Three-dimensional fixing method of micro-naked coupling lens

A technology of coupling lens and fixing method, which is applied in the coupling of optical waveguide, etc., can solve the problems of affecting assembly yield, unable to measure optical coupling efficiency in real time, large optical coupling loss, etc., and achieve good control, small error, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

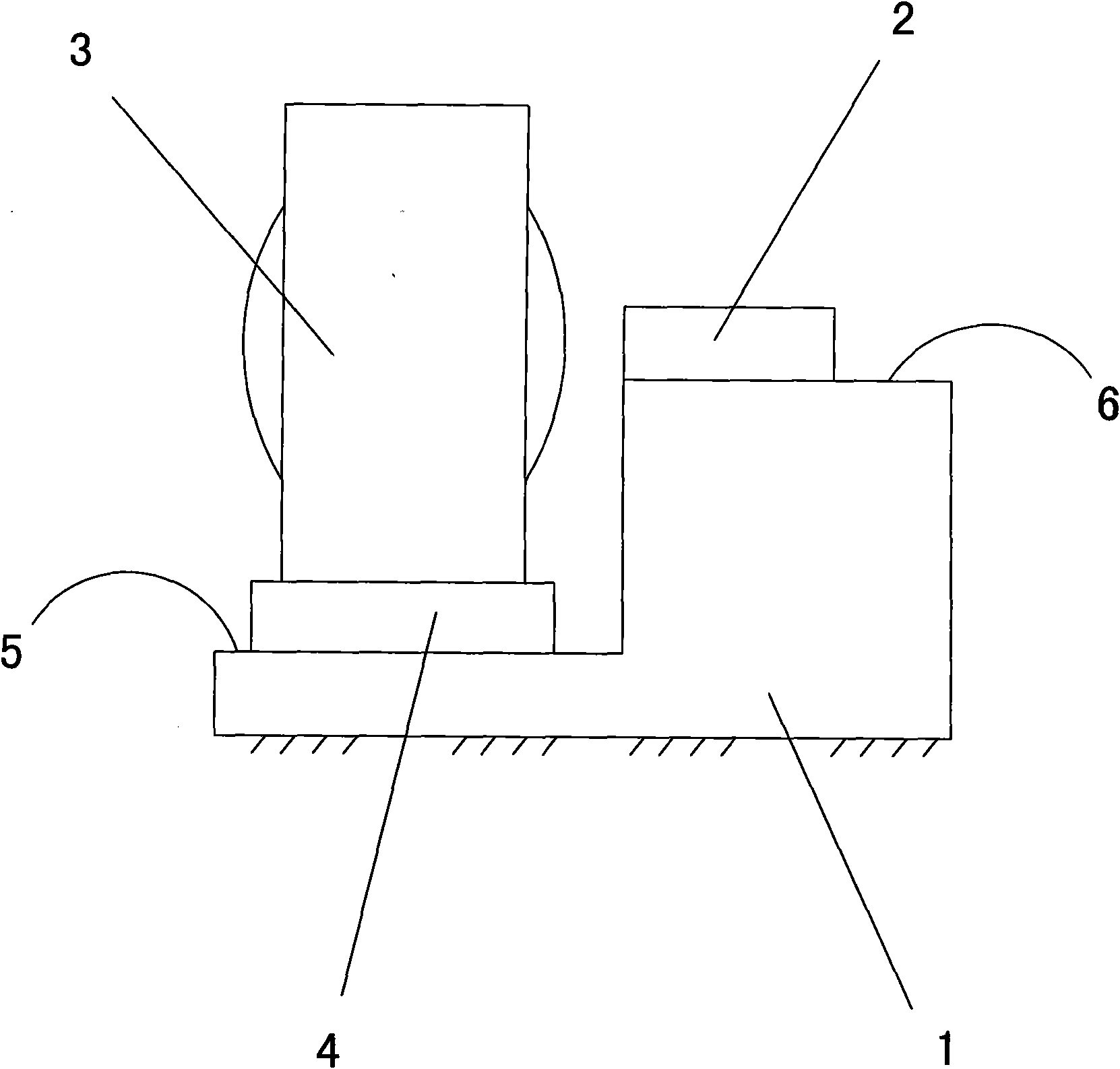

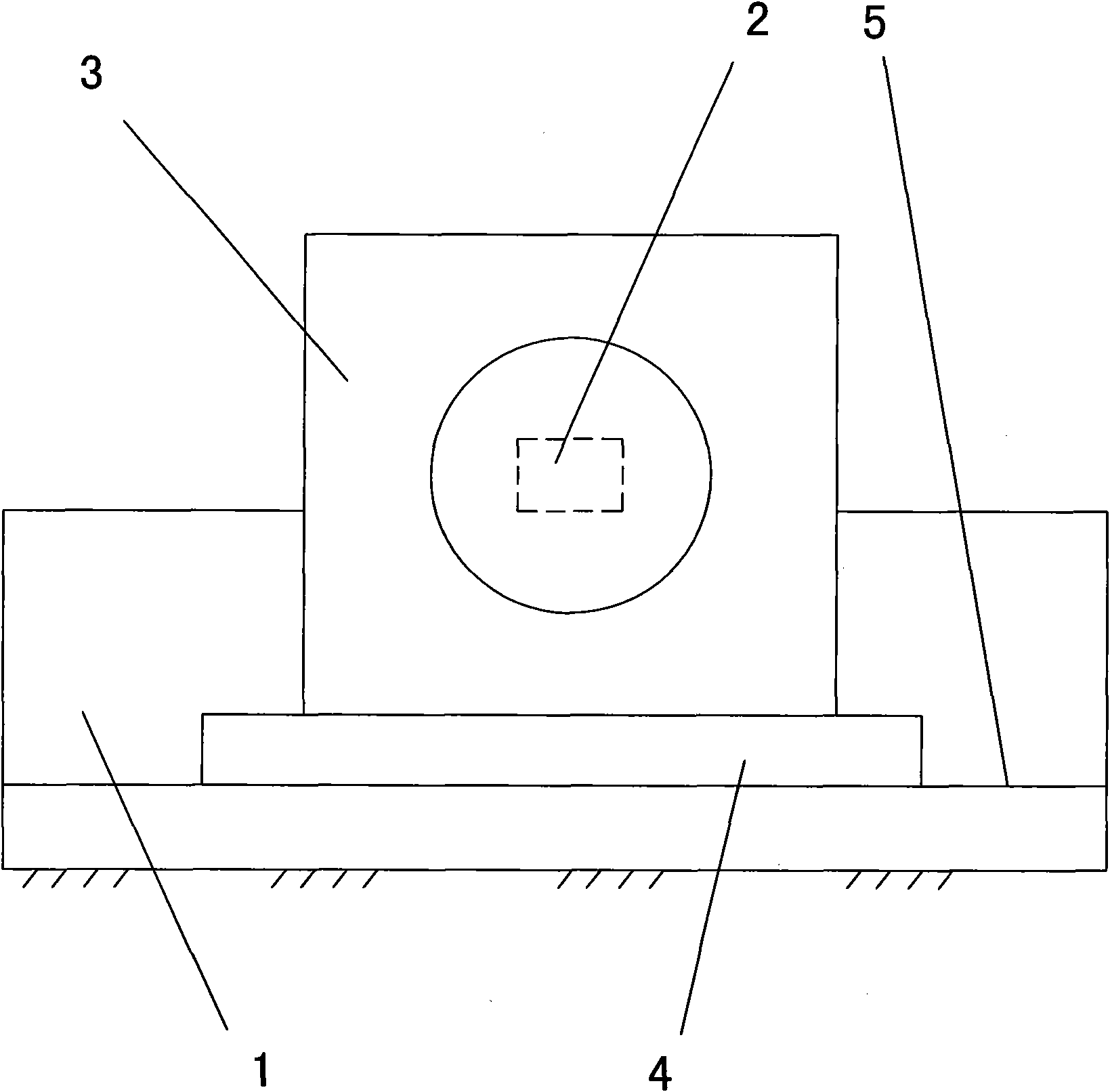

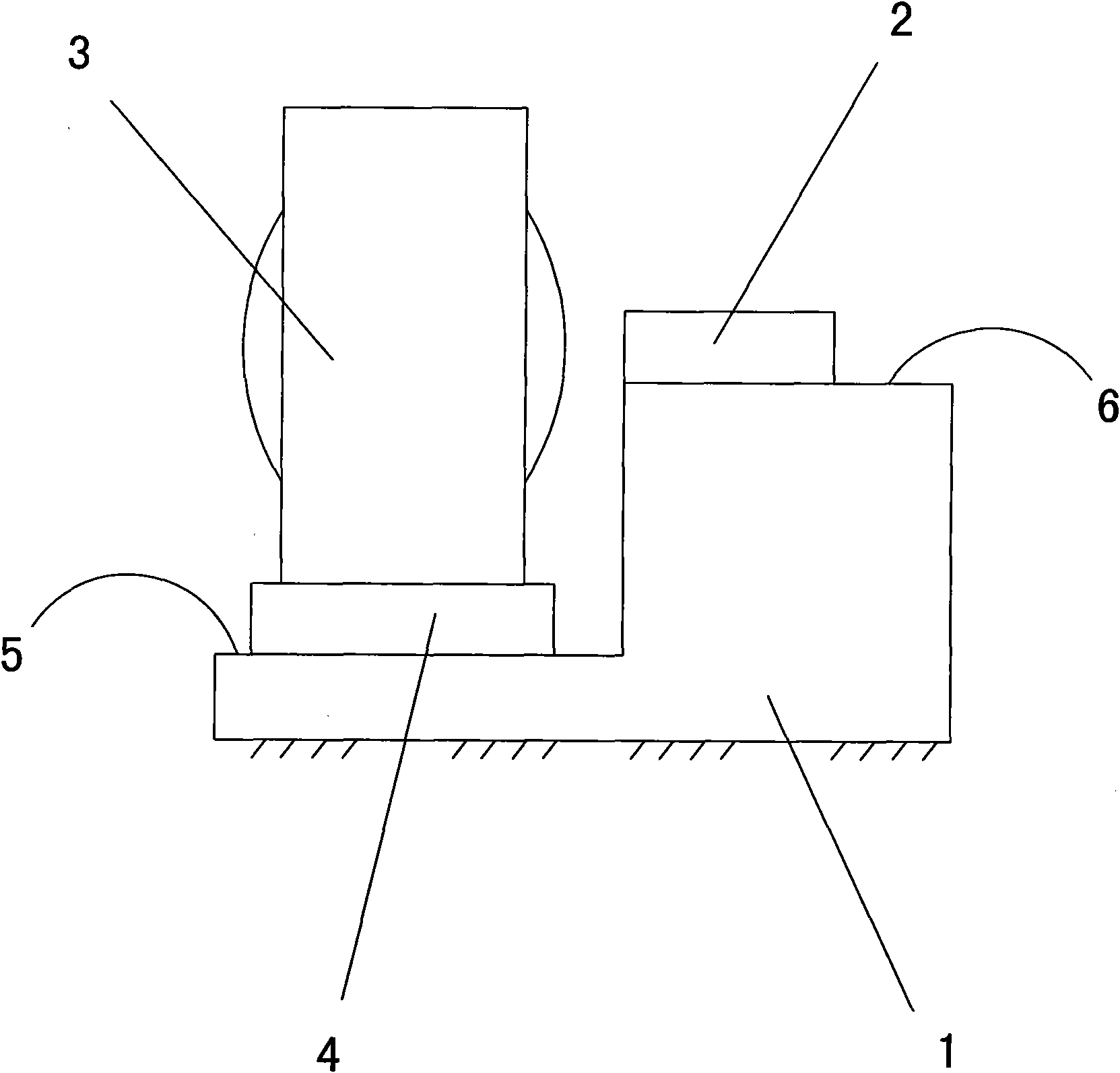

[0013] Such as figure 1 , 2 Shown: 1 is a step seat, there is a top support surface 6 above the rear side of the step seat 1, and the front side of the step seat 1 is at the bottom of and parallel to the bottom support surface 5 of the top support surface 6.

[0014] The steps of the present invention are as follows:

[0015] a. Paste the LD chip 2 on the top support surface 6 above the step seat 1, the front side of the step seat 1 has a bottom support surface 5 lower than and parallel to the top support surface 6;

[0016] b. Suspend the tiny bare coupling lens 3 above the bottom support surface 5 using a straw-type fixture, and adjust the position of the tiny bare coupling lens 3 through the straw-type fixture, so that the tiny bare coupling lens 3 is coupled with the LD chip 2 in place;

[0017] c, utilize the CCD camera to measure the gap height between the bottom surface of the tiny bare coupling lens 3 and the bottom support surface 5 from the side;

[0018] d. Move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com