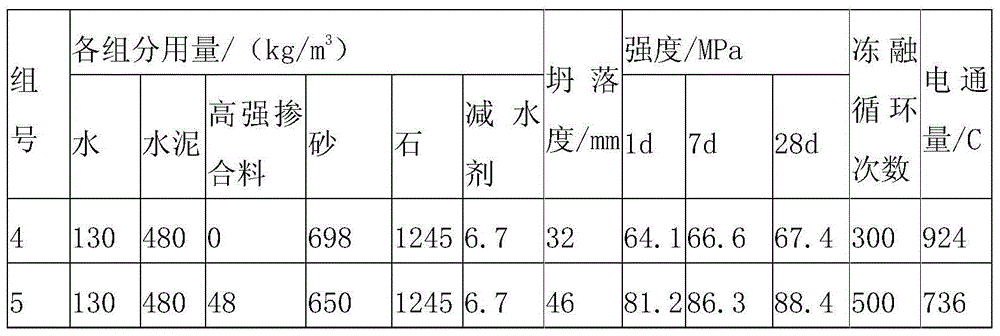

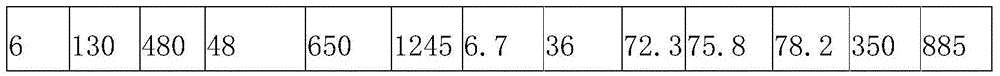

[0050] Comparative test 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com