Optical fiber with light-focusing function, and mfg. method thereof

A manufacturing method and optical fiber technology, which are applied in the directions of cladding optical fibers, optical waveguide light guides, and optical waveguide coupling, etc., can solve the problems of not being able to obtain good coupling between optical fibers and optical devices, and achieve easy operation, improved optical coupling efficiency, and improved manufacturing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Since the present invention may be implemented in many different ways, the embodiments described below should not be construed as limiting the present invention. The following embodiments are the following fully disclosed embodiments, and are provided so that those skilled in the art can fully understand the scope of the present invention.

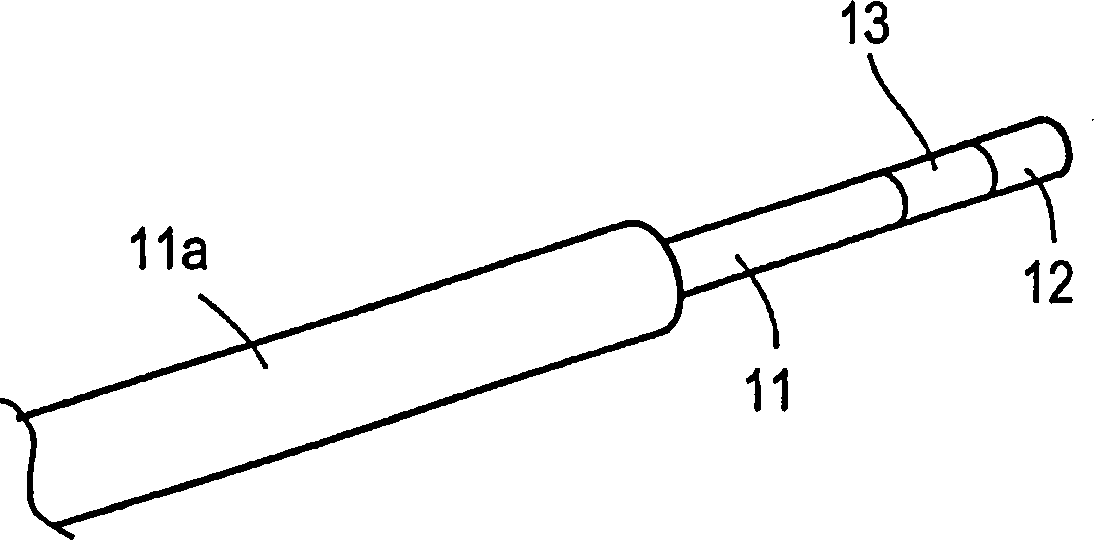

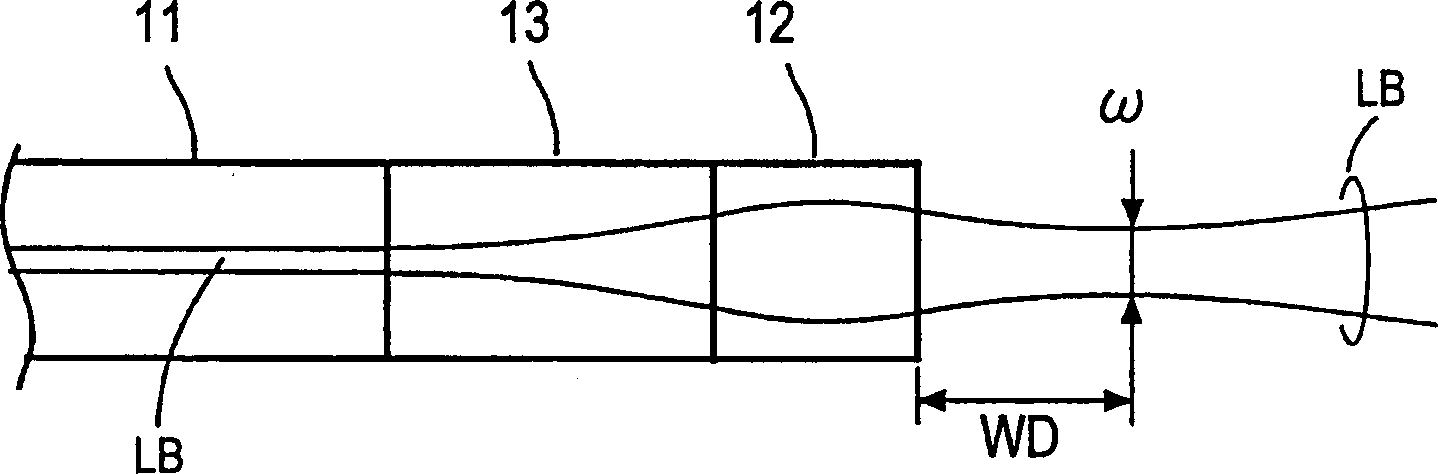

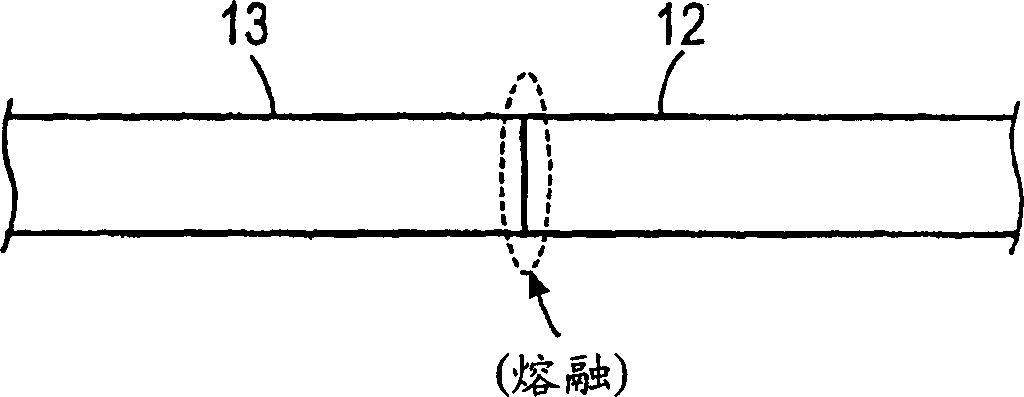

[0024] figure 1 is a perspective view showing a first embodiment of the optical fiber of the present invention, particularly showing its end configuration. The optical fiber of this first embodiment has an end face of a single-mode optical fiber 11 connected to one end face of a short block spacer 13 of a set length having the same refractive index as the core portion, and the other end face of the spacer 13 is connected to a set length of the spacer 13 . The short block-shaped GI fiber (the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com