3D printing based cement based inorganic gelling material and preparation method thereof

An inorganic cementitious material, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of long bonding time, inability to print high-precision building components, clogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

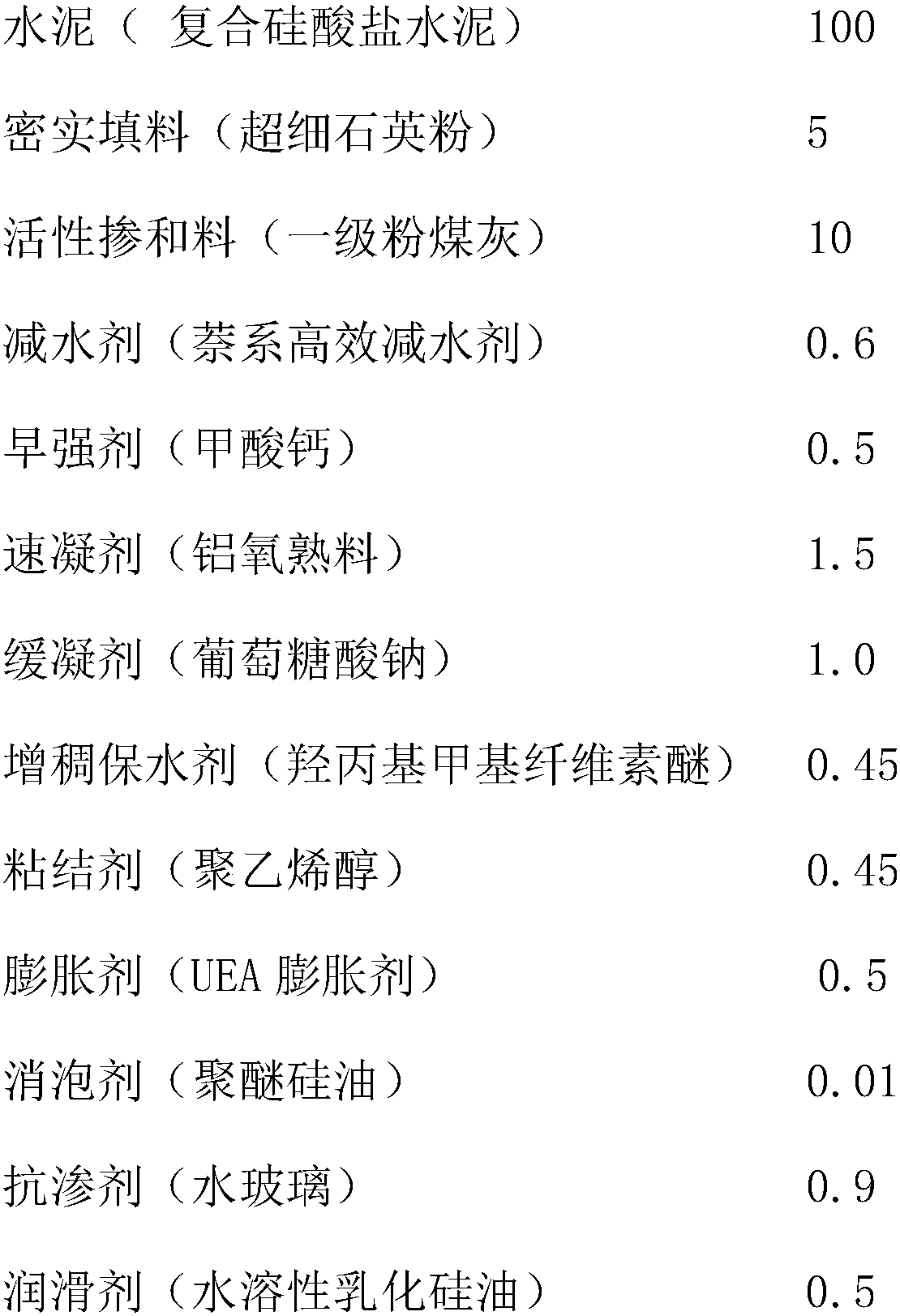

[0044] 1. Prepare the following substances in parts by weight:

[0045]

[0046]

[0047] Preparation method: Weigh the raw materials according to the formula, and add cement (composite Portland cement), dense filler (ultrafine quartz powder), active admixture (first-class fly ash), and water reducer to the cement slurry mixer in sequence (naphthalene-based high-efficiency water reducer), early strength agent (calcium formate), accelerator (alumina clinker), retarder (sodium gluconate), expansion agent (UEA expansion agent), impervious agent (water glass ) and fiber (polyvinyl alcohol fiber), fully stirred evenly, so as to obtain powdery cement-based inorganic gelling material;

[0048] Take 45 parts of water, add thickening water-retaining agent (hydroxypropyl methylcellulose ether), defoamer (polyether silicone oil), binder (polyvinyl alcohol) and lubricant (water-soluble emulsified silicone oil), stirred evenly to obtain a mixed solution.

[0049] Add the stirred mi...

Embodiment 2

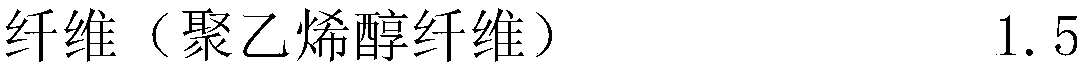

[0052] Prepare the following materials in parts by weight:

[0053]

[0054]

[0055] Preparation method: Weigh the raw materials according to the formula, add cement 1 (composite Portland cement), cement 2 (double fast sulphoaluminate cement), dense filler (ultrafine clay), active blending Material (first-class fly ash), water reducer (calcium lignosulfonate), accelerator (calcium fluoroaluminate), retarder (citric acid), expansion agent (AEA expansion agent), anti-seepage agent ( Sodium hydroxide) and fiber (alkali-resistant glass fiber), fully stir evenly, obtain powdery cement-based inorganic gelling material with this;

[0056] Measure 45 parts of water, add thickening water-retaining agent (hydroxypropyl methyl cellulose ether), binding agent (epoxy resin), defoamer (high carbon alcohol) and lubricant (rosin) in magnetic stirrer with this NaOH), stirred evenly to obtain a mixed solution. Add the stirred mixed solution into the powdered cement-based inorganic ceme...

Embodiment 3

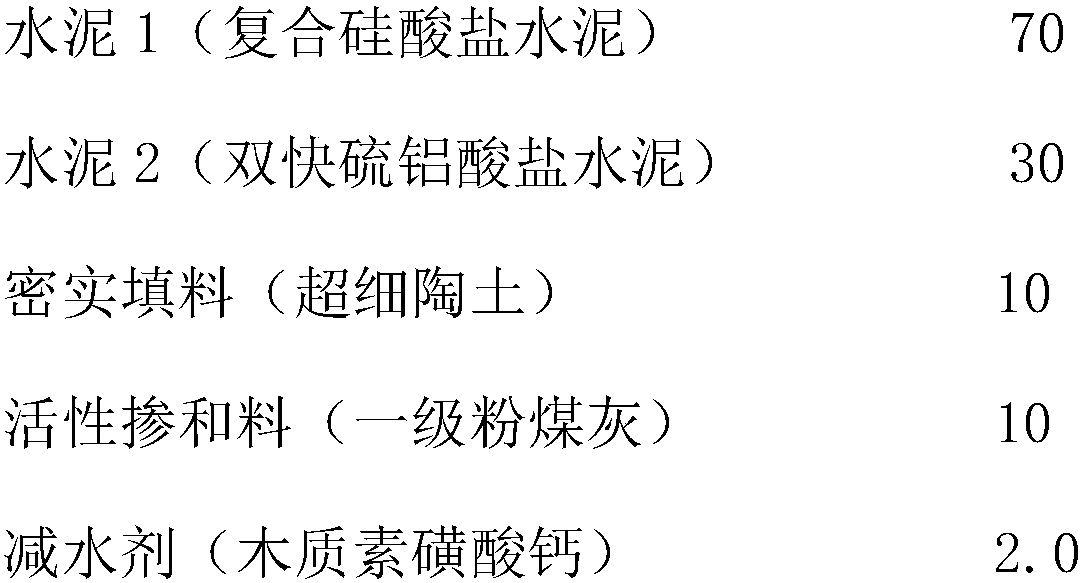

[0059] Prepare the following substances in parts by weight:

[0060]

[0061] Preparation method: Weigh the raw materials according to the formula, add cement 1 (composite Portland cement), cement 2 (double-fast sulphoaluminate cement), cement 3 (white Portland cement), dense Filler (limestone powder), active admixture (aluminum slag powder), water reducer (naphthalene superplasticizer), accelerator (calcium fluoroaluminate), retarder (sodium hexametaphosphate), expansion agent 1 (AEA expansion agent), expansion agent 2 (UEA expansion agent), anti-seepage agent (sodium carbonate) and fiber (ceramic fiber), fully stirred evenly, so as to obtain powdery cement-based inorganic gelling material;

[0062] Measure 50 parts of water, add thickening water-retaining agent (carboxymethyl hydroxyethyl cellulose), binding agent (vinyl acetate), defoamer (polycarboxylic acid) and lubricant 1 (water-soluble emulsified silicone oil), lubricant 2 (sodium abietate), and stirred evenly to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com