Pulse fiber laser of fiber bragg grating modulation Q

A technology of fiber lasers and fiber gratings, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of large volume, increase optical alignment, etc., achieve the effect of reducing coupling loss and improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

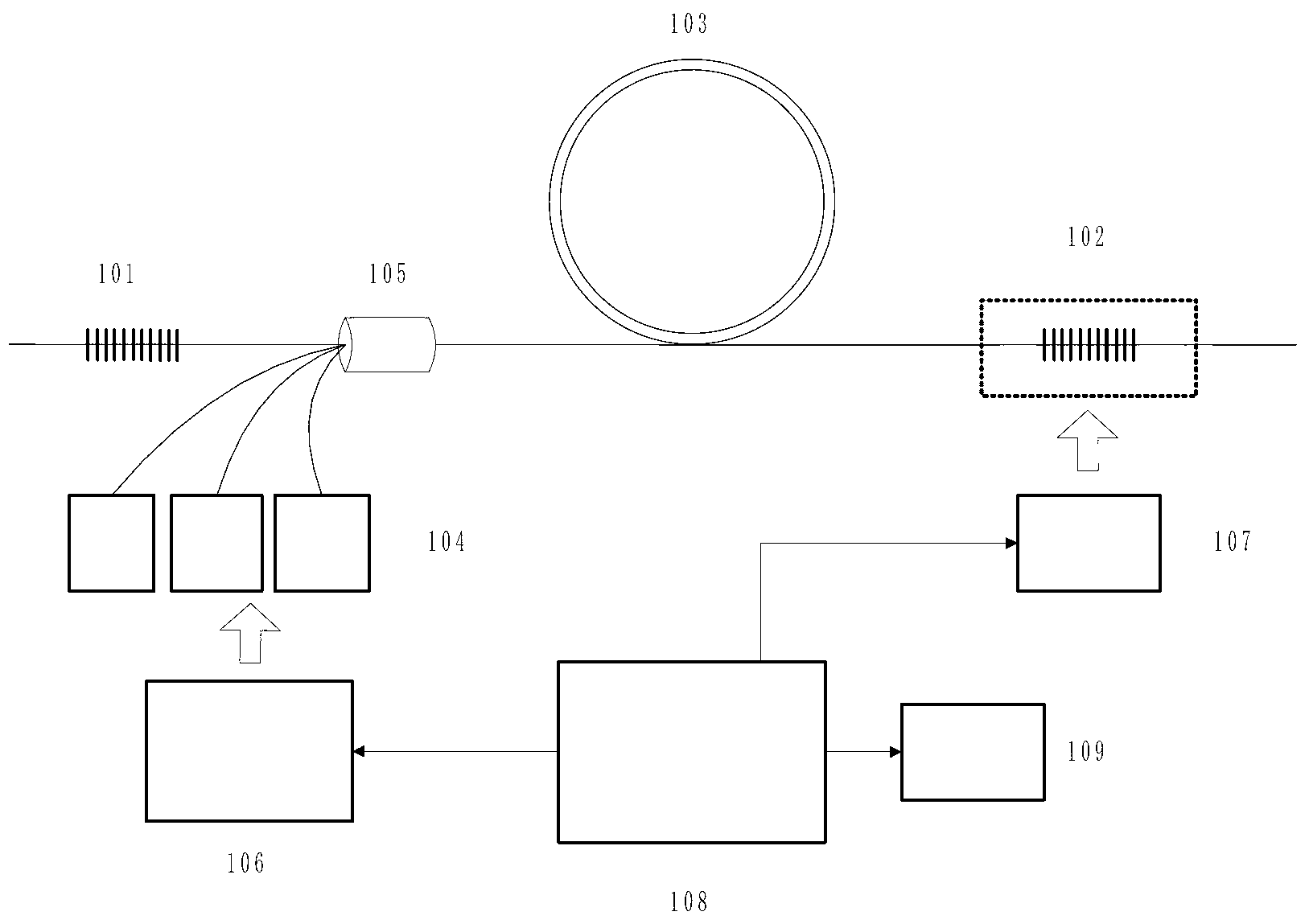

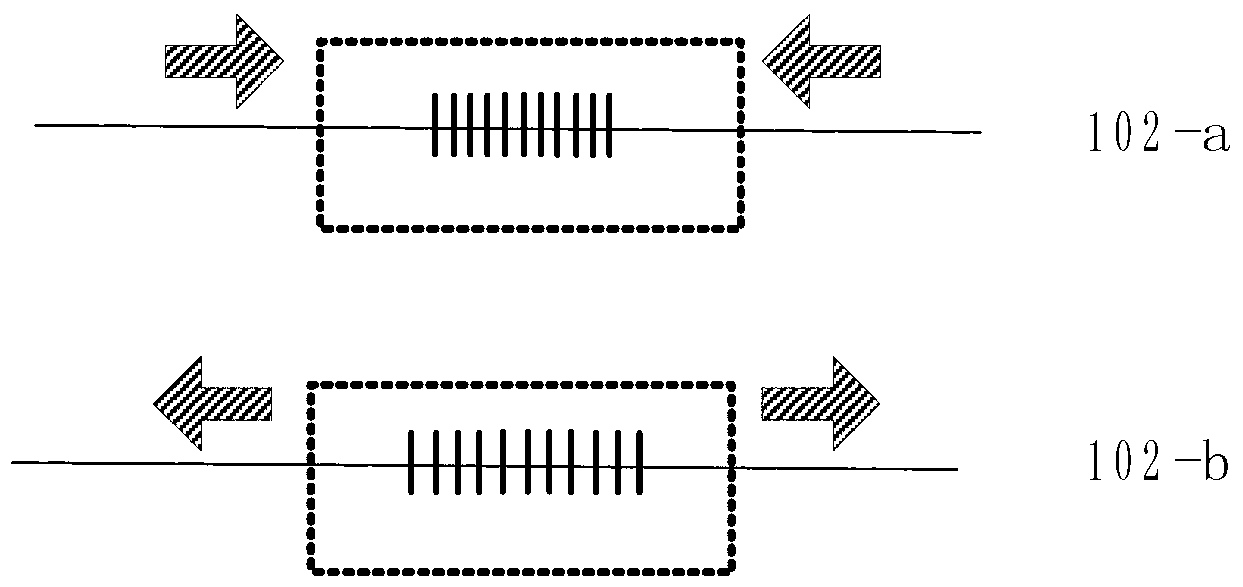

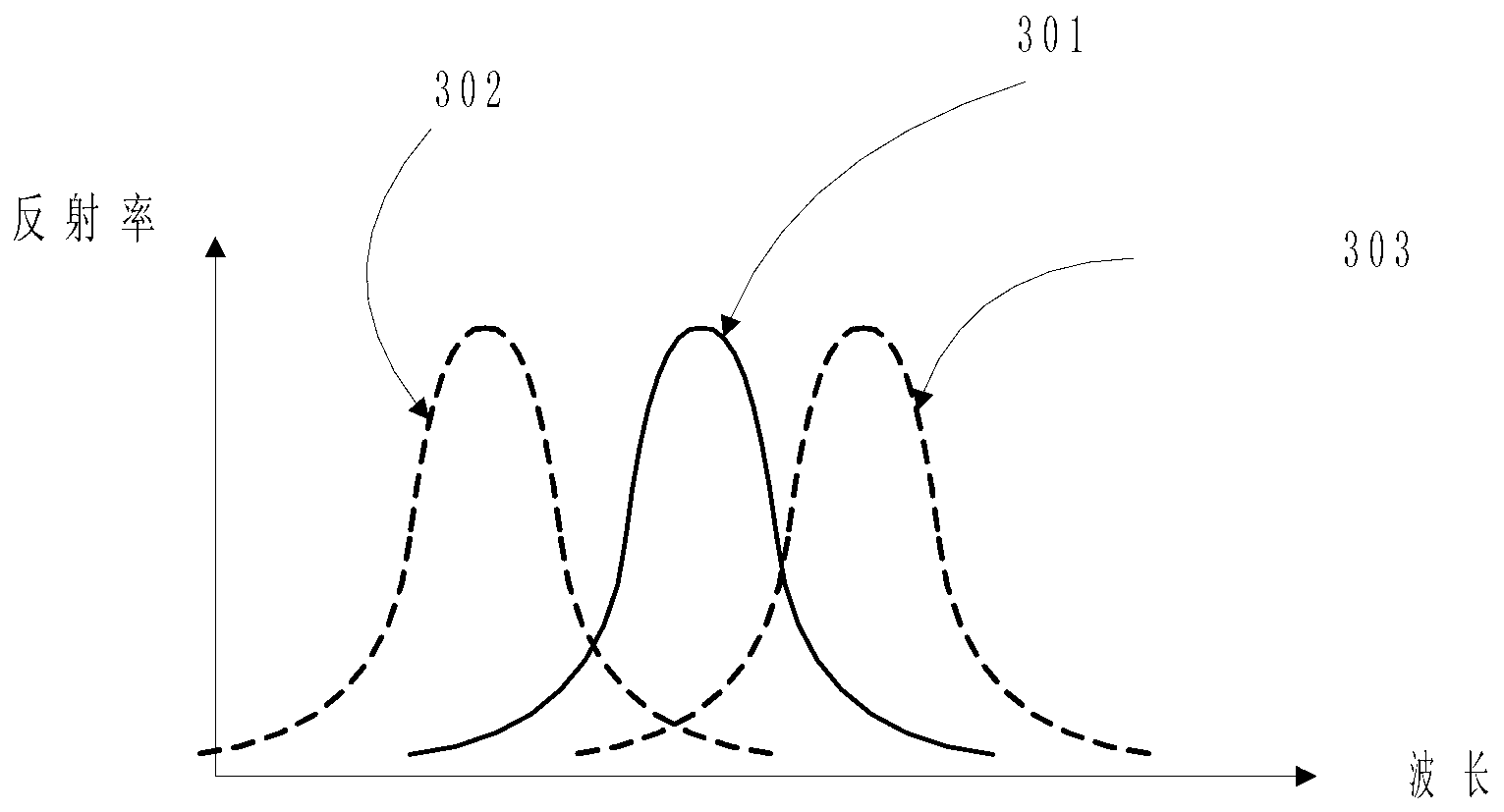

[0014] Depend on figure 1 It is known that a pulsed fiber laser with fiber grating Q switching consists of a fixed wavelength fiber grating 101, a tunable fiber grating 102, an active doped double-clad fiber 103, a pumping semiconductor laser 104, a fiber pumping optical beam combiner 105, Fiber isolator and collimator, pump driving circuit 106, piezoelectric ceramic or magnetostrictive driver 107, main control circuit 108 and interface circuit 109, fixed wavelength fiber grating 101 and tunable fiber grating 102 form two parts of fiber laser A reflector, the tunable fiber grating 102 is packaged on the piezoelectric ceramic or magnetostrictive material, the described tunable fiber grating 102 is connected with the piezoelectric ceramic or magnetostrictive driver 107, the piezoelectric ceramic or magnetostrictive driver 107 compressing 102-a or stretching 102-b the tunable fiber grating 102 can change the reflection center wavelength of the tunable fiber grating 102, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com