Preparation process of high-compression-resistance light weight foam concrete

A technology of compressive performance and lightweight foam, which is applied in the field of foam concrete preparation technology, can solve the problems affecting foam concrete thermal insulation, sound insulation performance, low compressive strength, low strength, etc., and achieve good sound insulation and heat insulation effect, and compressive performance Excellent, homogeneous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

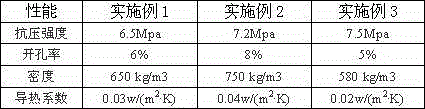

Examples

Embodiment 1

[0025] The preparation process of lightweight foamed concrete with high compressive performance consists of the following steps:

[0026] (1) Preparation of active mixed material: mixing river sand, glass fiber, naphthalenesulfonate superplasticizer and active silica evenly;

[0027] (2) Preparation of slurry: inject water, cement, active mixed material, and propylene-based organic thickener into the twin-shaft mixer through the water pump and the injection machine according to the ratio in the stirring state, among which water, injection, and stirring power supply The input frequency is controlled within the range of 0-70HZ;

[0028] (3) Foam preparation by foaming agent: use the host computer control of the automatic foaming cement equipment, and make the foaming agent into foam through the plunger pump and air compressor;

[0029] (4) Mixing: Under the control of the main machine of the automatic foaming cement equipment, the slurry prepared in step (2) and the foam prepar...

Embodiment 2

[0035] The difference between this embodiment and Example 1 is that the composition ratios used in this embodiment are different, and the ratios of the components are as follows:

[0036] 305 parts of cement, 335 parts of river sand, 17 parts of glass fiber, 8 parts of foaming agent, 10 parts of naphthalenesulfonate water reducer, 10 parts of propylene organic thickener, 35 parts of activated silica, 110 parts of water share.

Embodiment 3

[0038] The difference between this embodiment and embodiment 1 is that the composition ratios used in this embodiment are different, and the ratios of the components are as follows:

[0039] The proportion of each component is as follows: 285 parts of cement, 325 parts of river sand, 16 parts of glass fiber, 11 parts of foaming agent, 6 parts of naphthalenesulfonate water reducer, 13 parts of propylene organic thickener, active diacetate 39 parts of silicon oxide, 120 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com