Novel cement with high breakage resistance value and preparation method of novel cement

A high fracture and resistance technology, applied in cement production and other directions, can solve the problems of low flexural strength and prone to fracture, and achieve the effect of improving fracture resistance, enhancing flexural strength, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

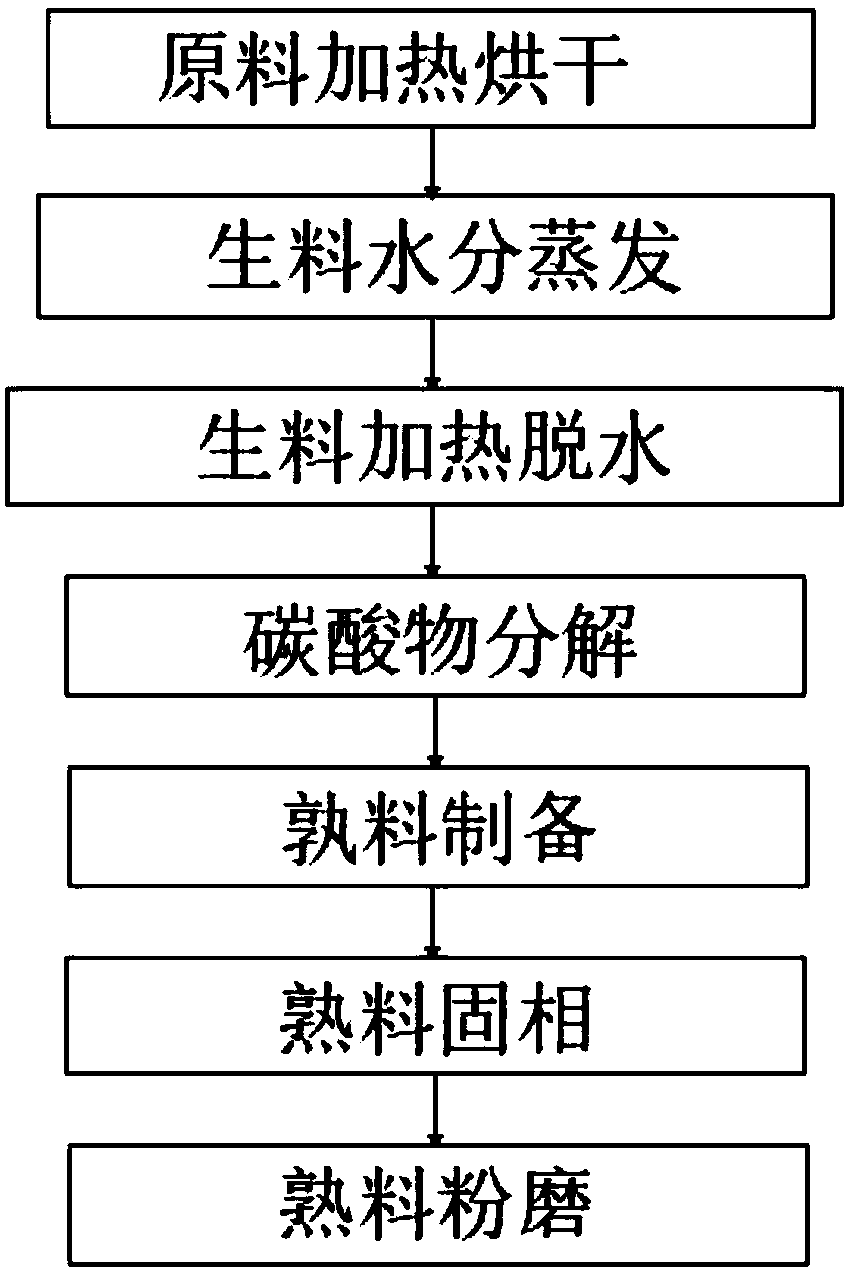

[0042] see figure 1 , a new type of cement with high fracture resistance value and its preparation method, the cement includes by weight percentage: 50% limestone, 5% clay raw material, 3.5-30% fly ash, 9-30% inactive mixed material, 3.5-6% gypsum, 2% water-soluble resin and 1.5-30% active mixed material, the preparation method of which comprises the following steps:

[0043] Step 1: heating and drying the raw materials, drying the limestone, fly ash and gypsum, and cooling them for later use;

[0044] Step 2: Evaporate the water in the raw meal, grind the raw material prepared in step 1 in a ball mill, prepare the raw meal according to the weight ratio, and heat the raw meal so that the free moisture in the raw meal increases with the temperature of the material And gradually evaporate, in step 2, during the water evaporation process of the raw meal, the temperature of the raw meal is heated, and when the temperature rises to 100-150°C, all the free water in the raw meal is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com