Active bauxite dressing tailing micro-powder, and preparation method thereof

A technology of activated bauxite and tailings micro-powder, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of inapplicable bauxite beneficiation and tailings activation, and achieve a simple and easy preparation method , the effect of solving discharge and stockpiling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

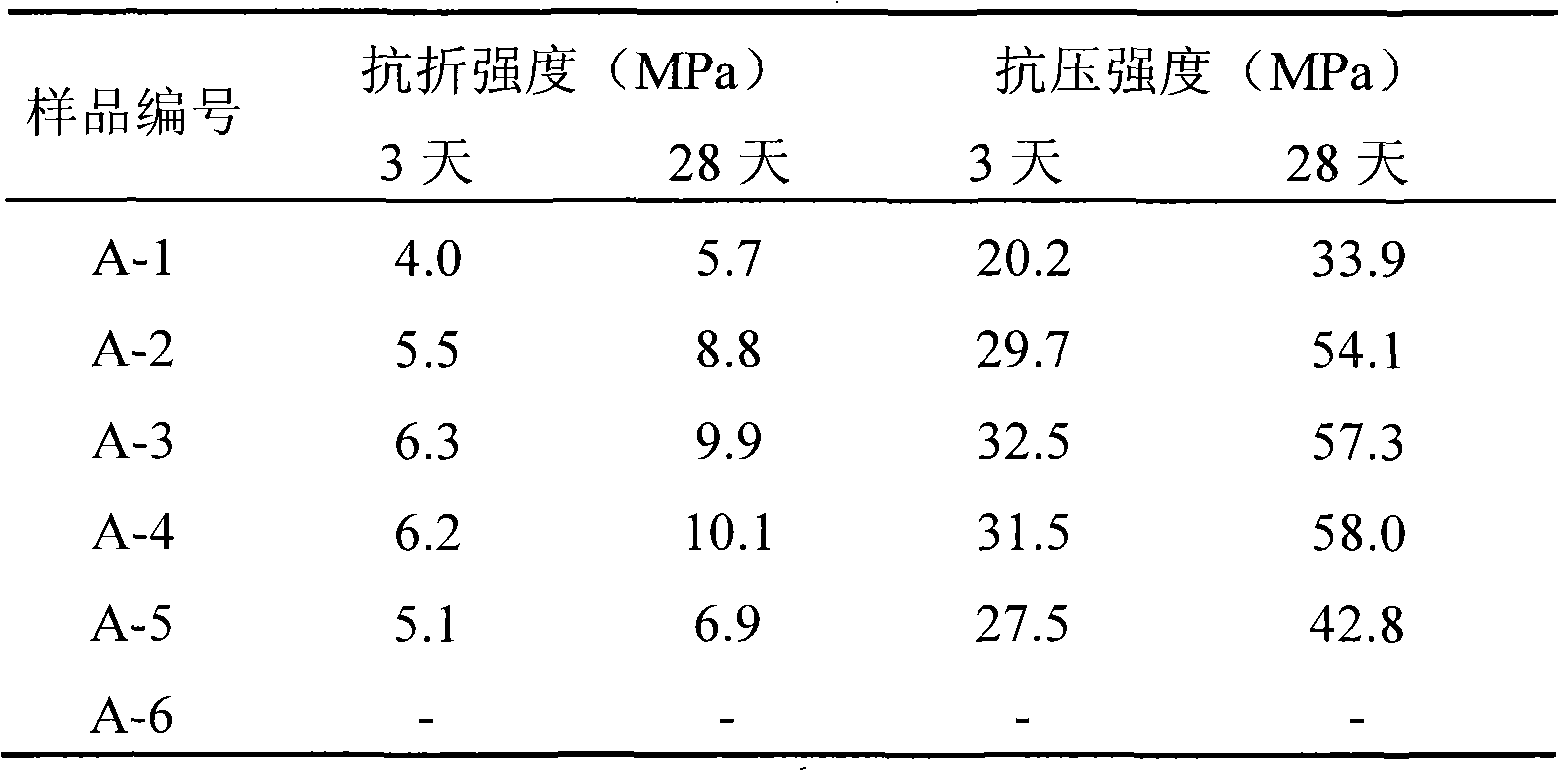

[0034] Embodiment 1: Determination of lime content in bauxite dressing tailings

[0035] Calcinate 100 kg of bauxite tailings at 800°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through a 80 μm square hole sieve, and mix 15 wt% of Slag fine powder, obtained powder A-1.

[0036] Mix 98 kg of bauxite tailings with 2 kg of lime evenly, calcinate at 800°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through an 80 μm square hole sieve, and the sieve residue is in the range of 10.0% Inside, 15wt% of slag fine powder was added to obtain powder A-2.

[0037] Mix 96 kg of bauxite tailings with 4 kg of lime evenly, calcinate at 800°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through a 80 μm square hole sieve, and the sieve residue is in the range of 10.0% Inside, 15wt% of slag fine powder was added to obtain powder...

Embodiment 2

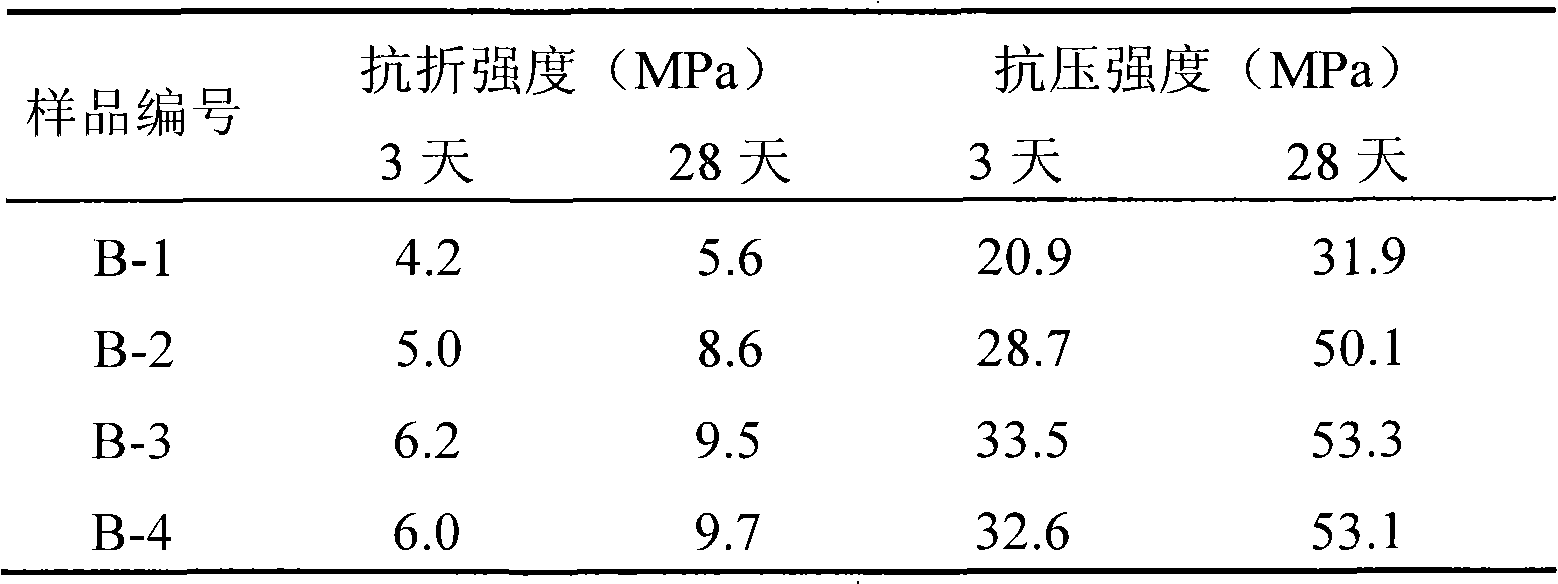

[0046] Example 2: Preparation of active micropowder by mixing fly ash in bauxite dressing tailings

[0047] Calcinate 100kg of bauxite tailings at 850°C for 1.0 hour and 30 minutes, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through a 80μm square hole sieve, and mix 15wt % of slag powder, the resulting powder B-1.

[0048] Mix 98 kg of bauxite tailings with 2 kg of fly ash evenly, calcinate at 850°C for 1.0 hour and 30 minutes, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through an 80μm square hole sieve, and sieve the remaining In the range of 10.0%, 15wt% of slag fine powder was added to obtain powder B-2.

[0049] Mix 88 kg of bauxite tailings with 12 kg of fly ash evenly, calcinate at 850°C for 1.0 hour and 30 minutes, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through an 80μm square hole sieve, and sieve the remaining In the range of 10.0%, ...

Embodiment 3

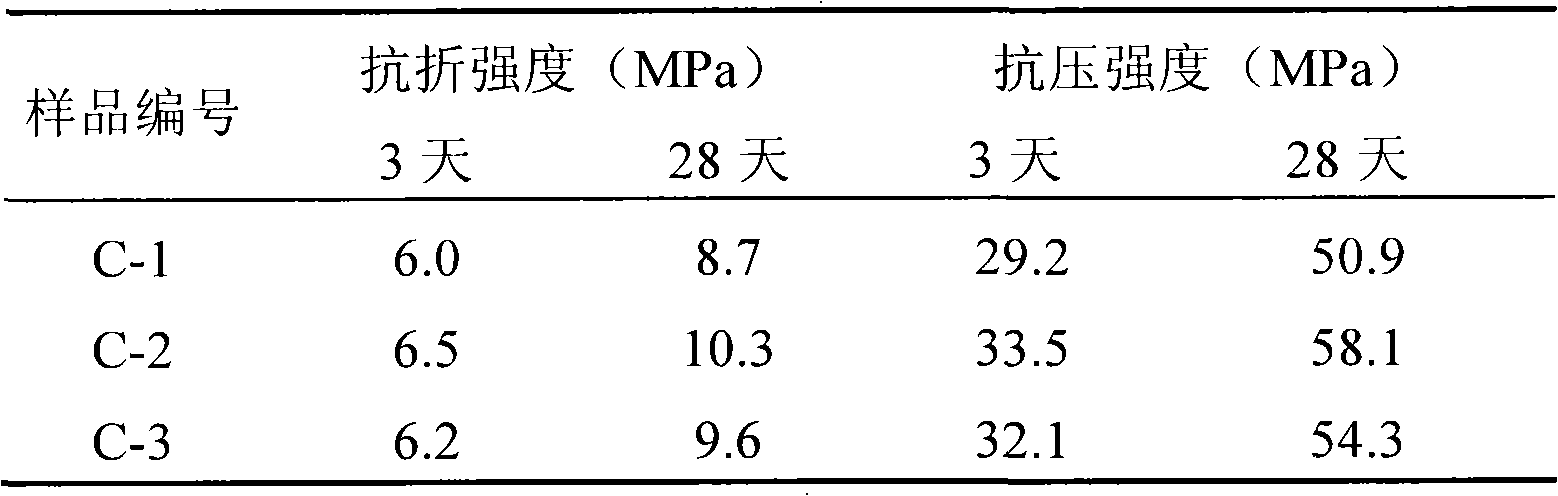

[0055] Embodiment 3: the control of calcining temperature

[0056] Mix 96 kg of bauxite tailings with 4 kg of lime evenly, calcinate at 700°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through a 80 μm square hole sieve, and the sieve residue is in the range of 10.0% Inside, 15wt% of slag fine powder was added to obtain powder C-1.

[0057] Mix 96 kg of bauxite tailings with 4 kg of lime evenly, calcinate at 800°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through a 80 μm square hole sieve, and the sieve residue is in the range of 10.0% Inside, 15wt% of slag fine powder was added to obtain powder C-2.

[0058] Mix 96 kg of bauxite tailings with 4 kg of lime evenly, calcinate at 900°C for 1.0 hour, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through an 80 μm square hole sieve, and the sieve residue is in the range of 10.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com