Method for preparing active mixing material by mine tailing

A technology of active mixed materials and tailings, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low comprehensive utilization rate of tailings, high production cost, complex comprehensive utilization process, etc. Achieve important environmental benefits and economic benefits, increase added value, and make the preparation process simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

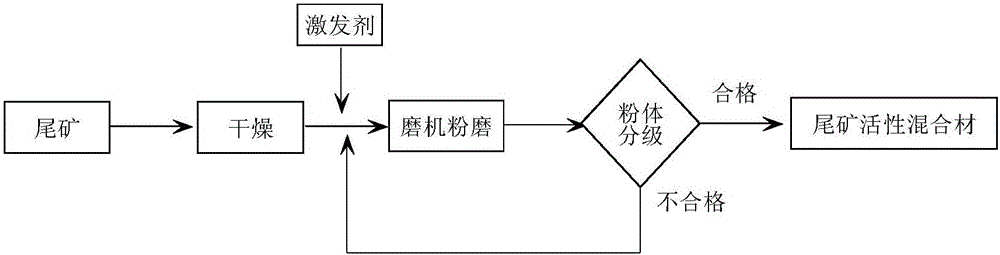

Method used

Image

Examples

Embodiment 1

[0023] Weigh the tailings and activator according to the weight percentage, weigh 3.5kg of tailings; take the quality of tailings as the basis, add 0.015% polyolamine type macromolecule, 0.2% water glass and 0.005% organic glycol , the activator was added in the form of aqueous solution. A mill is used to grind the tailings, and the grinding time is 20 minutes to obtain the tailings active mixture.

[0024] The cement used is P.O52.5 ordinary Portland cement with a specific surface area of 357m 2 / Kg.

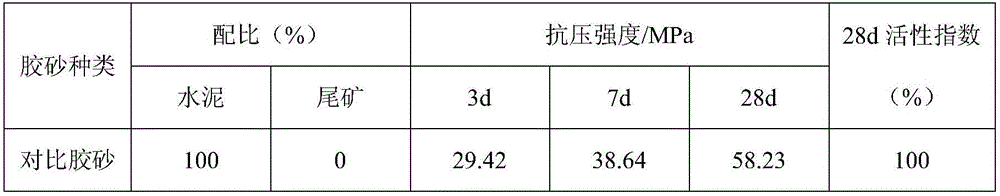

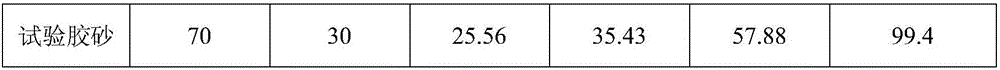

[0025] According to the percentage by weight, the tailings fine powder is uniformly proportioned with P.O52.5 cement according to 30%. According to GB / T17671-2005 "Cement Mortar Strength Test Method" (ISO method), cement mortar test blocks were prepared, and according to GB / T12957-2005 "Industrial Waste Residue Activity Test Method for Cement Mixtures", it was concluded that tailings were used as Activity test results of cement active admixture under different conditions. ...

Embodiment 2

[0030] 1. Weigh 3.5kg of tailings and activator according to the weight percentage; take the quality of tailings as the basis, add 0.02% polyolamine polymer, 0.4% water glass and 0.02% organic Glycol. A mill is used to grind the tailings, and the grinding time is 50 minutes to obtain the tailings active mixture.

[0031] 2. The cement used is P.O52.5 ordinary Portland cement with a specific surface area of 357m 2 / Kg.

[0032] 3. According to the percentage by weight, the tailings fine powder is uniformly proportioned with P.O52.5 cement by 30%. Prepare cement mortar test blocks according to GB / T17671-2005 "Cement Mortar Strength Test Method" (ISO method), and according to GB / T12957-2005 "Test Method for Activity of Industrial Waste Slag Used in Cement Mixtures", it is concluded that tailings are used as Activity test results of cement active admixture under different conditions. The test results are shown in Table 2.

[0033] Table 2 tailings used as cement admixture a...

Embodiment 3

[0036] 1. Weigh 3.5kg of tailings and activator according to the weight percentage; based on the quality of tailings, add 0.03% polyolamine polymer, 0.3% water glass and 0.01% organic Glycol. A mill is used to grind the tailings, and the grinding time is 30 minutes to obtain the tailings active mixture.

[0037] 2. The cement used is P.O52.5 ordinary Portland cement with a specific surface area of 357m 2 / Kg.

[0038] 3. According to the percentage by weight, the tailings fine powder is uniformly proportioned with P.O52.5 cement by 30%. Prepare cement mortar test blocks according to GB / T17671-2005 "Cement Mortar Strength Test Method" (ISO method), and according to GB / T12957-2005 "Test Method for Activity of Industrial Waste Slag Used in Cement Mixtures", it is concluded that tailings are used as Activity test results of cement active admixture under different conditions. The test results are shown in Table 3.

[0039] Table 3 tailings used as cement admixture activity t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com