Patents

Literature

111results about How to "Improve optical coupling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

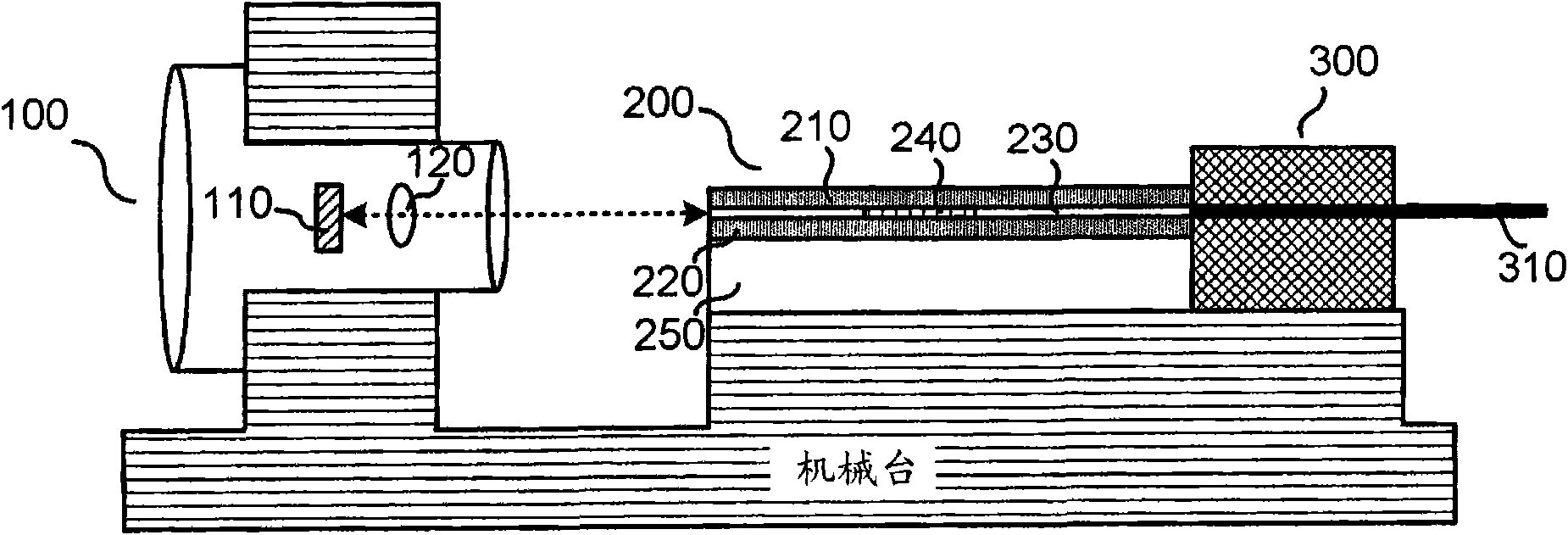

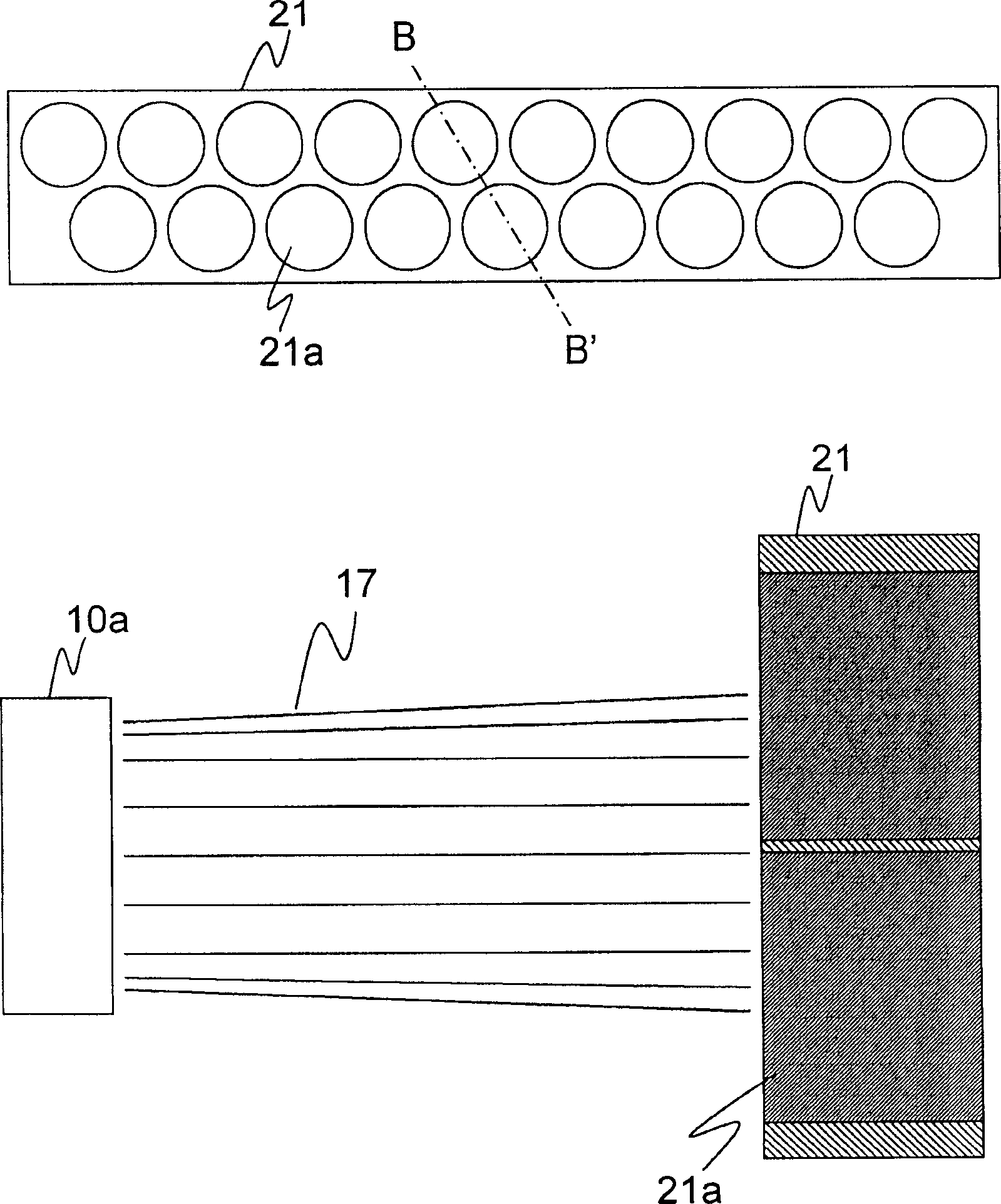

Tunable laser module based on polymer waveguides

InactiveCN101652941AHigh outputImprove optical coupling efficiencyLaser detailsCoupling light guidesTemperature controlGrating

The present invention relates to a laser module based on a waveguide tunable in a broad wavelength band. More specifically, the laser module comprises: a broadband light source based on an external resonator that generates optical signals; a waveguide; at least one Bragg grating formed on the waveguide; an optical lens provided between the light source and the waveguide; a first temperature controlling device configured of a thin film heater; and a second temperature controlling device that includes a temperature sensor and a thermoelectric cooler, wherein the light output from the light source being condensed through the optical lens and input to the waveguide, and a reflecting band of the Bragg grating is controlled by a thermo-optic effect, and an oscillation wavelength is controlled bya second temperature controlling device independently of external temperature environment.

Owner:CHEM OPTICS

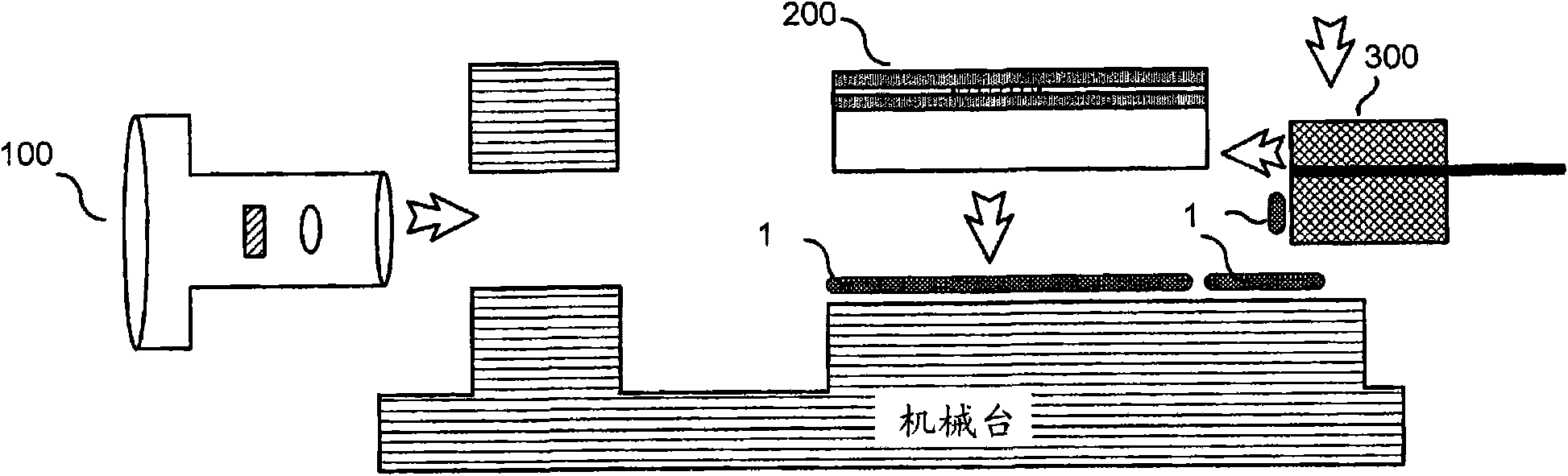

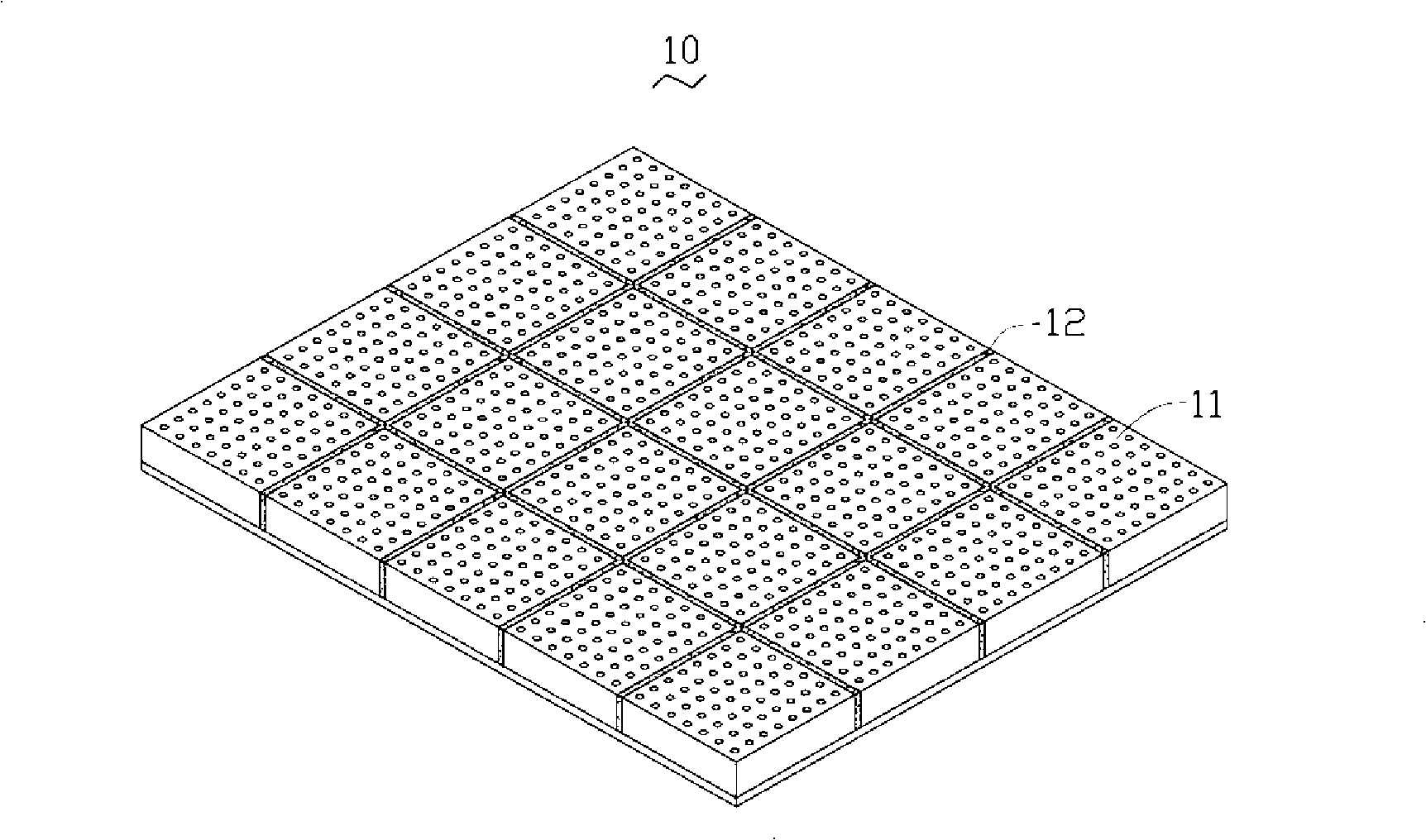

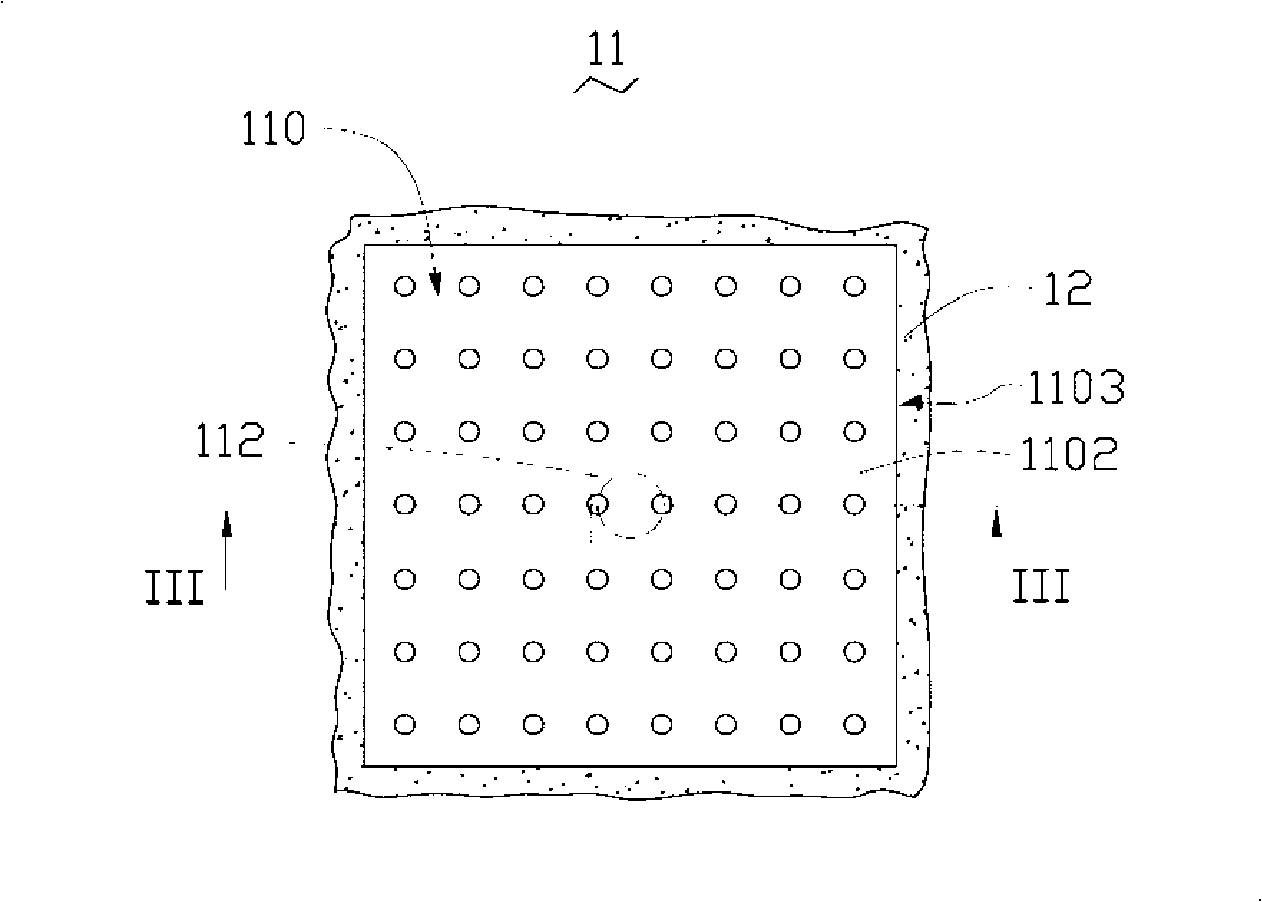

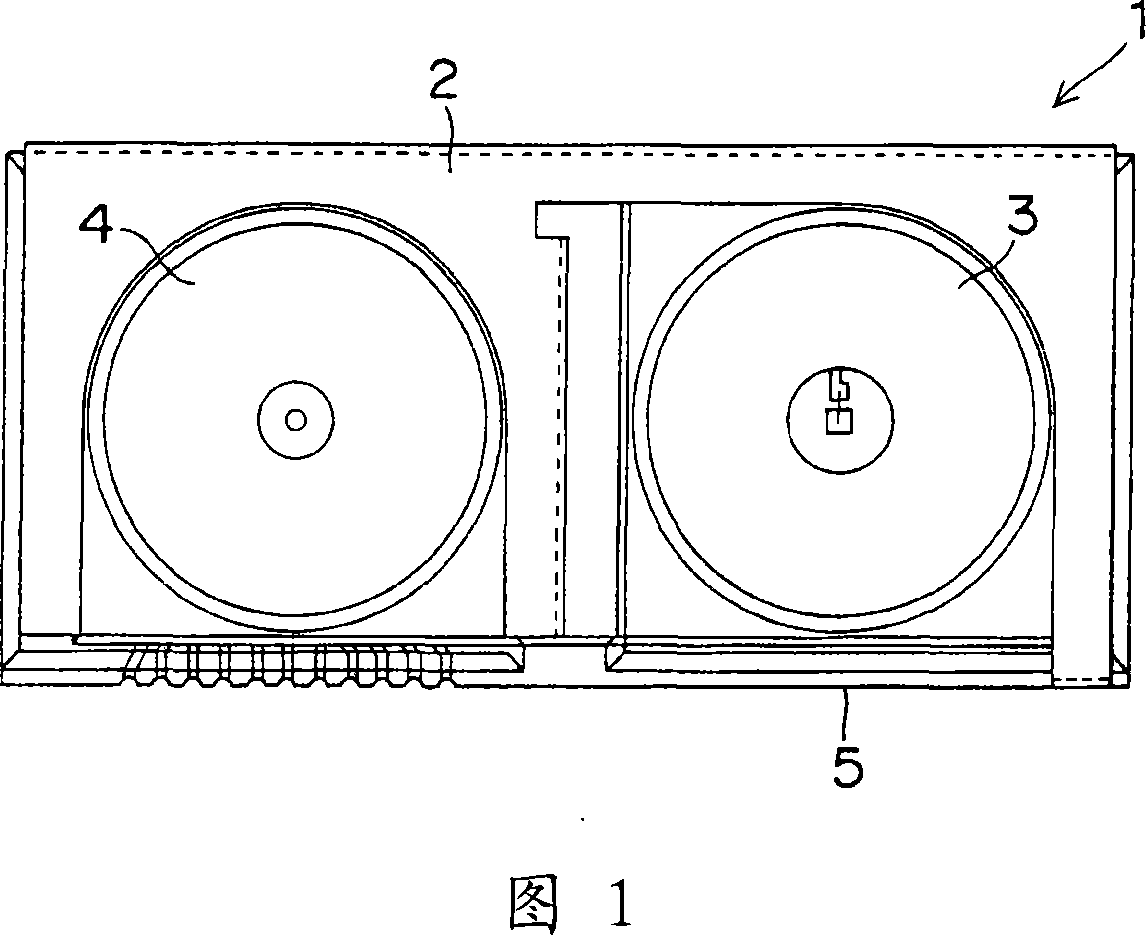

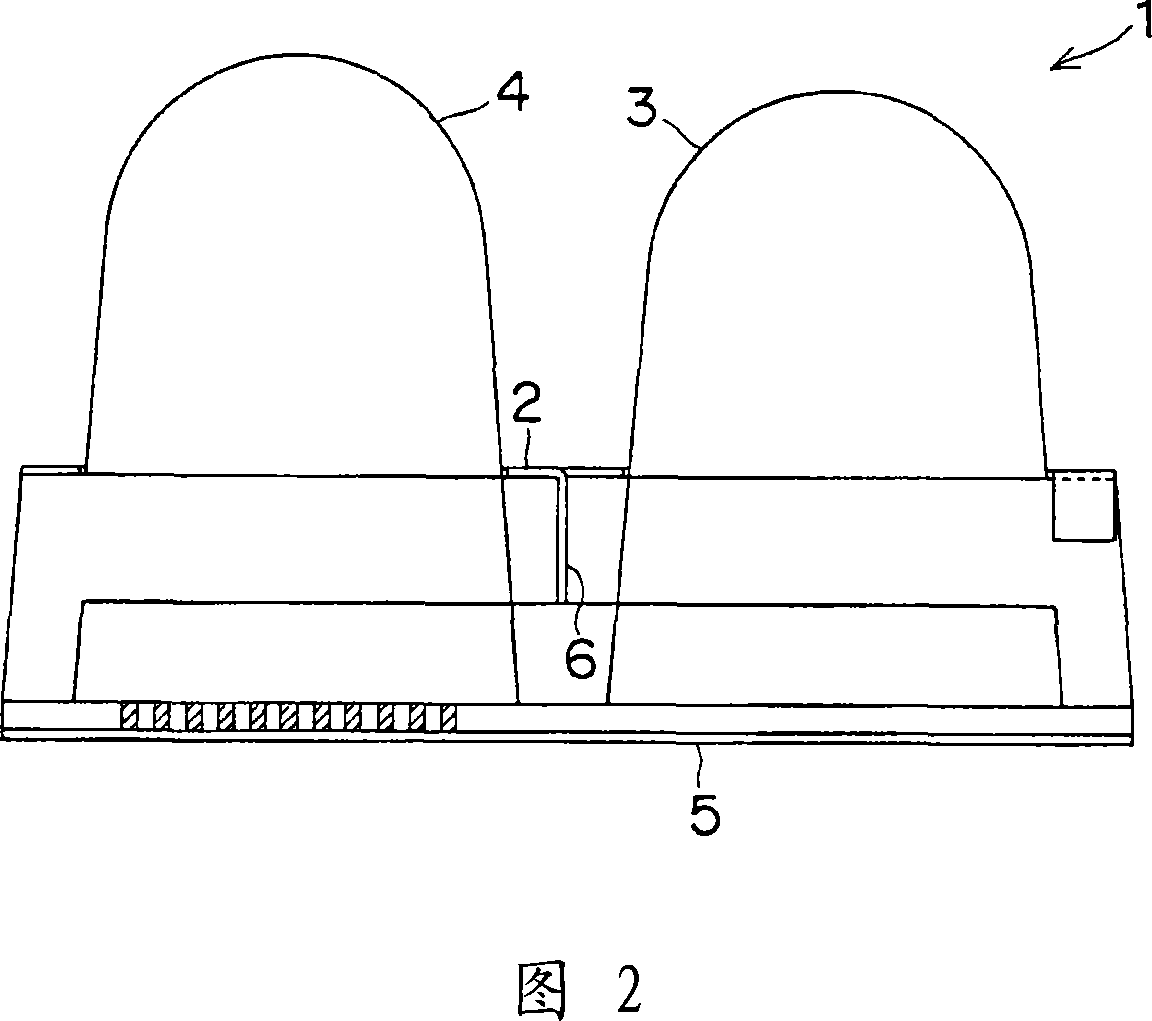

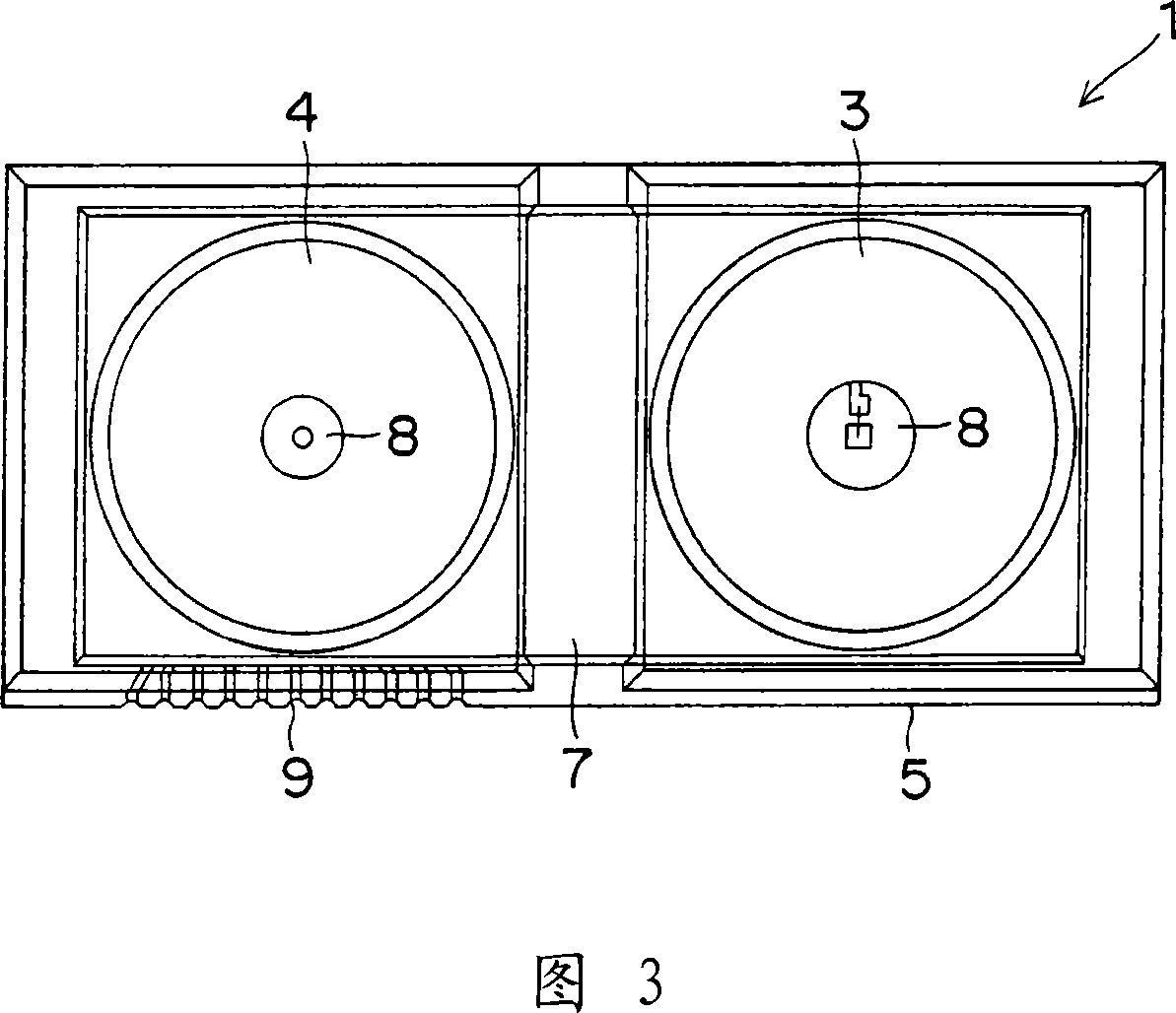

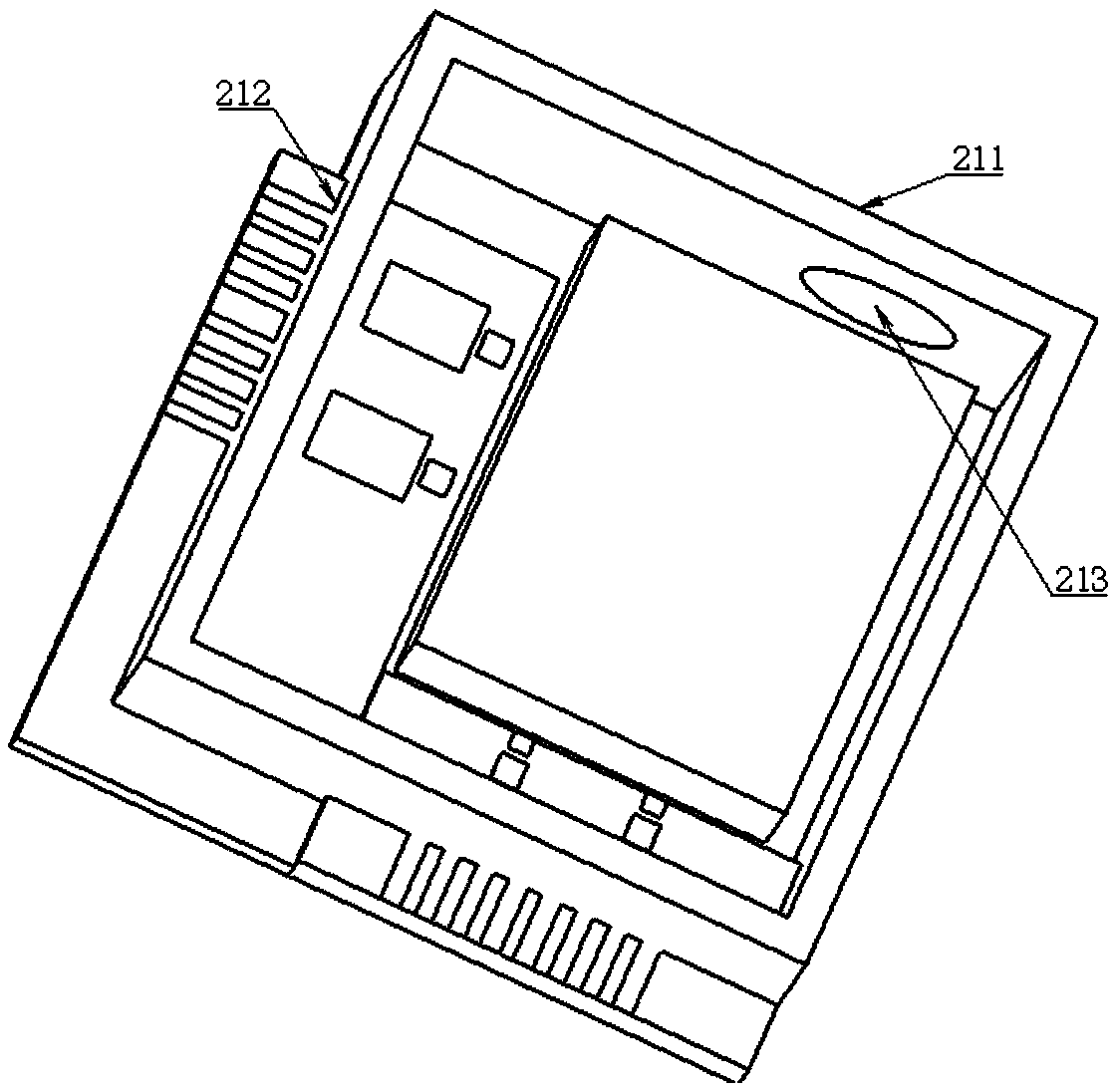

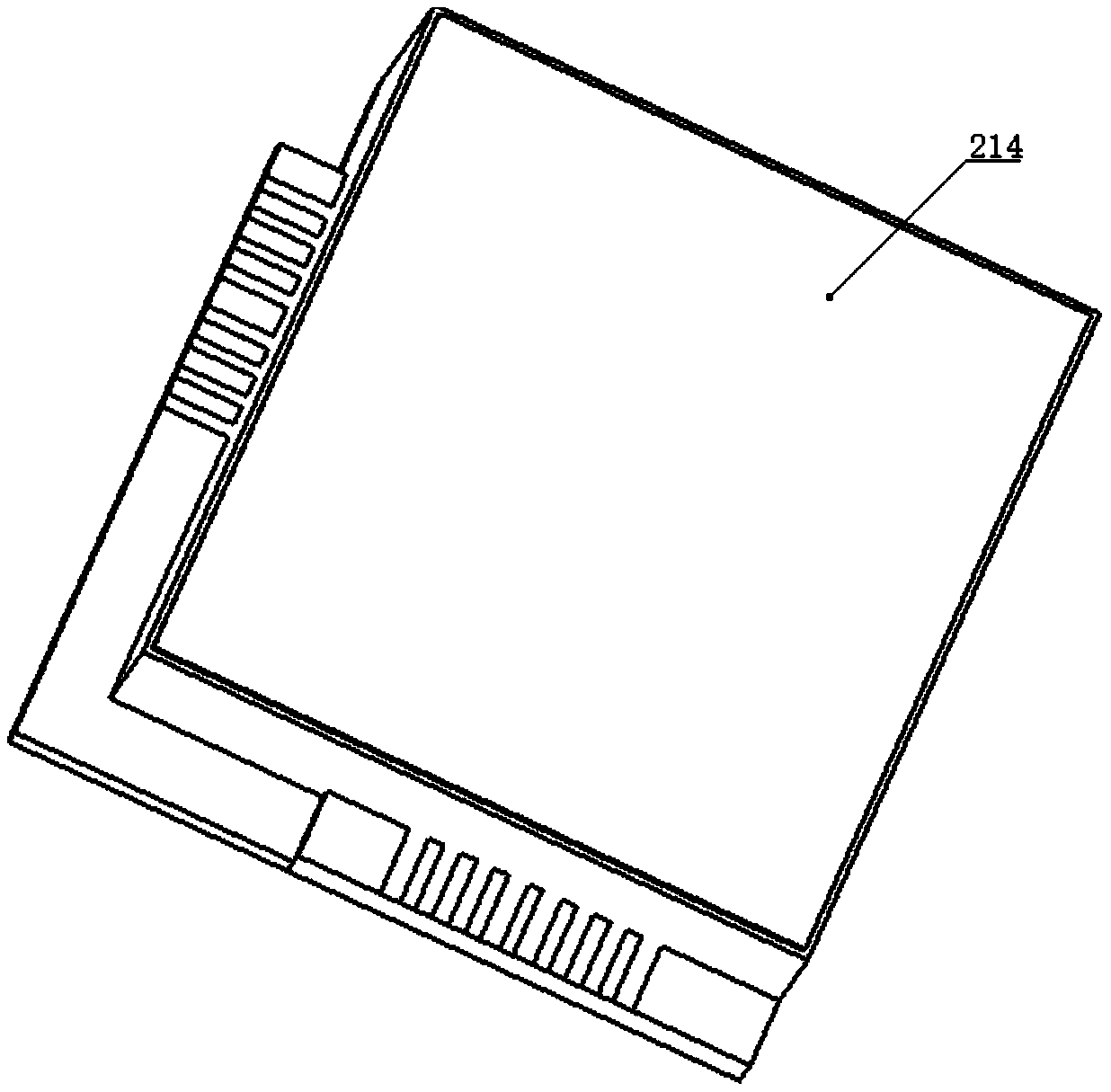

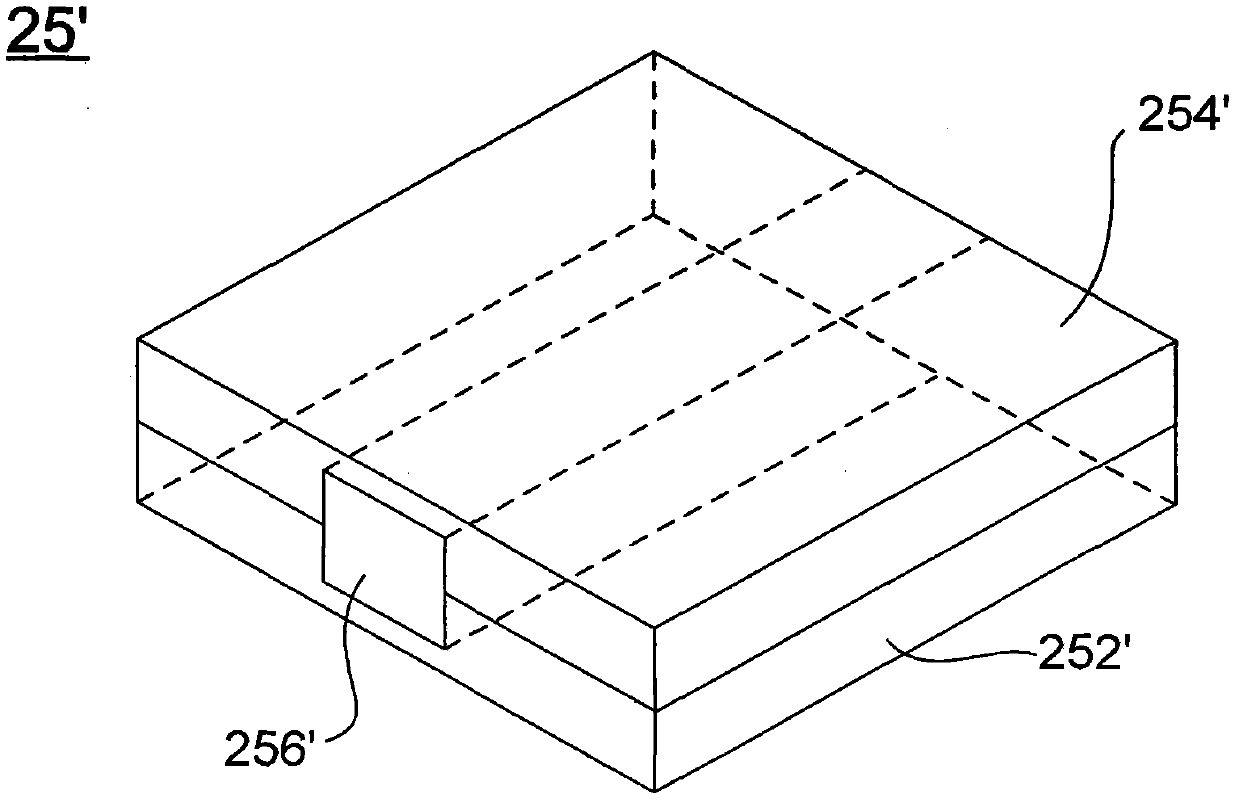

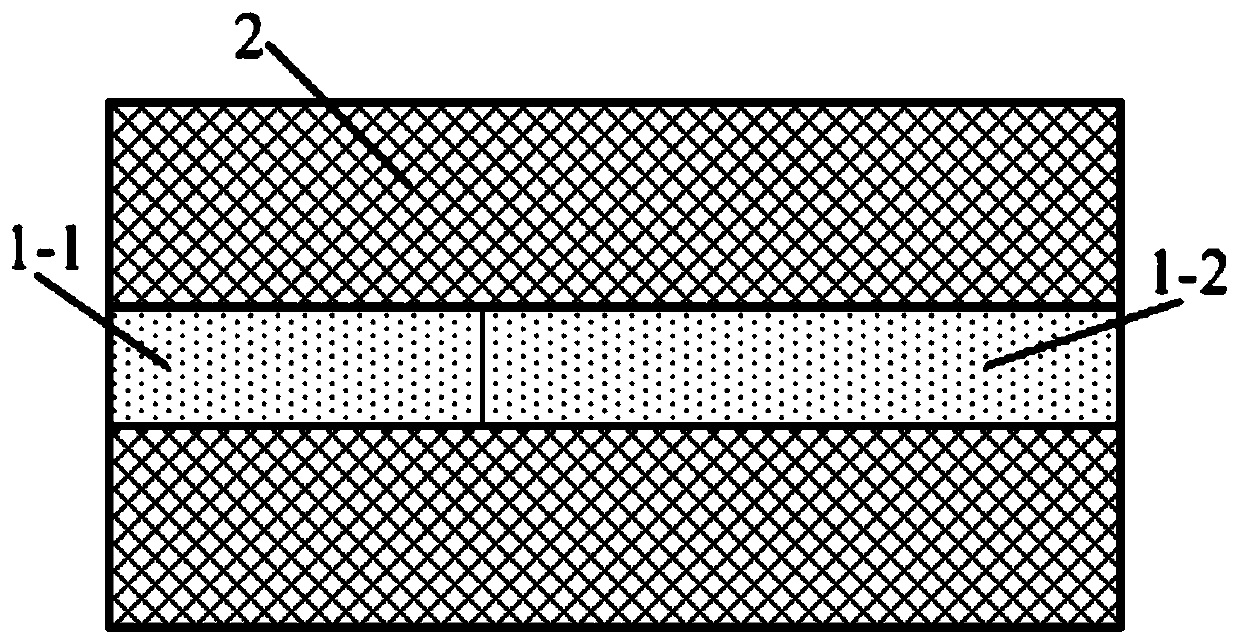

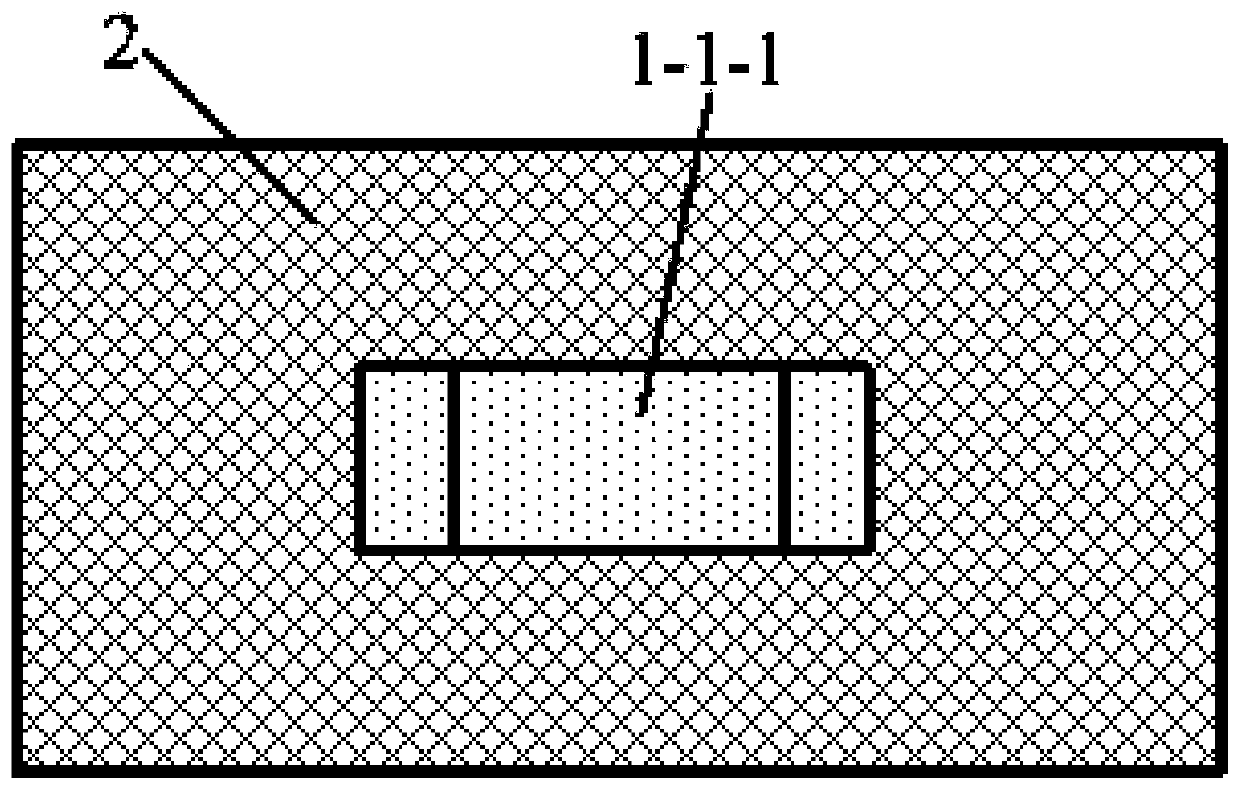

Light source module group

InactiveCN101408640AImprove optical coupling efficiencyAvoid formingPoint-like light sourceLighting support devicesLight guideAdhesive glue

The invention relates to a light source module which comprises multiple light emitting units, the multiple light emitting units respectively comprise a light guide plate and at least one light emitting component, the light guide plate is optically coupled with the at least one light emitting component, the light guide plate comprises a bottom surface, a light emitting surface opposite to the bottom surface, and a side face arranged between the bottom surface and the light emitting surface, and the side faces of two adjacent light guide plates are connected by transparent adhesive glue. In the light source module, the light guide plates of the two adjacent lighting units are bonded by the transparent adhesive glue, which causes the light rays to be evenly transmitted in the transparent adhesive glue and improves the optical coupling efficiency of the two adjacent light emitting units.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

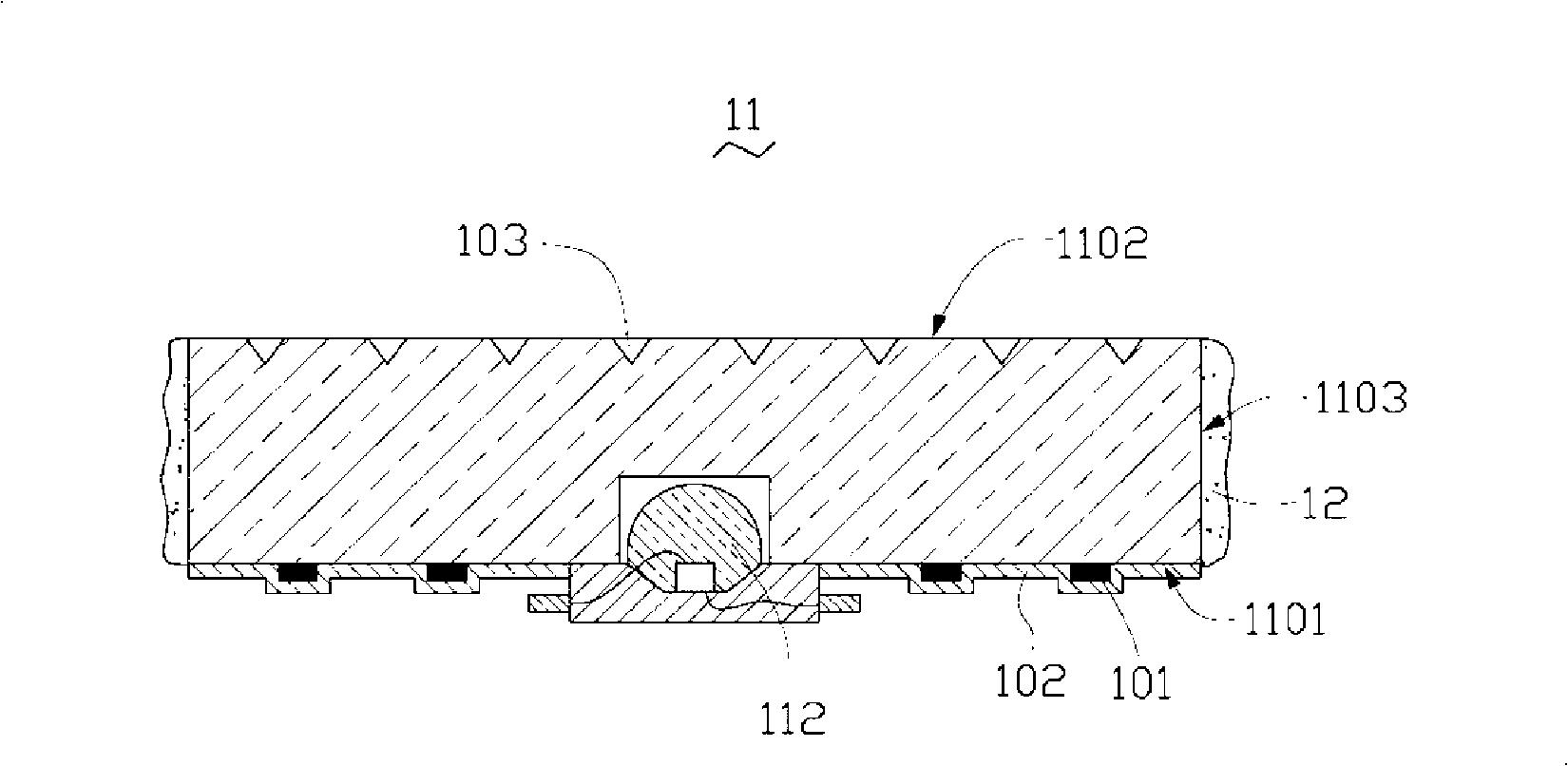

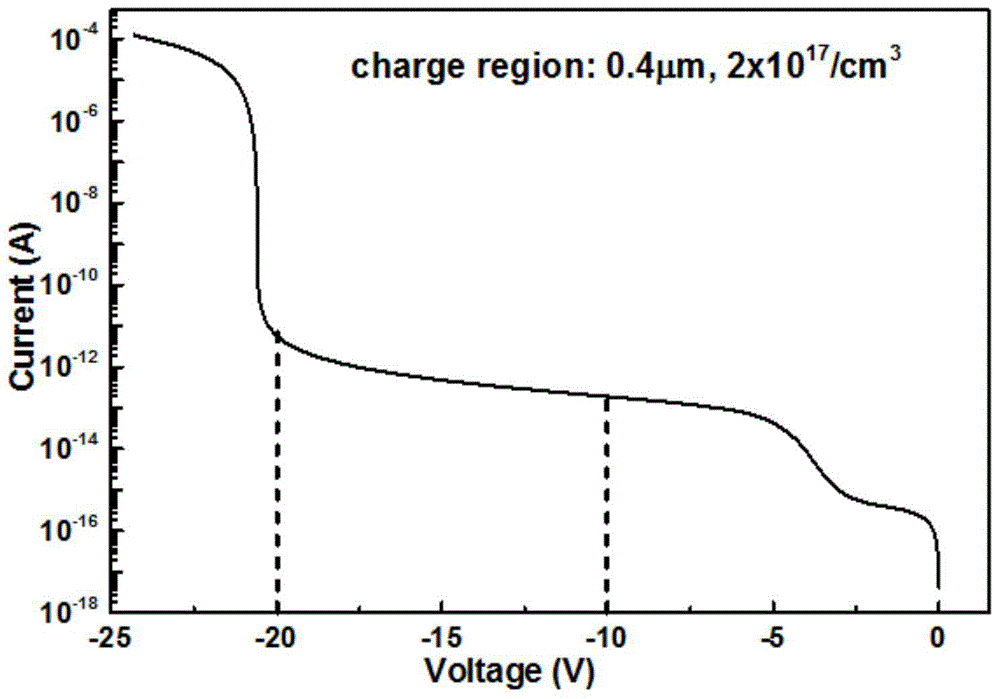

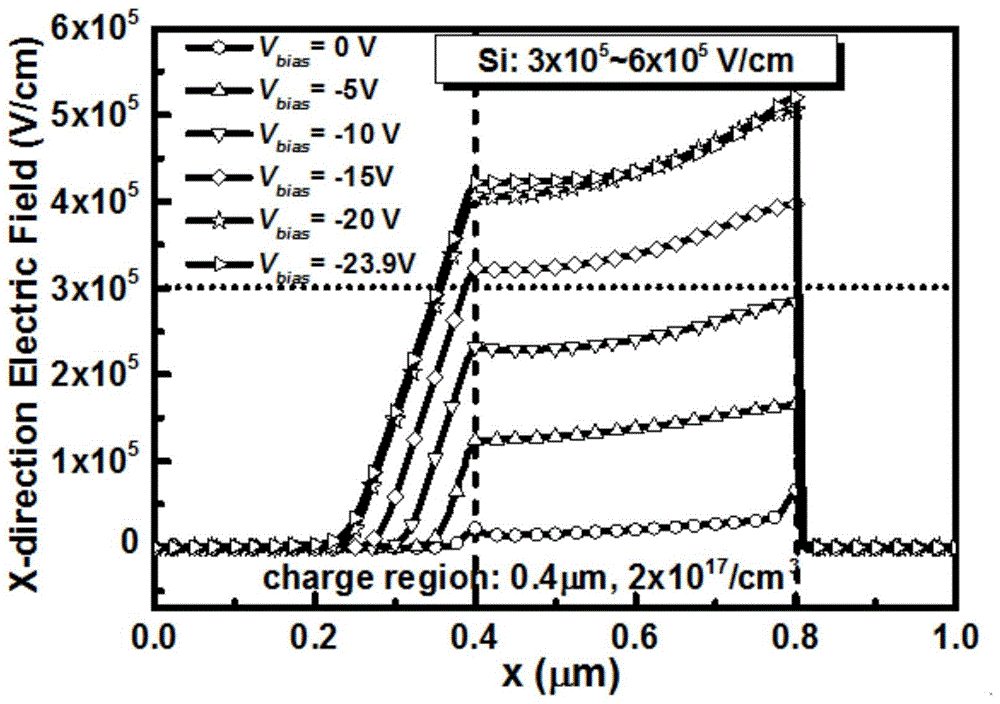

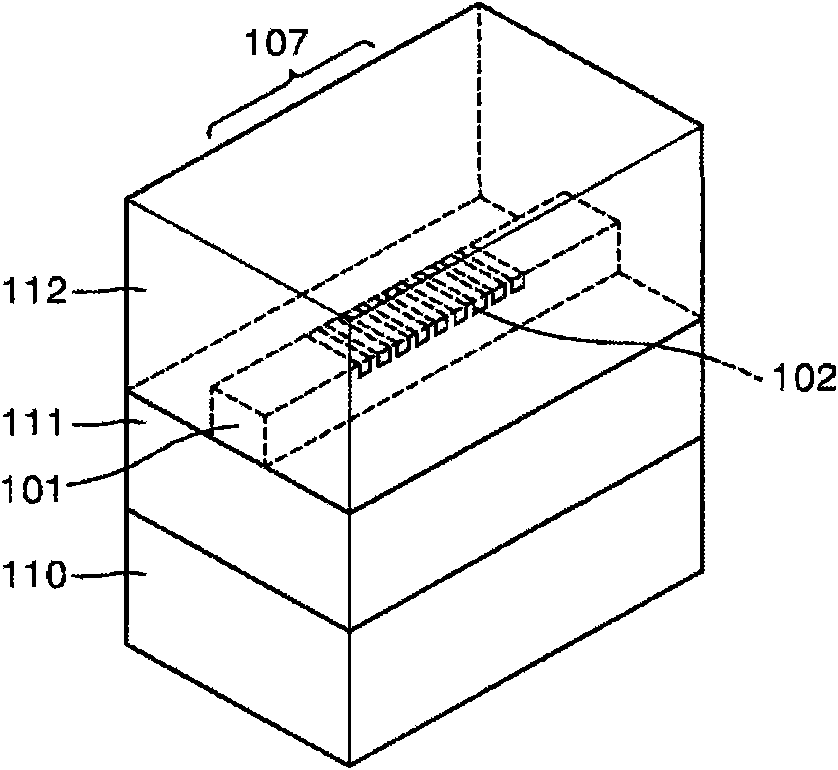

Waveguide coupling type separate absorption and multiplication avalanche diode

ActiveCN104681634AAvoid disturbance phenomenonImprove optical coupling efficiencySemiconductor devicesNanoscopic scaleTransition time

The invention discloses a waveguide coupling type separate absorption and multiplication avalanche diode, which relates to the field of semiconductor photoelectric devices and the field of optical interconnection. The waveguide coupling type separate absorption and multiplication avalanche diode comprises a p plus type ohmic contact electrode, a p plus type ohmic contact layer, an absorption layer, a p type charge region, a multiplication region, an n plus type ohmic contact electrode, an n plus type ohmic contact region, an insulated burial layer, a substrate and a single-mode waveguide; the waveguide coupling type separate absorption and multiplication avalanche diode is characterized that the p type charge region is positioned at the tail end of the single-mode waveguide, the absorption layer is positioned at the top part of the p type charge region, the multiplication region and the n plus type ohmic contact region are coplanar with the single-mode waveguide and are tightly close to the p type charge region to be sequentially arranged, stretching directions of the p type charge region, the multiplication region and the n plus type ohmic contact region are vertical to a light transmission direction of the single-mode waveguide, and the p type charge region, the multiplication region and the n plus type ohmic contact region are in the same thickness with the single-mode waveguide. According to the waveguide coupling type separate absorption and multiplication avalanche diode disclosed by the invention, the optical coupling efficiency is increased by a device by utilizing the coupling of the single-mode waveguide while the separate absorption and multiplication is realized, a disturbance phenomenon of electric signals of double multiplication regions is avoided, the size of the device can be reduced to nanometer size, the transition time and the dark current can be reduced, and the sensitivity is increased.

Owner:江苏浦丹光电技术有限公司

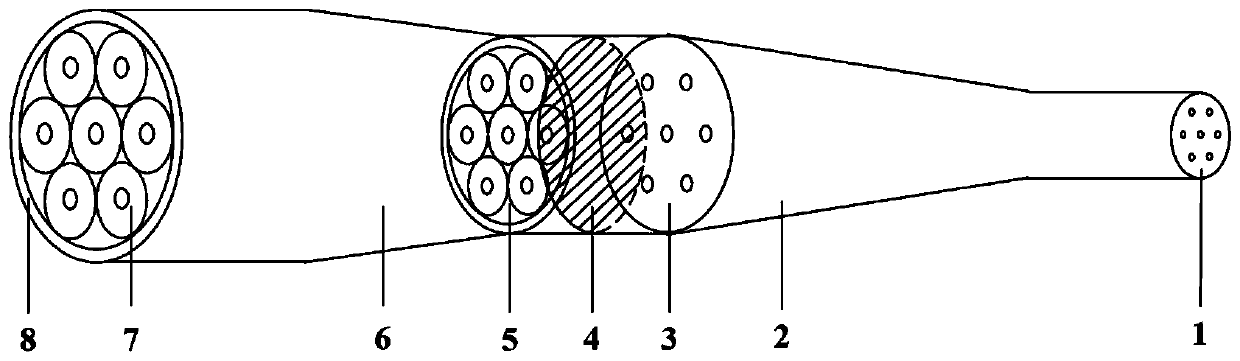

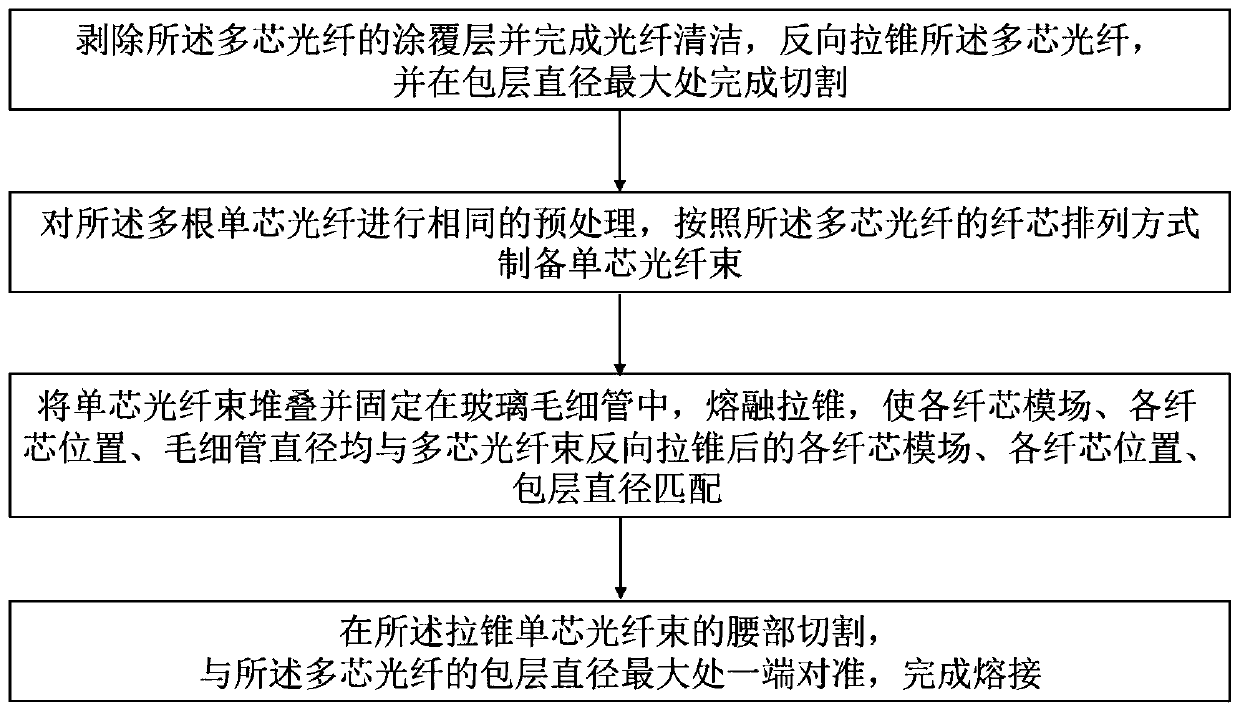

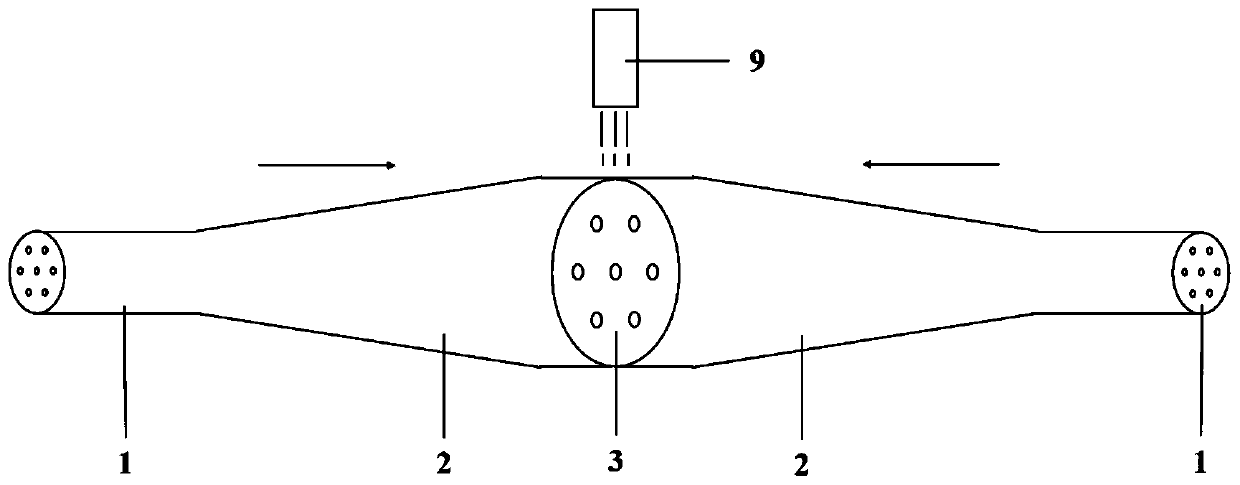

Multi-core optical fiber coupler preparation method based on reverse tapering technology

ActiveCN110488417AReduce sensitivityLarge mode field diameterCoupling light guidesFiberWeld strength

The invention belongs to the technical field of optical fiber communication, and particularly relates to a multi-core optical fiber coupler preparation method based on reverse tapering technology. Themethod comprises the following steps: stripping a coating layer of a multi-core optical fiber, reversely tapering the multi-core optical fiber, and finishing cutting at the position with the maximumcladding diameter; preprocessing the plurality of single-core optical fibers, and preparing a single-core optical fiber bundle according to a fiber core arrangement mode of the multi-core optical fibers; stacking and fixing the single-core optical fiber bundle in a glass capillary tube, and performing fused biconical taper to enable each fiber core mode field, each fiber core position and the diameter of the capillary tube to be matched with each fiber core mode field, each fiber core position and the cladding diameter after reverse biconical taper of the multi-core optical fiber bundle; and cutting the waist of the tapering single-core optical fiber bundle, and aligning with one end of the maximum cladding diameter of the multi-core optical fiber to finish welding. According to the method, the alignment precision requirement can be reduced, and the optical coupling efficiency between multiple single-core optical fibers and each core of the multi-core optical fiber can be effectively improved; inter-core crosstalk during coupling is effectively suppressed, and meanwhile, the welding strength is improved.

Owner:FUDAN UNIV

Optical distance measuring device and manufacturing method therefor

InactiveCN101078771AReduce light transmission lossLow refractive indexElectromagnetic wave reradiationRefractive indexFirst light

The present invention provides an optical distance measuring device and manufacturing method therefor. In the optical distance measuring device of the invention, a second optical path is formed by a transparent resin formed in a region where a light emitting element and a second light receiving part are connected directly to each other. As the temperature increases, the length of the optical path increases while its refractive index decreases, so that the optical path length itself becomes generally constant. Therefore, the length of the second optical path can be kept generally constant independently of temperature. Further, a first light receiving part for a first optical path and a second light receiving part for the second optical path 18 are formed in one identical light receiving element. Therefore, characteristic variations of the first light receiving part and the second light receiving part due to temperature can be reduced. This optical distance measuring device can achieve high distance measuring accuracy even under environments of intense temperature changes.

Owner:SHARP KK

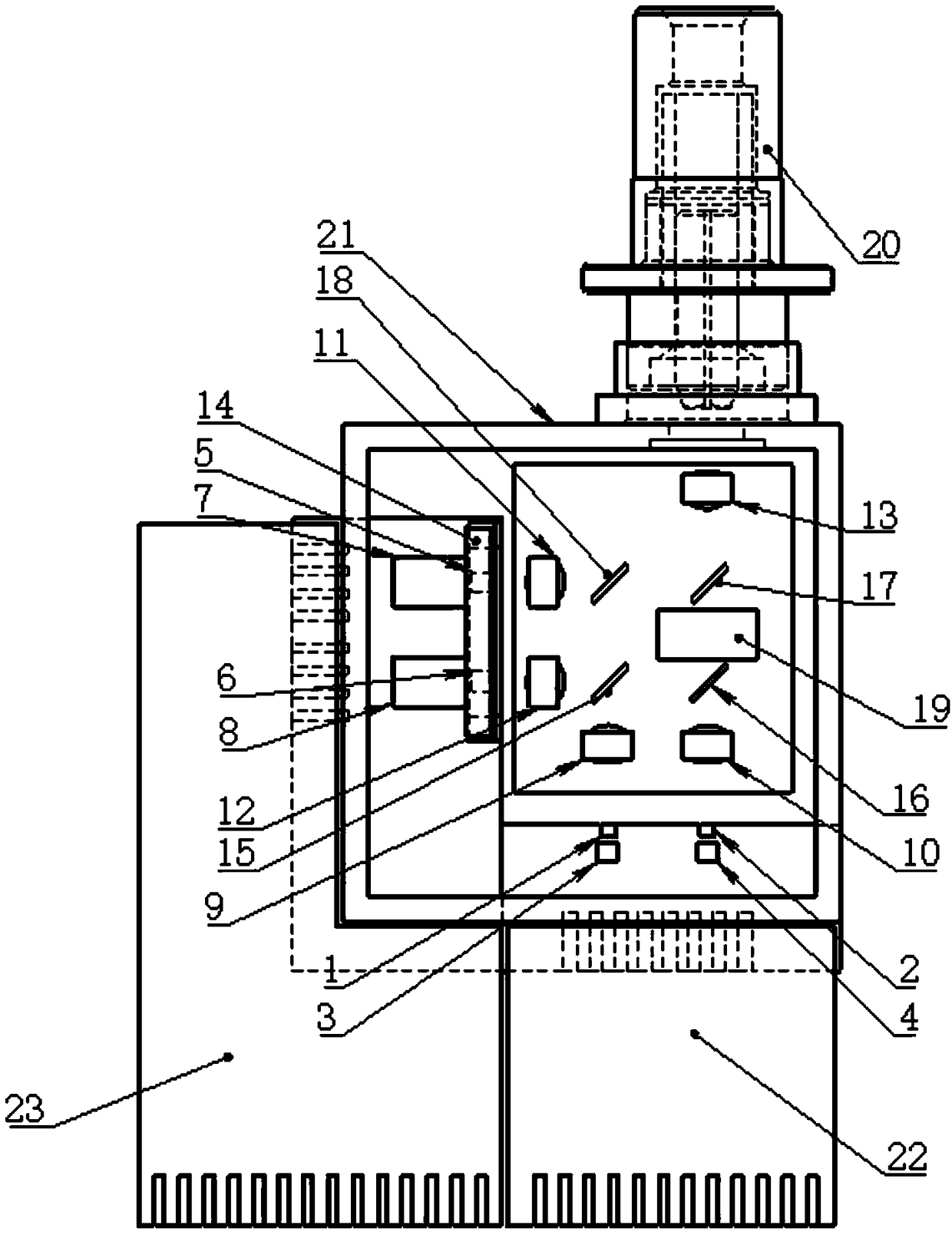

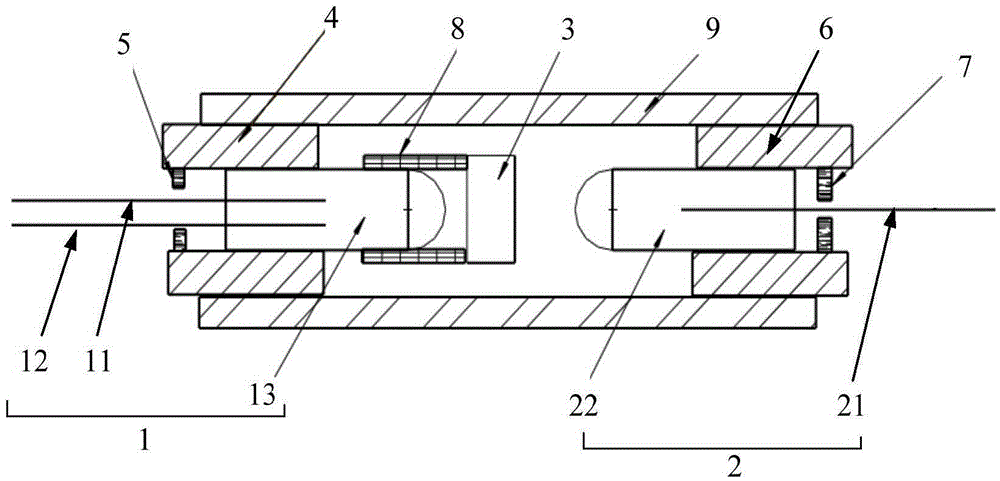

Parallel optical structure double receiving and double transmitting box seal packaging optical device

The invention discloses a parallel optical structure double receiving and double transmitting box seal packaging optical device comprising a box seal tube shell having a multilayer ceramic circuit. Afirst flexible circuit board and a second flexible circuit board are electrically connected on the circuit of the multilayer ceramic circuit outside the box seal tube shell. The box seal tube shell isinternally provided with a first laser, a second laser, a first photodiode, a second photodiode, a first trans-impedance amplifier, a second trans-impedance amplifier, a reflecting mirror, a first filter, a second filter, a third filter, a fourth filter, a first collimating lens, a second collimating lens, a first focusing lens and a second focusing lens. The outer side of the third filter insidethe box seal tube shell is provided with a common end lens. The position, which is close to the common end lens, of the outside of the box seal tube shell is provided with an optical fiber insertingcore sleeve component. The degree of integration of the optical device can be enhanced, the volume can be reduced, the packaging process can be further simplified and the coupling efficiency of the device can be enhanced.

Owner:SUSR COMM TECH

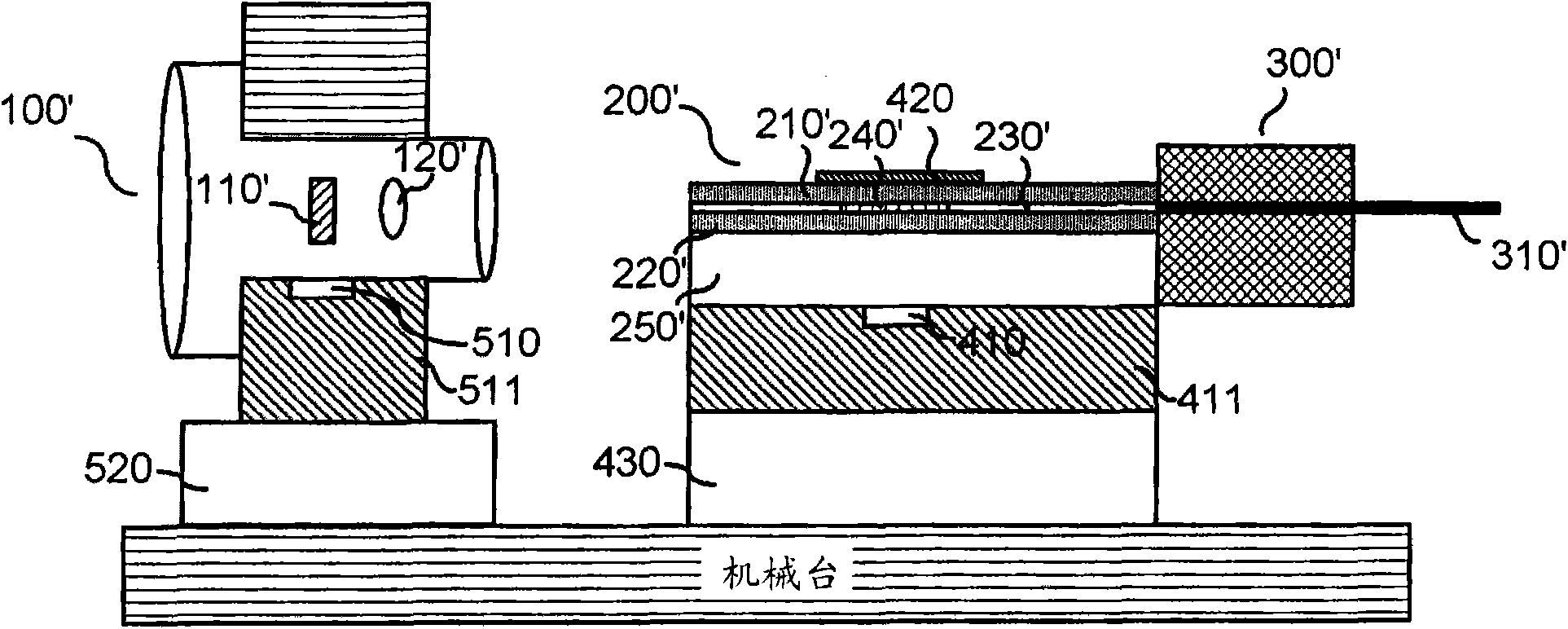

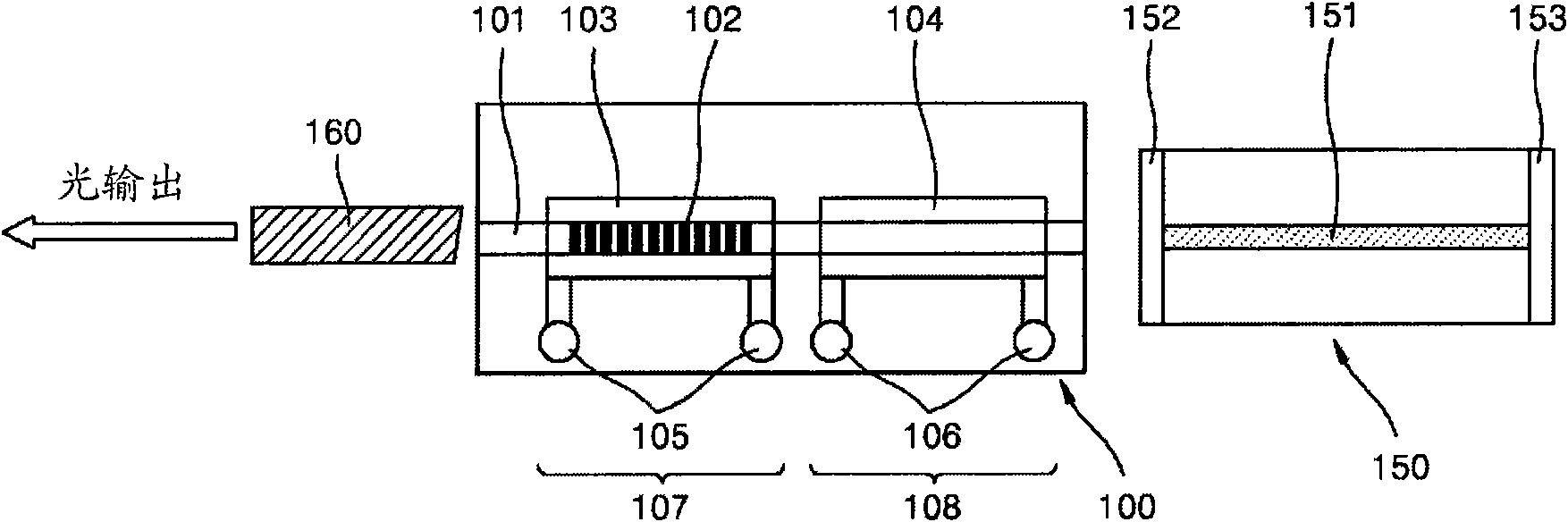

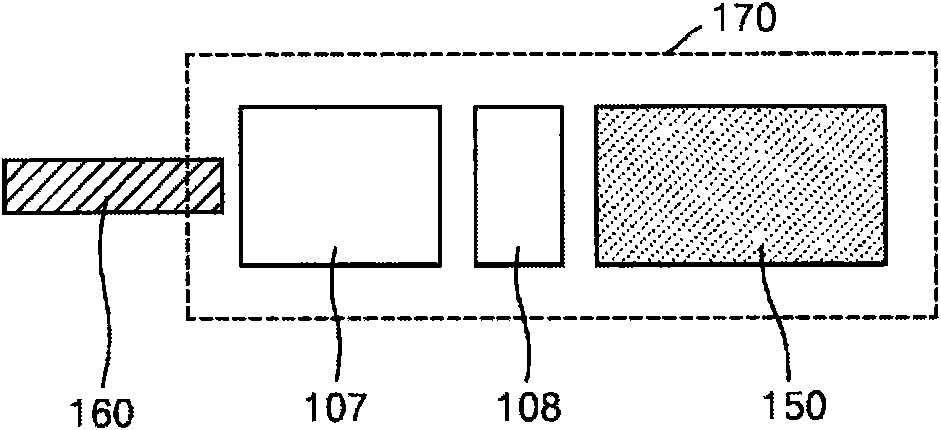

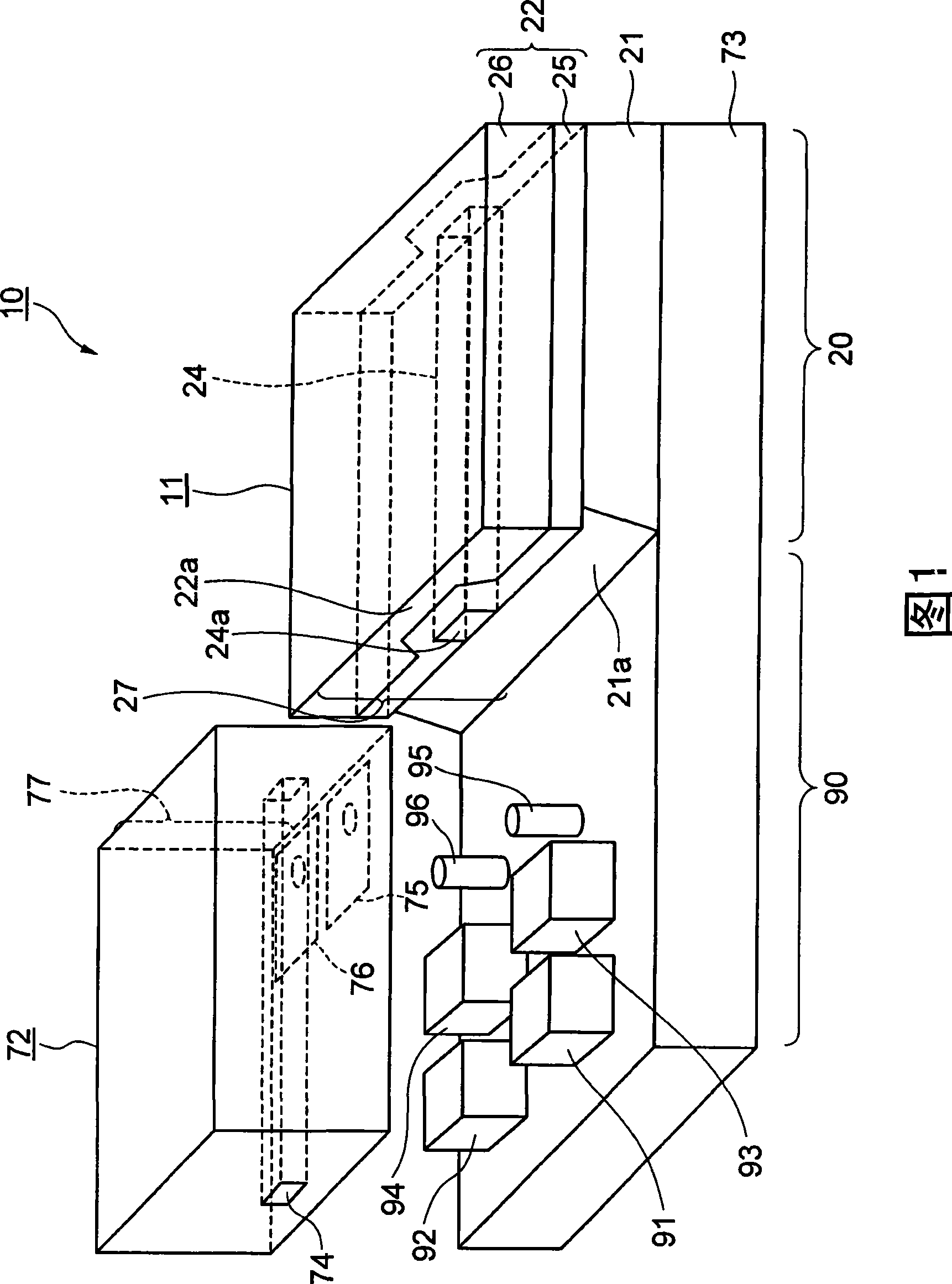

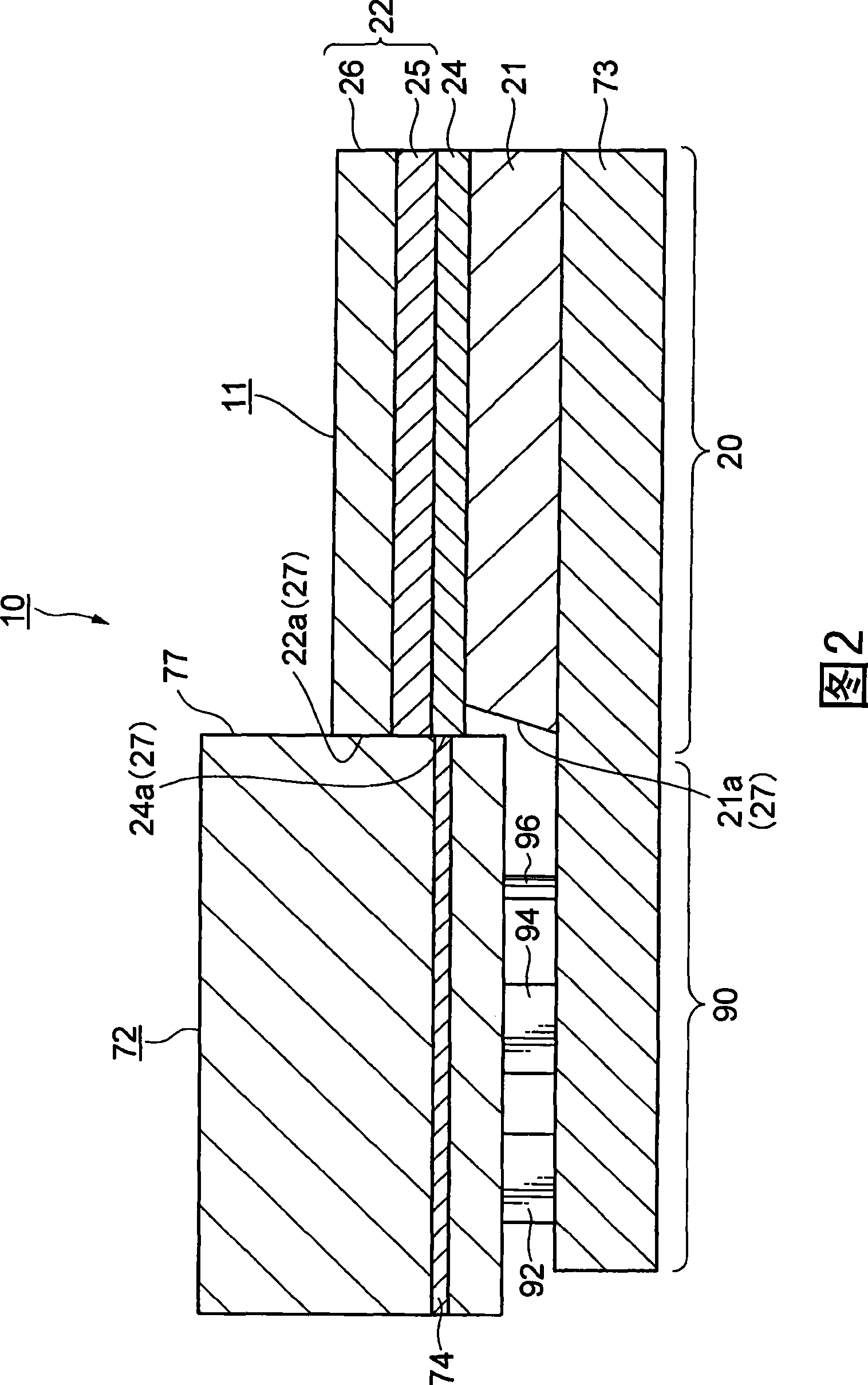

Planar lightwave circuit(plc) device, wavelength tunable light source comprising the same device and wavelength division multiplexing-passive optical network(wdm-pon) using the same light source

ActiveCN101601176AGain mechanical stabilityReduce power consumptionLaser detailsSolid-state devicesExternal cavity laserOptical axis alignment

In the manufacture and application of a PLC-ECL type wavelength tunable light source, provided is a wavelength tunable mechanism with improved performance and stability, a light source with improved packaging performance and mass productivity, and a light source applied to a WDM-PON with initialization and stabilization functions. The wavelength tunable light source having a PLC(planar lightwave circuit)-ECL(external cavity laser) structure includes a first housing in which a semiconductor optical gain medium is mounted, a second housing in which a PLC device is mounted, and a third housing in which an optical fiber is mounted. The first, second, and third housings make an optical axis alignment through an optical coupling lens and combinded in a laser welding method.

Owner:ELECTRONICS & TELECOMM RES INST

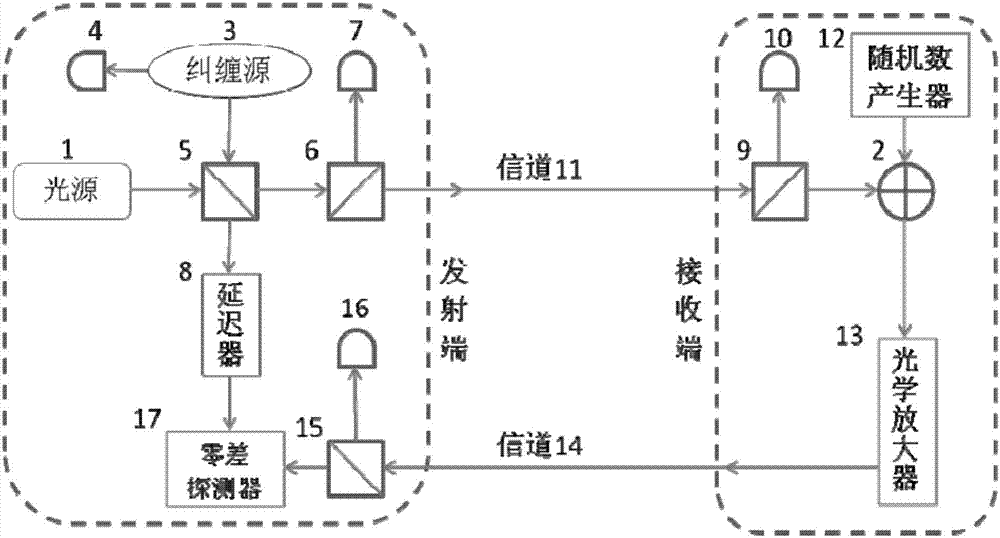

High-speed quantum key distribution method

ActiveCN107453819AImprove assessment accuracyAchieve distributionKey distribution for secure communicationPhotonic quantum communicationTwo-way communicationOptical efficiency

The present invention relates to a high-speed quantum key distribution method. The method includes the following steps that: after the first photon of an entangled photon pair emitted by an entanglement source in a transmitting terminal is triggered, and the time label A of each signal is recorded, after the second photon and laser emitted by a light source are combined together, reflected light and transmitted light are obtained, part of light is detected from the reflected light is selected so as to be detected, the time label B of each signal is recorded, and the remaining part of the reflected light is outputted to a receiving end; delaying processing is performed on the transmitted light, so that delayed light can be obtained; the receiving end selects part of light from received light so as to detect the selected light, records the time label C of each signal, sequentially modulates and amplifies the remaining part of the received light, and outputs the modulated and amplified received light to the transmitting end; and the transmitting end selects part of light from received light so as to detect the light, records the time label D of each signal, and performs zero-difference detection on the remaining part of the received light and the delayed light. With the high-speed quantum key distribution method of the invention adopted, the accuracy of channel safety assessment and the optical efficiency of a transmitting system are significantly improved, and the security of a two-way communication link can be greatly improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

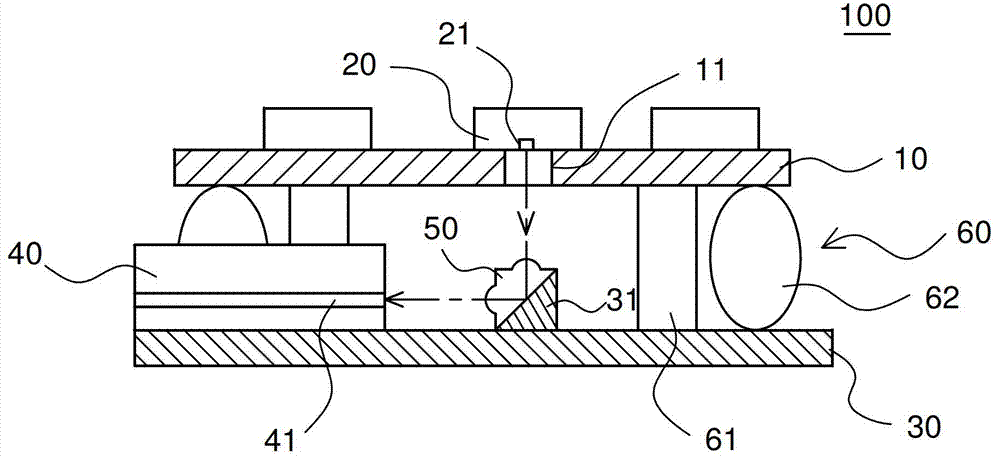

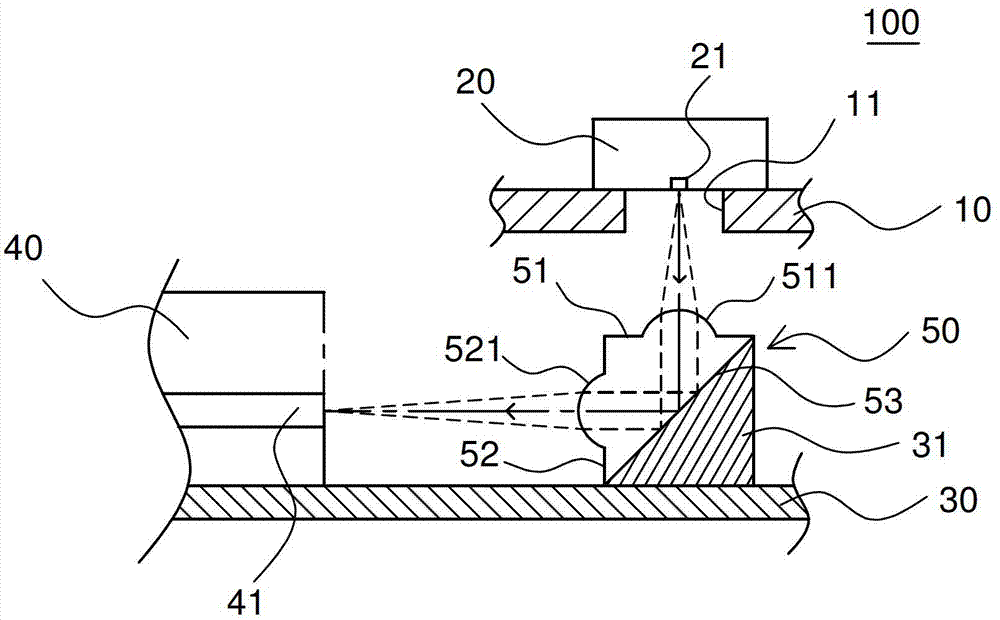

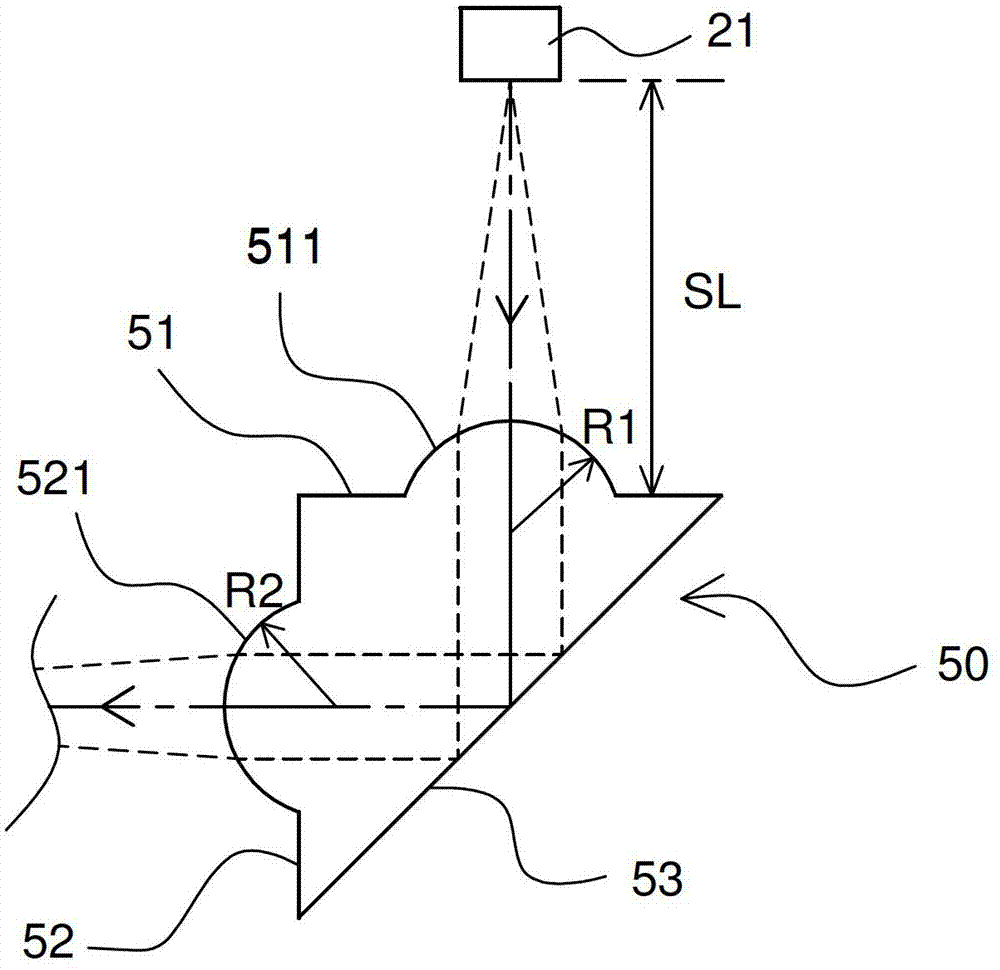

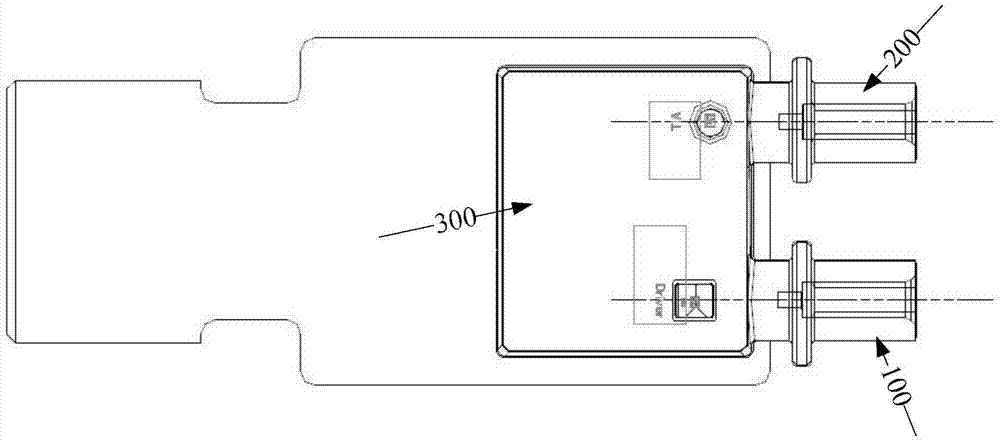

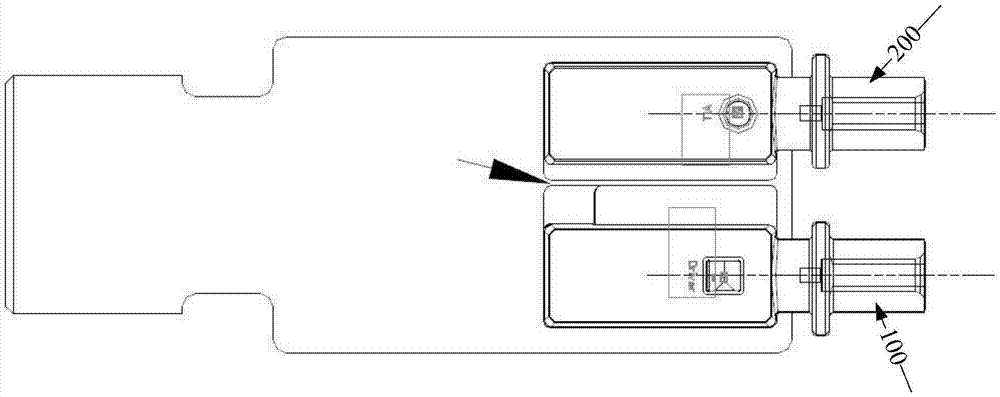

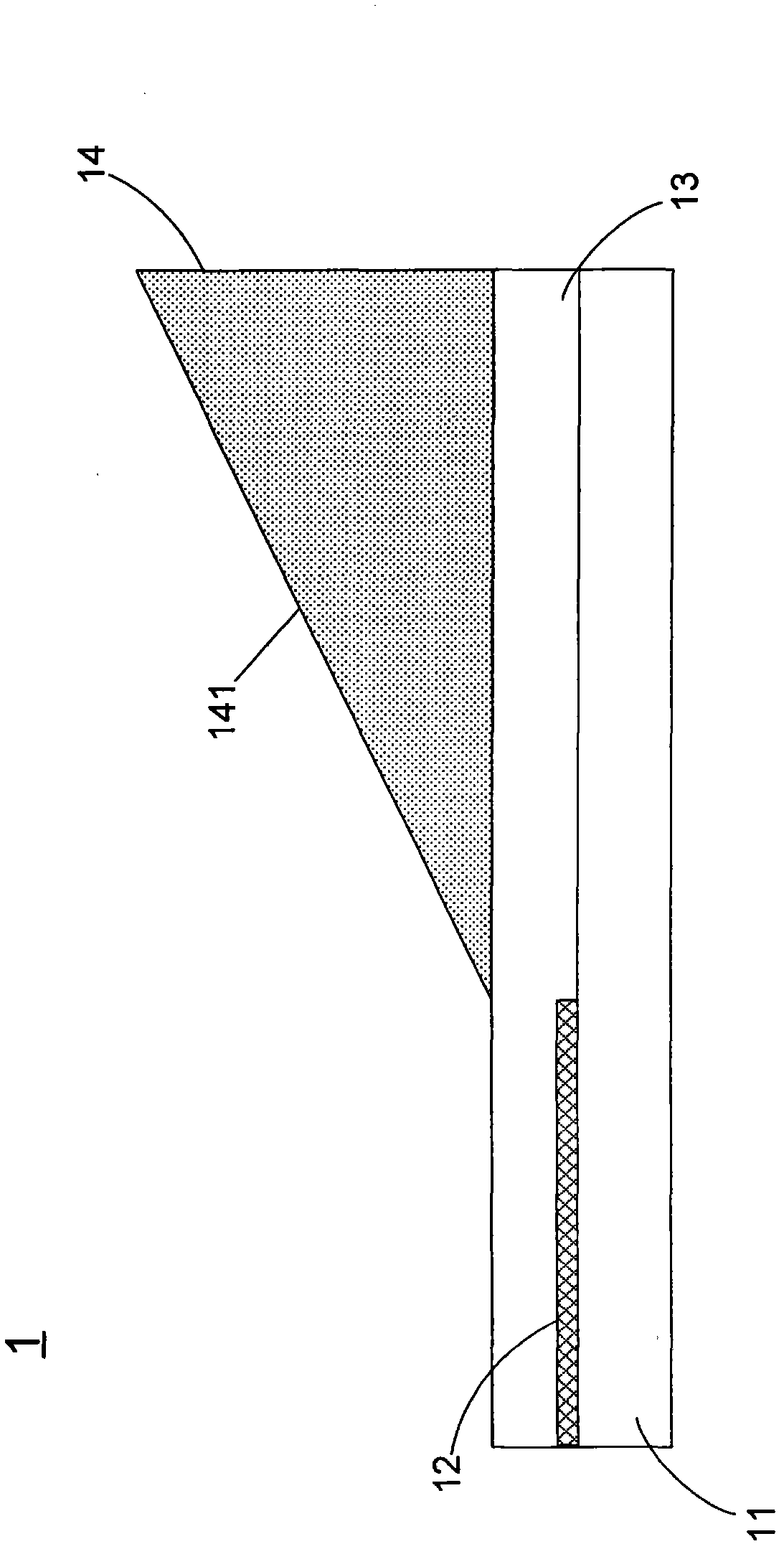

Optical module structure

InactiveCN103048746AImprove optical coupling efficiencyCoupling light guidesTotal internal reflectionOptical Module

The invention discloses an optical module structure. The optical module structure comprises a first optical element, a second optical element and a prism. The prism is a lens with a triangular or trapezoid cross section and is positioned below an optical action part of the first optical element. The prism is provided with a first side surface, a second side surface and a total internal reflection inclined plane, wherein a first spherical raised part is also formed on the first side surface, and a second spherical raised part is also formed on the second side surface. Lights which are sent from the first optical element are emitted into the prism through the first spherical raised part to form parallel lights, are turned for 90 degrees through the total internal reflection inclined plane, are emitted from the prism through the second spherical raised part to form focus convergent lights and are received by the second optical element. The prism can turn the lights of the optical elements, and the spherical raised parts of the prism can appropriately correct the divergence angels of the lights.

Owner:ADVANCED SEMICON ENG INC

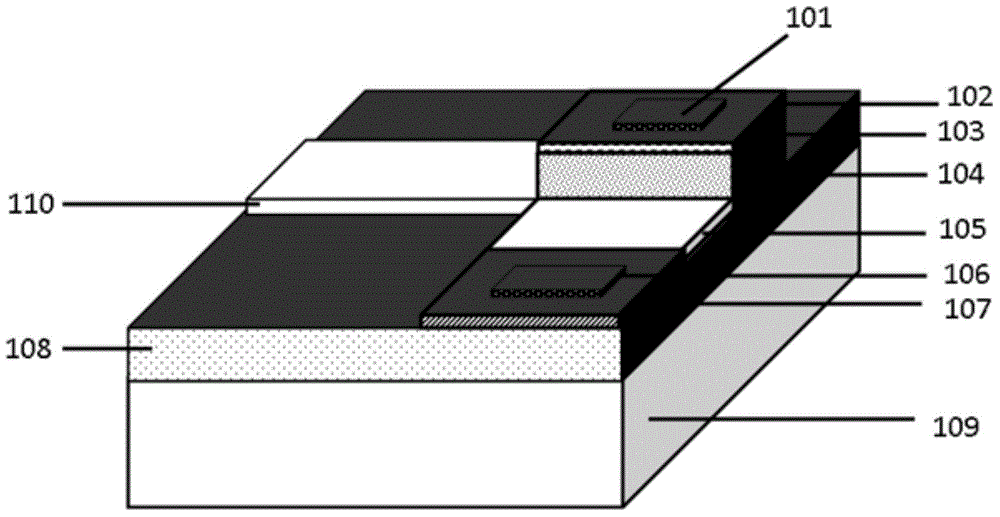

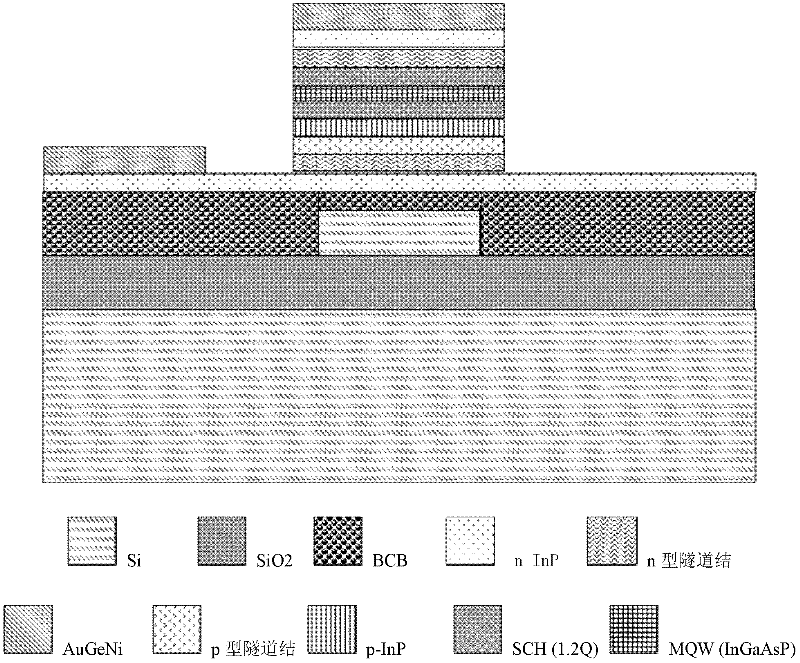

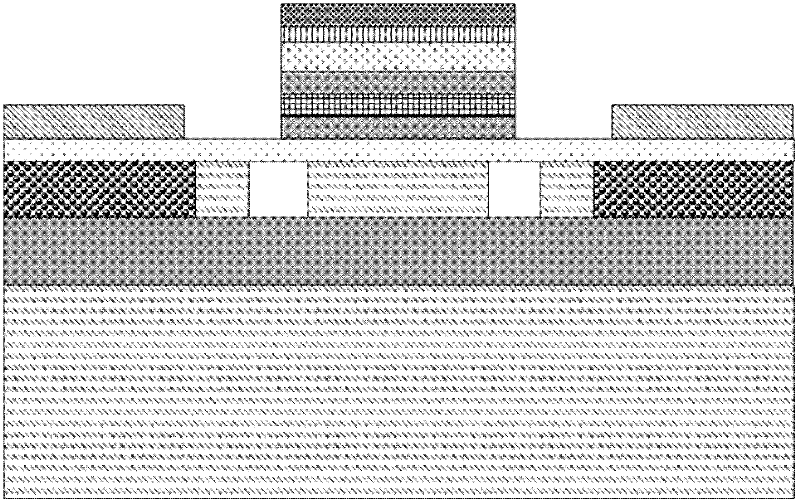

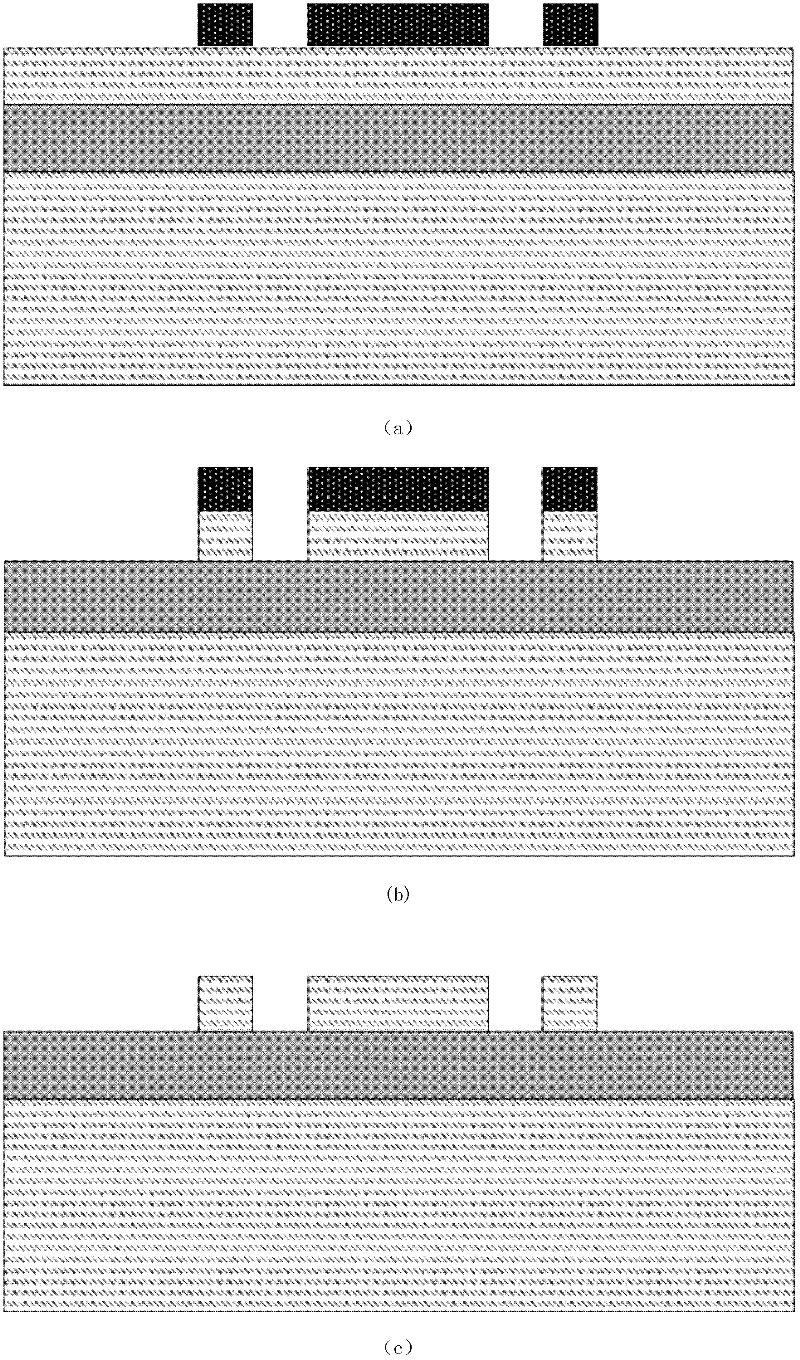

Selected area polymer bonded-silicon-based mixing laser and manufacturing method thereof

InactiveCN102244367APromote growthEasy to operateOptical wave guidanceLaser detailsPolymer bondingOhmic contact

The invention discloses a selected area polymer bonded-silicon-based mixing laser and a manufacturing method thereof, belonging to the field of silicon-based electronic devices. The laser comprises an SOI (silicon on insulator) layer on which a bonded area and an optical coupling area are etched, wherein the SOI layer is provided with a multiregion layer; a bonding polymer, a silicon barrier wall, an air gap, a silicon waveguide, an air gap, a silicon barrier wall and a bonding polymer are arranged in the multiregion layer sequentially from left to right; the multiregion layer is provided with an n-type III-V group material layer; a multilayer structure is arranged at a position corresponding to the silicon waveguide on the n-type III-V group material layer; the multilayer structure comprises a first SCH (separate confinement heterostructure) layer, an MQW (multiple quantum well) layer, a second SCH layer, a p-type III-V group material layer, a p-type etching barrier layer and a p-type ohmic contact layer in sequence from top to bottom; and ohmic contact layers made of n-type III-V group materials are arranged at the left and right sides of the multilayer structure on the n-type III-V group material layer respectively. The laser can be applied to monolithic-silicon-based optoelectronic integration as a silicon-based light source, and is easy to manufacture and low in cost.

Owner:PEKING UNIV

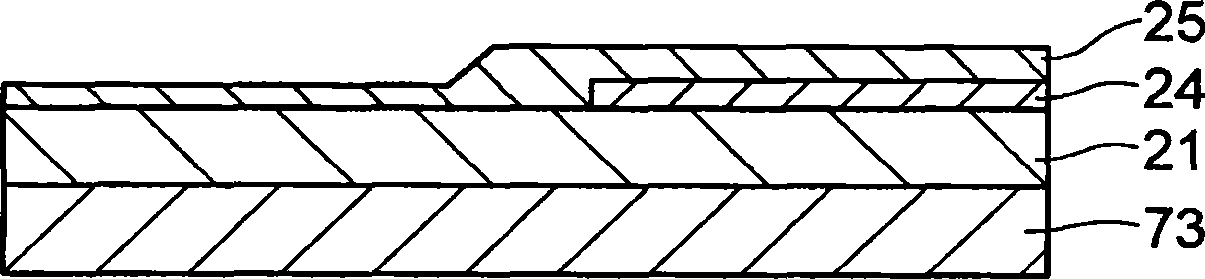

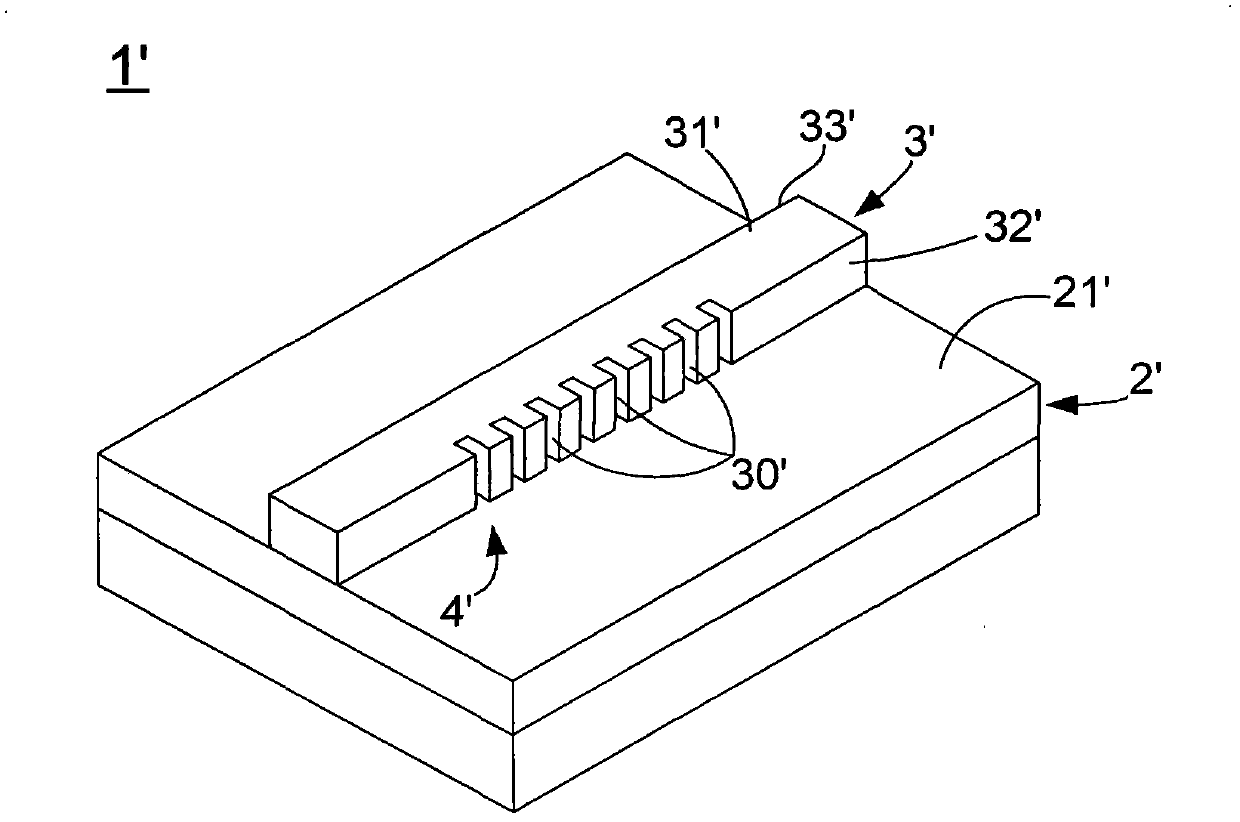

Planar lightwave circuit, manufacturing method thereof, and light waveguide device

InactiveCN101398512AImprove Optical Coupling EfficiencyCoupling light guidesOptical waveguide light guideWaveguideOptical coupling

To provide a PLC and the like, which can improve the optical coupling efficiency by coupling an optical element to a light waveguide part without having a gap. The PLC includes a light waveguide part and an optical element mount part. The light waveguide part has a lower clad layer, a core layer, and an upper clad layer formed on a part of a silicon substrate as a substrate. The optical element mount part has an LD, which is to be optically coupled at the light waveguide end face as an end face of the light waveguide, loaded on the silicon substrate. At the light waveguide end face, an end face of the lower clad layer is recessed with respect to an end face of the core layer and an end face of the upper clad layer towards a direction away from the LD.

Owner:NEC CORP

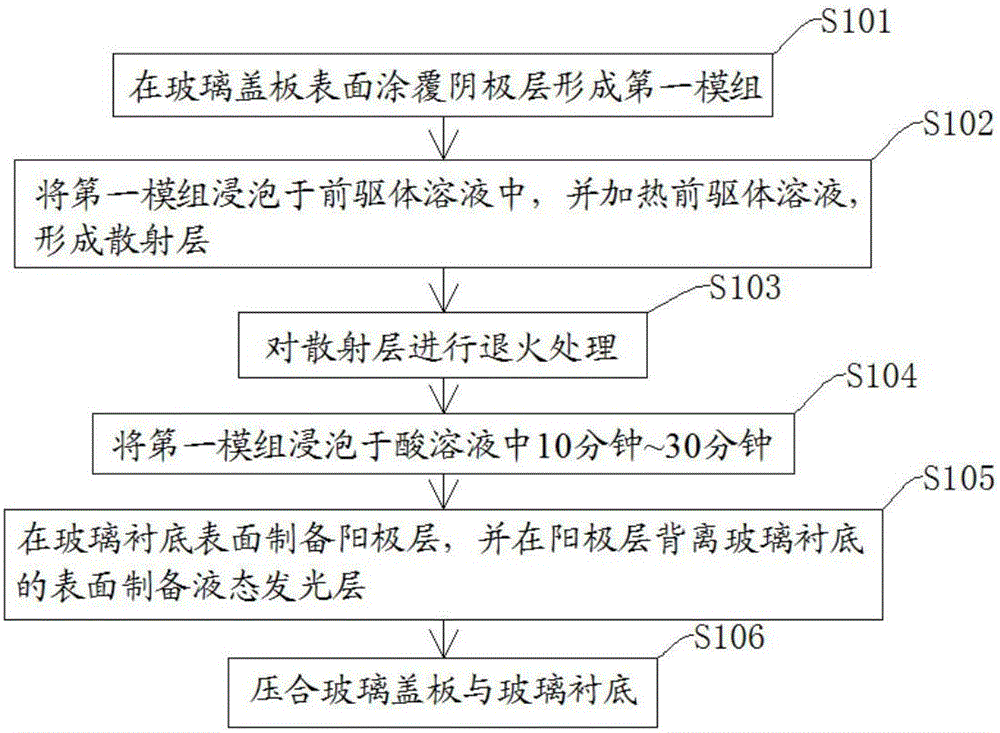

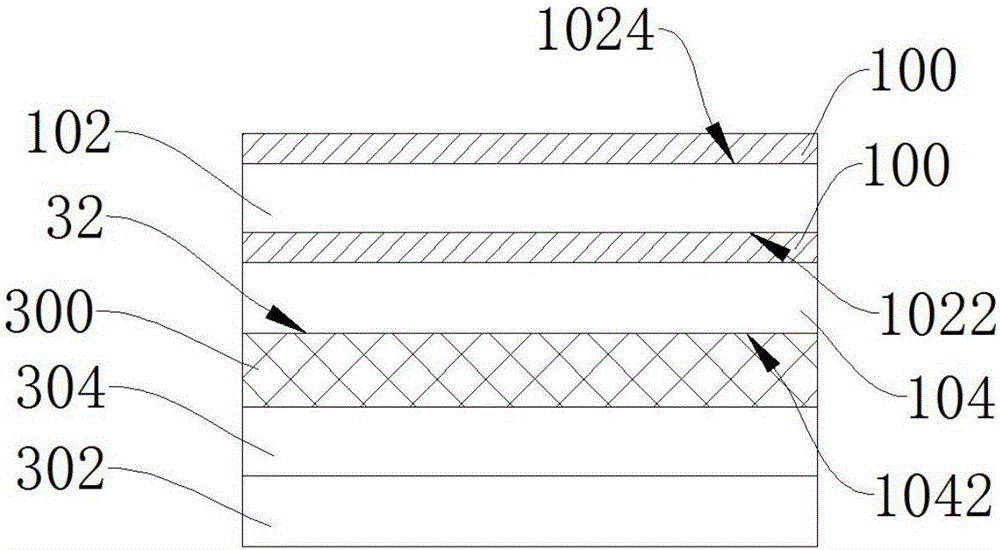

Organic light-emitting device and manufacturing method thereof

ActiveCN106450022AImprove optical coupling efficiencyImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingGlass coverOrganic light emitting device

The invention discloses an organic light-emitting device. The organic light-emitting device comprises a glass cover plate, a cathode layer and a liquid-state light-emitting layer which are sequentially stacked, wherein one side, facing the liquid-state light-emitting layer, of the glass cover plate is coated with the cathode layer to form a first module, the first module comprises a first surface facing the liquid-state light-emitting layer and a second surface away from the liquid-state light-emitting layer, each of the first surface and the second surface is provided with a scattering layer, and each scattering layer is used for changing the transmission directions of light rays emitted by the liquid-state light-emitting layer so as to increase the efficiency of the light rays entering the first surface and going out of the second surface. The invention further discloses a manufacturing method organic light-emitting device. The organic light-emitting device has the advantages that each scattering layer is annealed after being formed, the visible light transmittance of each scattering layer after crystallization is increased, and the light-coupling efficiency of the organic light-emitting device is increased evidently.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

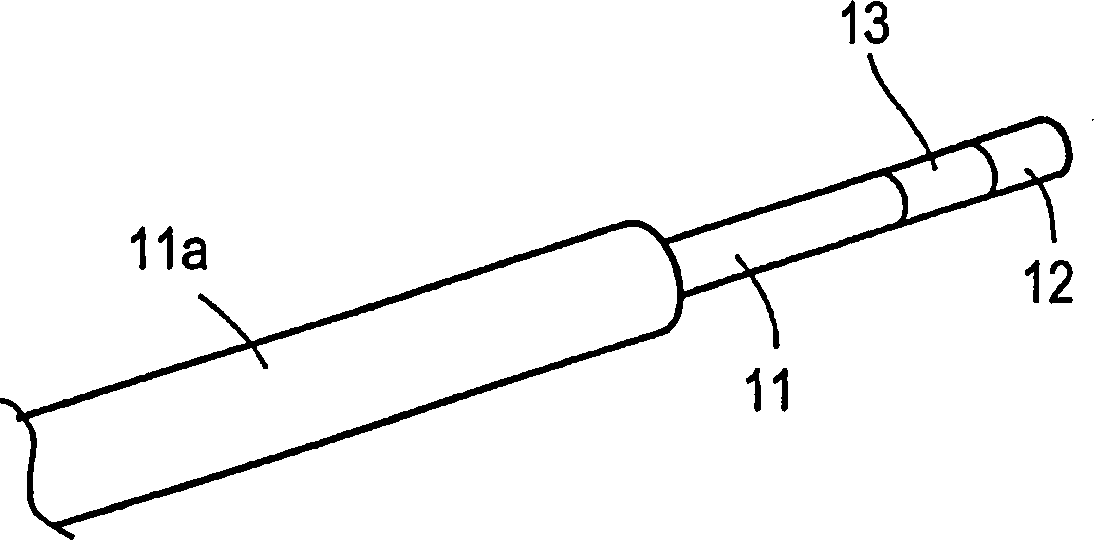

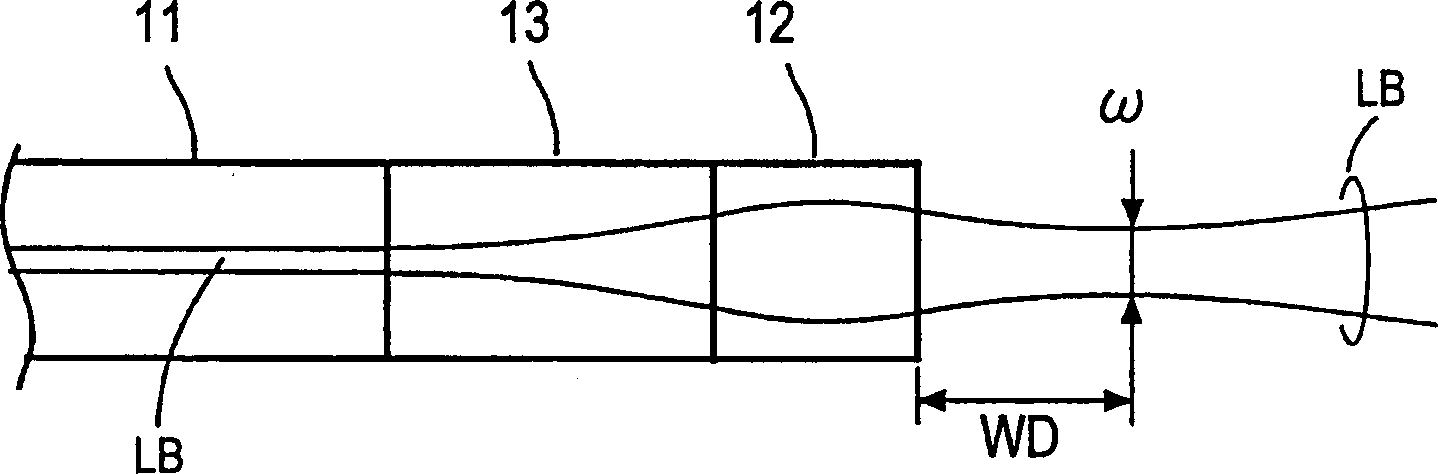

Optical fiber with light-focusing function, and mfg. method thereof

InactiveCN1402029AIncrease freedomWide range of designsCladded optical fibreCoupling light guidesRefractive indexOptical fiber cable

There are provided an optical fiber having a light focusing function and capable of setting the distance WD to the beam waist position and the beam waist diameter omega independently, and a method of manufacturing the optical fiber efficiently and at high accuracy. An end surface of a single mode optical fiber is connected to one end surface of a very short piece of spacer constituted of an optical fiber the diameter of which is identical to that of the single mode optical fiber and the refractive index of which is uniform. The other end surface of the spacer is connected to one end surface of a very short piece of graded index optical fiber the diameter of which is identical to that of the single mode optical fiber and the refractive index of which varies continuously in the direction of its diameter. The lengths of the spacer and / or the GI fiber can be adjusted to set the beam waist distance WD and the beam waist diameter omega to a proper value suitable for an optical device to be optically coupled to the optical fiber.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

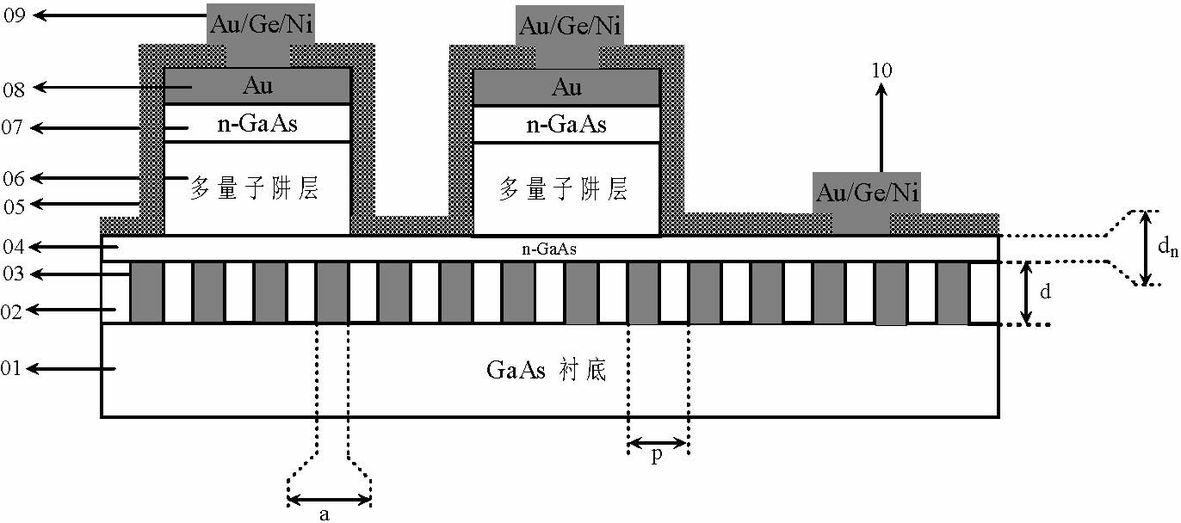

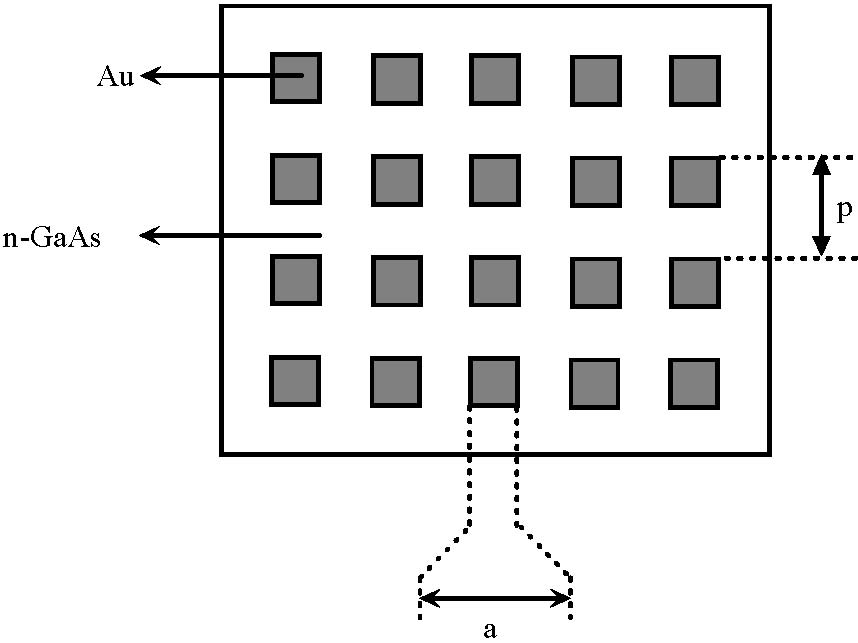

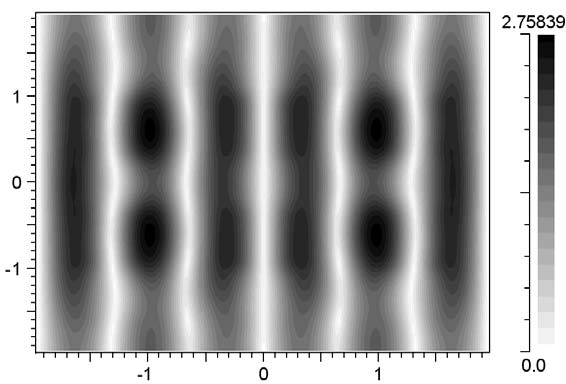

Quantum well infrared focal plane photosensitive element chip with grating in bottom coupling mode and preparation method thereof

InactiveCN102437228AImprove optical coupling efficiencyNovel structureFinal product manufactureSemiconductor devicesGratingManufacturing technology

The invention relates to a quantum well infrared focal plane photosensitive element chip with a grating in a bottom coupling mode and a preparation method thereof; therefore, problems that a manufacturing process of a focal plane photosensitive element chip is simplified and grating coupling efficiency is improved can be effectively solved. The chip is characterized in that: a transmission grating that is formed by n type gallium arsenide and Au in an alternative and periodic arrangement is formed on a gallium arsenide substrate; a lower contact layer is arranged on the transmission grating; multi-quantum well layers are formed on the lower contact layer; upper contact layers are formed on the multi-quantum well layers; Au reflecting layers are arranged on the upper contact layers; alloy upper electrodes are arranged on the Au reflecting layers; an alloy common lower electrode is formed on one end of the lower contact layer; and silica passivation layers are formed at two sides of thelower contact layer, the multi-quantum well layers, the upper contact layers, the Au reflecting layers, the alloy upper electrodes and the alloy upper electrodes. According to the preparation method,a wafer bonding technology and a conventional semiconductor technology are employed to place a transmission grating at the bottom of multi-quantum well layers, so that an integrated structure is formed. According to the invention, the structure is novel and unique; optical coupling efficiency is improved; and the manufacturing technology and the method are simple.

Owner:HENAN POLYTECHNIC UNIV

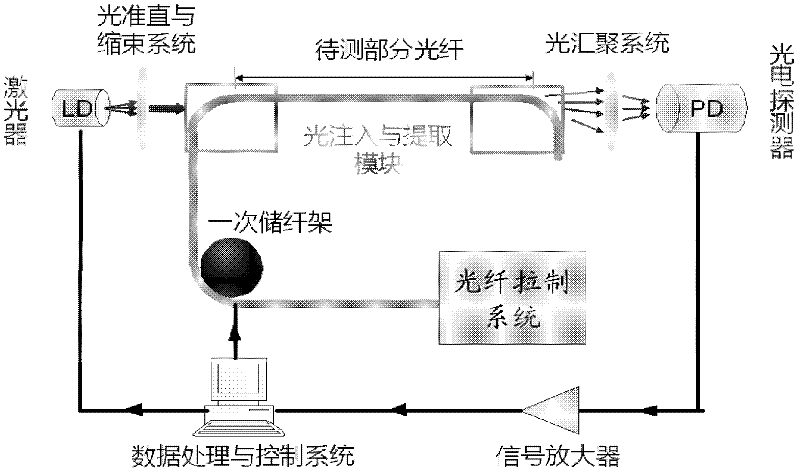

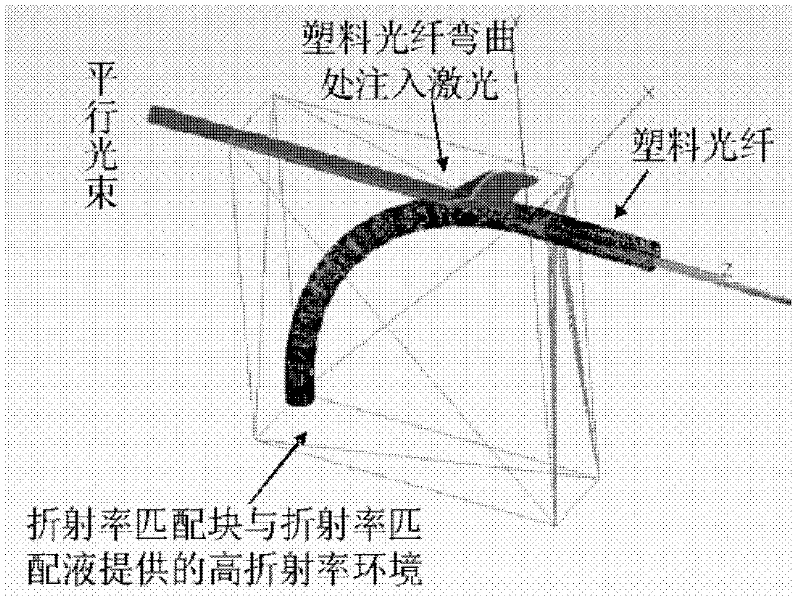

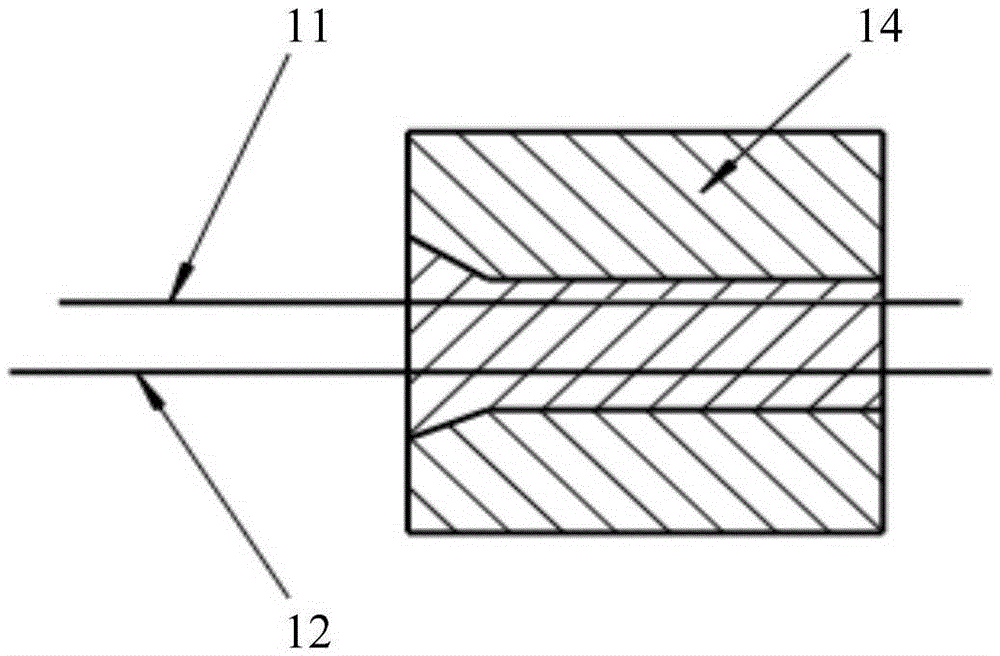

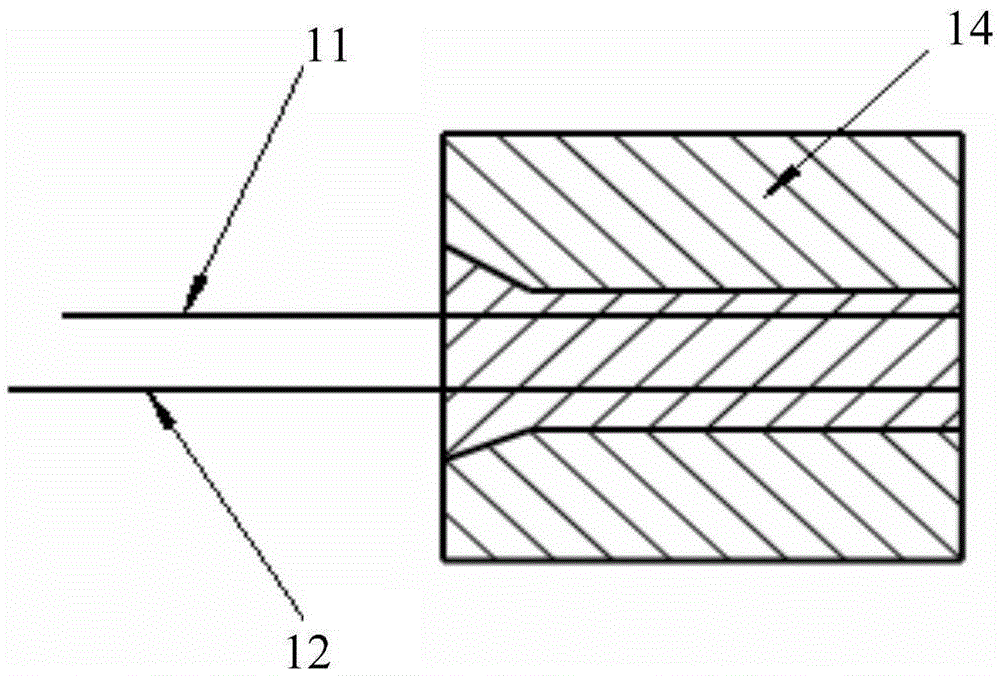

Plastic optical fiber transmission loss nondestructive detection method

InactiveCN102645320AReal-time measurementRealize online monitoring of production processTesting optical propertiesProduction lineOptical power

The invention provides a plastic optical fiber transmission loss nondestructive detection method which comprises the following steps that light signal injection and light signal extraction are respectively realized by a light injection module and a light extraction module at any one section of proper length of two optical fiber nodes on a production line, wherein the light injection module and the light extraction module are respectively and mainly formed by a refractive index matching block, refractive index matching liquid and an optical fiber bending clamper; optical fiber transmission loss coefficients are obtained through treating detected optical power information; and further, the real-time measurement of the transmission loss coefficients on the production line is realized, and the all-weather online monitoring production process is realized. Meanwhile, the method has the beneficial effects that optical fibers does not need to be cut off, and no any damage can be generated to the optical fibers in the processes of light injection and light extraction, so that the nondestructive measurement can also be realized.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

Superconducting nanowire single photon detector fabricated on micro-nano fiber surface

ActiveCN106129141ADirect Efficient Optical CouplingImprove optical coupling efficiencyMaterial nanotechnologyNanosensorsMicro nanoInductance

The invention provides a superconducting nanowire single photon detector fabricated on a micro-nano fiber surface. The superconducting nanowire single photon detector comprises a micro-nano fiber and a superconducting nanowire, wherein the superconducting nanowire is arranged on the micro-nano fiber surface, and the length direction of the superconducting nanowire is consistent with the length direction of the micro-nano fiber. In the superconducting nanowire single photon detector, the superconducting nanowire is formed on the micro-nano fiber surface, direct and high-efficiency optical coupling of the micro-nano fiber and the superconducting nanowire can be achieved by means of optical transmission and coupling characteristics of the micro-nano fiber on a micro-nano scale, and the optical coupling efficiency of the superconducting nanowire single photon detector is improved; compared with a traditional device, the effective area of the superconducting nanowire is not limited by the size of an end surface of the fiber, the length of the superconducting nanowire can be reduced, thus, the dynamic inductance of the superconducting nanowire single photon detector is effectively reduced, and the rate of the superconducting nanowire single photon detector is further improved; and the superconducting nanowire is directly formed on the surface of the micro-nano fiber, and the long-term working stability of the superconducting nanowire single photon detector is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

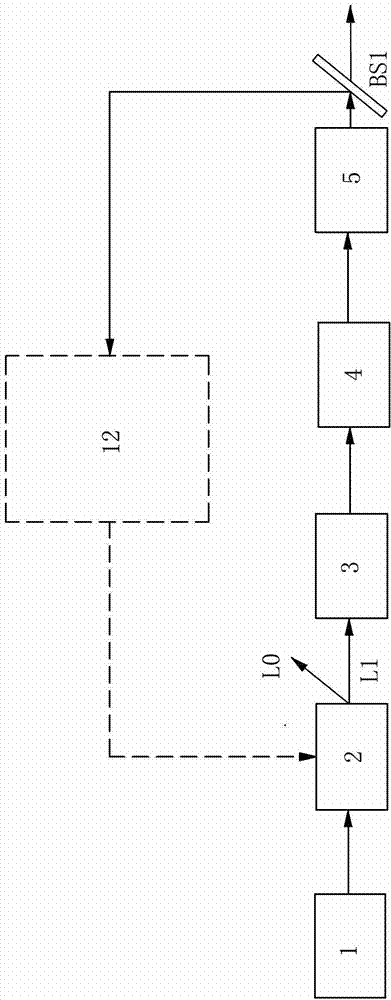

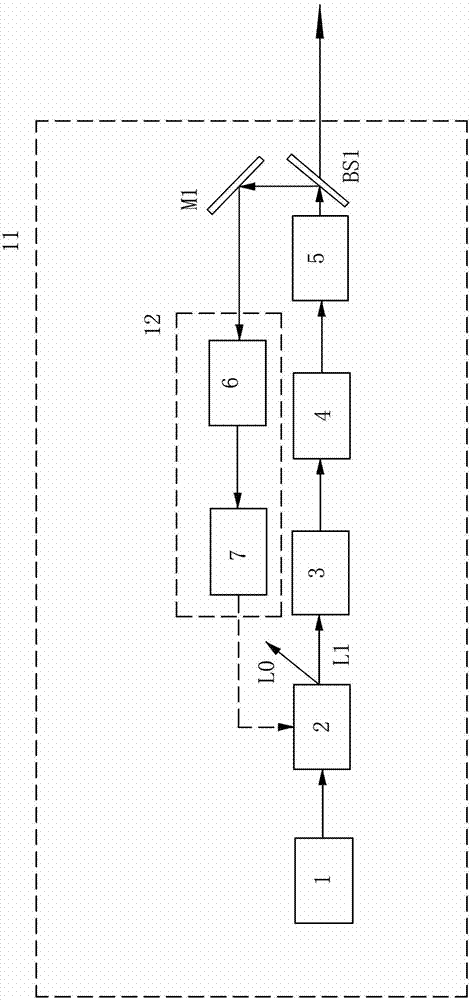

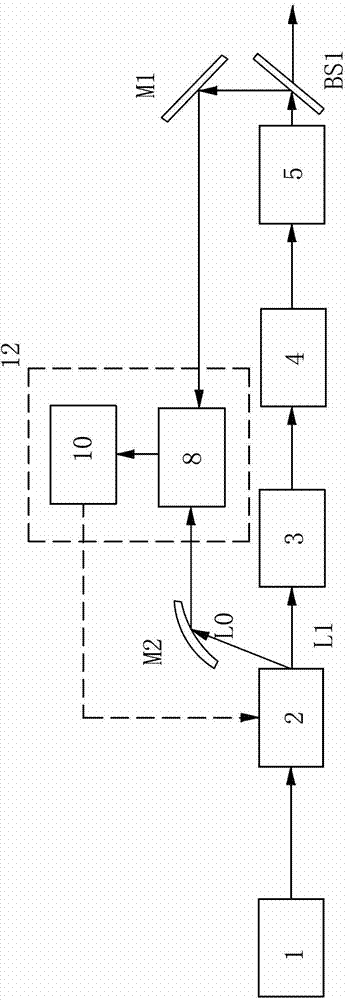

Phase noise compensative amplification system

The invention discloses a phase noise compensative amplification system, and the phase noise compensative amplification system comprises an oscillator (1) for outputting a seed light source, and the phase noise compensative amplification system is characterized in that the output end of the oscillator (1) is provided with an acoustic-optic frequency shifter (2) for outputting zero-order light (LO) and first-order light (L1) after processing the seed light source, wherein the output end of the first-order light (L1) of the acoustic-optic frequency shifter (2) is provided with a stretcher (3), the output end of the stretcher (3) is provided with a cascade amplifier (4), the output end of the cascade amplifier (4) is provided with a compressor (5), the output end of the compressor (5) is provided with a number one beam splitting sheet (BS1), the reflection light of the number one beam splitting sheet (BS1) is communicated with a compensative amplification system (12), and the compensative amplification system (12) is connected with the acoustic-optic frequency shifter (2) and supplies a control signal to the acoustic-optic frequency shifter (2).

Owner:广东华快光子科技有限公司

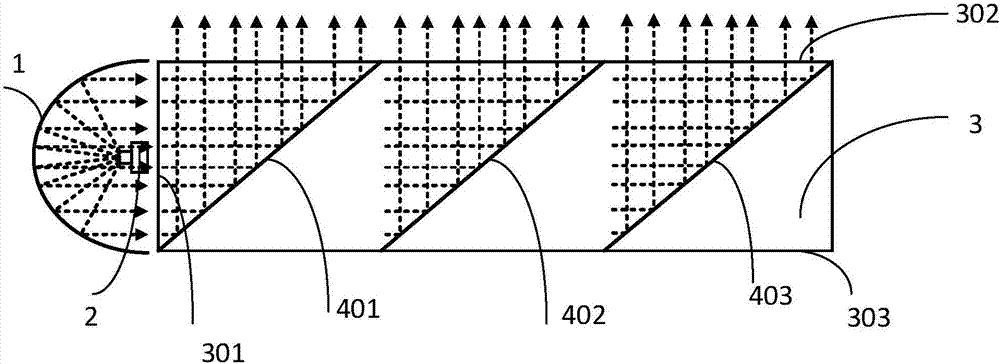

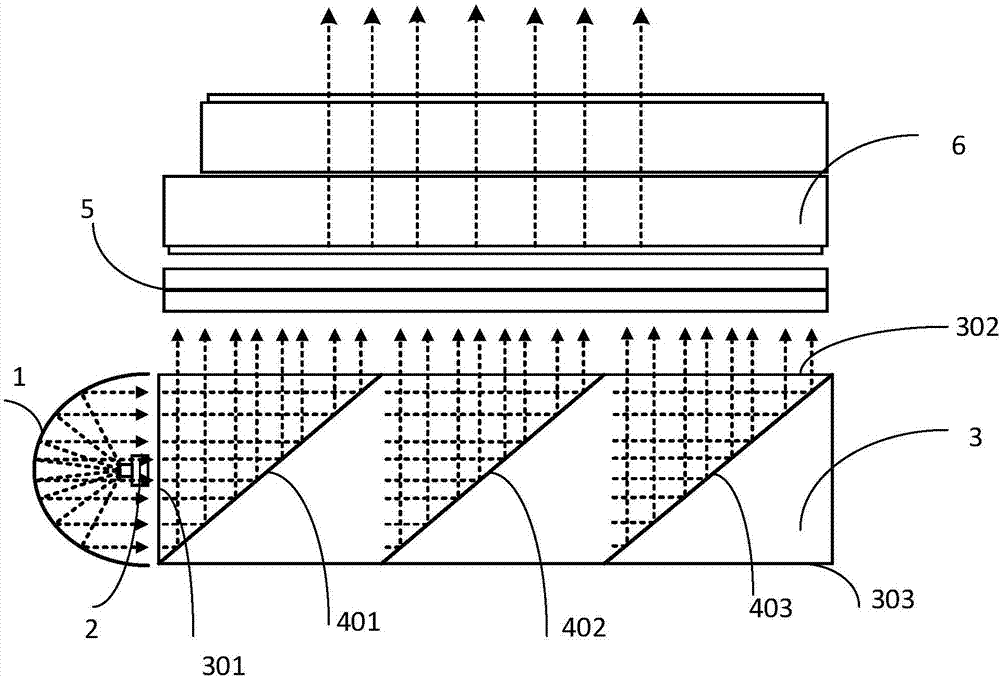

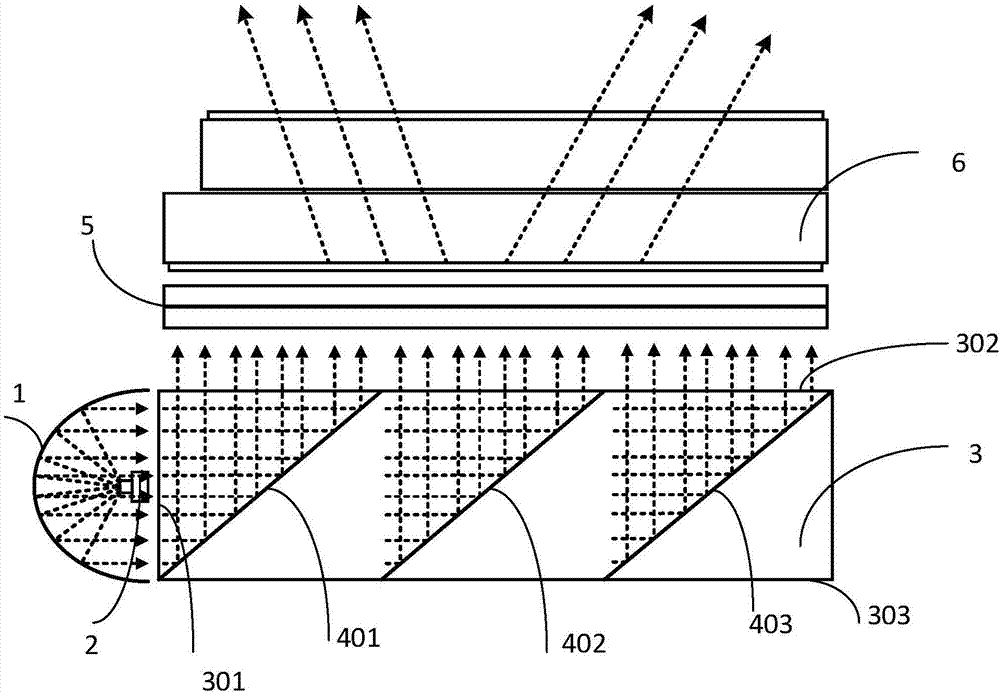

Backlight module and display device

InactiveCN107300806ALossless brightnessThere will be no absorptionPlanar/plate-like light guidesNon-linear opticsLight guideDisplay device

The invention relates to the technical field of display, in particular to a backlight module and a display device. The backlight module comprises a light guiding plate and a light emitting assembly capable of emitting light rays and making the emitted light rays enter into the light guiding plate in a parallel mode; the light guiding plate further includes a light inlet surface, a bottom surface, a light outlet surface on the top and at least one oblique reflection surface, wherein the oblique reflection surface is positioned between the bottom surface and the light outlet surface, and the included angle between the oblique reflection surface and the plane, in the extension direction away from the light inlet surface, of the bottom surface is smaller then 90 degrees; the light inlet surface is positioned on one side of the light guiding plate. By the light emitting assembly, parallel light is emitted to the light inlet surface and reflected out of the light guiding plate by the oblique reflection surface, namely the light guiding plate does not need to be added with optical films, the condition that light is absorbed by the optical films is avoided, and the brightness of the parallel light emitted by the light guiding plate is not damaged; moreover, by not adding peep-proof protection films and other materials, the backlight assembly is much thinner.

Owner:BOE TECH GRP CO LTD +1

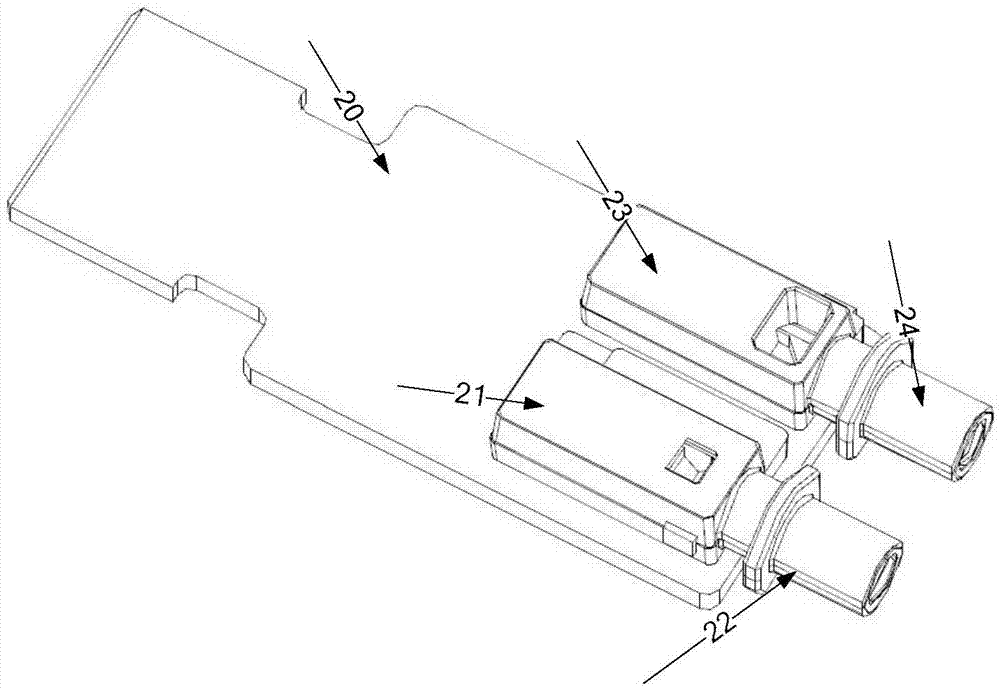

Optical module

ActiveCN107153236AUndisturbedImprove optical coupling efficiencyCoupling light guidesOptical ModuleLight signal

The present invention discloses an optical module comprising a circuit board, a first lens assembly and a laser chip. The first lens assembly is arranged above the laser chip; the first lens assembly includes a first optical fiber jack, a first reflective surface and a second reflective surface; the first optical fiber jack is for inserting the first optical fiber and the projection of the central axis of the first optical fiber jack on the circuit board does not pass through the center of the effective light emitting surface of the laser chip; the first reflecting surface is for receiving the first incident light signal from the laser chip so that the first incident light signal is reflected on the first reflecting surface to obtain a first reflected light signal; and the second reflecting surface is for receiving the first reflected light signal such that the first reflected light signal is reflected on the second reflecting surface to obtain a second reflected light signal and the second reflected light signal is transmitted through the second lens assembly and received by the first optical fiber. The optical module can realize independent lens assembly package of transmission and reception ends, thereby improving the optical coupling efficiency of the transmission end and the reception end of the optical module.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

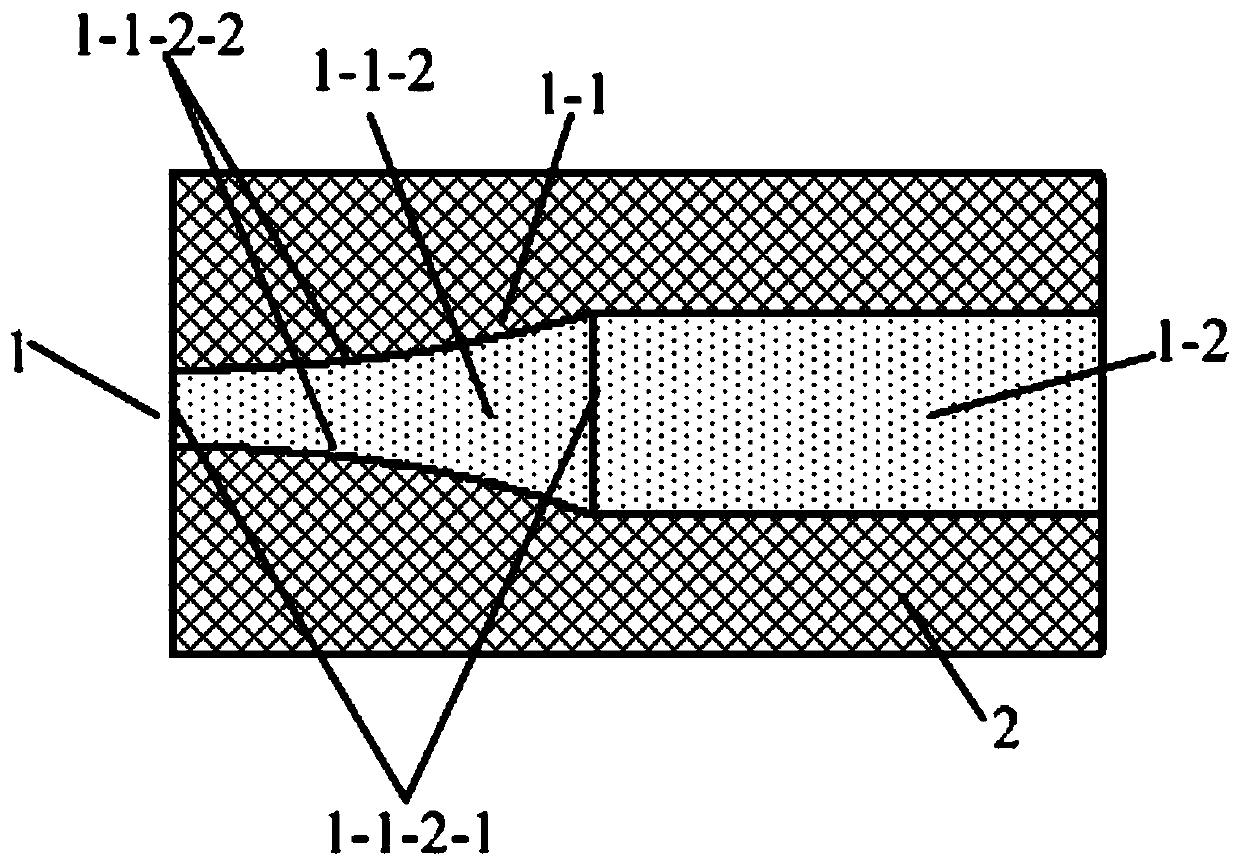

Waveguide coupling element with forward and backward coupling properties and manufacturing method thereof

The invention relates to a waveguide coupling element with forward and backward coupling properties and a manufacturing method thereof. The waveguide coupling element with the forward and backward coupling properties comprises a base layer, at least one backward-coupling layer, a medium layer and at least one forward-coupling layer, wherein one end of the forward-coupling layer can be connected with an external optical fiber to couple light waves transmitted by the optical fiber; and the light waves can be efficiently coupled into the backward-coupling layer in a coupling order from the forward-coupling layer to the medium layer to the forward-coupling layer, and are limited to be transmitted in the backward-coupling layer. Furthermore, with the adoption of the manufacturing method, the waveguide coupling element with the forward and backward coupling properties can be manufactured in a large scale with low cost by using the conventional semiconductor process.

Owner:李明昌

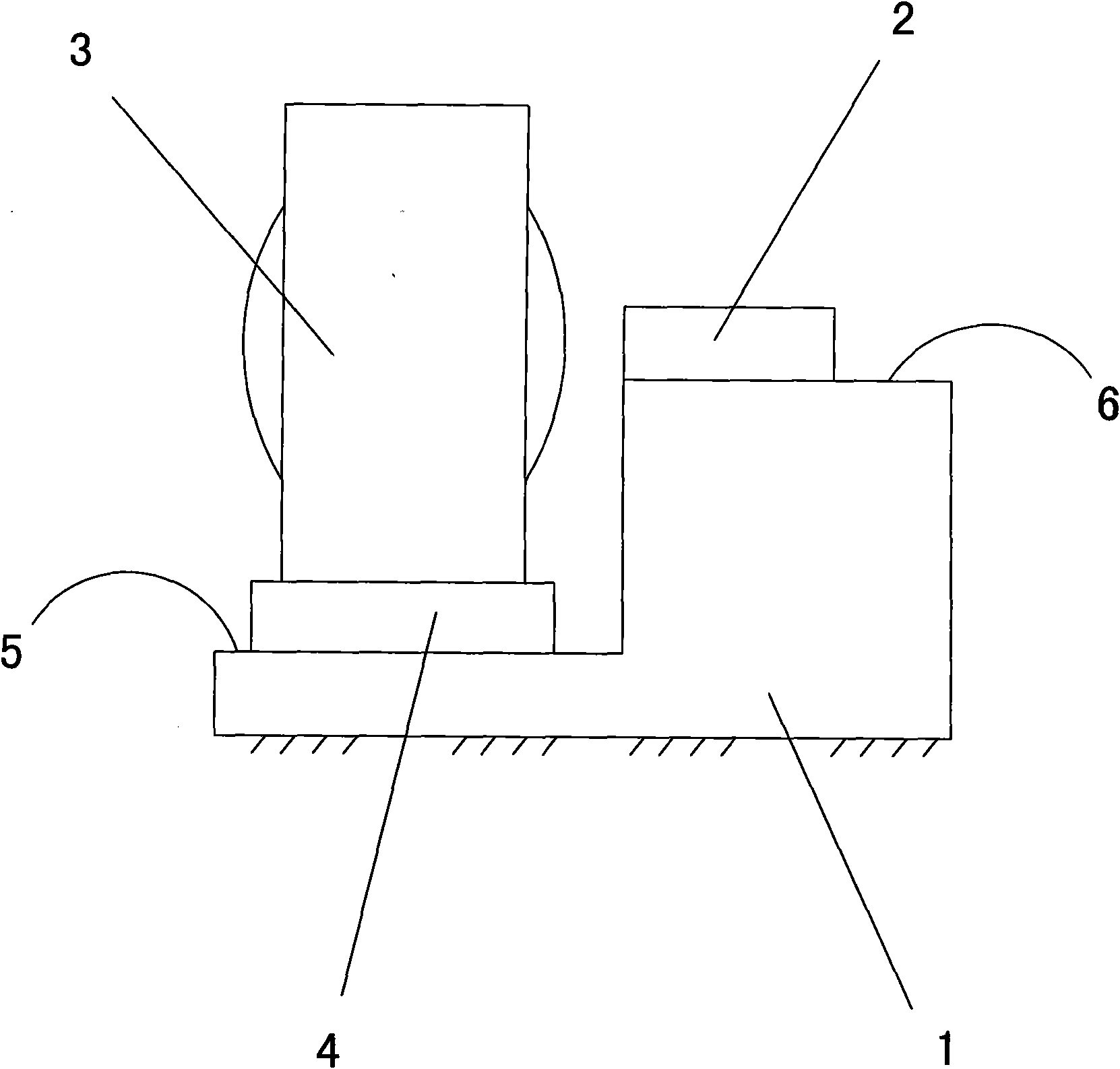

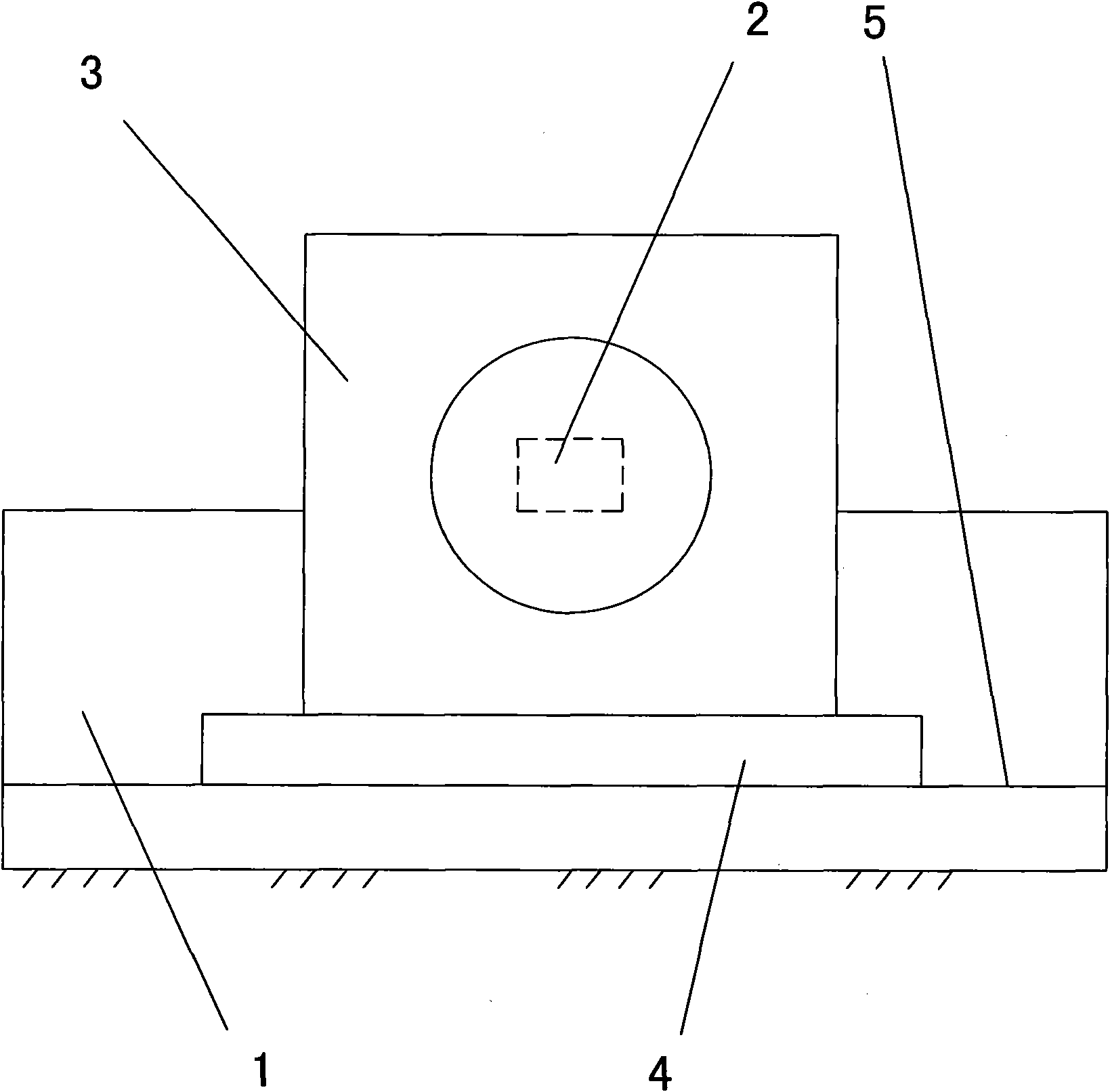

Three-dimensional fixing method of micro-naked coupling lens

InactiveCN102096161AReduce mistakesSimple and fast operationCoupling light guidesEngineeringOptical coupling

The invention provides a three-dimensional fixing method of a micro-naked coupling lens, comprising the steps: attaching an LD (laser diode) chip on a top supporting surface on a step seat, wherein the front side of the step seat is provided with a bottom supporting surface which is lower than and parallel to the top supporting surface; utilizing a suction pipe type clamp to hang the micro-naked coupling lens above the bottom supporting surface and adjusting the position of the micro-naked coupling lens by the suction pipe type clamp so as to lead the coupling of the micro-naked coupling lens and the LD chip to be in place; utilizing a CCD (charged coupled device) camera to measure the height of a gap between the bottom surface and the bottom supporting surface of the micro-naked coupling lens; utilizing the suction pipe type clamp to move the micro-naked coupling lens upwards, then selecting and putting a gasket on the bottom supporting surface, and moving the micro-naked coupling lens downwards to lead the micro-naked coupling lens to be located on the gasket, wherein the thickness of the gasket is consistent to the height of the measured gap; and utilizing the conventional sticking mode to fix the micro-naked coupling lens and the gasket. The three-dimensional fixing method has the advantages that the operation is simple and convenient, the control is easy, the error is less, the optical coupling efficiency is high, the time and the labor are saved, and simultaneously the repairability is achieved.

Owner:大连艾科科技开发有限公司

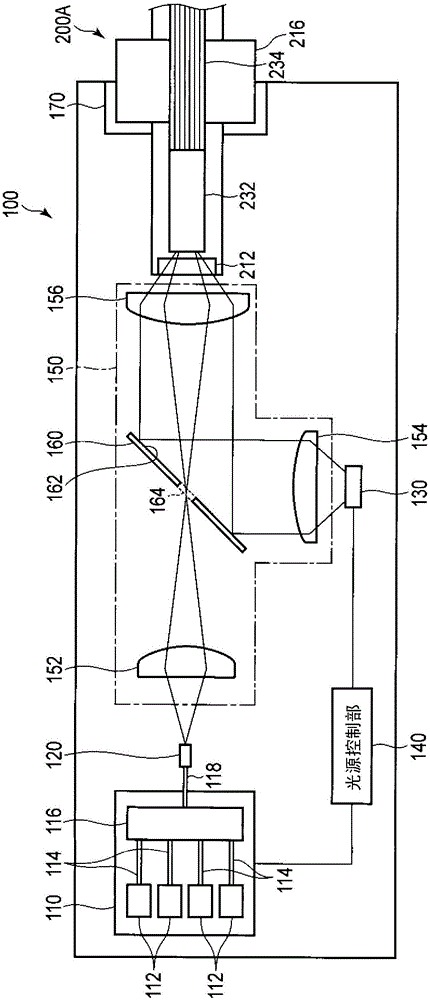

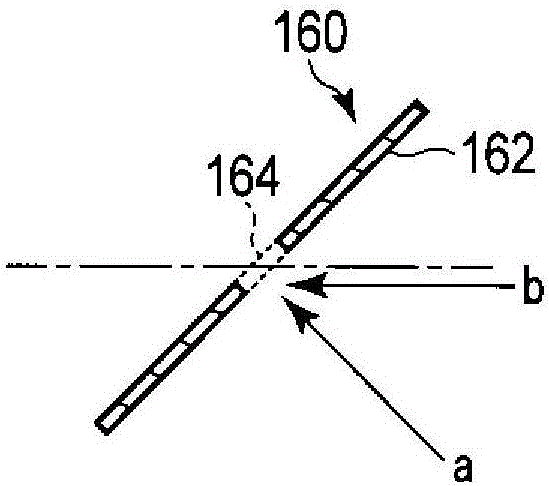

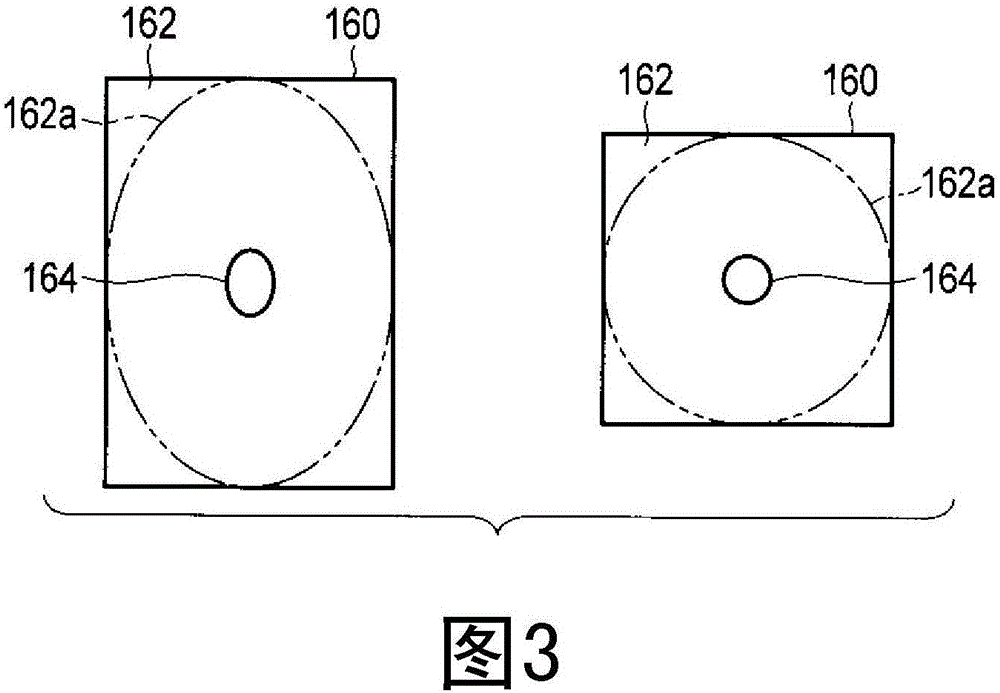

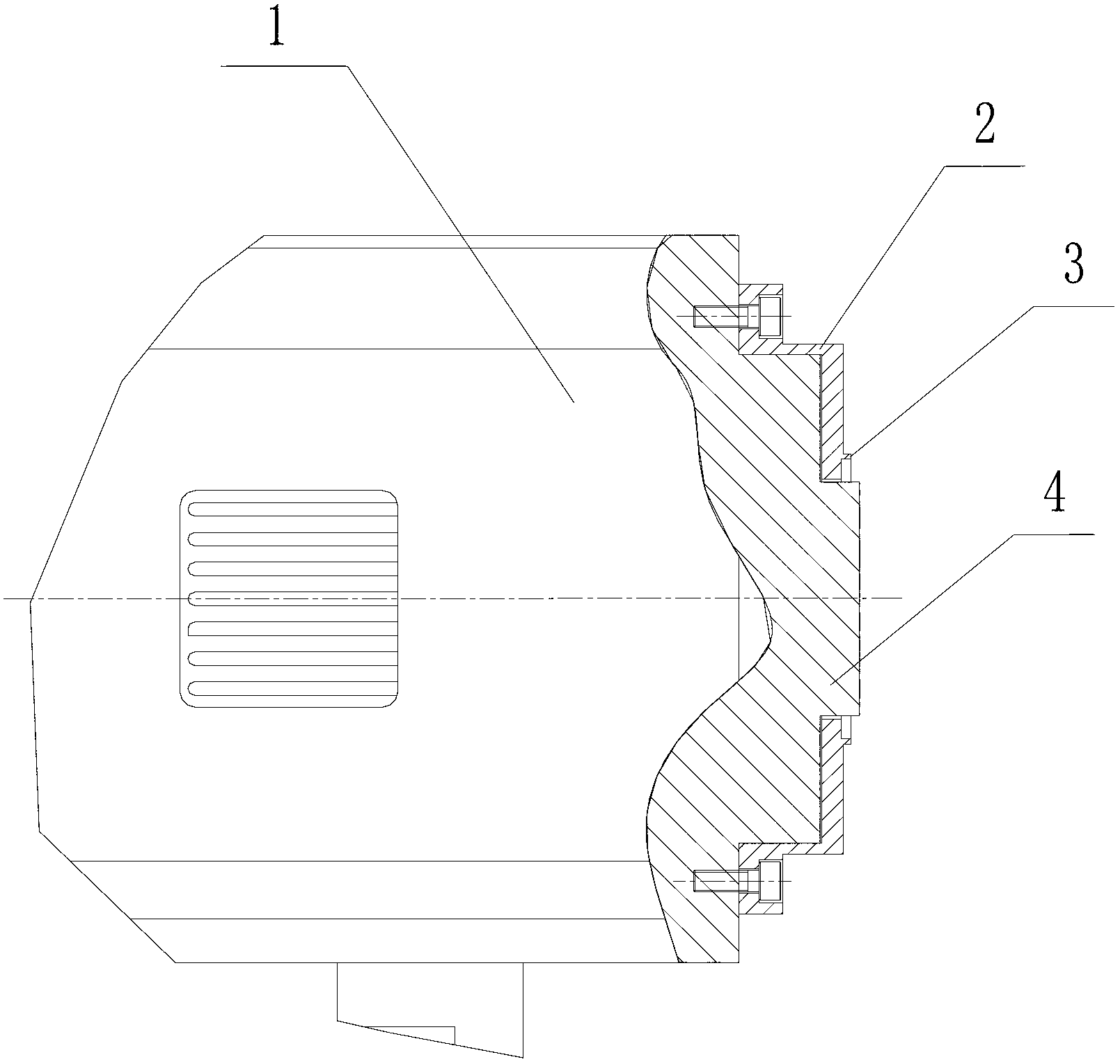

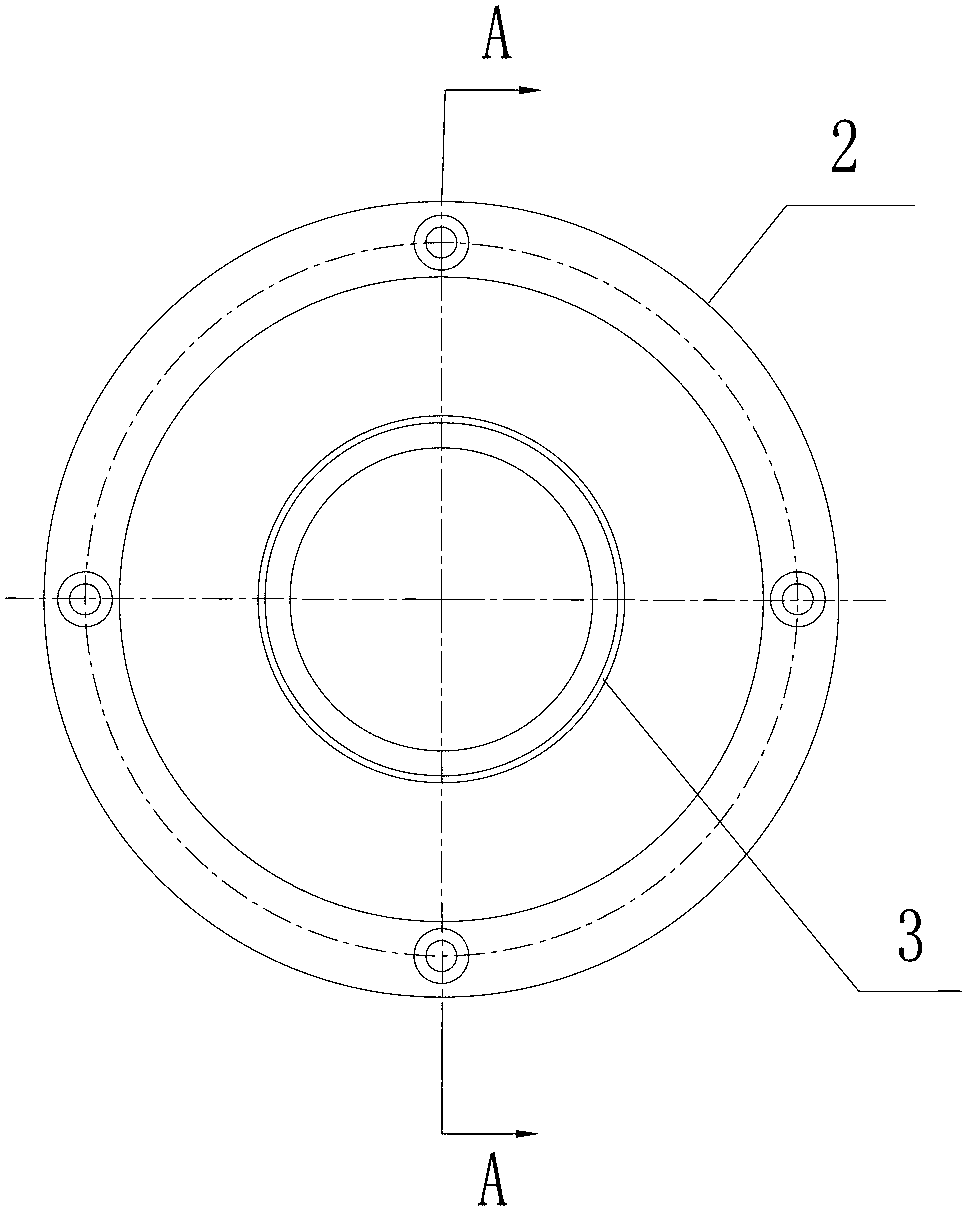

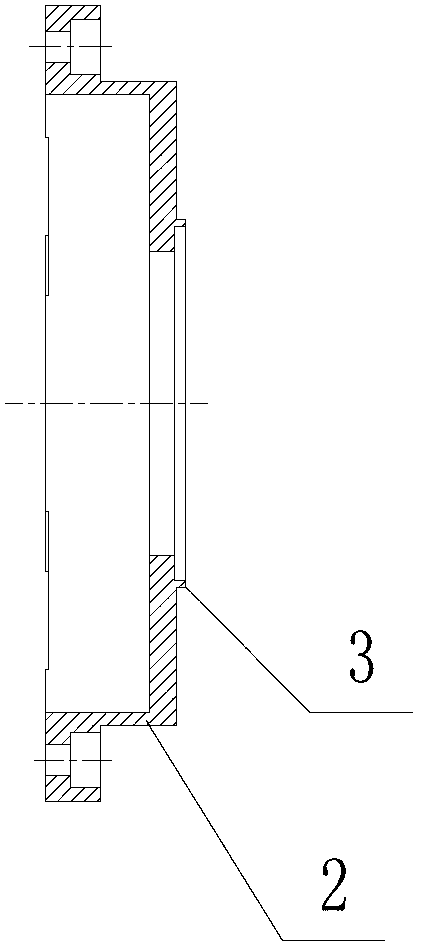

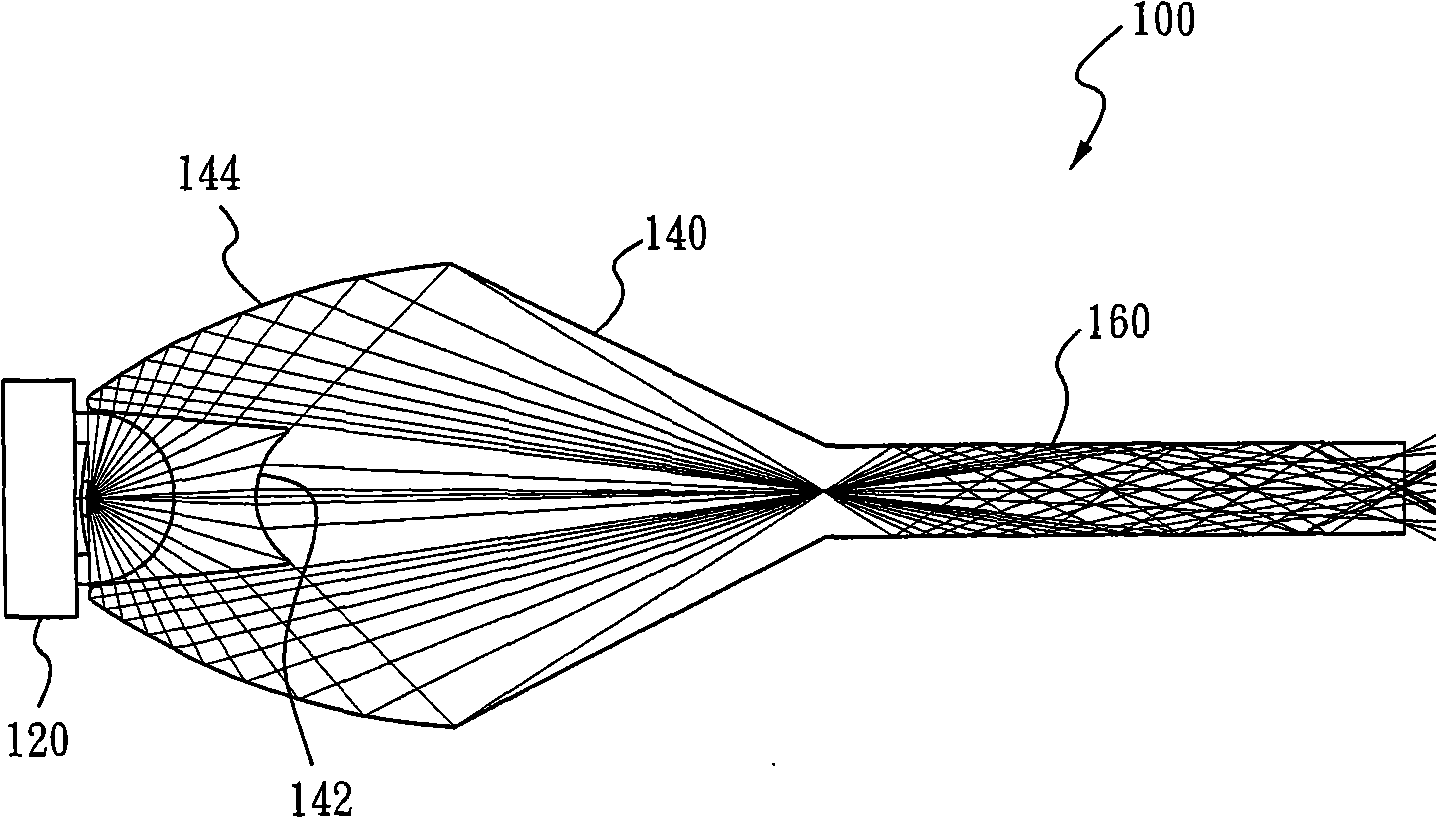

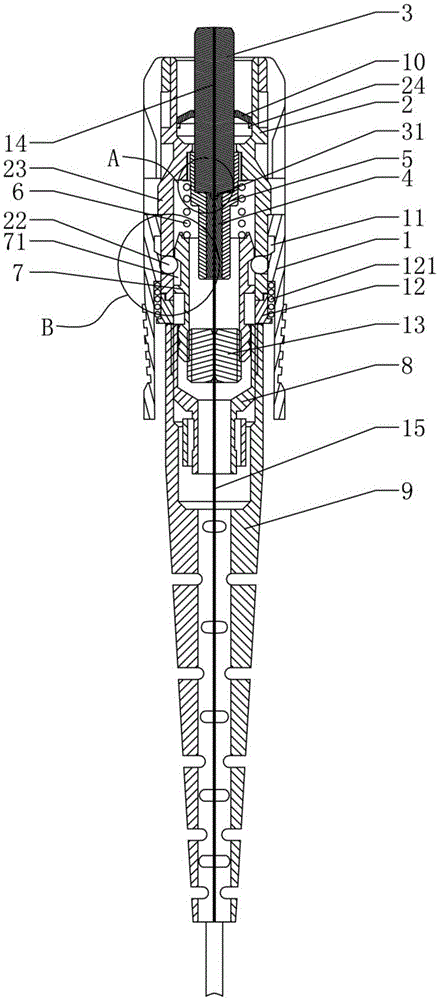

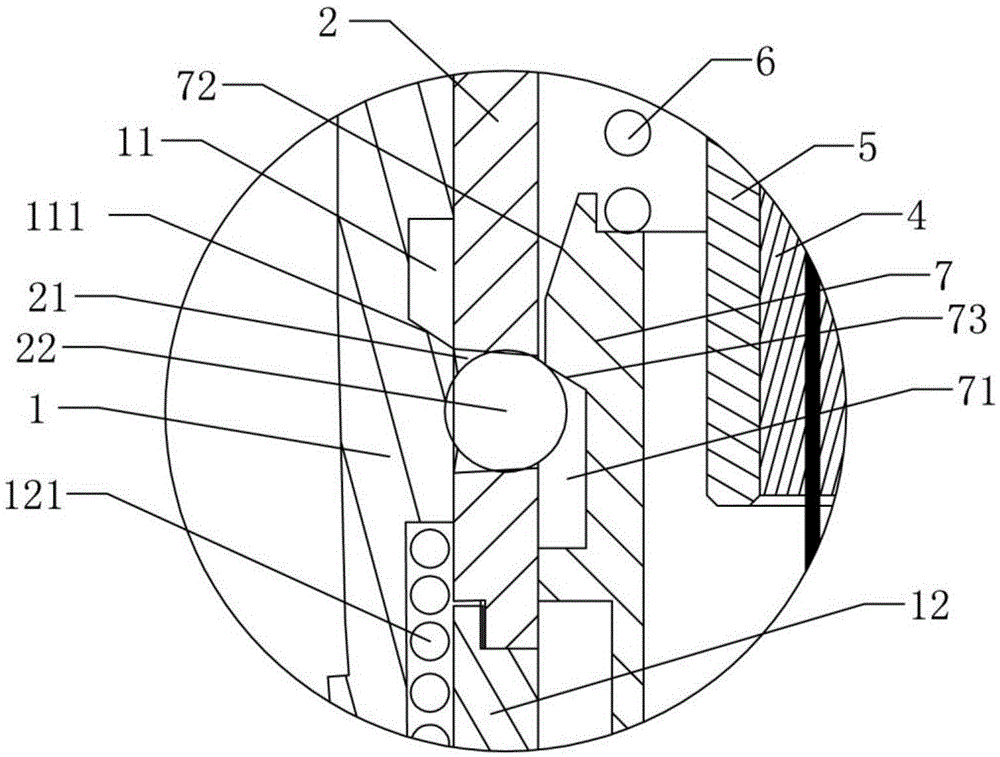

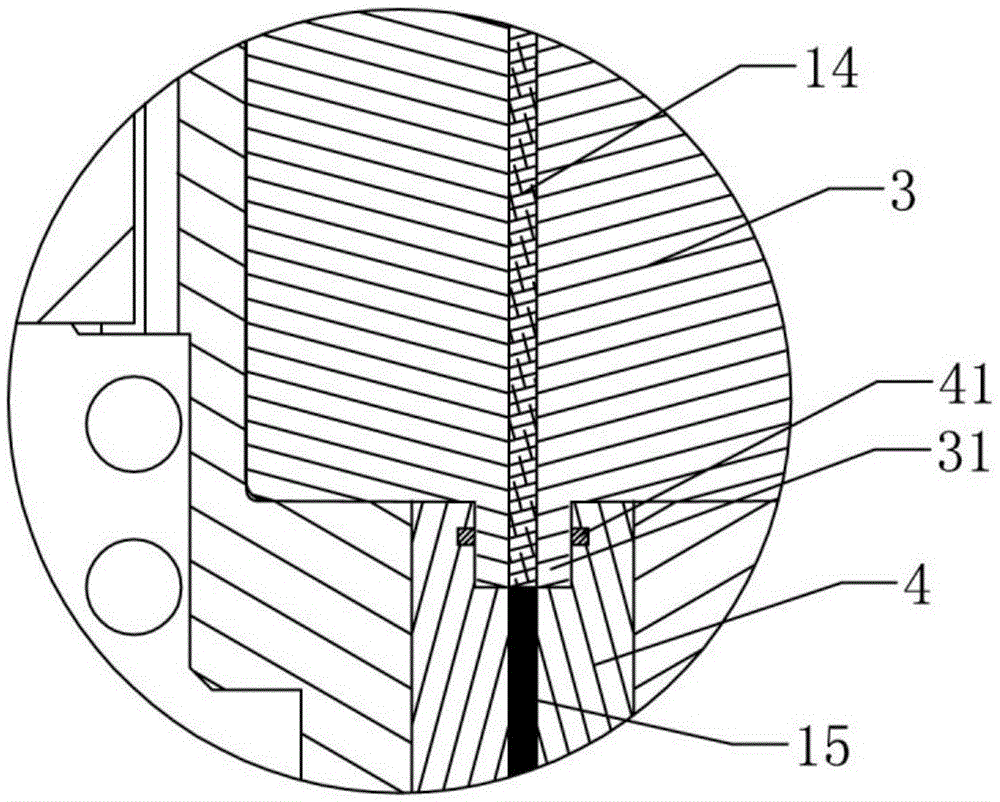

Endoscope light source device

ActiveCN106413521AIncreased Design FreedomImprove optical coupling efficiencySurgeryEndoscopesLaser lightOptoelectronics

This endoscope light source device (100) comprises: a laser light source unit (110) that emits a laser beam; an LED light source unit (130) that emits an LED beam; and an optical path merging member (160) that merges the optical path of the laser beam and the optical path of the LED beam. The etendue of the laser light source unit (110) is smaller than the etendue of the LED light source unit (130). The optical path merging member (160) has a reflection surface (162) that reflects the LED beam, and has, in a region of the reflection surface (162), an opening (164) that lets the laser beam pass through. The optical path merging member (160) reflects the LED beam such that the central axis of the optical path of the LED beam reflected by the reflection surface (162) matches the central axis of the optical path of the laser beam that has passed through the opening (164).

Owner:OLYMPUS CORP

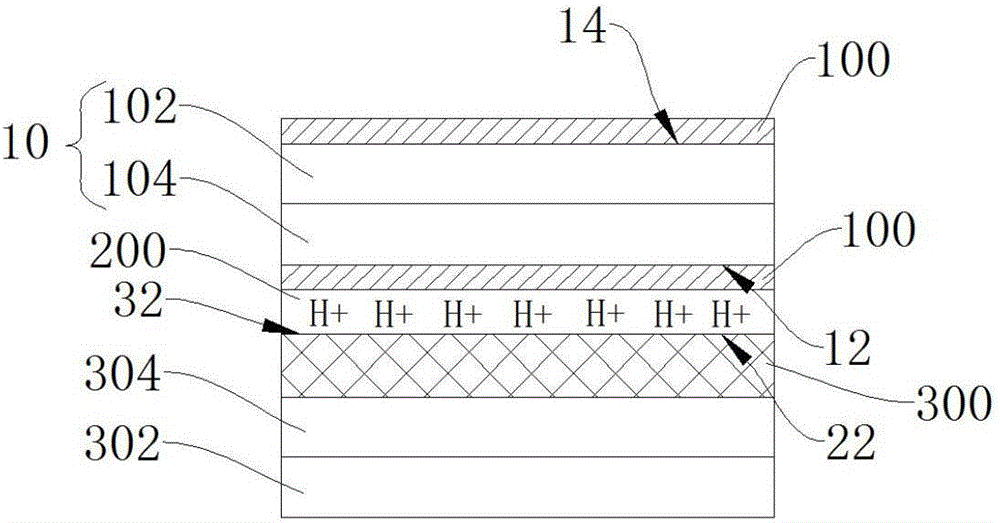

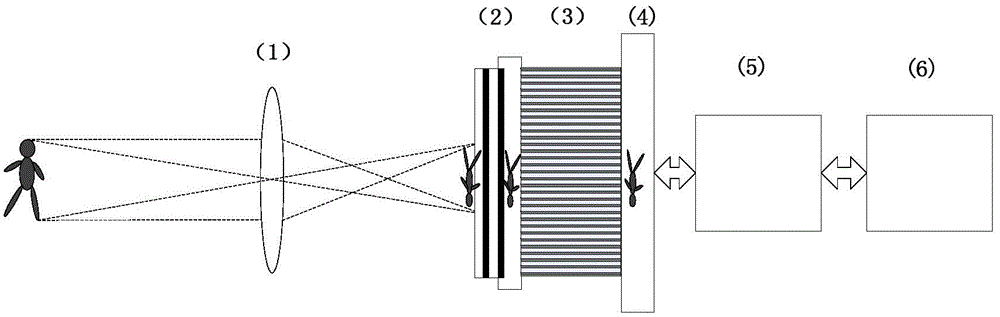

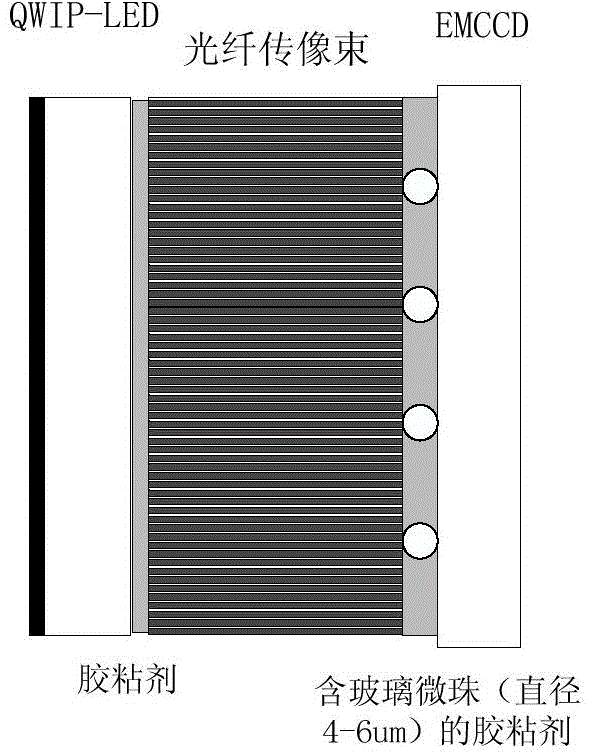

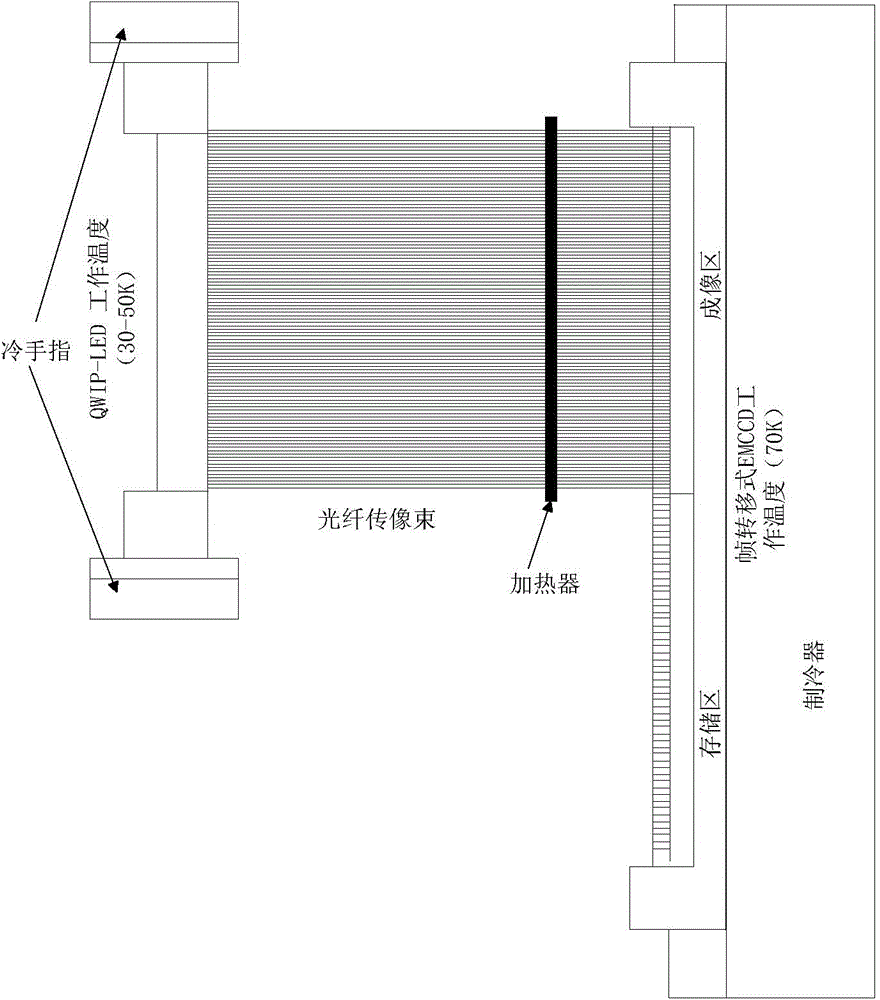

Infrared imaging detecting system through optical fiber coupling between QWIP-LED and EMCCD

InactiveCN103913806AImprove optical coupling efficiencyIncreased infrared detection rateRadiation pyrometryCoupling light guidesLong wave infraredLongwave

The invention discloses an infrared imaging detecting system through optical fiber coupling between a QWIP-LED and an EMCCD. According to the system, an optical fiber image transmission bundle is used for coupling near-infrared images obtained by QWIP-LED infrared up converting to the EMCCD for imaging, and EMCCD detecting of a long-wave infrared target is achieved. The system has the advantages that the transmission efficiency of infrared images from the QWIP-LED to the EMCCD can be effectively improved through the optical fiber image transmission bundle, accordingly the detecting efficiency of the system is high, and in addition, the space size of the detecting system can be obviously reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

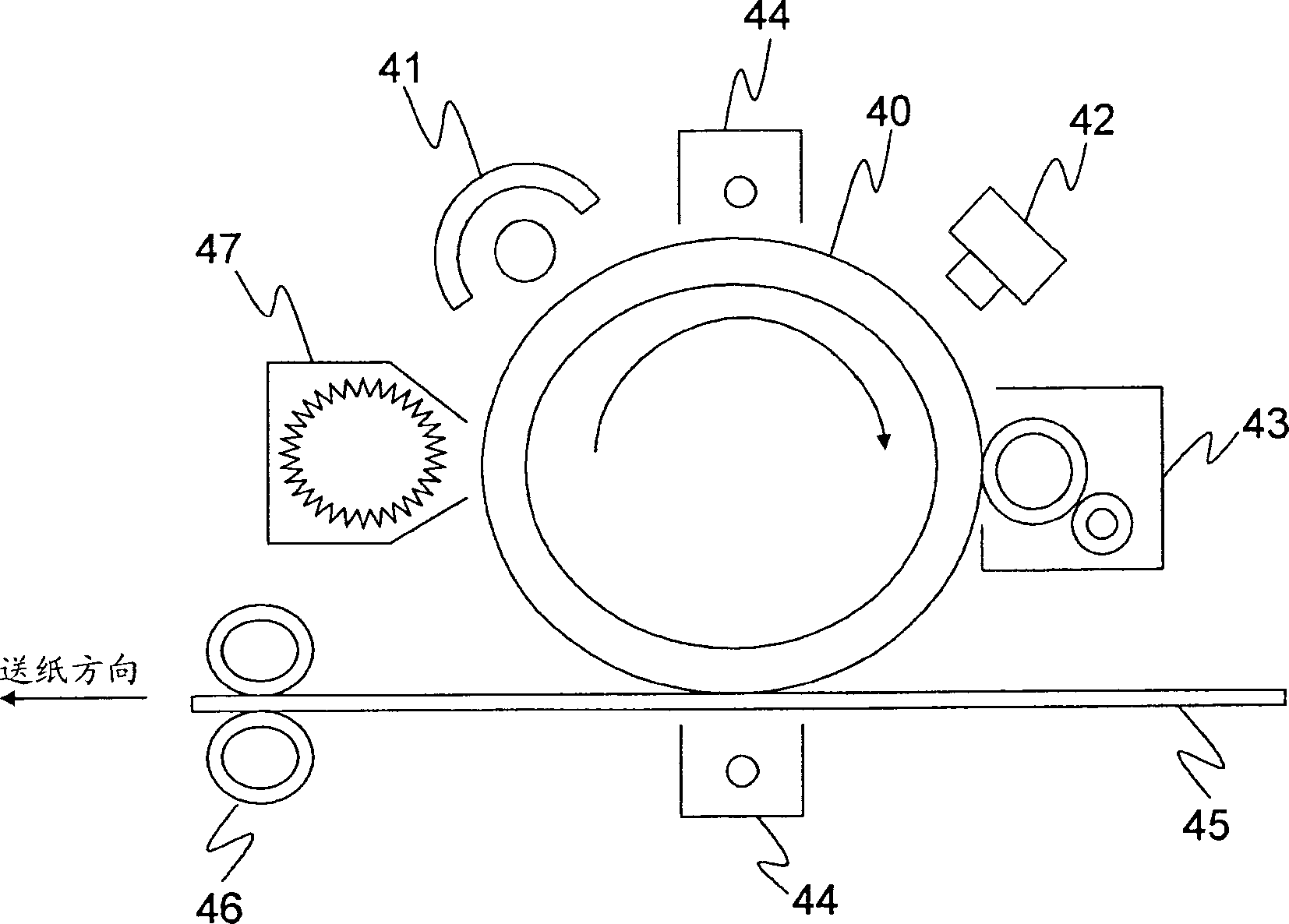

Optical printing head and its usage

The present invention is one optical printing head and its usage. The optical printing head has matrix form condensing micro lens combination set between its LED plate and the matrix form self-focusing micro lens combination to converge the light from the LED plate to the matrix form self-focusing micro lens combination to raise the light strength to the matrix form self-focusing micro lens combination and raise the photocoupling efficiency.

Owner:LITE ON TECH CORP

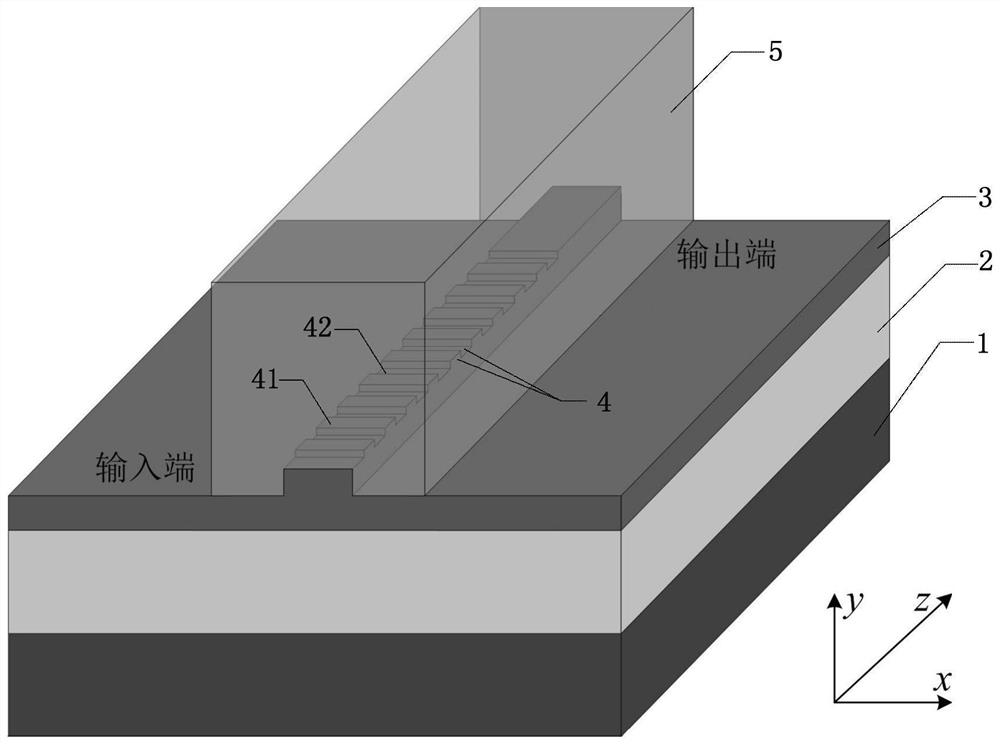

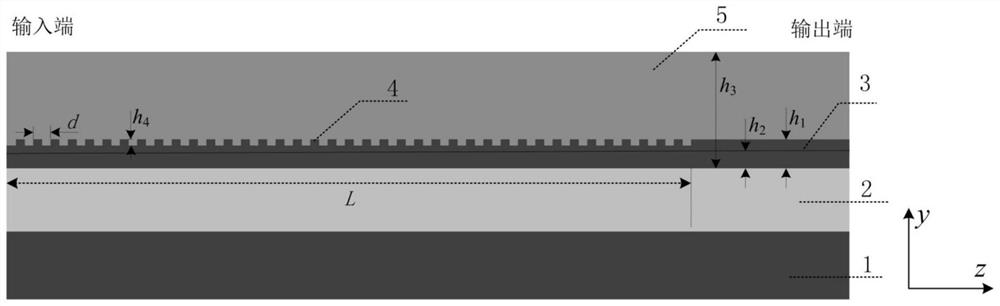

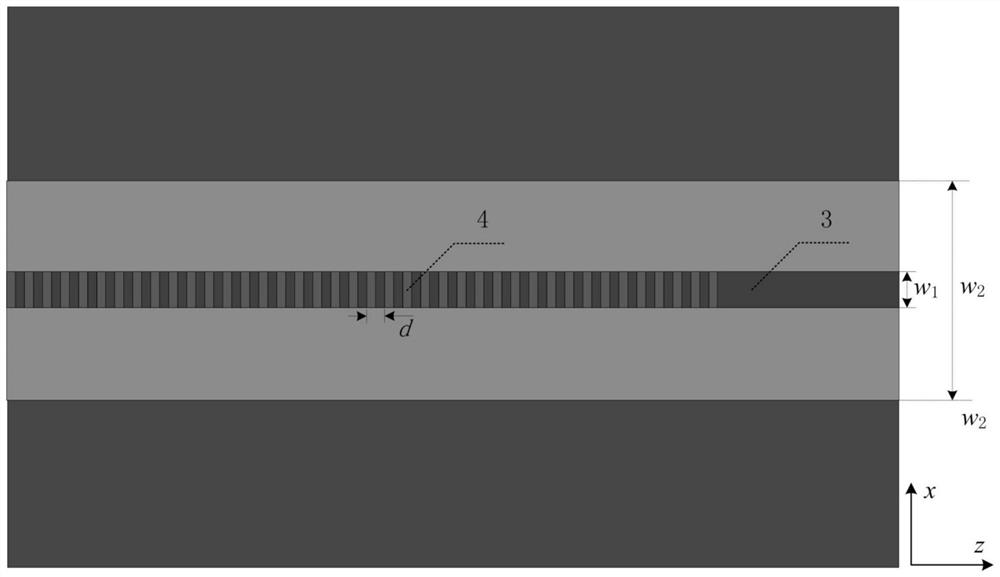

Spot size converter based on long-period grating

ActiveCN113376743AImprove optical coupling efficiencyImprove robustnessOptical waveguide light guideLight waveEngineering

The invention discloses a spot size converter based on a long-period grating. The spot size converter is applied to the field of optical communication and optical waveguide devices, realizes the conversion of the spot size of an optical wave mode, and comprises a substrate, a buffer layer, a high-refractive-index waveguide core, the long-period grating and a low-refractive-index upper cladding strip waveguide, wherein one surface of the buffer layer is fixedly connected with the substrate, and the other opposite surface of the buffer layer is fixedly connected with one surface of the high-refractive-index waveguide core; the other opposite surface of the high-refractive-index waveguide core is used for etching to obtain the long-period grating; and the other opposite surface of the high-refractive-index waveguide core and the long-period grating are fixedly connected with the low-refractive-index upper cladding strip waveguide. According to the invention, the problems of complex structure, high manufacturing difficulty, high technical cost and poor long-term stability of a traditional nanometer photonic waveguide end face coupling spot size converter are solved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

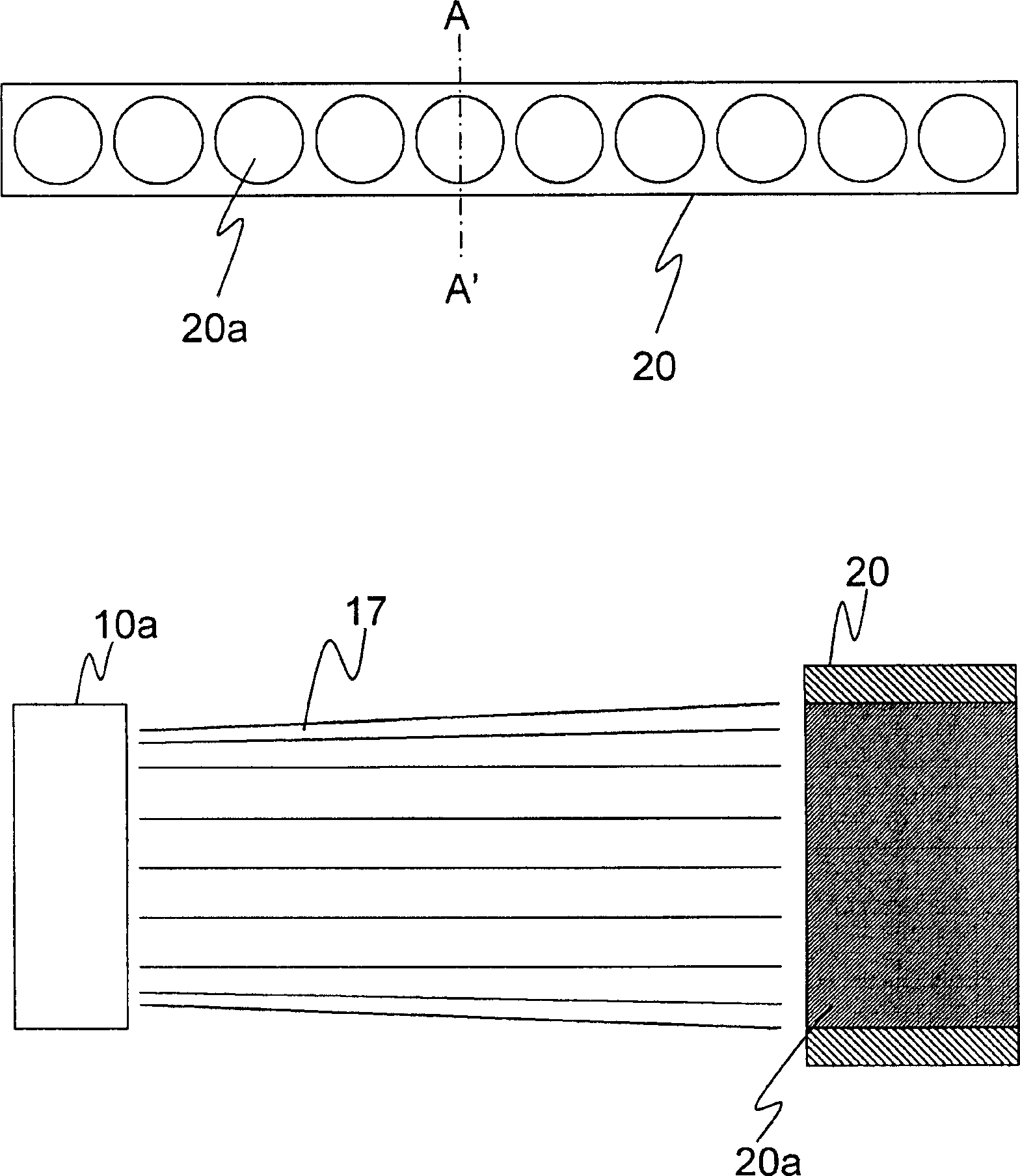

CCD (charge coupled device) camera directly coupled with sequencing chip

ActiveCN102703310AQuality improvementEasy accessBioreactor/fermenter combinationsBiological substance pretreatmentsA-DNADNA sequencer

The invention discloses a CCD (charge coupled device) camera directly coupled with a sequencing chip. The CCD camera comprises a sequencing chip clamped in an installation base of a DNA (deoxyribonucleic acid) sequencer, a camera body and an optical fiber panel for catching optical signals of the sequencing reaction, wherein one end of the optical fiber panel extends out from the front end of thecamera body and is directly contacted one side of the sequencing chip located on the installation base of the sequencing chip of the DNA sequencer in order to obtain optical signals produced by sequencing reaction at the other side of the sequencing chip. With the adoption of the CCD camera directly coupled with the sequencing chip, due to the optical fiber panel directly coupled with the sequencing chip, the weak visible light produced on the sequencing chip can be directly received by the optical fiber panel to be converted into an electric signal; therefore, the optical coupling efficiencyis improved; the optical coupling efficiency can be more than 70%; and the condition that the high-quality sequencing signal is acquired can be ensured.

Owner:BEIJING INST OF GENOMICS CHINESE ACAD OF SCI CHINA NAT CENT FOR BIOINFORMATION +1

Beam combiner and laser comprising same

InactiveCN106772808AReduce light attenuationImprove optical coupling efficiencyCoupling light guidesUltrasound attenuationLaser technology

The present invention is suitable for the laser technology field, and provides a beam combiner. The beam combiner comprises a dual fiber collimator, a single fiber collimator and an optical filter. The dual fiber collimator comprises input fibers configured to transmit pump light, active fibers configured to perform light amplification and a first lens in non-interface welding with the end portions of the input fibers and the active fibers, wherein the welding end of the first lens is a plane, one end opposite to the welding end is a curve, the optical filter is arranged on the output light path of the curve, the pump light is reflected to the active fibers and transmits signal light, the single fiber collimator comprises output fibers and a second lens in non-interface welding with the end portion of the output fibers, and the non-welding end of the first lens is opposite to the non-welding end of the second lens. Because there is no interface between each fiber and each lens, there is no attenuation when the pump light and the signal light are transmitted between the fibers and the lens, and the optical coupling efficiency is high; the power bearing capacity is high, and the high-power transmission is realized; a fiber fusion-elongation technology is not employed, the fiber performance itself can be maintained, the pump conversion efficiency is high, and the product performance is stable.

Owner:深圳朗光科技有限公司

Waveguide coupling structure and light emitter system

ActiveCN111239895AReduce lossImprove optical coupling efficiencyCoupling light guidesOptical waveguide light guideCoplanar waveguideMiniaturization

The embodiment of the invention provides a waveguide coupling structure and a light emitter system. The waveguide coupling structure comprises a waveguide core structure and a first cladding, and thefirst longitudinal sectional area of the rectangular surface of the coupling structure of the waveguide core structure changes from small to large in the length direction of the coupling structure; the cross section of the coupling structure is a quadrangle of which the first opposite sides are parallel and the second opposite sides in curve change are symmetrical along the perpendicular bisectorof the cross section; one end surface of the conduction structure is coplanar with the connection surface of the coupling structure, the waveguide core structure is embedded in the first cladding, thesmall end surface of the coupling structure is coplanar with one end surface of the first cladding, and the other end surface of the conduction structure is coplanar with the other end surface of thefirst cladding. Therefore, by applying the technical scheme provided by the embodiment of the invention, the optical coupling efficiency can be improved on the basis of ensuring the miniaturization and integration of the structure.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Optical elements and projecting system including optical elements

InactiveCN101276134AImprove optical coupling efficiencyImprove uniformityProjectorsColor photographyLight guideProjection system

The present invention provides an optical element and a projection system containing the optical element. The optical element includes a condensing part, the condensing part includes a reflecting surface and a refracting surface, used for condensing the light from the light source; and a light guide part, connected to the output end of the condensing part and evenly emitting the light condensed by the condensing part. The invention provides an optical element and a projection system, capable of improving more even brightness and more high light coupling efficiency.

Owner:HONG KONG APPLIED SCI & TECH RES INST

SC-type optical fiber connector

ActiveCN105629393AImprove stabilityUniform radial forceCoupling light guidesSteel ballOptical fiber connector

The invention discloses a SC-type optical fiber connector comprising a packaging housing, a sleeve seat, a first inserting core, a second inserting core, a tail handle, a balance spring, a bearing seat, a clamp screw nut, and a rubber sleeve pipe. The end part of the first inserting core is provided with a small diameter connecting part in an extended manner, and the corresponding end part of the second inserting core is provided with a connecting groove. The middle part of the first inserting core is connected with an elastic support, and the outermost edge of the elastic support abuts against the inner wall of the sleeve seat. The rear end outer wall of the sleeve seat is provided with an installation groove, in which is movably disposed a steel ball. The front end outer wall of the bearing seat is provided with an annular clamping groove. The inner wall of the packaging housing is provided with an annular avoiding groove cooperated with the steel ball, and the rear end of the sleeve seat is fixedly connected with a rear seat, and a reset spring is disposed between the rear seat and the packaging housing in an abutting manner. The middle part outer wall of the sleeve seat is provided with a large diameter part, and the packaging housing is movably disposed between the large diameter part and the rear seat. The SC-type optical fiber connector has advantages of simple and reasonable structure, convenient and fast installation, high optical coupling efficiency, stable working performance, and long service lifetime.

Owner:灏讯电缆连接器制造(常州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com