Patents

Literature

44results about How to "Wide range of designs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

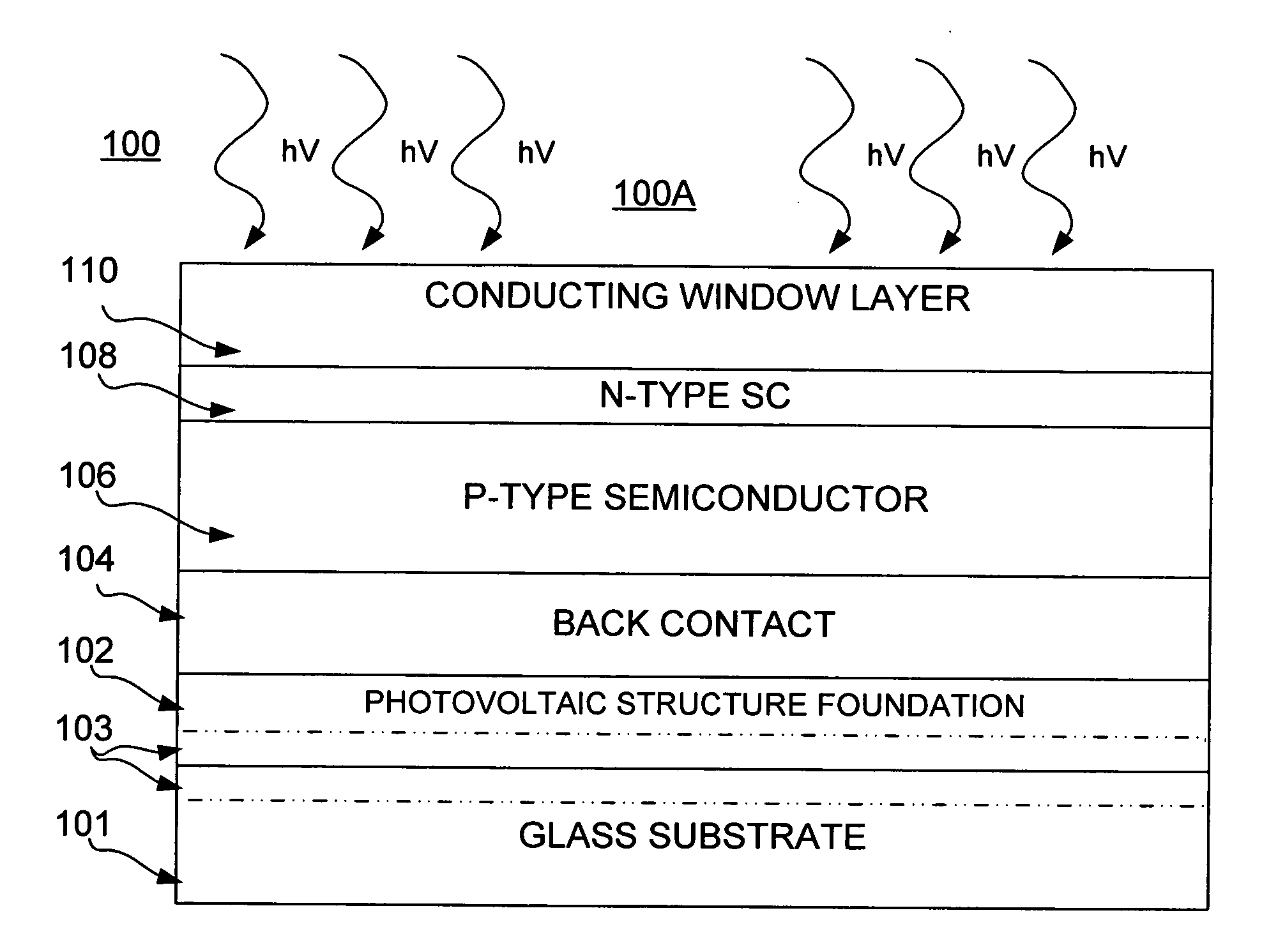

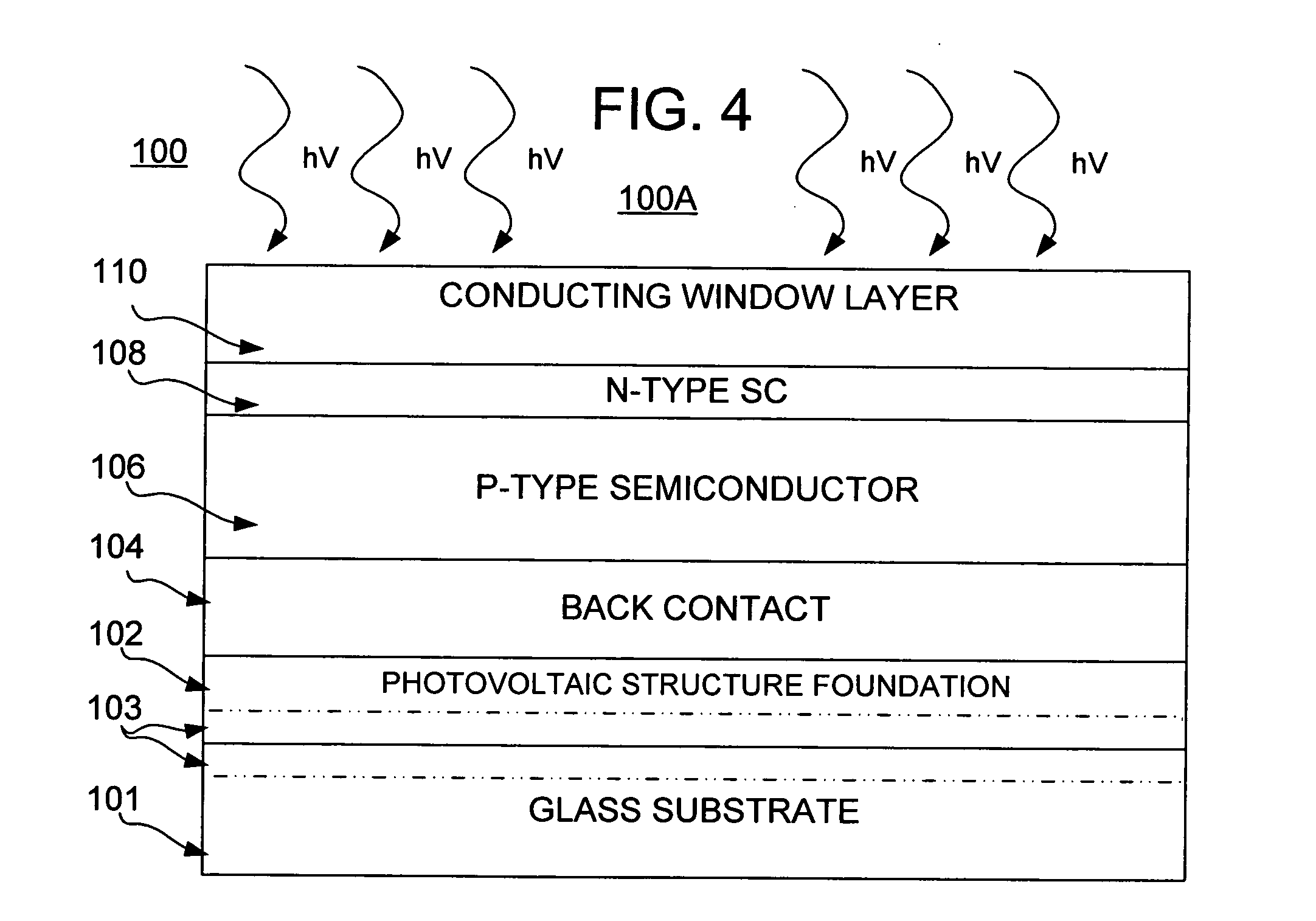

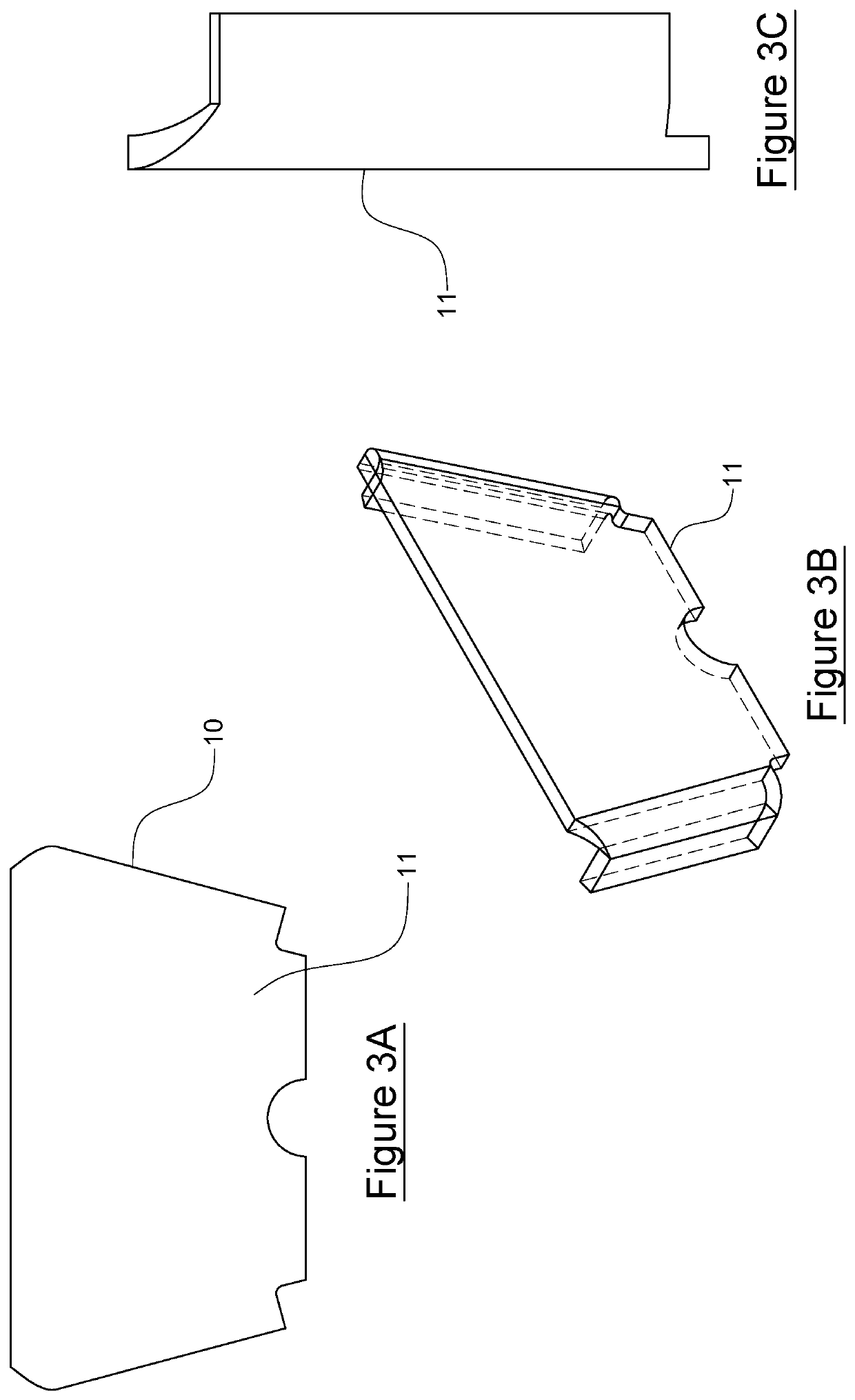

Thin film photovoltaic structure

InactiveUS20070277875A1Improve conversion efficiencyWide range of designsPhotovoltaic energy generationSemiconductor devicesSingle crystalEngineering

Photovoltaic devices include an insulator structure bonded to an exfoliation layer, preferably of a substantially single-crystal donor semiconductor wafer, and at least one photovoltaic device layer, such as a conductive layer. In a preferred embodiment, a device may include a conductive layer adjacent to the insulator substrate and integral to the exfoliation layer, near the side that faces the insulator substrate, such as between the insulator substrate and the exfoliation layer. In a further preferred embodiment, a device may include a plurality of photovoltaic device layers distal to the insulator substrate and in or on the exfoliation layer, preferably having been epitaxially grown on the exfoliation layer after the exfoliation layer has been anodically bonded to the insulator substrate by means of electrolysis.

Owner:CORNING INC

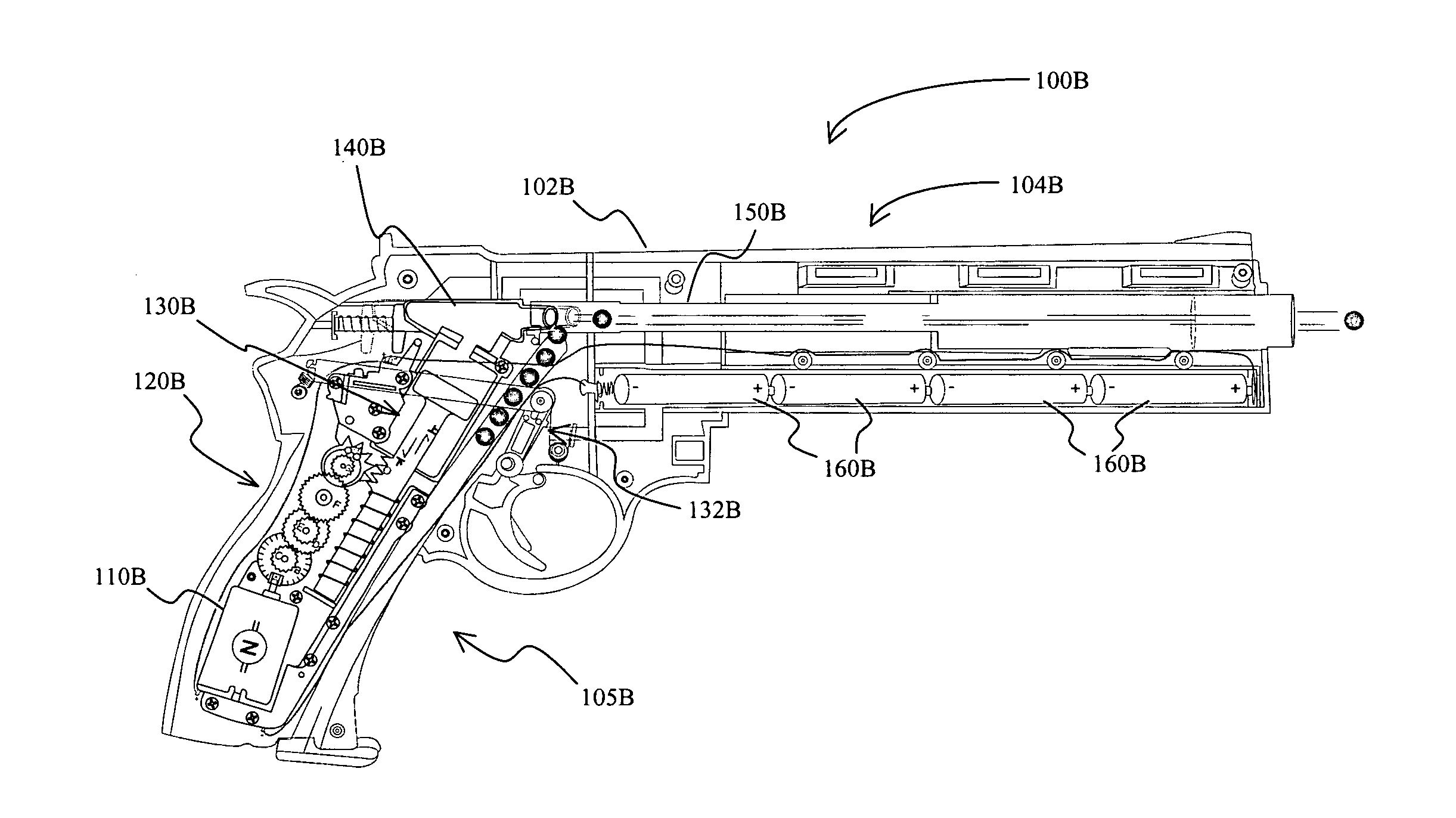

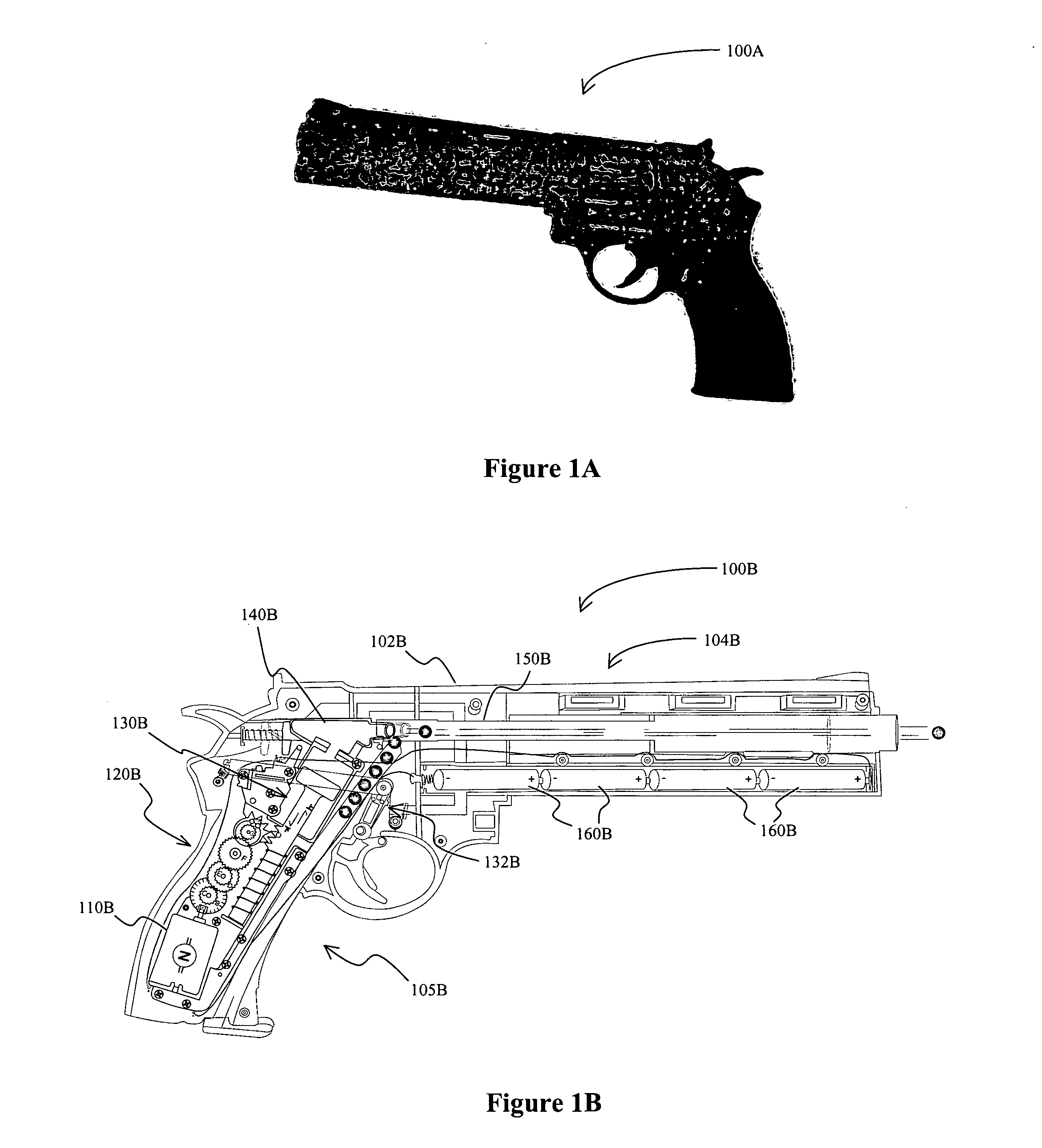

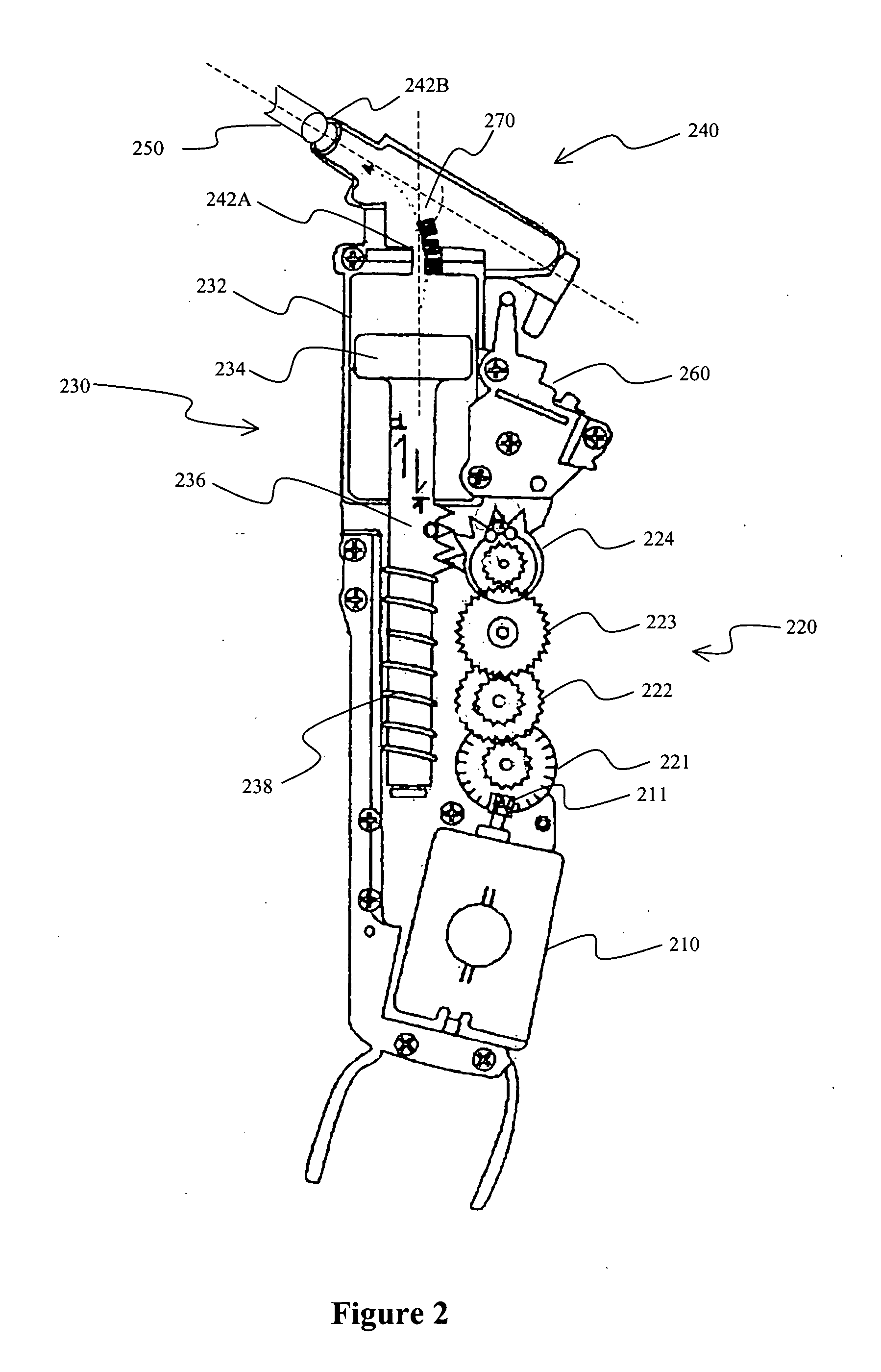

Motorized airgun

InactiveUS20080078369A1Easy constructionWide range of designsCompressed gas gunsSubject matterSpace requirements

An airgun has a pneumatic mechanism that is driven by an electrical motor to provide a blast of air, wherein the pneumatic mechanism is in a non-coaxial and angled position relative to the barrel, and wherein the air is delivered to the barrel via a preferably angled intermediate conduit. Spatial separation of the pneumatic mechanism from the axis of the barrel allows for substantially simplified constructions and use of light-weight material, and further provides a wide variety of handgun designs as the only space requirement for the projectile delivery portion is the barrel. Therefore, in one especially preferred aspect of the inventive subject matter, the airgun is configured a revolver.

Owner:VINBO INDAL

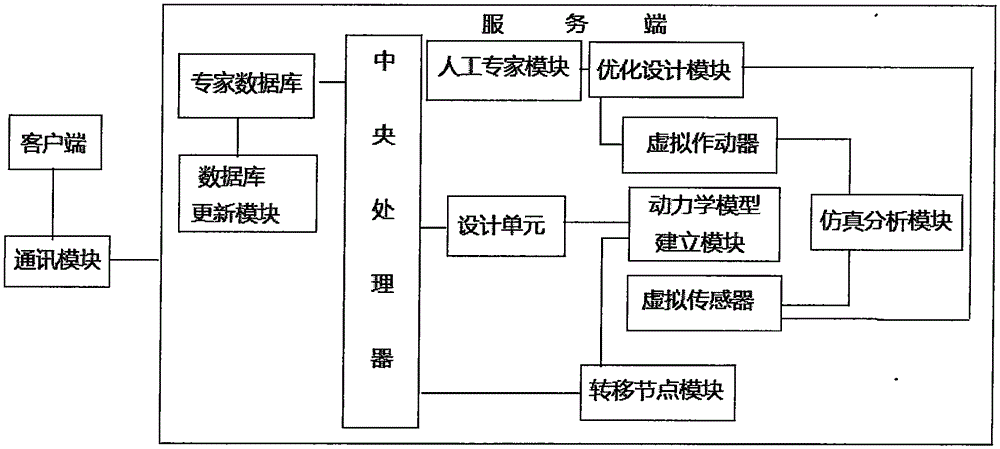

Industrial design service platform

InactiveCN105468859AQuality improvementComprehensive dataData processing applicationsDesign optimisation/simulationClient-sideActuator

The invention discloses an industrial design service platform which comprises a client and a server, wherein the client and the server are connected by a communication module; the client is used for inputting a client request, sending the client request to the server, receiving data sent by the server, and displaying the data; and the server comprises an expert database, a database updating module, a design unit, a kinetic model establishing module, a virtual actuator, a virtual sensor, a node transferring module, a simulation analysis module, an optimization design module, an artificial expert module and a central processing unit. According to the industrial design service platform disclosed by the invention, different design works can be generated according to different requirements; the database is perfect in data; the industrial design service platform has updating and inquiring functions; the server has a data optimization function; the integral design optimization process is wide in design range, simple in operation and visual in display; and quality of the generated works is greatly improved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

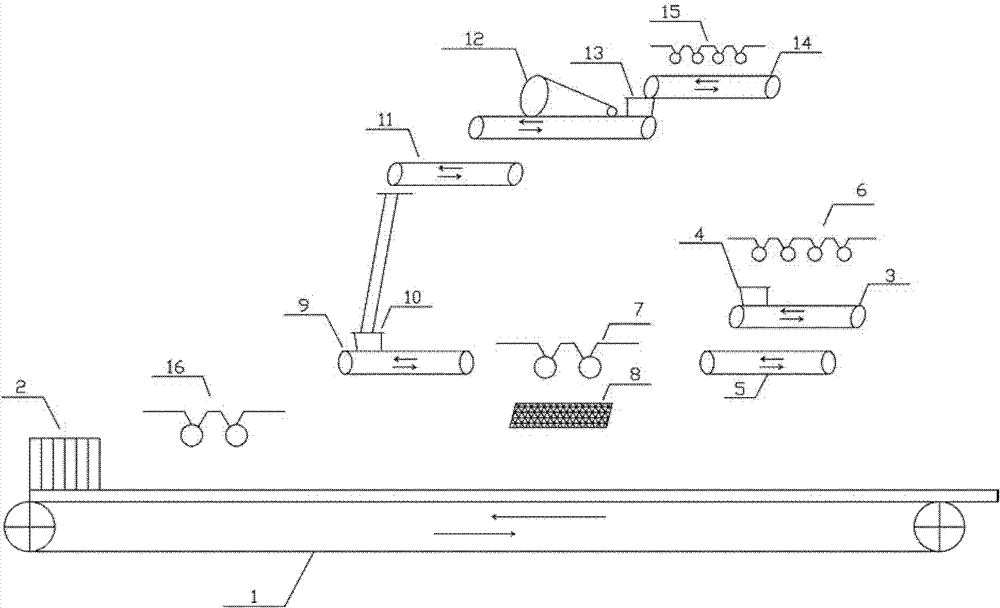

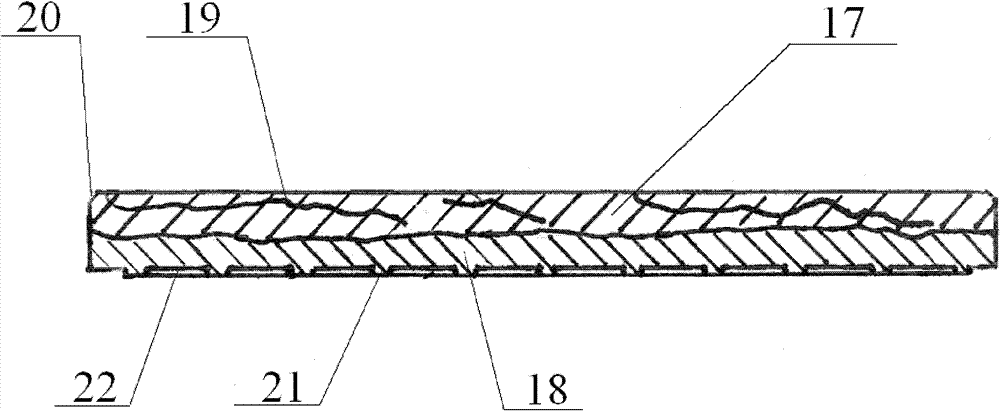

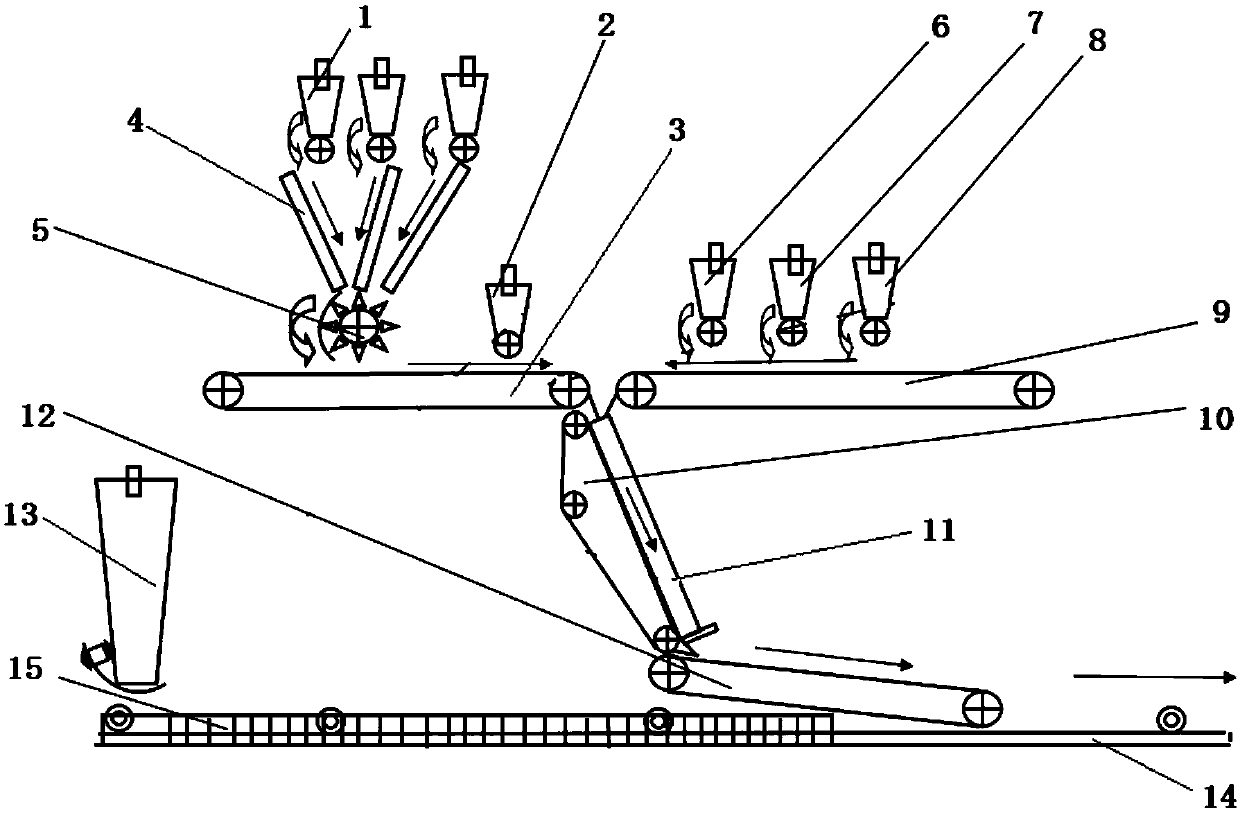

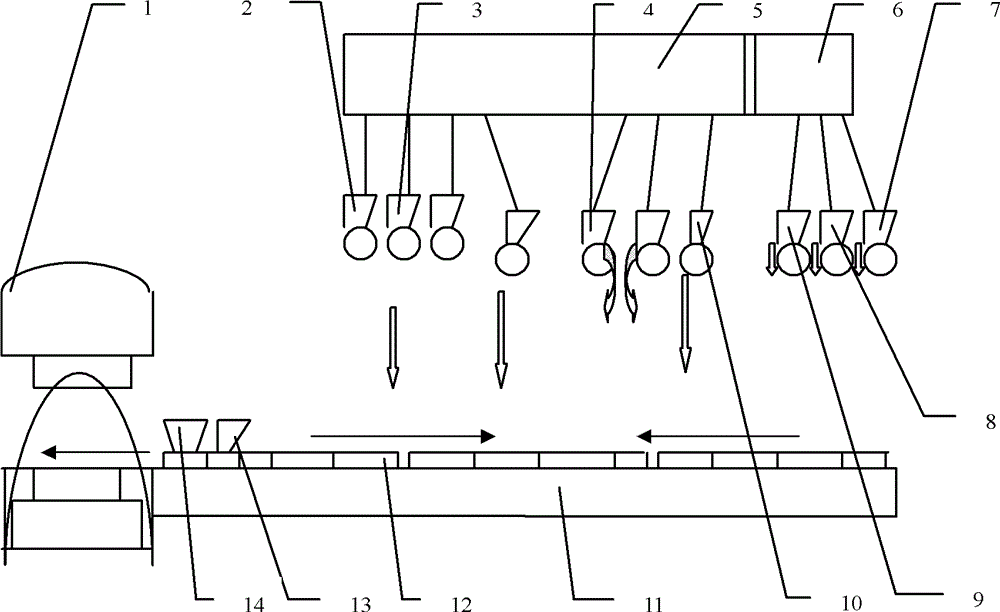

Tablet line flower fabric technology for vitrified tiles

InactiveCN102773912ANatural and smooth texture linesRealistic imitation marble effectShaping conveyorsFree fallingControllability

The invention relates to a tablet line flower fabric technology for vitrified tiles. The technology comprises the steps of fabric conveying, line fabric conveying, tablet pelletizing and fabric combining and stacking in areas. The fabric conveying includes that micro powder fabric is placed into a fabric hopper, and subjected to blanking in a rotary mode into a fabric storage hopper through a fabric roller, free falling and stack on a plane plate; the line fabric conveying includes that the line fabric is blanked onto a baffle and a shaking screen by the rotation of a line blanking roller and evenly scattered below the baffle and the shaking screen, and covers the fabric; the tablet pelletizing includes that powder fabric is ground into micro powders and pressed into tablet pellets, the pellets are added into the fabric storage hopper and fall on the fabric and the line fabric in a suspension mode; and the tablet pelletizing and fabric combining and stacking in areas includes that the fabric, the line fabric and the sheet pellets are stacked successively in a circulation running board mode, fillers are filled to perform flattening, and the mixtures are conveyed to a press machine cavity through a fidelity grille to complete the pressing. The tablet line flower fabric technology for vitrified tiles has the advantages of showing polycrystalline elements in natural stones, being natural and smooth in grains and lines, few in human traces, high in controllability and the like.

Owner:JIANGXI CIMIC CERAMICS +1

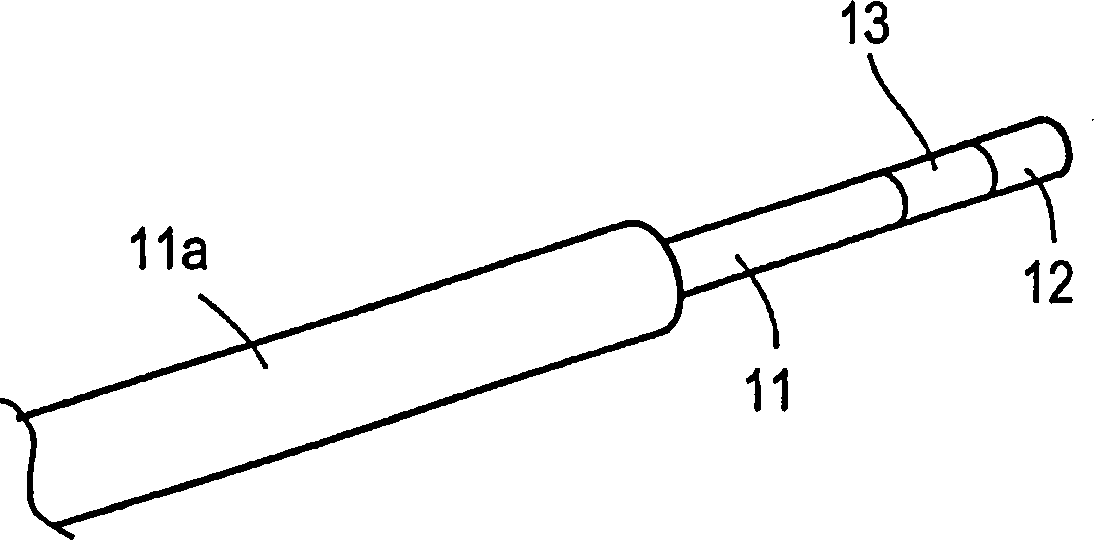

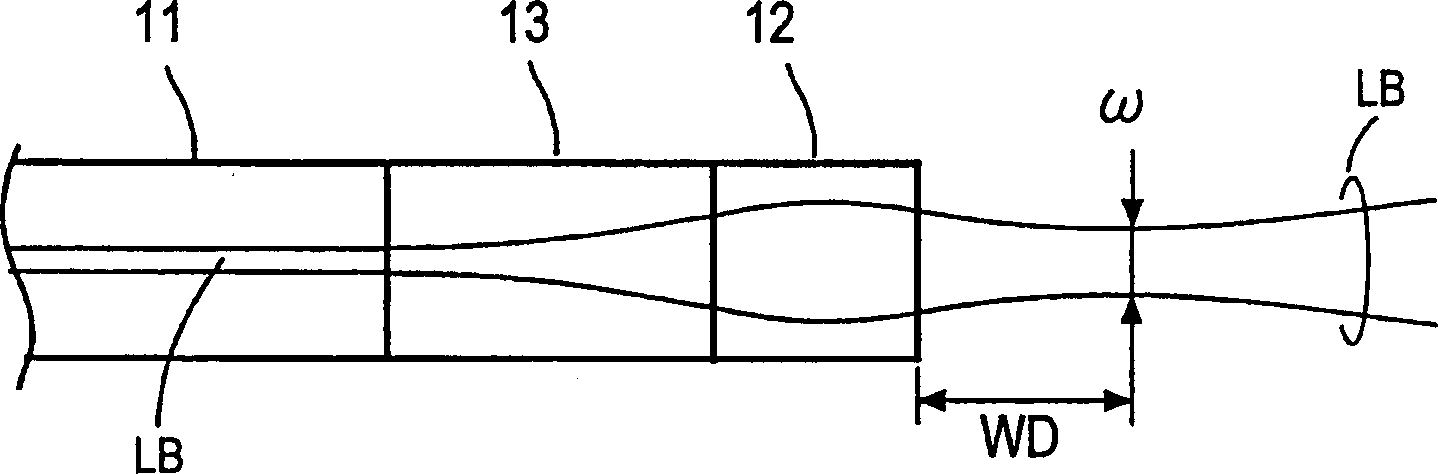

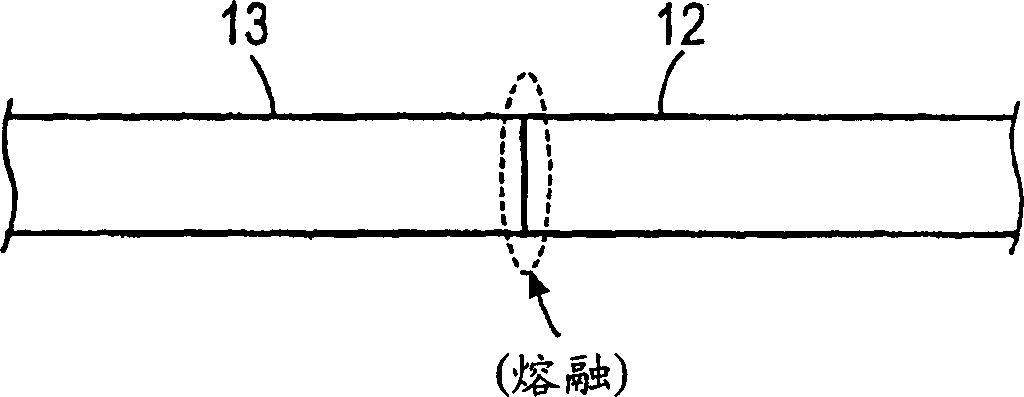

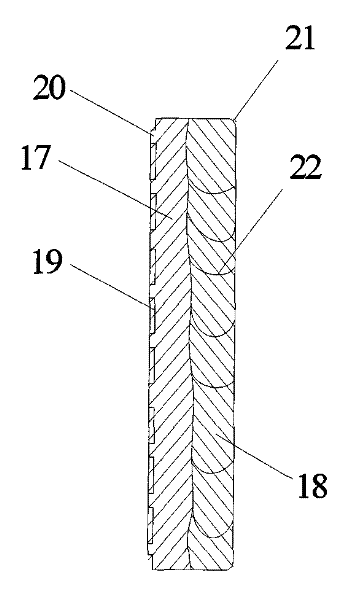

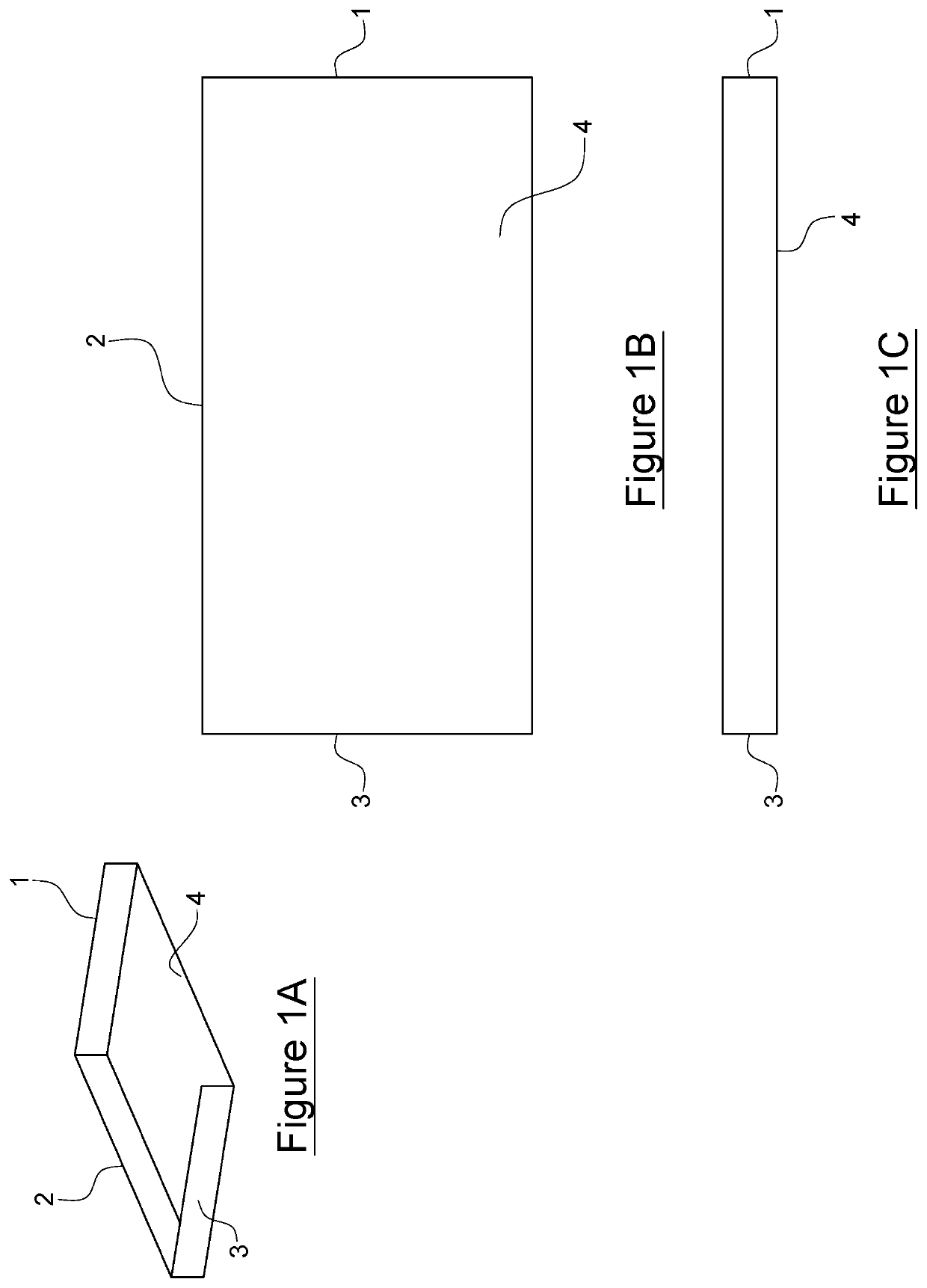

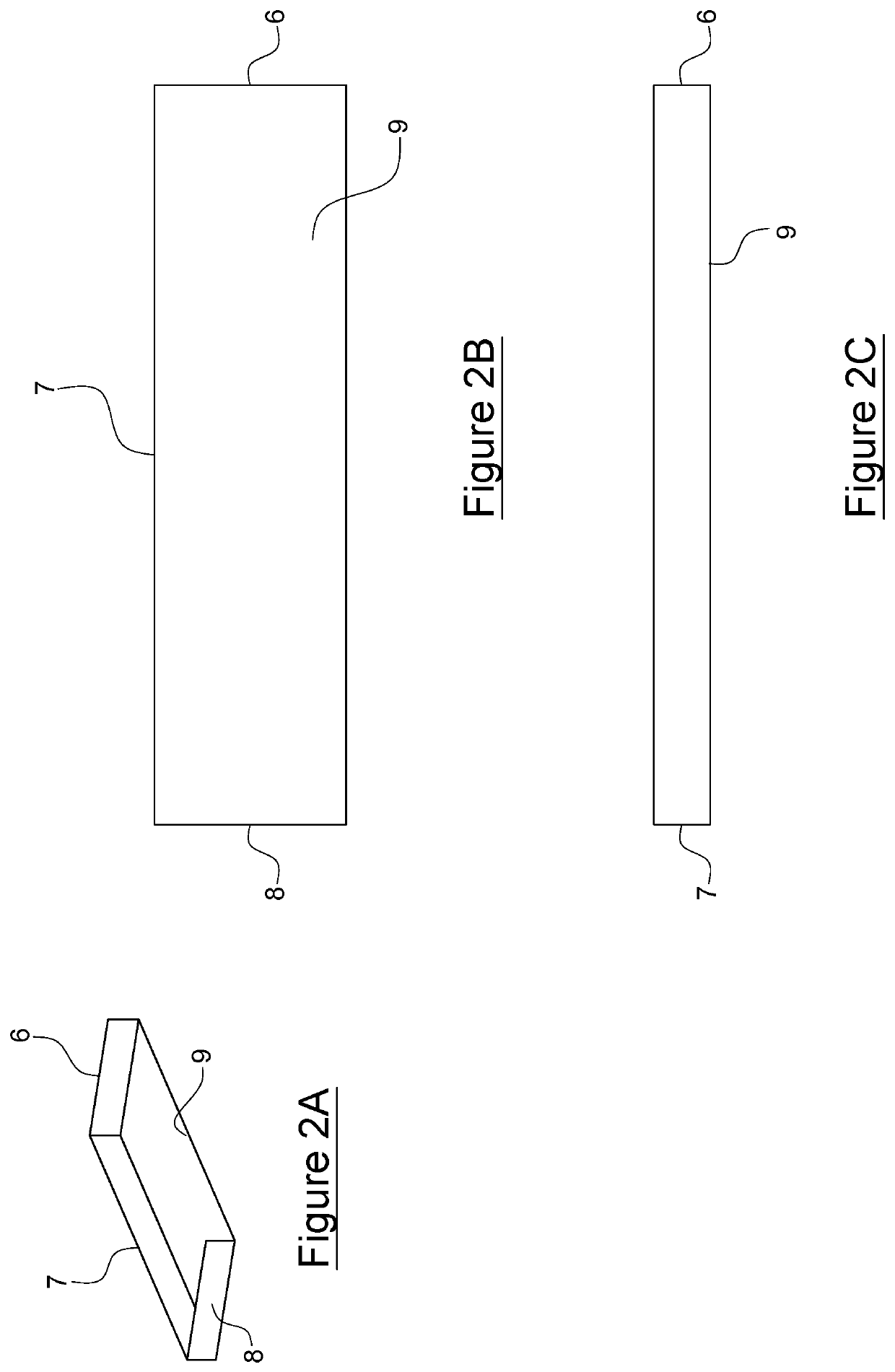

Optical fiber with light-focusing function, and mfg. method thereof

InactiveCN1402029AIncrease freedomWide range of designsCladded optical fibreCoupling light guidesRefractive indexOptical fiber cable

There are provided an optical fiber having a light focusing function and capable of setting the distance WD to the beam waist position and the beam waist diameter omega independently, and a method of manufacturing the optical fiber efficiently and at high accuracy. An end surface of a single mode optical fiber is connected to one end surface of a very short piece of spacer constituted of an optical fiber the diameter of which is identical to that of the single mode optical fiber and the refractive index of which is uniform. The other end surface of the spacer is connected to one end surface of a very short piece of graded index optical fiber the diameter of which is identical to that of the single mode optical fiber and the refractive index of which varies continuously in the direction of its diameter. The lengths of the spacer and / or the GI fiber can be adjusted to set the beam waist distance WD and the beam waist diameter omega to a proper value suitable for an optical device to be optically coupled to the optical fiber.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

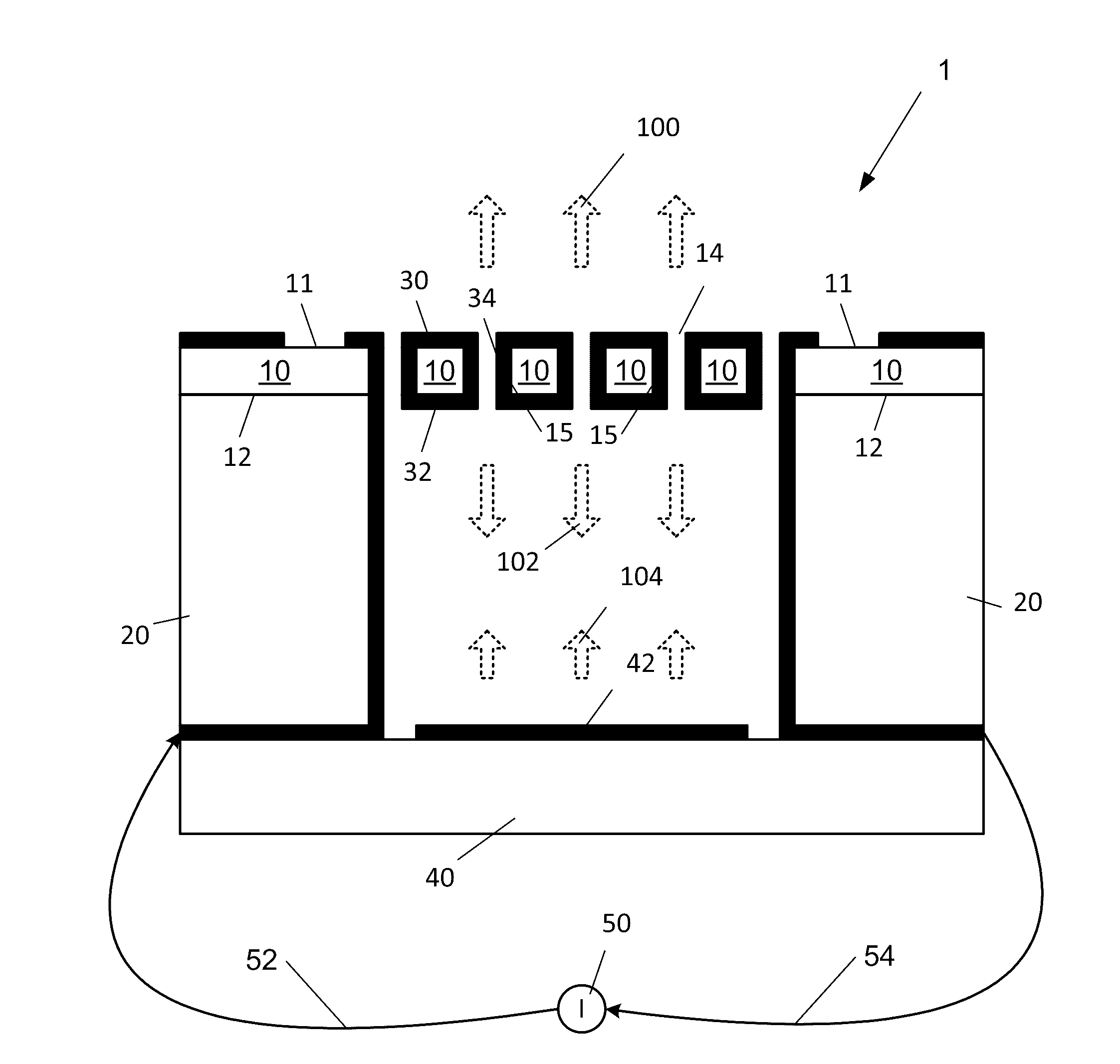

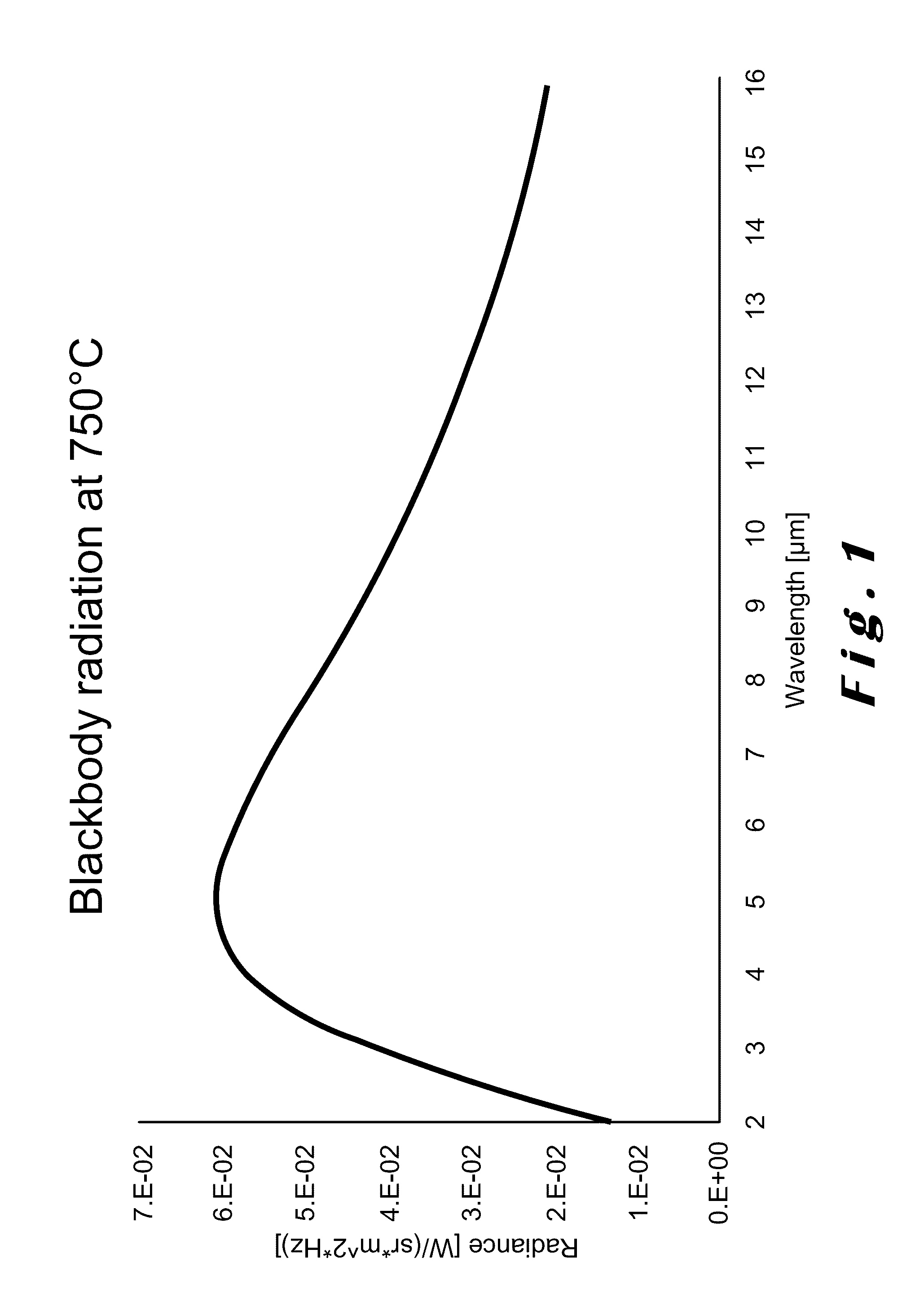

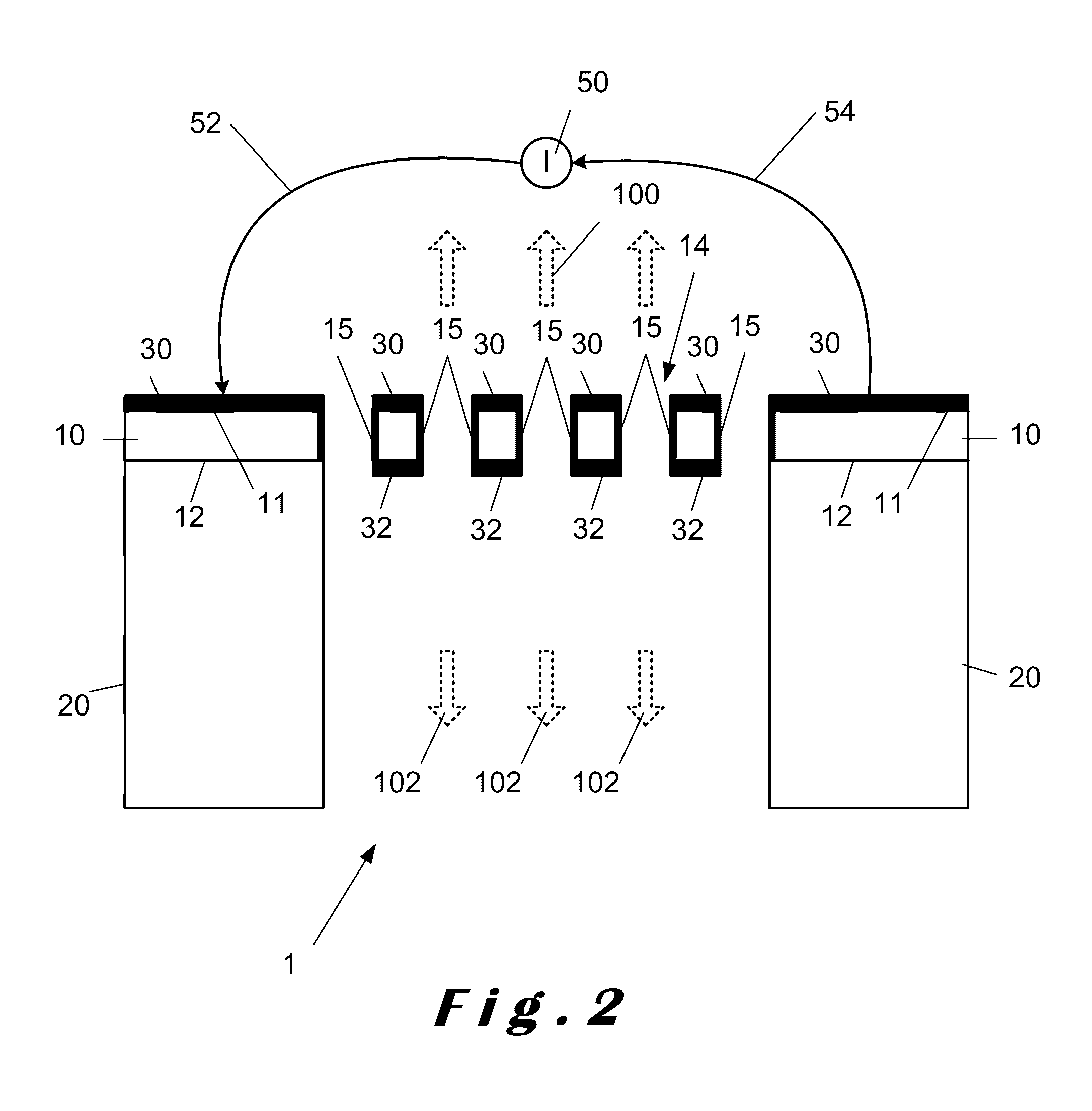

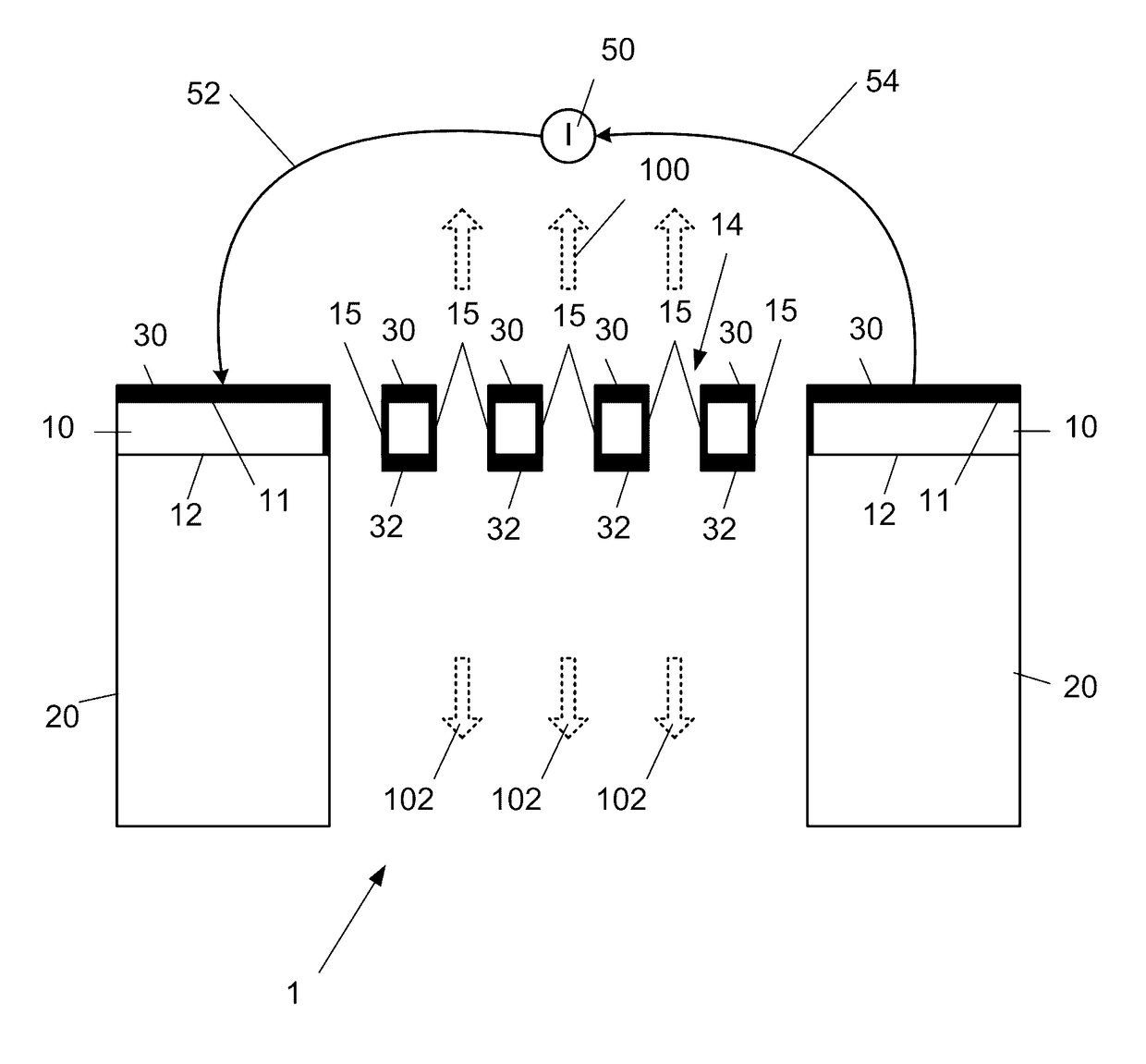

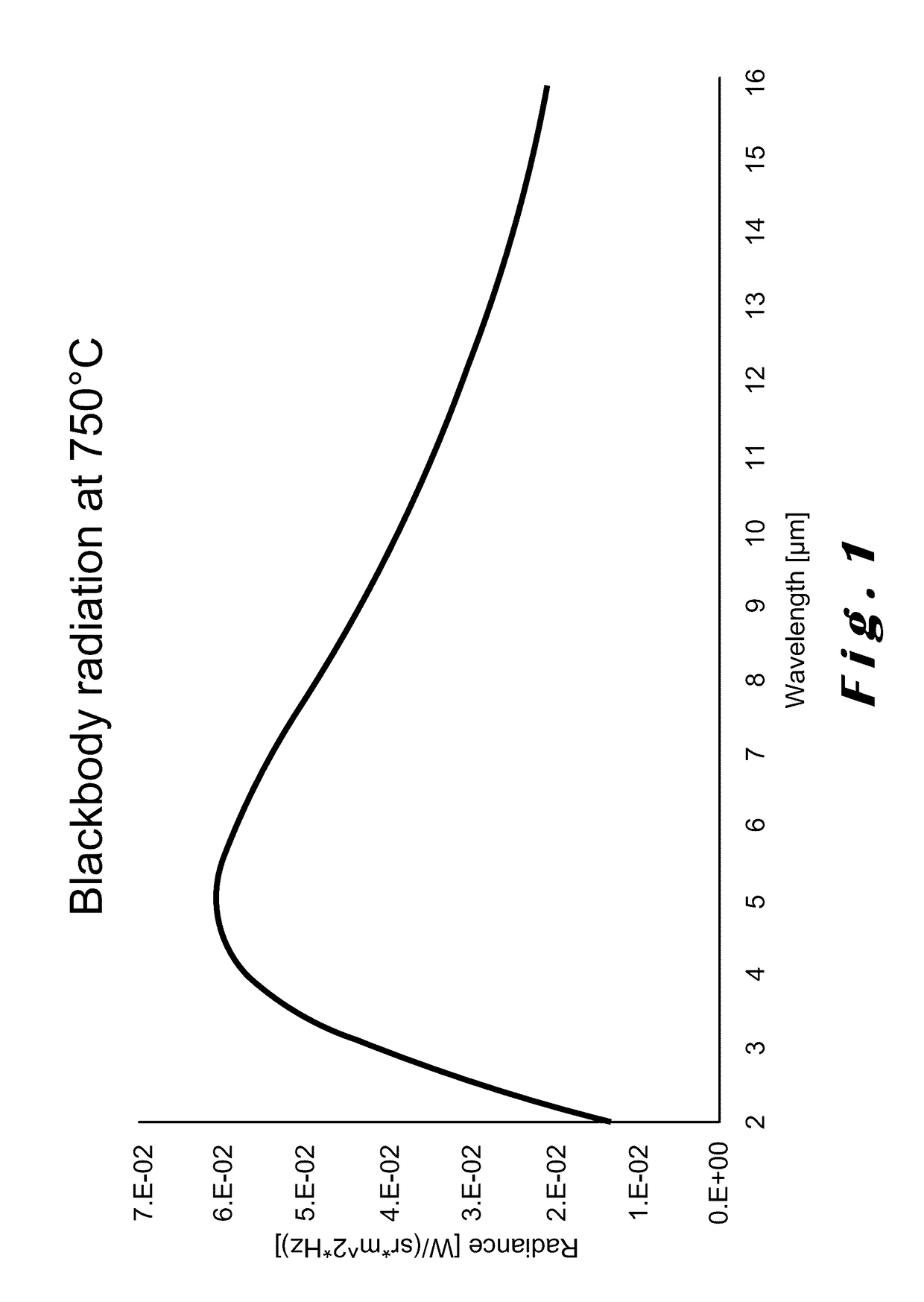

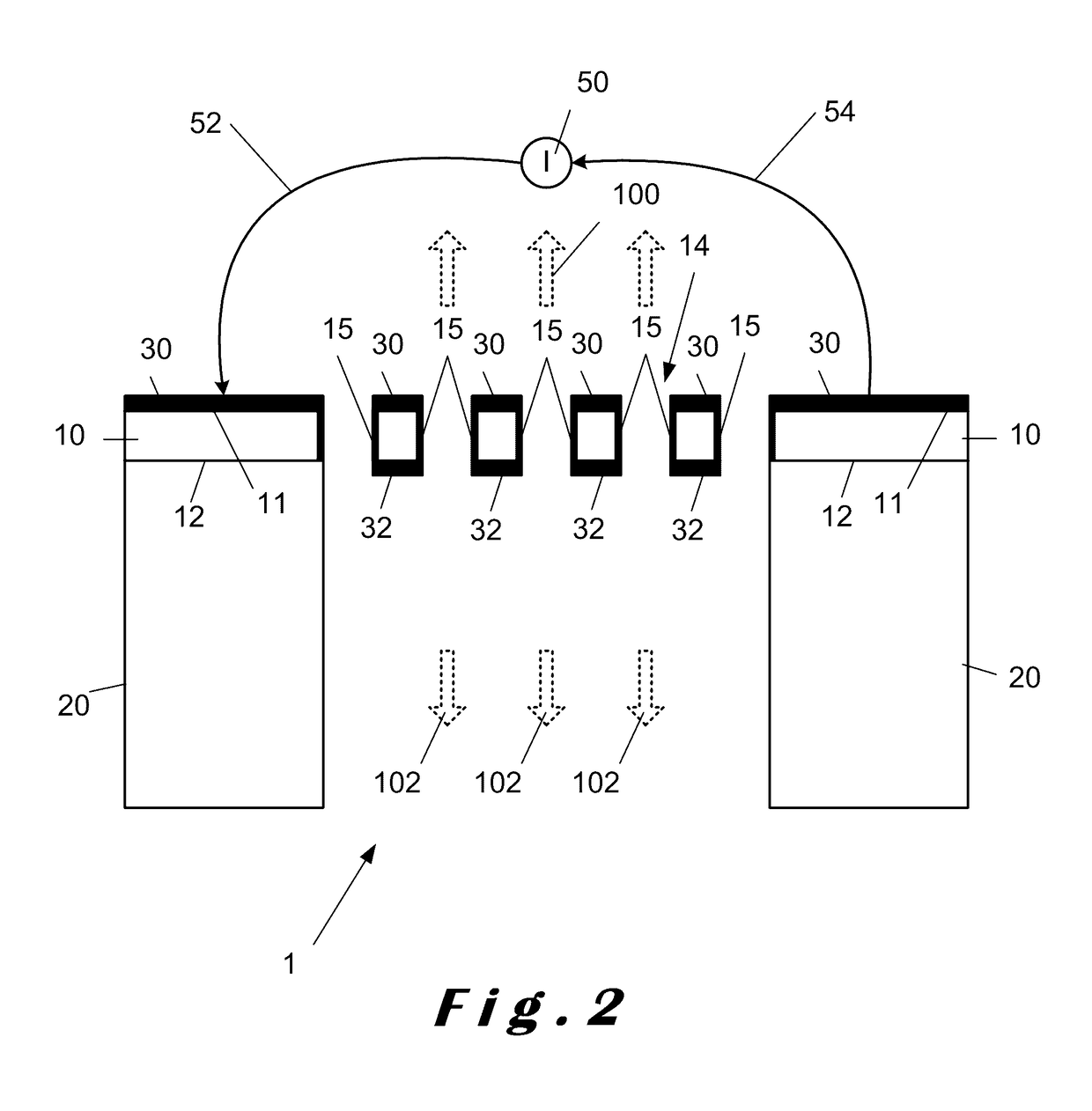

Infrared emitter

ActiveUS20160343921A1Enhancing emitted infrared light intensitySuppression frequencyLamp incadescent bodiesSolid-state devicesThin metalLight beam

The disclosure concerns an infrared emitter is provided comprising a metalized membrane emitting infrared light in operation. The membrane comprises a two dimensional array of infrared wavelength sized through-holes and to each side a thin metal layer comprising also an array of through-holes. The through-holes are arranged as a two-dimensional periodic array and each of said through-holes have a cross section having a maximum and a minimum dimension of less than any wavelength of the emitted infrared light. The peak wavelength of the emitted infrared light is proportional to the periodicity of the through-holes. At least one of the metal layers is connected to an electrical current source that provides an electrical current that heats at least one of the metal layers so that a narrow bandwidth and highly directive light beam of infrared light is emitted. The membrane is arranged on a membrane support and both are made of a material that resists to temperatures higher than 400°.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

High-emulation art drawing tile copying method

ActiveCN105082857ARealistic color effectImprove controllabilityImage analysisDecorative surface effectsColor effectComputer graphics (images)

The invention relates to a high-emulation art drawing tile copying method. The method includes the following steps that firstly, a laser radiation device is arranged on a digital scanner, an existing drawing is scanned through the digital scanner under the effect of laser radiation, and the existing drawing is converted into a digital image; secondly, color comparison and color difference management are conducted on the obtained digital image; thirdly, printed materials are selected, and printing is conducted through a high-end inkjet printer; and fourthly, high-temperature fidelity color sintering is performed, and then post-processing is conducted. Compared with the prior art, the method has the beneficial effects of being realistic in product color effect, high in controllability and the like.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

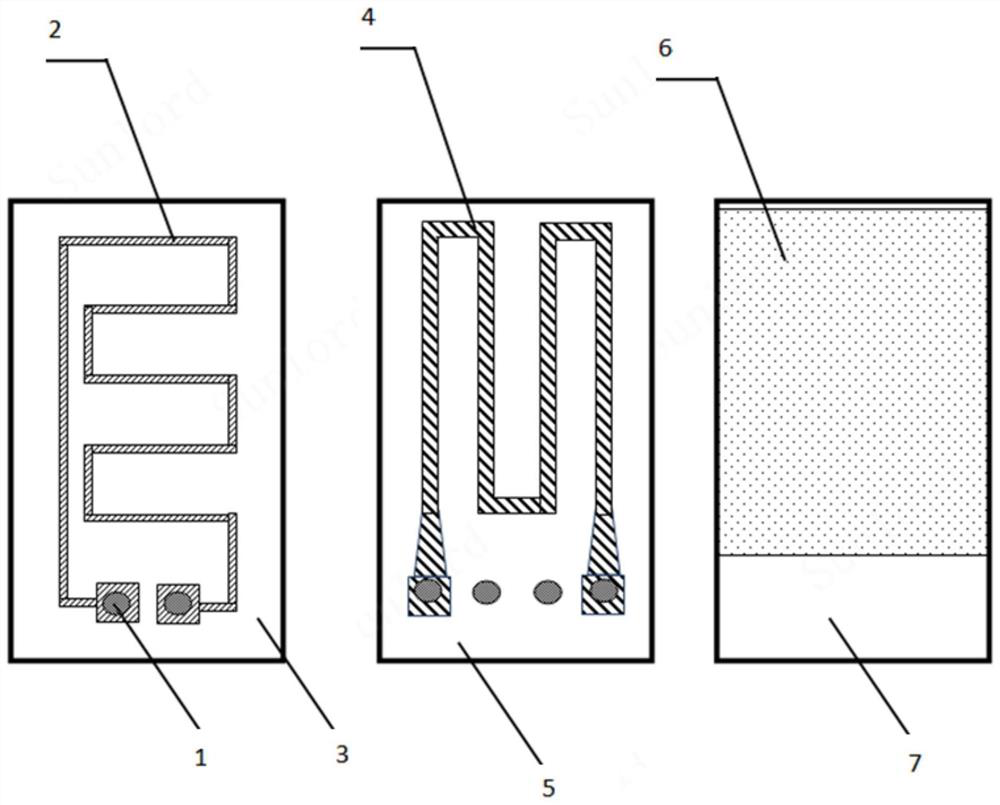

Shifting-sand-textured glass ceramic tile preparation device

InactiveCN109986689AControllable feeding timeThe feeding amount is easy to controlFeeding arrangmentsAuxillary shaping apparatusMetallurgyCascading effects

The invention relates to a shifting-sand-textured glass ceramic tile preparation device. The shifting-sand-textured glass ceramic tile preparation device comprises a material vehicle, a base materialfeeding unit arranged at the back part of the material vehicle, an aggregate and transfer printing unit arranged at the middle front part of the material vehicle, a color powder feeding unit and a line texture powder feeding unit arranged at an inlet of the aggregate and transfer printing unit, and a controller used for controlling the feeding order of each feeding unit. During working, the controller controls the front and back movement of the material vehicle, and then controls the feeding order of the base material, the color powder and the line texture powder, the shifting-sand texture isformed on a flat plate on the upper surface of the material vehicle, and then burning and completing are conducted. Compared with the prior art, the texture cascade effect of the product of the preparation device is imitation-stone, realistic, natural and smooth, the color and the powder sandiness are soft in transition, each texture is matched with the color by adjusting the technical parameters,the products of different color systems can be produced, the effect is ahead the effect of the similar product in the market, and the preparation process is high in controllability.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

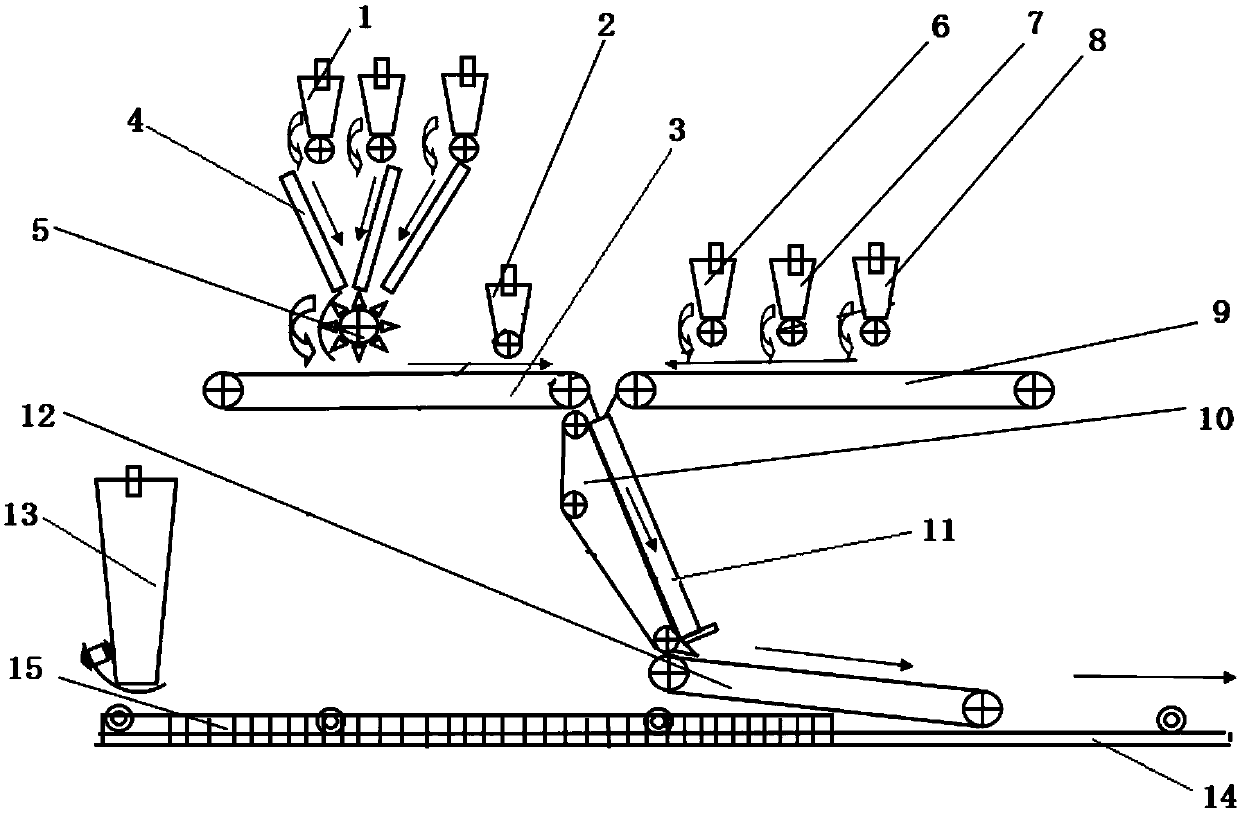

Distributing technology simulating crystal granite by vitrified tiles

InactiveCN105500512ARealistic effectImprove controllabilityFeeding arrangmentsEngineeringControllability

The invention relates to a distributing technology simulating crystal granite by vitrified tiles. The equipment comprises a powder distributing vehicle, wherein a tabletting and pelletizing device, a grinding disc pulverizing and separating device, a particle conveying device, a powder distribution conveying device and a stacking device are arranged above the powder distributing vehicle, the tabletting and pelletizing device and the grinding disc pulverizing and separating device are arranged above the particle conveying device, and the powder distribution conveying device and the stacking device are arranged below the particle conveying device. Compared with the prior art, the distributing technology has the advantages that a crystal particle effect is realized, and particles are even in distribution, free of cracks, high in controllability and the like.

Owner:JIANGXI CIMIC CERAMICS +1

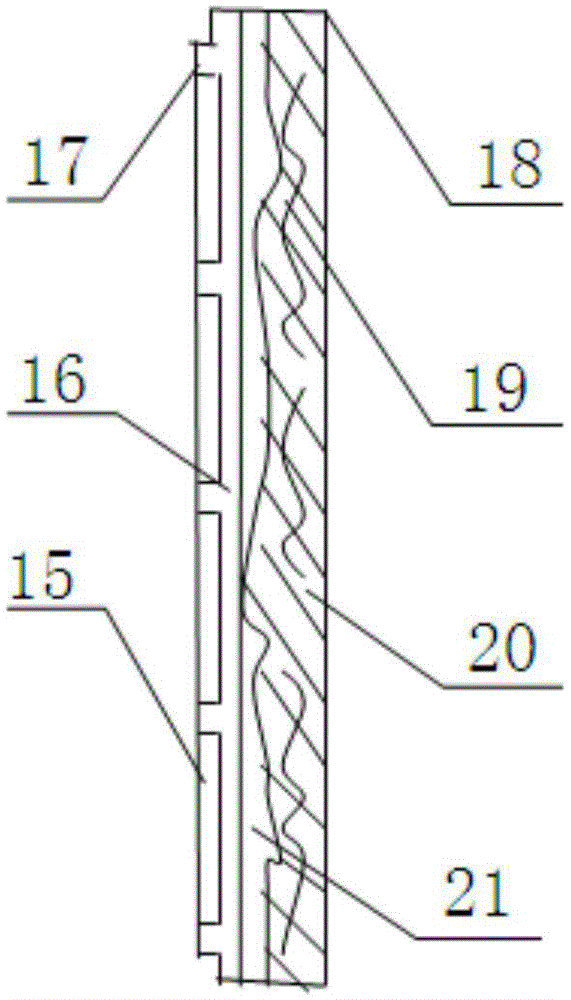

Flocking corset and preparation method thereof

The invention discloses a flocking corset including a front piece and a back piece which comprise elastic spandex. The external surface or the internal surface of each of the front piece and the back piece is provided with a flocking area, and the flocking areas are uniformly fixedly provided with villi; one side of the front piece is connected with one side of the back piece in a suturing mode, and the other side of the front piece and the other side of the back piece are in detachable and adjustable connection; the internal surface layer of the abdomen of the front piece is provided with a health-care paste, and the health care paste comprises a heat-emitting fabric and a plurality of circular or hexagon prismatic spontaneous hot spots evenly coated on the internal layer of the heat-emitting fabric. The invention also discloses a preparation method of the flocking corset. The corset provided by the invention has the tensile resilience of up to more than 95%, does not delaminate with water washing, has long effective service life, is convenient and comfort to wear, and has a warm-keeping effect; the corset can accelerate abdominal blood circulation, promotes metabolism, keeps human abdomens warm, and has a certain health care function for people with cold abdomens; and the corset can massage abdominal skin, plays roles in activating cells and burning fat, and is in favor of reducing abdominal fat and keeping in shape.

Owner:KUNSHAN TENGFEI UNDERWEAR TECH

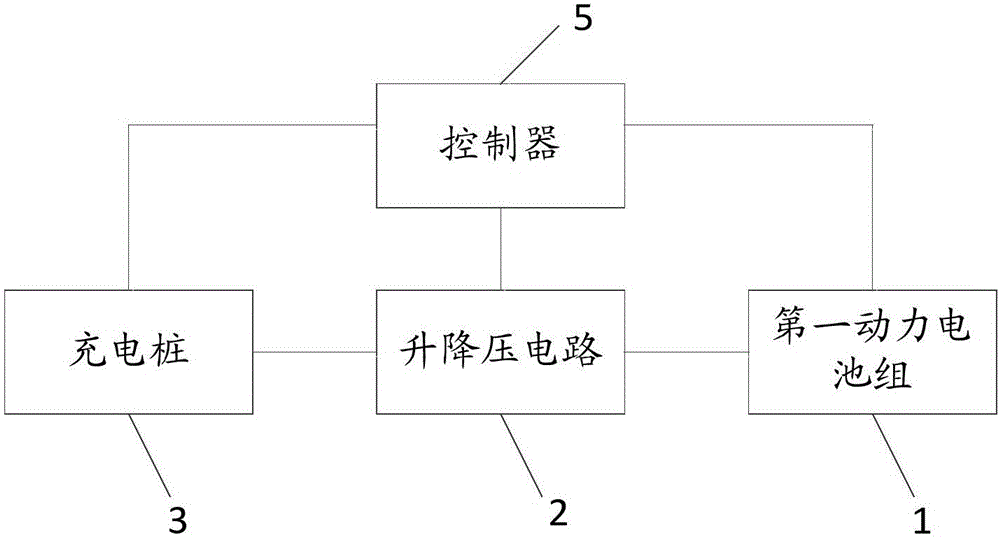

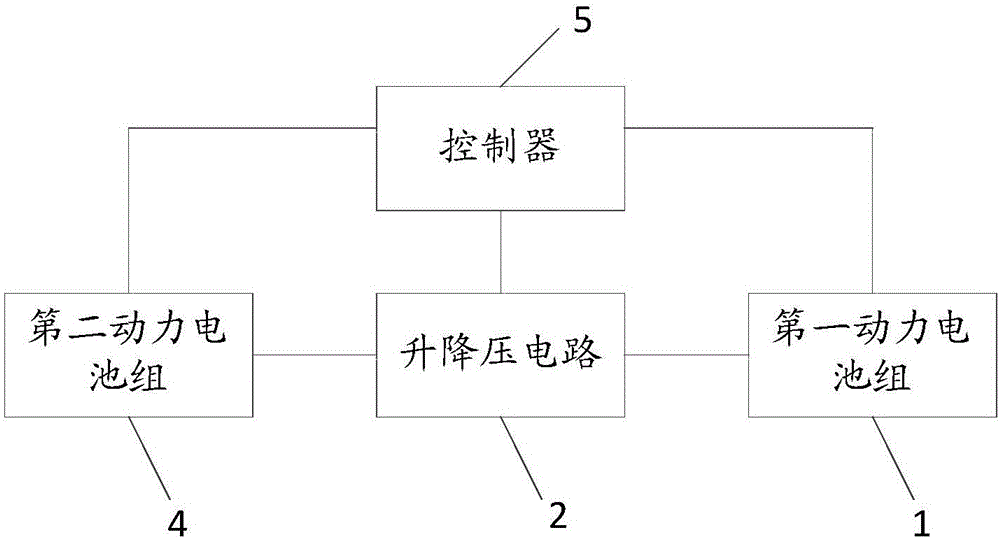

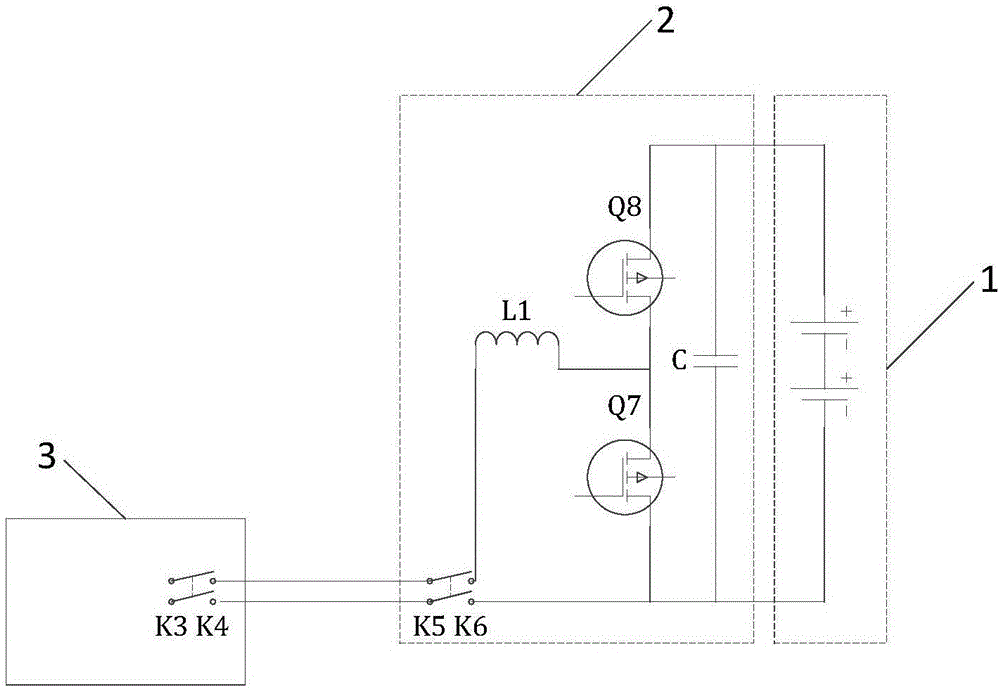

Charging system of electromobile and electromobile

InactiveCN107176050AIncrease the output voltageWide output voltage rangeCharging stationsDc-dc conversionPower batteryElectrical battery

The embodiment of the invention provides a charging system of an electromobile and the electromobile. The charging system comprises a first power battery unit and a buck-boost circuit. The first end of the buck-boost circuit and the first power battery pack are connected. When the second end of the buck-boost circuit is connected with a charging pile, and the maximum output voltage used for the charging pile is less than the battery voltage of the first power battery pack, the output voltage of the charging pile is enlarged; and when the second end of the buck-boost circuit is connected with a second power battery pack of other electromobiles, the voltage of the first power battery pack is output to the second power battery pack. According to the charging system of the electromobile and the electromobile, the problem that the voltage design range of the battery voltage is limited by the output voltage range of the quick charging pile in the prior art is solved.

Owner:BEIJING ELECTRIC VEHICLE

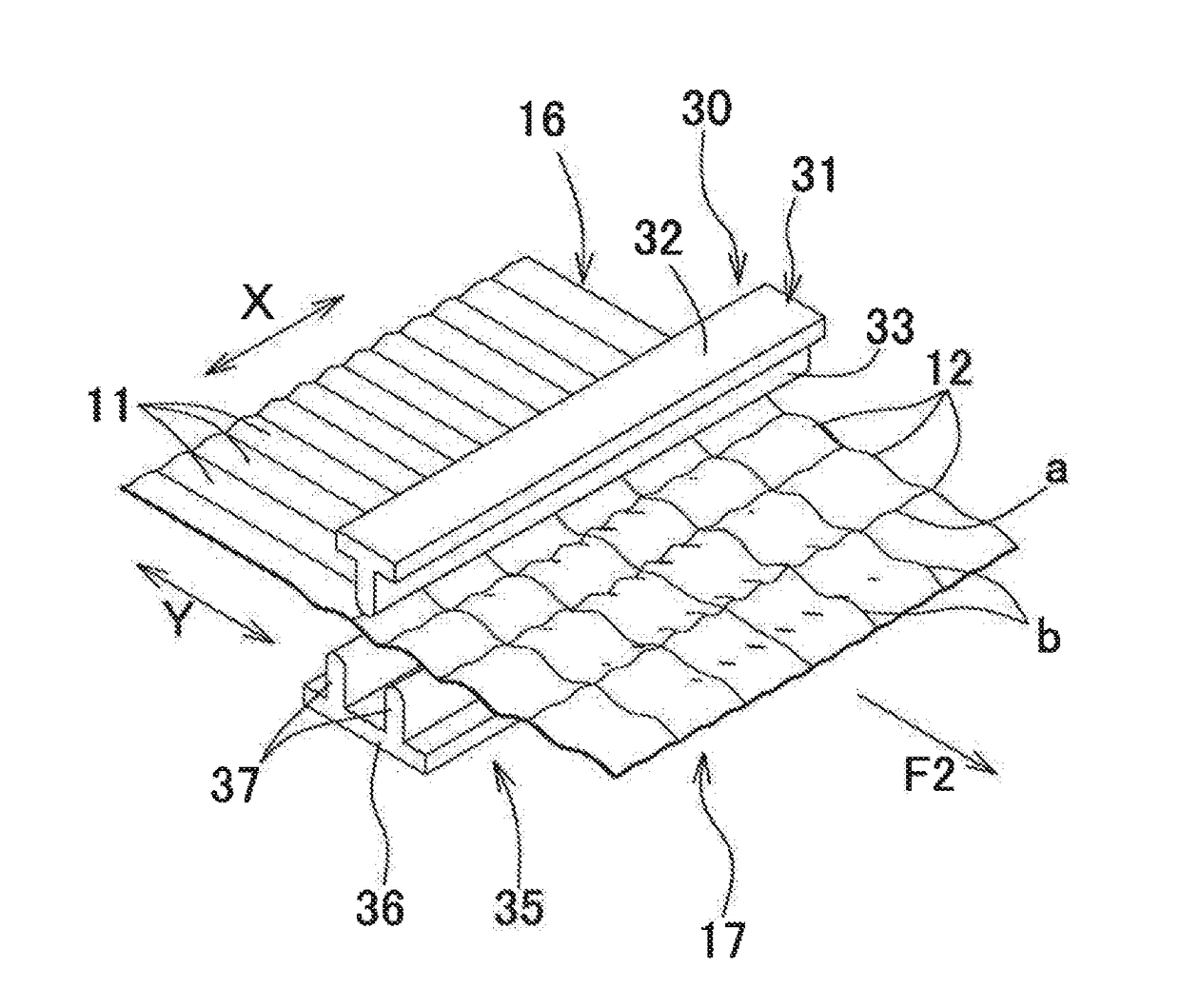

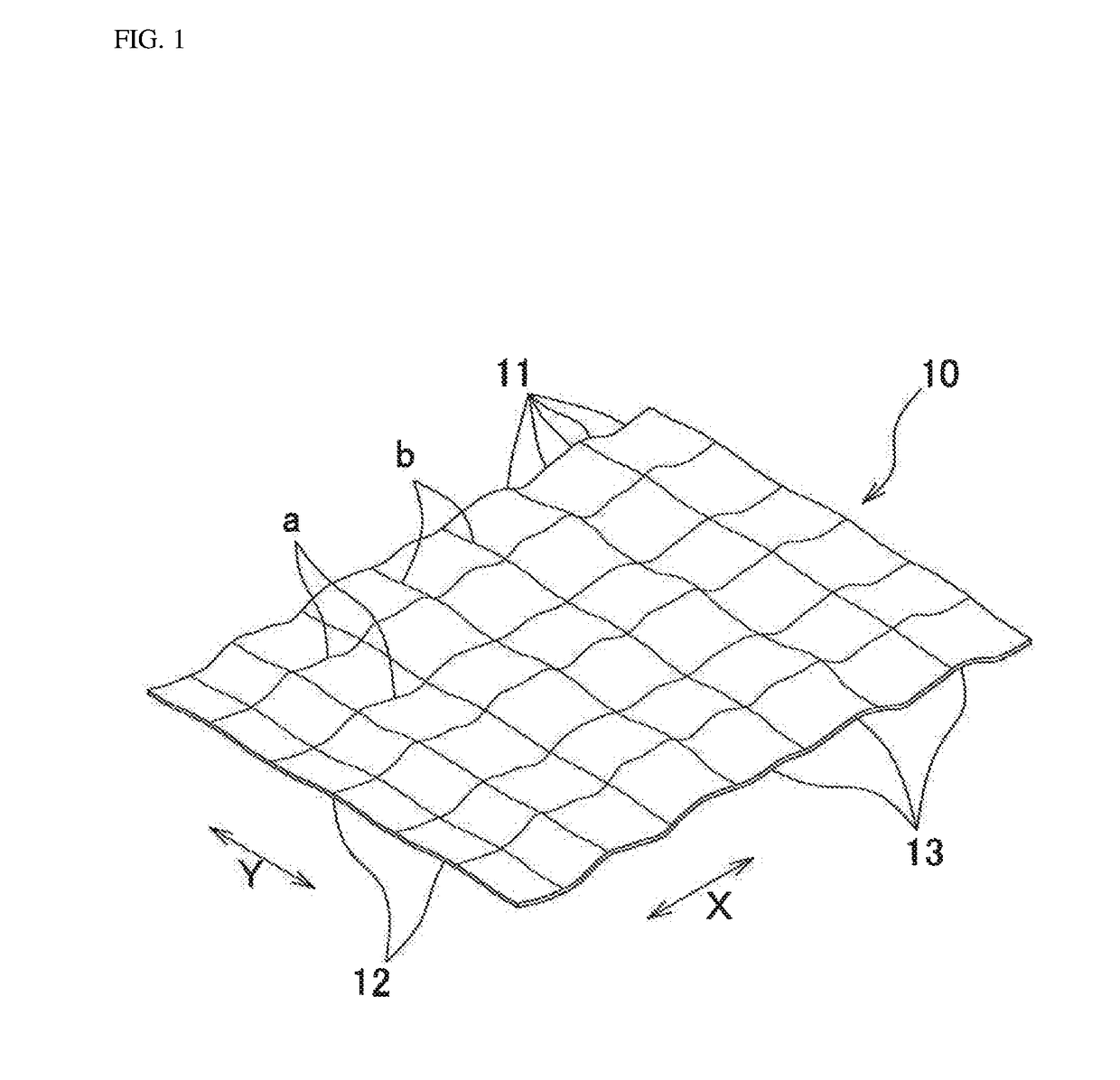

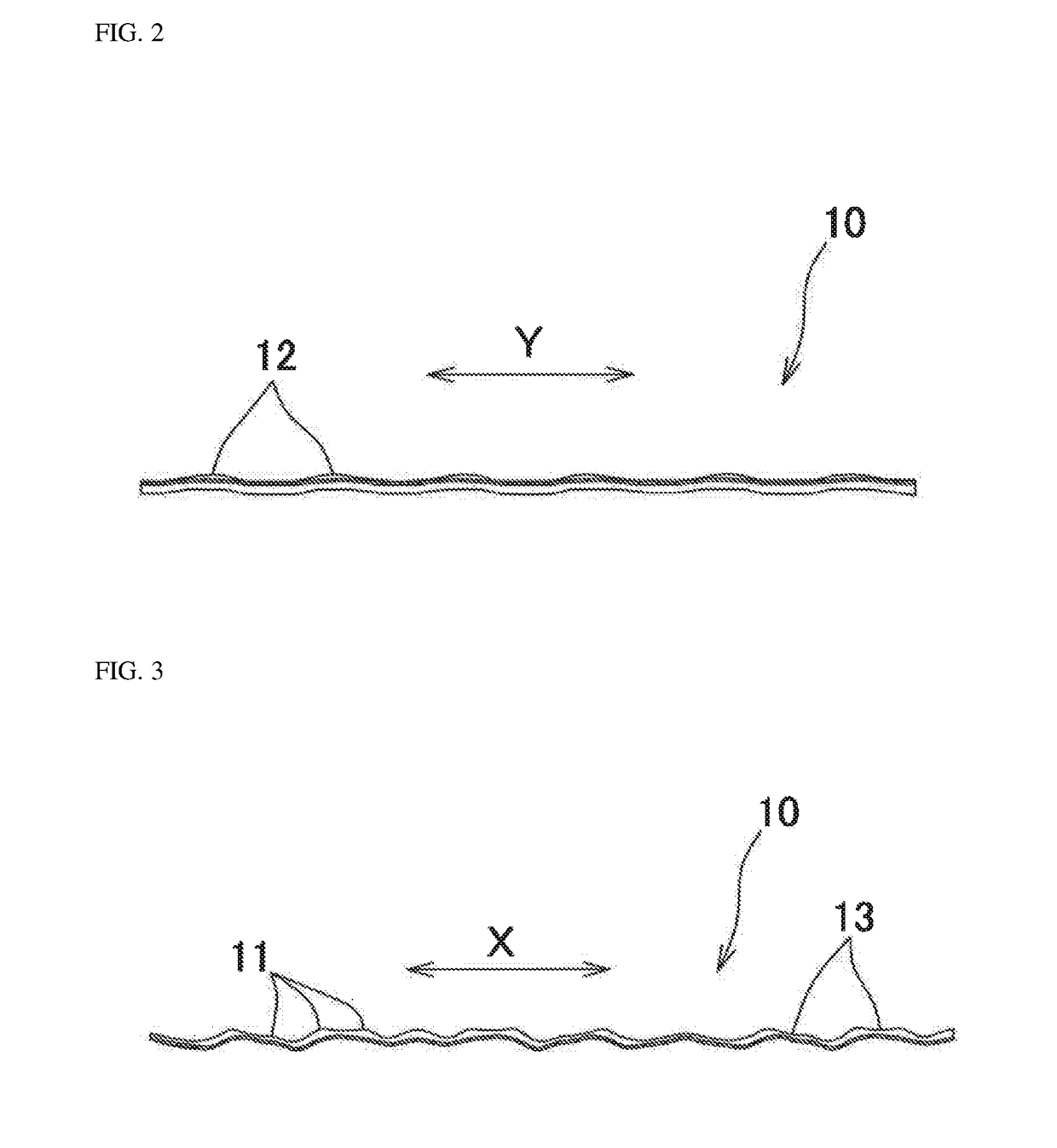

Method of manufacturing metal embossed plate

InactiveUS20180281040A1Lowering residual strainIncreasing the thicknessVehicle componentsEngineering

First corrugated portions in a first direction are sequentially formed by die-pressing a raw metal plate. Second corrugated portions formed in a second direction intersecting the first direction are sequentially formed by die-pressing a primary formed plate having the first corrugated portions using elongate projections, so that each of the second corrugated portion has a half-height and a pitch larger than those of each of the first corrugated portion. Third corrugated portions formed approximately in the first direction are sequentially formed by die-pressing a secondary formed plate having the second corrugated portions using elongate projections, so that each of the third corrugated portions has a half-height and a pitch larger than those of the first corrugated portion.

Owner:KOKUSAN BUHIN INDS

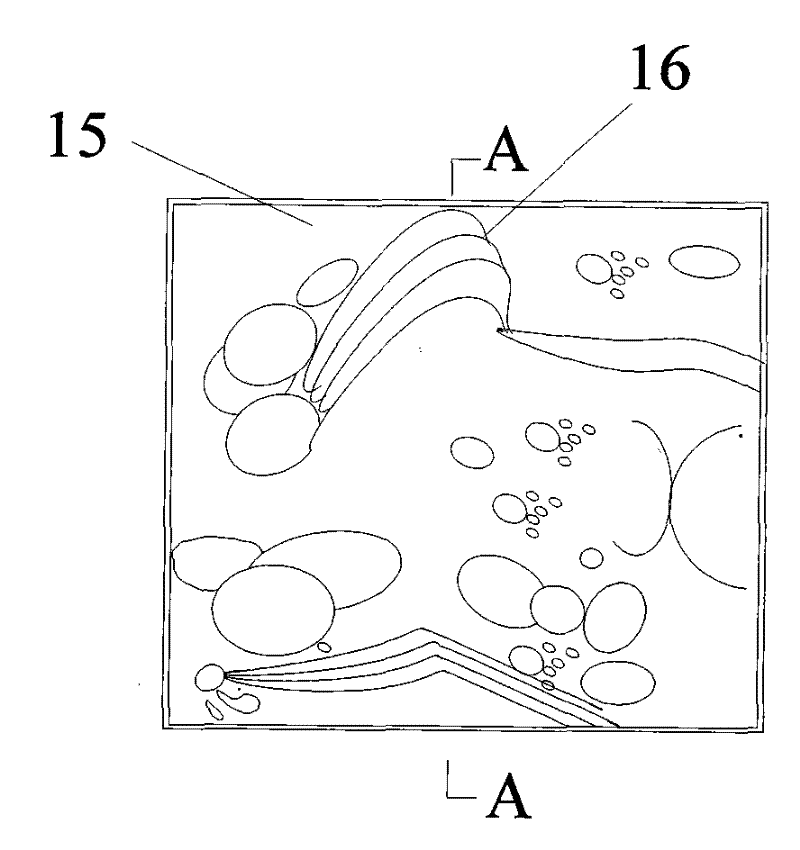

Distribution method for vitrified tiles high in simulated Xiuyan jade effect

InactiveCN105082337ANatural and smooth texture linesImitation jade effect is realisticFeeding arrangmentsMetallurgyDistribution method

The invention relates to a distribution method for vitrified tiles high in simulated Xiuyan jade effect. The distribution method includes a process of manufacturing micro powder through powder, a micro powder combined discharge process, a material falling and conveying process, a stacking whole conveying process and a process for feeding the powder to a pressing machine. Required surface powder is prepared through the process for manufacturing micro powder through powder, and is supplied to the micro powder combined discharge process. Various types of surface powder are received through the micro powder combined discharge process and conveyed to the material falling and conveying process. In the stacking whole conveying process, various types of surface powder coming from the material falling and conveying process are unceasingly received in the rotating process, and therefore various types of surface powder can form texture on a stacking whole conveying belt. Middle materials and bottom materials sequentially fall onto the surface powder forming the texture in the process for feeding powder into the pressing machine, and all powder is fed into the pressing machine to be formed in a pressed manner. Compared with the prior art, by means of the distribution method, the vitrified tiles high in simulated Xiuyan jade effect can be manufactured, the manufactured vitrified tiles have ribbon grains and circular-line-profiled texture, lines are natural and smooth, and simulated Xiuyan jade is lifelike and high in controllability.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Powder distributing device for ceramic tile with extended fine sand texture effect

The invention relates to a powder distributing device for a ceramic tile with the extended fine sand texture effect. The device comprises a colored powder roller combination blanking device, a main-color powder blanking roller, a base material blanking roller, a line-texture powder control roller combination blanking device, a linear powder feeding belt, a texture and main powder feeding belt, a toothed roller, a powder collecting box, a transfer printing belt and a base material grid. With the adoption of the device in the production of the ceramic tile with the extended fine sand texture effect, the sense of motion and the change of the extended fine sand textures can be created. Compared with the prior art, the device has the advantages that extending and rolling textures are brought to the ceramic tile; the cascading and transition are natural and smooth; the color and sandiness of the powder are exquisite and soft; the products of different colors can be produced by adjusting the technical parameters and matching the color of each texture; the effect of the device is ahead of that of like products in the market, the controllability of the device is high, and a wide product design scope is provided.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

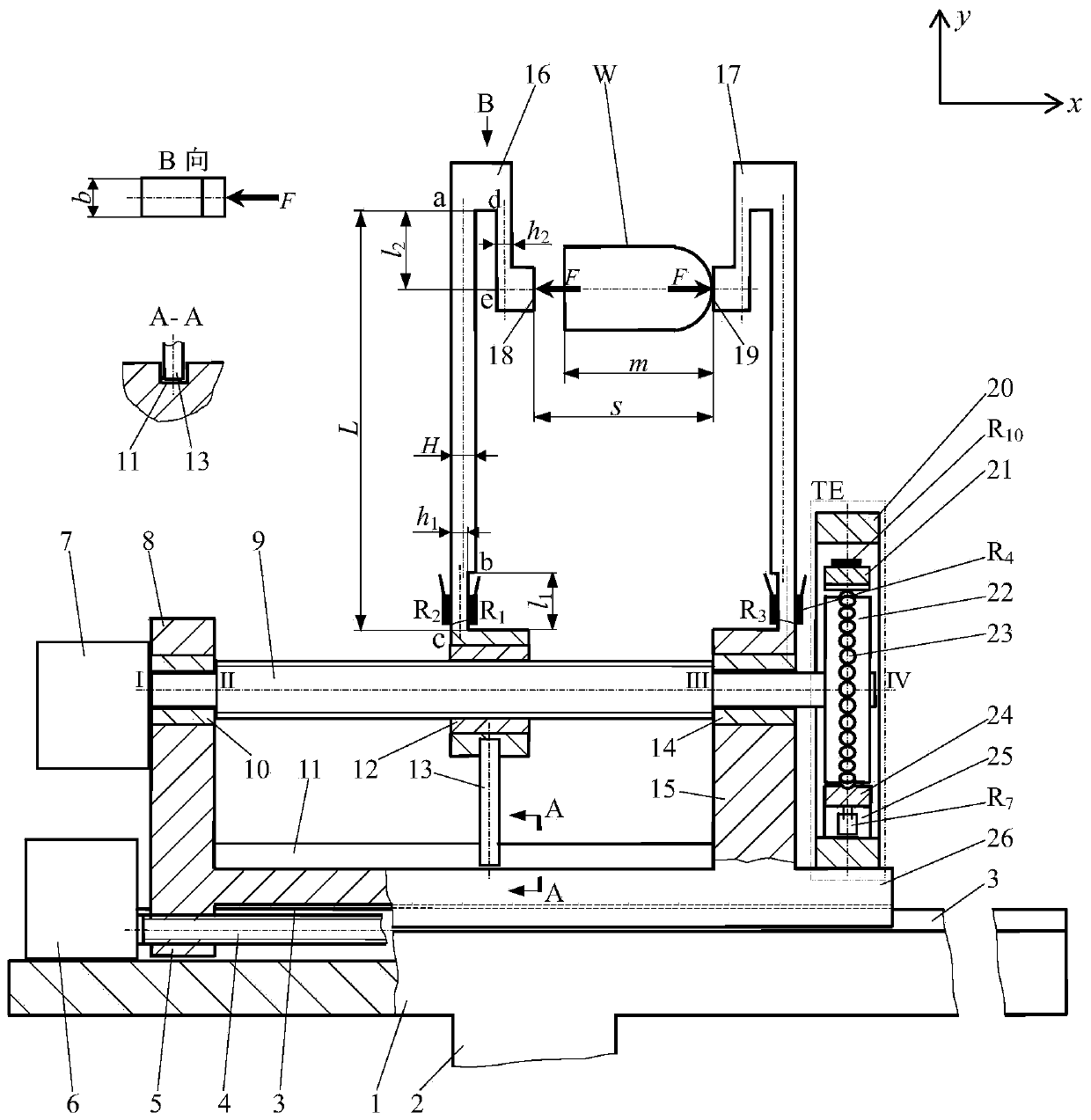

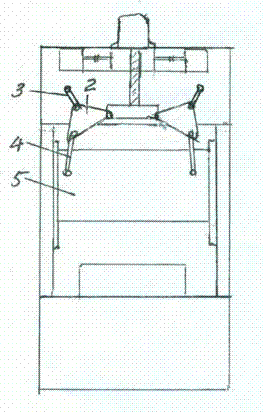

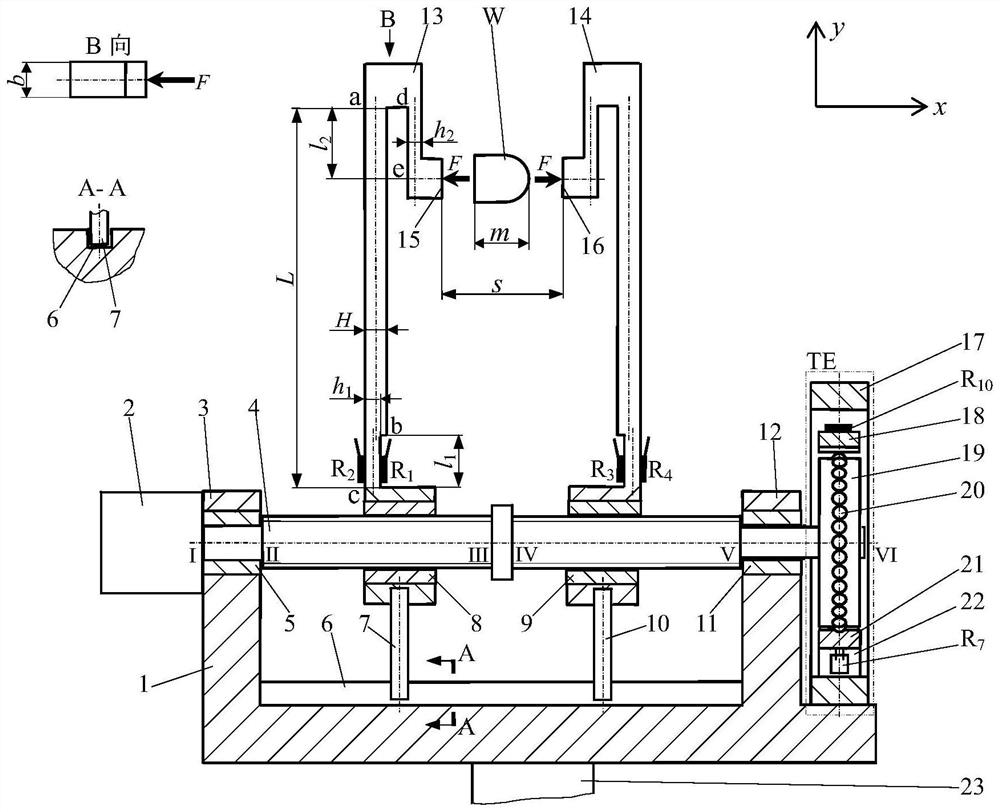

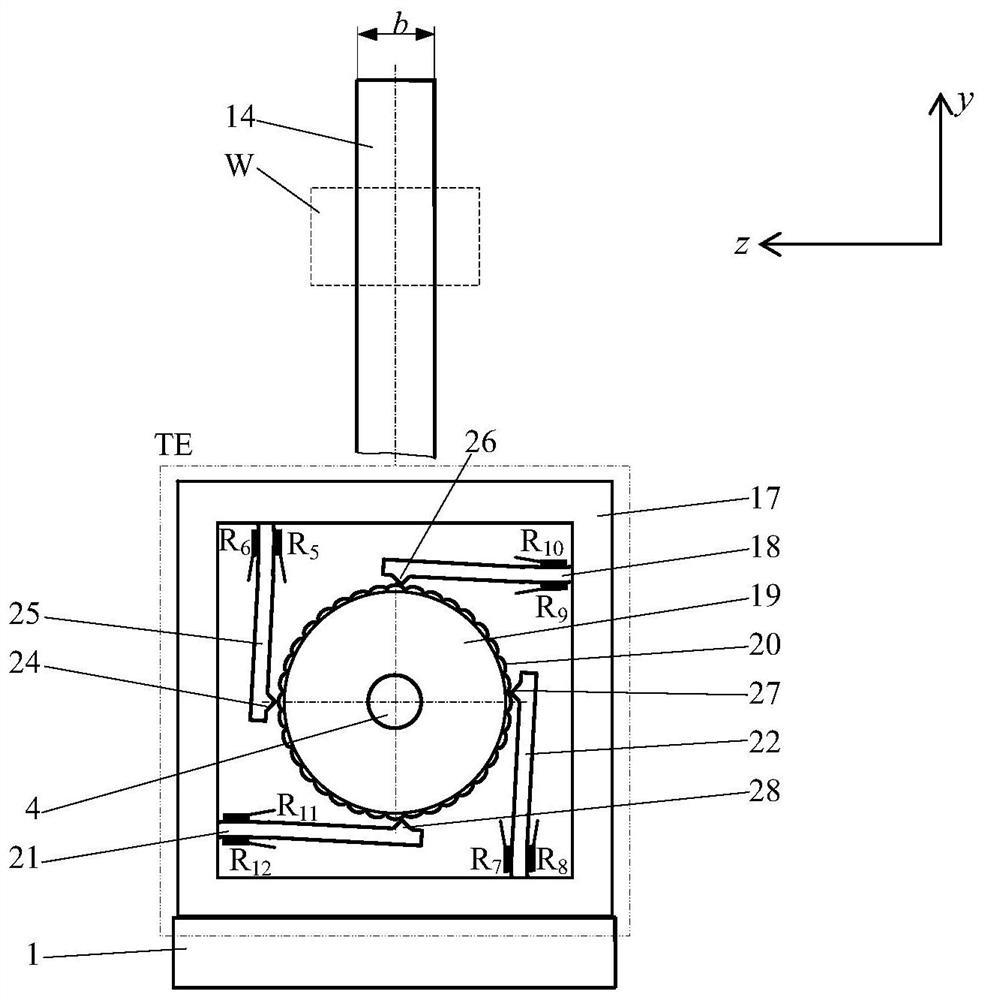

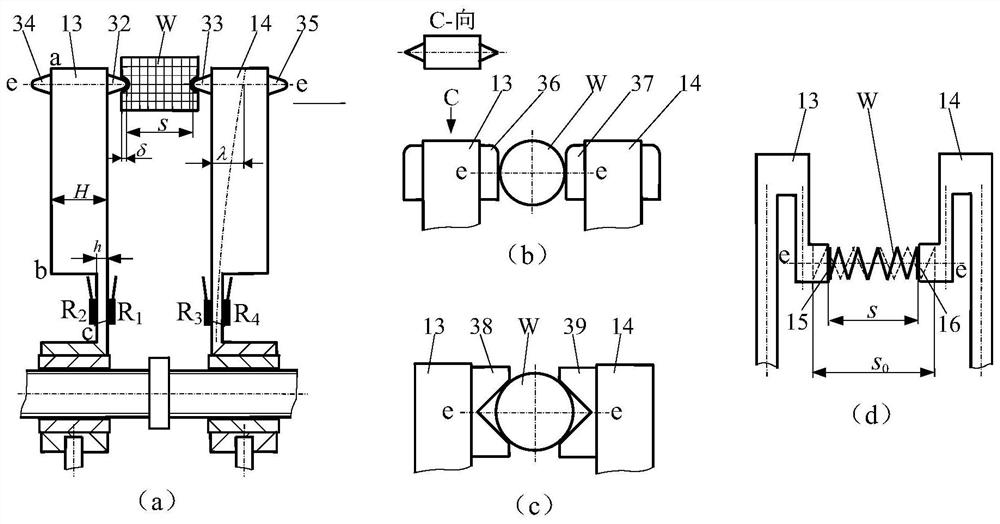

Manipulator capable of controlling clamping force and measuring distance between clamping points

ActiveCN110788874AWide range of designsImprove design flexibilityGripping headsCantilevered beamControl signal

The invention discloses a manipulator capable of controlling clamping force and measuring distance between clamping points. The manipulator is used for an industrial robot. The manipulator is composedof a clamping arm, an encoding lead screw, a rack, actuators and a numerical controller. The clamping arm comprises a movable arm and a fixed arm which have the force and deformation sensing function. The encoding lead screw is composed of a micrometering lead screw and a three-state encoder. The three-state encoder comprises a fluted disk and a cantilever beam sensor. The clamping arm and the encoding lead screw constitute a force-deformation-displacement combined sensing mechanism which is mounted on the rack. The numerical controller controls the clamping arm to clamp an object through theactuators and the encoding lead screw. The combined sensing mechanism and the numerical controller mutually transmit measurement control signals. The numerical controller controls clamping force andgives the distance between the clamping points.

Owner:CHINA ACAD OF ART

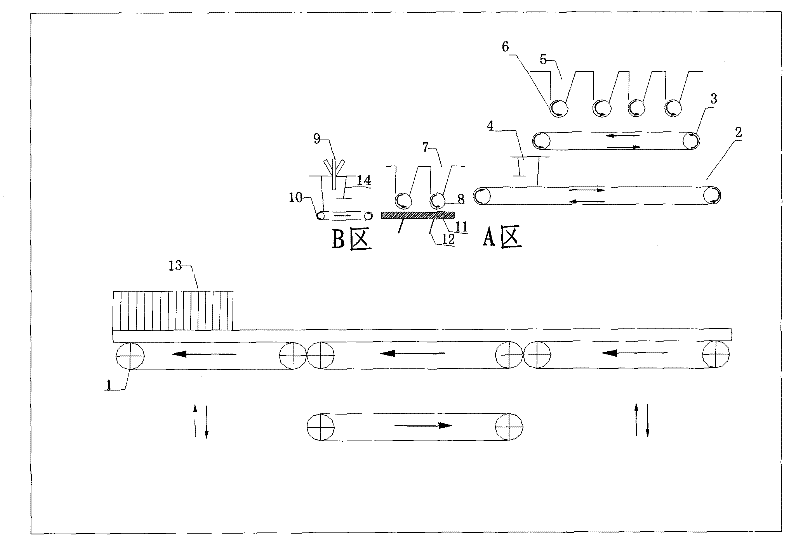

Process for partitioning and three-dimensional material distribution of ceramic tiles

ActiveCN101954668BNatural and smooth texture linesRealistic effectFeeding arrangmentsBrickMaterial distribution

The invention relates to a process for partitioning and three-dimensional material distribution of ceramic tiles. The process comprises partitioned facing material conveying and line material conveying, wherein for the partitioned facing material conveying, a micro-powder facing material is polished and then added into facing material hoppers of an area A and an area B respectively, the facing material in the area A falls into a facing material storage hopper through the rotation of a roller below the facing material hopper, the facing material storage hopper and an outlet below the facing material hopper of the area B are provided with a conveying belt, the front and the blow of the conveying belt are hung in the air, and the conveying belt rotates to convey the facing material to a stacking flat plate below the conveying belt; and for the line material conveying, a line material falls onto a baffle plate and a vibrating screen through the rotation of line blanking roller, the vibrating screen scatters the line material to the stacking flat plate below the vibrating screen thinly and uniformly, the stacking flat plate moves to partition and three-dimensionally distribute the facing material and the line material, and then a fidelity grizzly screen is used for conveying the materials to a die cavity of a pressing machine to finish the pressing of tile blanks. Compared with theprior art, the process has the advantages of texture lines naturally and smoothly added in the ceramic tiles, vivid imitation of granite, strong controllability and the like.

Owner:JIANGXI CIMIC CERAMICS +2

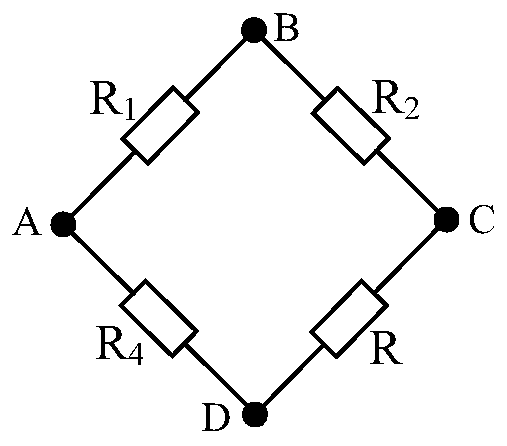

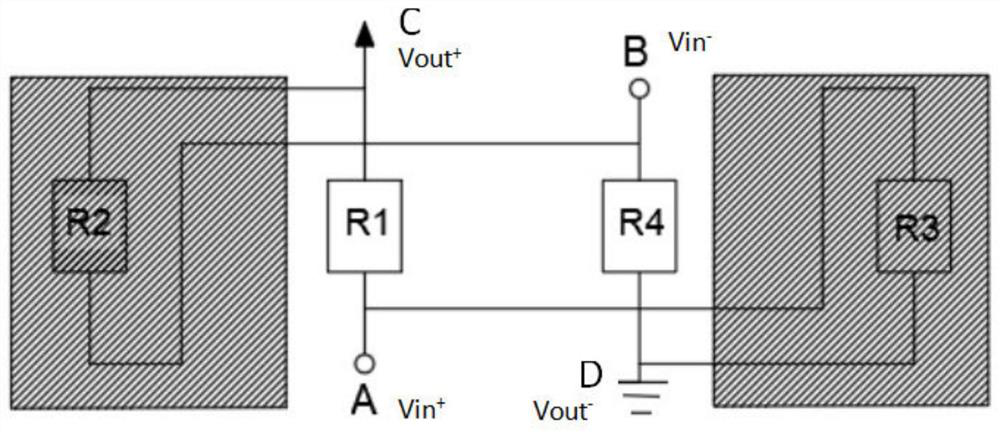

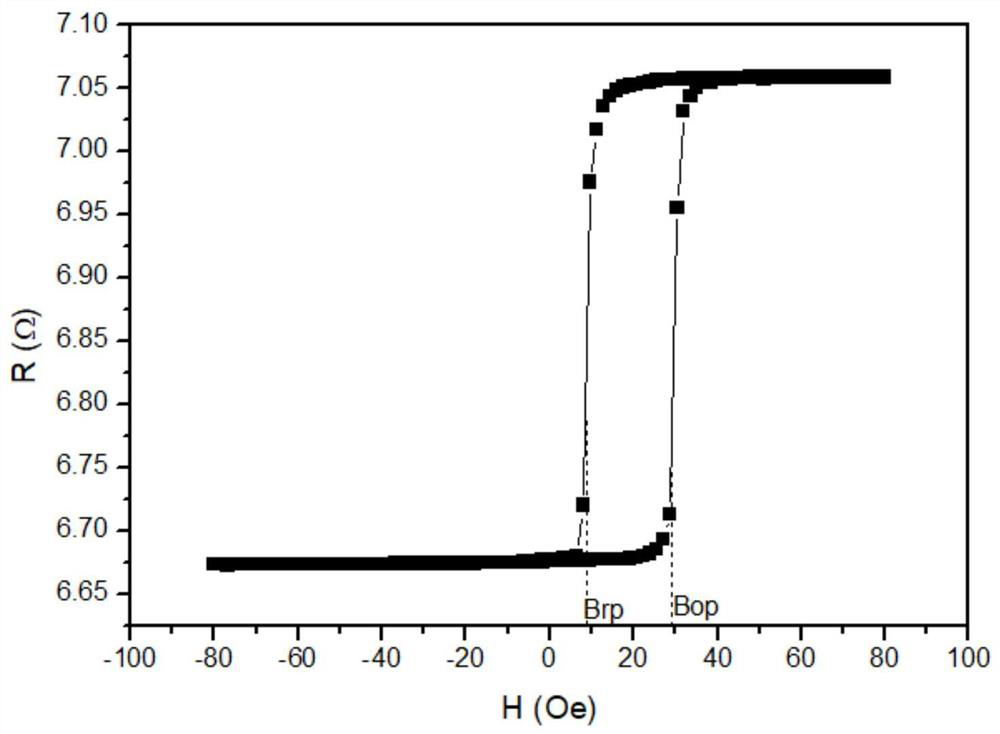

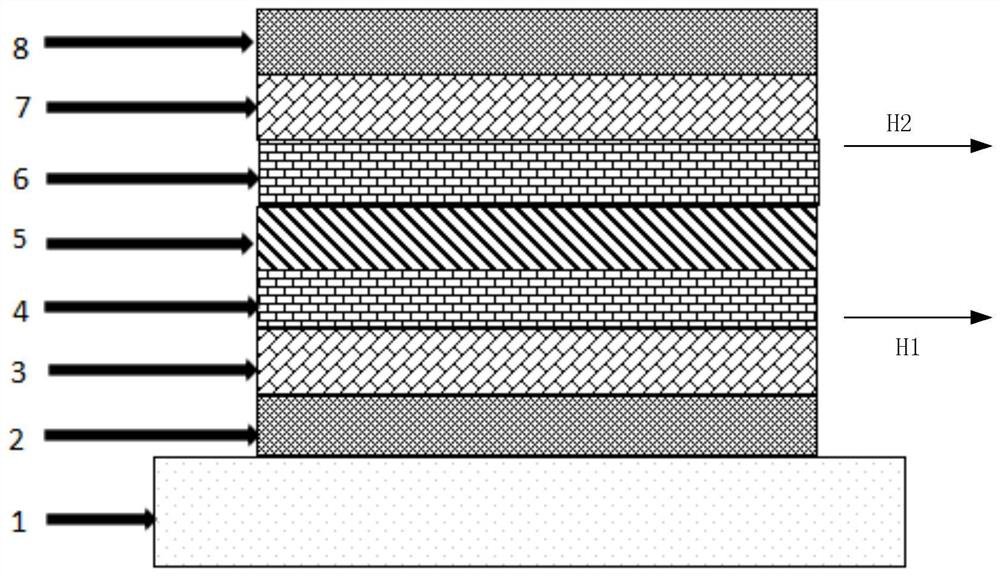

Giant magnetoresistance magnetic monopole switch sensor

PendingCN111769192AOvercoming the inability to meet the needs of larger switch yardsMeet needsMagnetic measurementsMagnetic-field-controlled resistorsGiant magnetoresistanceSpin valve

The invention belongs to the technical field of magnetic materials and components, and relates to a magnetic sensing technology, in particular to a giant magnetoresistance magnetic monopole switch sensor and a method for realizing the magnetic monopole switch sensor by utilizing a double-pinning structure. According to the invention, a double-pinning spin valve structure in the field of storage isused as a sensing unit; the advantage that an exchange bias field of double exchange bias can be modulated in a large range is utilized to replace a coupling field which can only be changed in a small range and is adopted in the prior art, so that a magnetic monopole switch realized based on the giant magnetoresistor is easier to design and meets the application requirements of a larger switch field.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Distribution device for vitrified tiles high in simulated Xiuyan jade effect

InactiveCN105082338ANatural and smooth texture linesImitation jade effect is realisticFeeding arrangmentsGratingBand shape

The invention relates to a distribution device for vitrified tiles high in simulated Xiuyan jade effect. The distribution device comprises a pulverizer, a micro powder combined discharging unit, a material falling and conveying unit, a stacking overall conveying belt, a micro powder conveying grating, a middle material hopper and a bed charge hopper. The micro powder combined discharging unit is arranged below the pulverizer. The material falling and conveying unit is arranged below the micro powder combined discharging unit. The stacking overall conveying belt is arranged below the material falling and conveying unit. The micro powder conveying grating is arranged at the tail end of the stacking overall conveying belt. The middle material hopper and the bed charge hopper are sequentially arranged on the micro powder conveying grating. Middle materials and bed charge fall into surface powder of the micro powder conveying grating, and all the materials are conveyed into a pressing machine through the micro powder conveying grating to be formed in a pressing manner. Compared with the prior art, the distribution device can develop the vitrified tiles high in simulated Xiuyan jade effect, the manufactured vitrified tiles have ribbon grains and circular-line-profiled texture, lines are natural and smooth, and simulated Xiuyan jade is lifelike and high in controllability.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Ceramic heating body and manufacturing method thereof

PendingCN112568506AReduce the probability of short circuitIncrease wiring areaTobaccoNixie tubeComposite structure

The invention relates to a ceramic heating body and a manufacturing method thereof. The ceramic heating body comprises a ceramic core rod and a multi-layer composite structure laminated and wound on the ceramic core rod, wherein the multi-layer composite structure and the ceramic core rod are sintered and molded together, the multi-layer composite structure at least comprises a heating circuit layer and a temperature measurement circuit layer, the heating circuit layer comprises a first ceramic chip and a heating circuit formed on the first ceramic chip, the temperature measurement circuit layer comprises a second ceramic chip and a temperature measurement circuit formed on the second ceramic chip, and the heating circuit layer and the temperature measurement circuit layer are respectivelyprovided with a through hole so as to lead out a wire from the corresponding circuit layer. According to the LED patch nixie tube, the probability of short circuit of different circuits on the ceramic heating body is greatly reduced, the wiring area is greatly increased, the design range is widened, the circuit distribution mode is diversified, the overall horizontal area is reduced, the number of turns of winding is reduced, and difficulty of the winding process is greatly reduced.

Owner:SHENZHEN SUNLORD ELECTRONICS

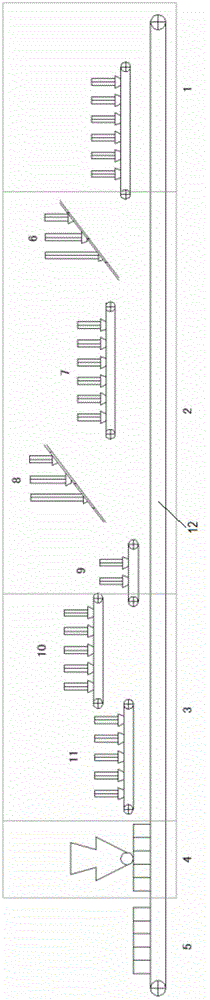

Material distribution device and process for multi-texture combined fine earthenware tiles

ActiveCN104690817ANatural and smooth texture linesGreat Texture ContrastFeeding arrangmentsEngineeringMaterial distribution

The invention relates to a material distribution device and process for multi-texture combined fine earthenware tiles. The material distribution device comprises a system constituted by a material supply system for 30 polishing machines and an integral conveying belt, wherein the power supply system for the 30 polishing machines is controlled by a controller to complete control of fineness of micro-powder and feeding control, and the integral conveying belt is used for conveying the micro-powder with a texture effect into a press for pressing. Compared with the prior art, the material distribution device provided by the invention has the advantages of natural and smooth texture lines of products, strong controllability, a wide range of product designs and the like.

Owner:JIANGXI CIMIC CERAMICS +1

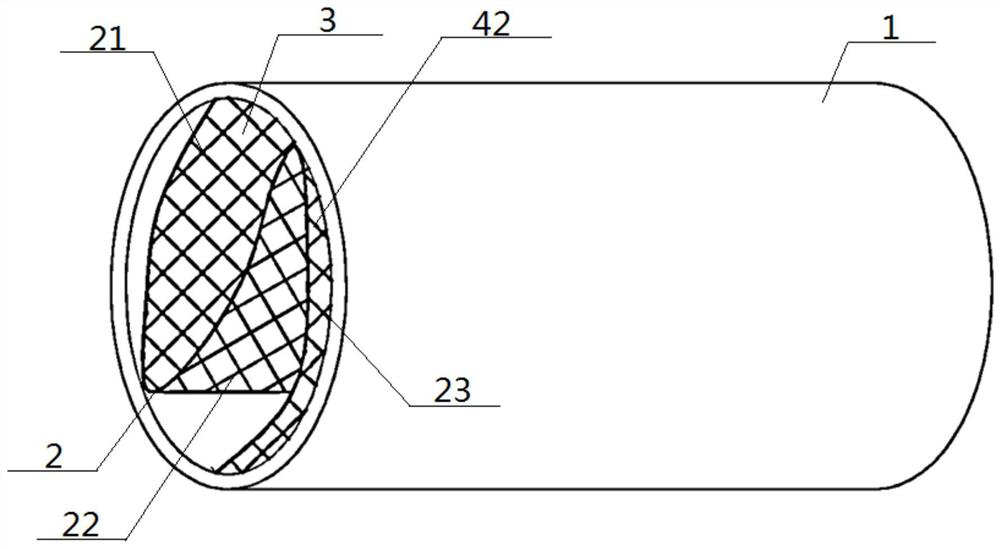

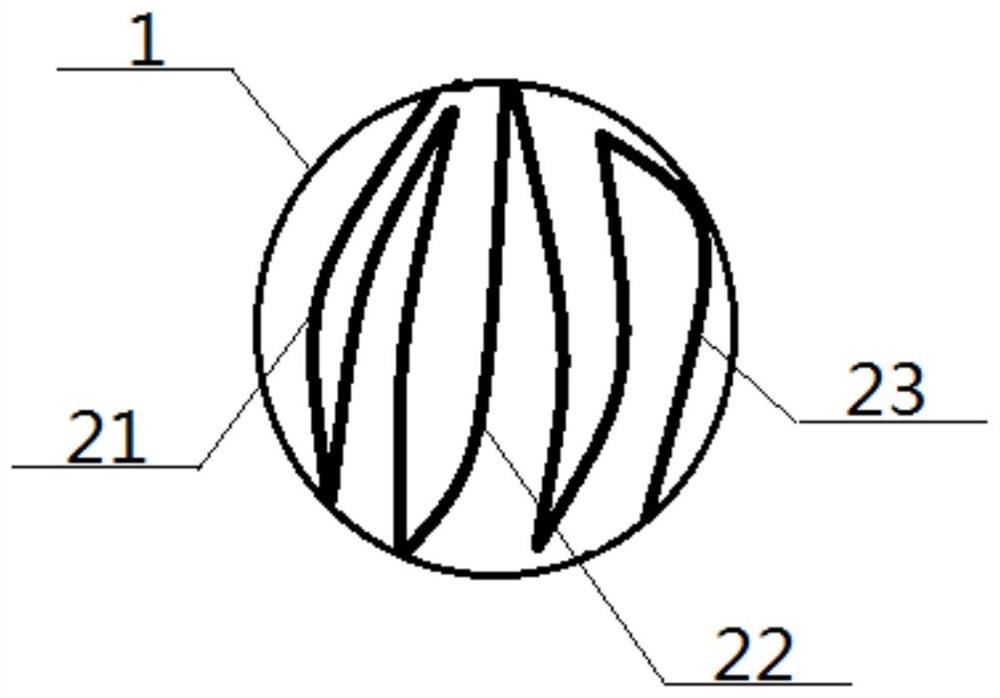

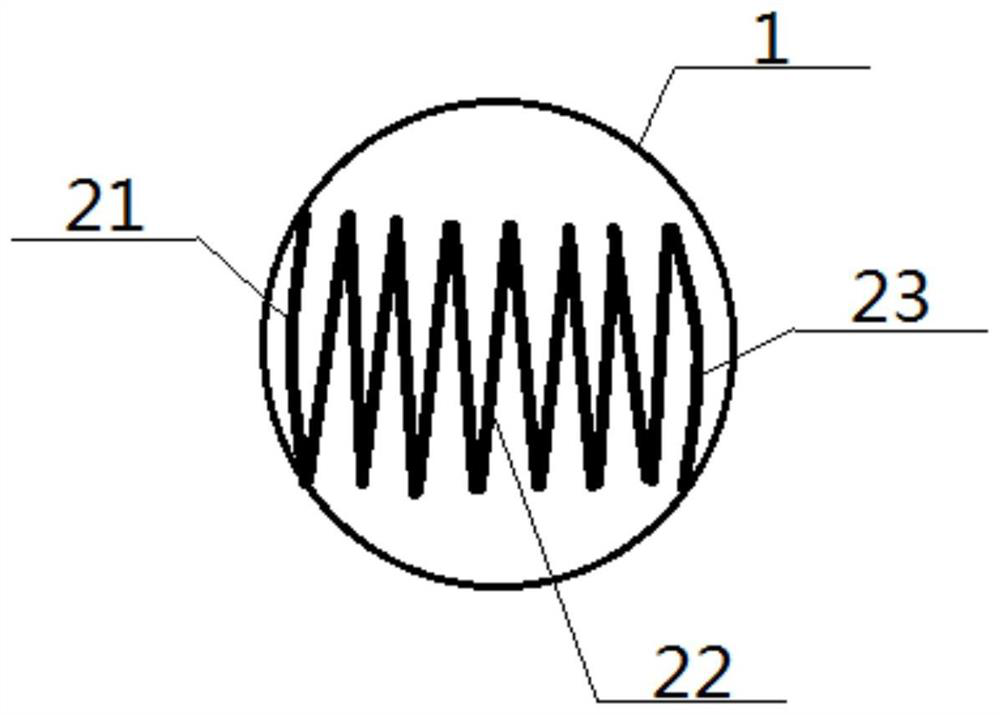

Multi-directional flue gas cooling element

A multi-directional flue gas cooling element comprises an outer wrapping cylinder and an inner filling body arranged in the outer wrapping cylinder, the inner filling body comprises a starting end net, at least one middle net and a terminal net which are connected into a whole, the starting end net, the middle net and the terminal net are all formed by weaving filaments, and through holes are woven to form vent holes; the top edge or the bottom edge of the starting end net is connected with the top edge or the bottom edge of one middle net adjacent to the starting end net, and the top edge or the bottom edge of the terminal net is connected with the top edge or the bottom edge of one middle net adjacent to the terminal net; and only one middle net is adjacent to the starting end net and connected with the starting end net, and only one middle net is adjacent to the terminal net and connected with the terminal net. According to the design, the cooling direction can be enriched, the cooling effect is high, adjust-ability is high, and the application range is wide.

Owner:WUHAN RED GOLDEN LEAF NEW MATERIAL TECH CO LTD

Infrared emitter

ActiveUS9660158B2Suppression frequencyGood directionLamp incadescent bodiesSolid-state devicesThin metalLight beam

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

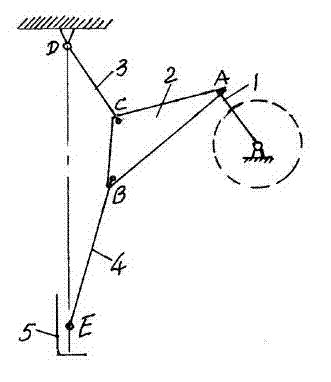

Multi-rod driving mechanism

The invention relates to a multi-rod driving mechanism which comprises connecting rods and a triangular block, wherein three angles of the triangular block are respectively connected to a driving rod and one ends of two connecting rods, and the other two ends of the two connecting rods are respectively connected to a fixed support point and a slide block. The triangular block is taken as one connecting rod of a three-rod driving mechanism and the connecting rod joints are respectively connected to the triangular block instead of being connected together through three shafts, thereby achieving simple structure, excellent load-carrying capability and wide design scope of connecting rod.

Owner:吕晶

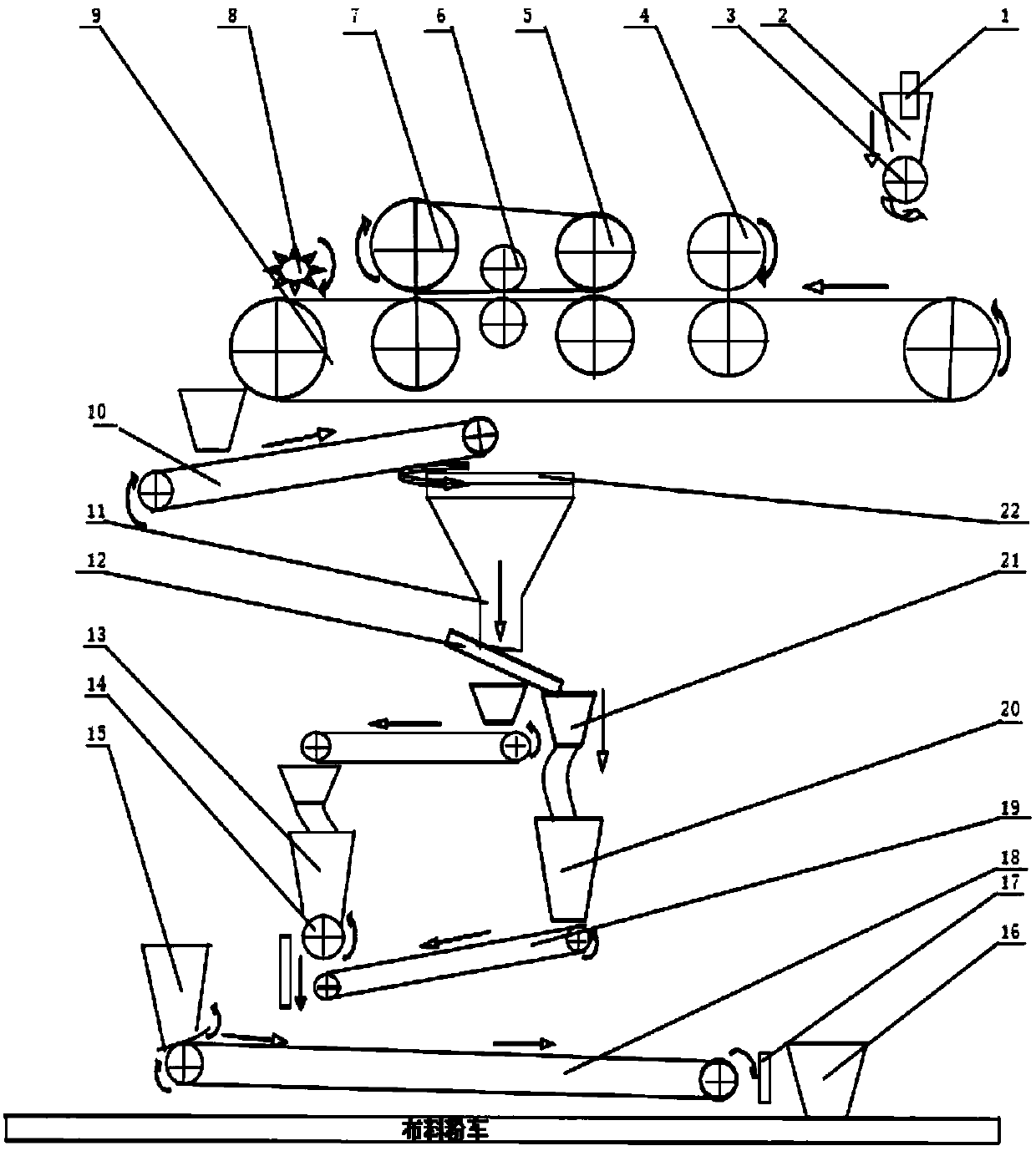

A process and equipment for making vitrified tiles imitating the Roman non-porous stone texture

ActiveCN103042587BUniform layoutThe layout can be expanded evenlyCeramic shaping apparatusEngineeringControllability

The invention relates to a process and a device for manufacturing vitrified tiles with imitation Roman non-hole travertine textures. The process controls a texture grid delivery unit to move from the front to the back; a corresponding micro powder blanking unit and a micro powder particle blanking unit perform blanking at corresponding positions; micro powder, lines and particles are fed in a grid layer upon layer; the grid moves frontwards after reaching a rear position; all blanking units blank the materials at grid vacancy positions, and the materials are driven by a fabric trolley to be sent into a press machine with intermediate materials and base materials in the front of the grid; and the vitrified tiles are formed through triple blanking filling and molding. The device comprises the texture grid delivery unit, a powder smashing micro powder manufacturing unit, the micro powder blanking unit and the micro powder particle blanking unit. Compared with the prior art, the vitrified tiles produced by the process and the device have the advantages of being natural and smooth in texture and line, vivid in imitation travertine straight grain and high in controllability.

Owner:JIANGXI CIMIC CERAMICS +1

A ceramic tile powder distributing device with the effect of continuous fine sand texture

The invention relates to a powder distributing device for a ceramic tile with the extended fine sand texture effect. The device comprises a colored powder roller combination blanking device, a main-color powder blanking roller, a base material blanking roller, a line-texture powder control roller combination blanking device, a linear powder feeding belt, a texture and main powder feeding belt, a toothed roller, a powder collecting box, a transfer printing belt and a base material grid. With the adoption of the device in the production of the ceramic tile with the extended fine sand texture effect, the sense of motion and the change of the extended fine sand textures can be created. Compared with the prior art, the device has the advantages that extending and rolling textures are brought to the ceramic tile; the cascading and transition are natural and smooth; the color and sandiness of the powder are exquisite and soft; the products of different colors can be produced by adjusting the technical parameters and matching the color of each texture; the effect of the device is ahead of that of like products in the market, the controllability of the device is high, and a wide product design scope is provided.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Universal replacement bottom assembly kit for commercial waste containers

ActiveUS11034513B2Reduce complexity and costEnsure long-term benefitsRefuse receptaclesEnvironmental engineeringCommercial waste

The present disclosure relates to a commercial waste container bottom assembly kit, capable of fitting a wide range of waste container and dumpster sizes. The system includes additional features such as an enhanced commercial waste container load rail and joggled end caps. The advantages over traditional methods of replacing container bottoms are significant.

Owner:PLASTIC RECOVERY TECH

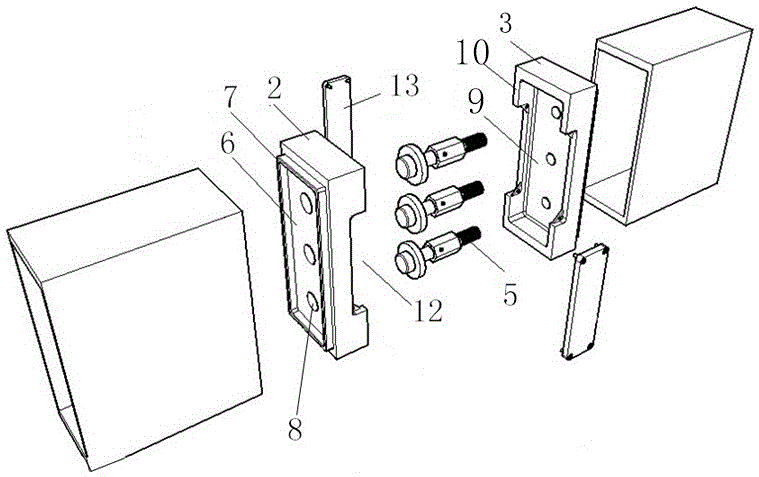

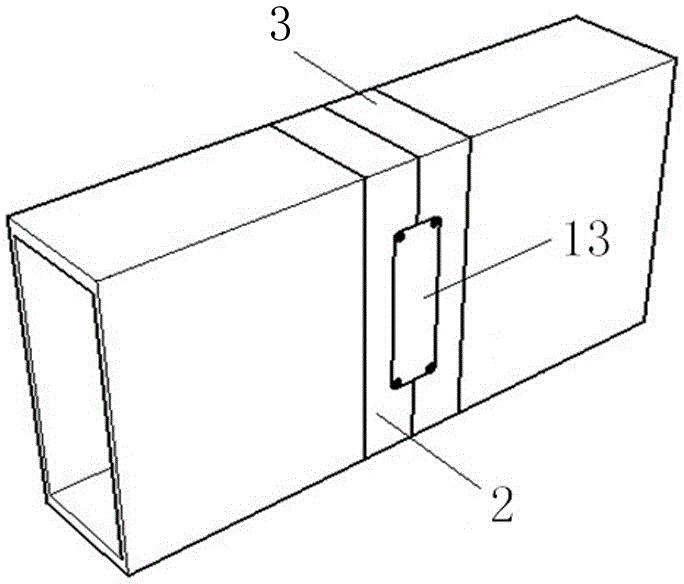

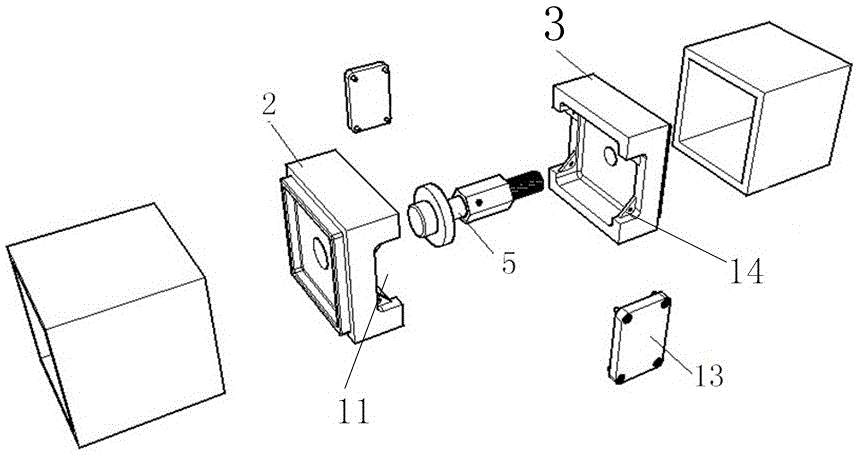

Assembling type connecting system of box-section single-layered reticulated shell as well as assembling method and design method of assembling type connecting system

ActiveCN106638949AIncreased bending stiffnessImprove carrying capacityBuilding constructionsAgricultural engineeringDesign methods

The invention relates to a connecting system and in particular relates to an assembling type connecting system of a box-section single-layered reticulated shell as well as an assembling method and a design method of the assembling type connecting system, belonging to the field of steel structures. The assembling type connecting system comprises an end plate I and an end plate II, wherein the end plate I is connected and fixed with the end plate II through a plurality of sleeve bolts; a mounting operation hole is formed between the end plate I and the end plate II; and the connecting system is formed by combining the end plate I, the sleeve bolts, the mounting operation hole and the end plate II. The structure is simple and convenient to mount and the universality is high.

Owner:浙江东南网架股份有限公司 +2

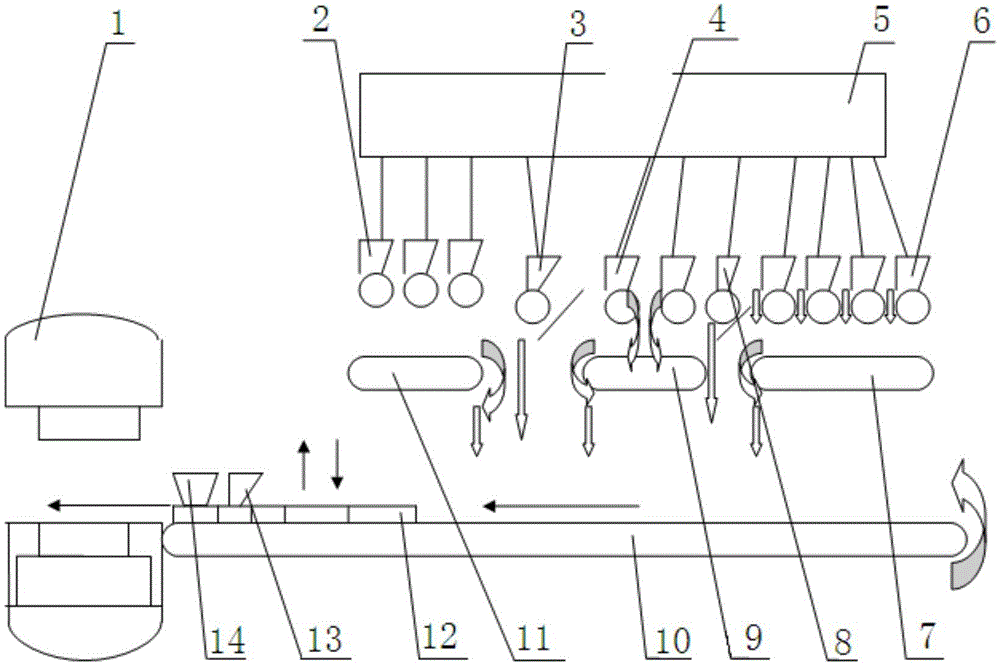

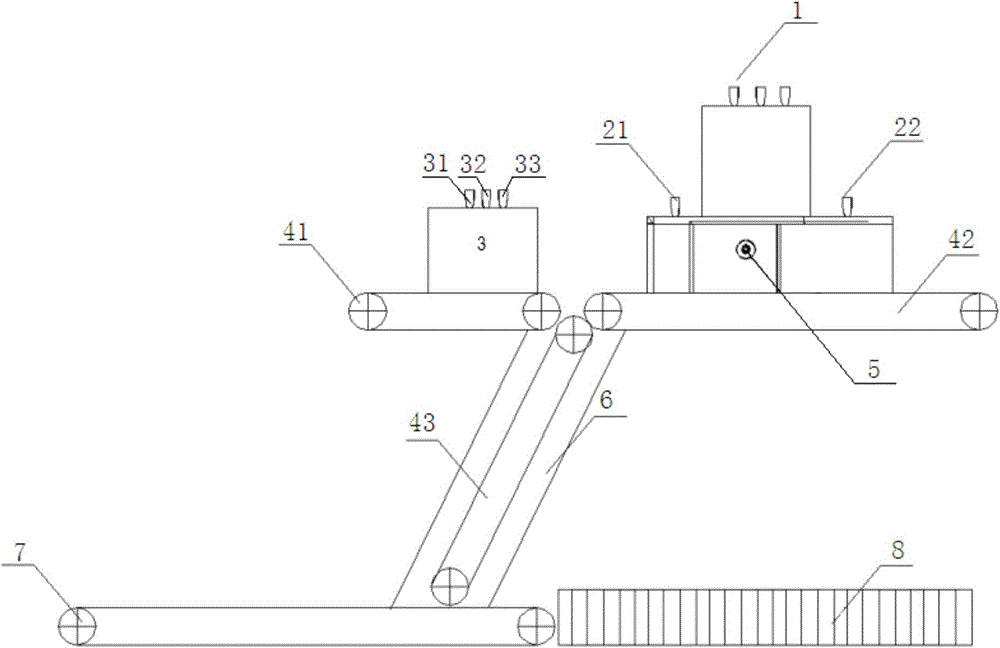

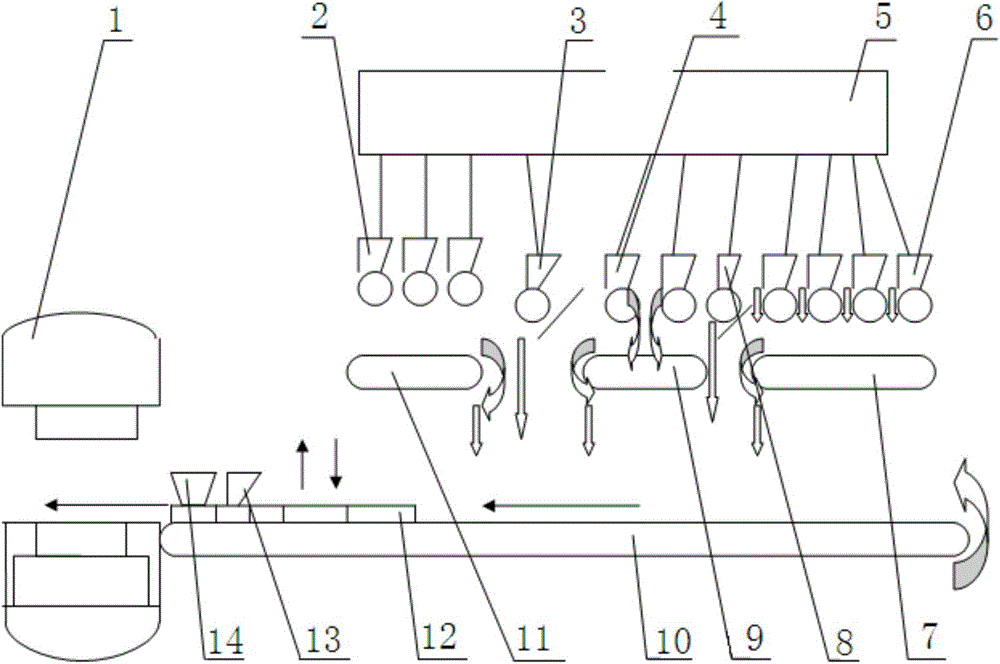

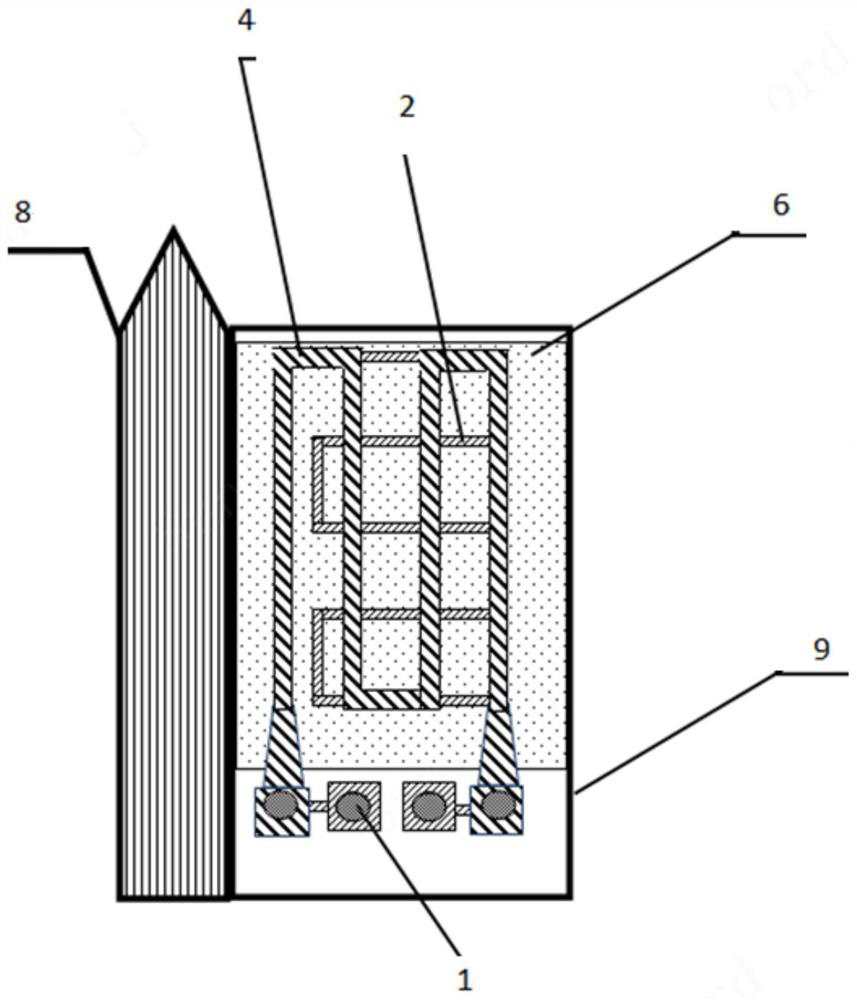

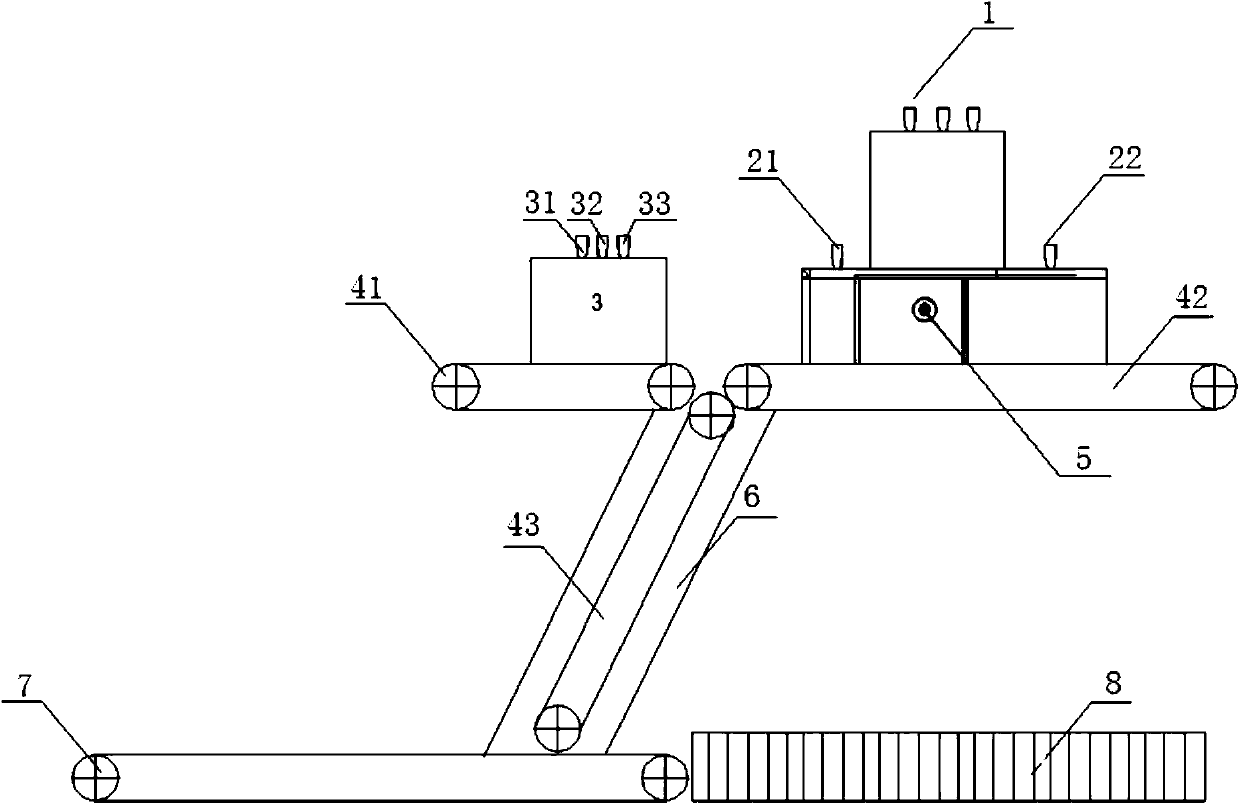

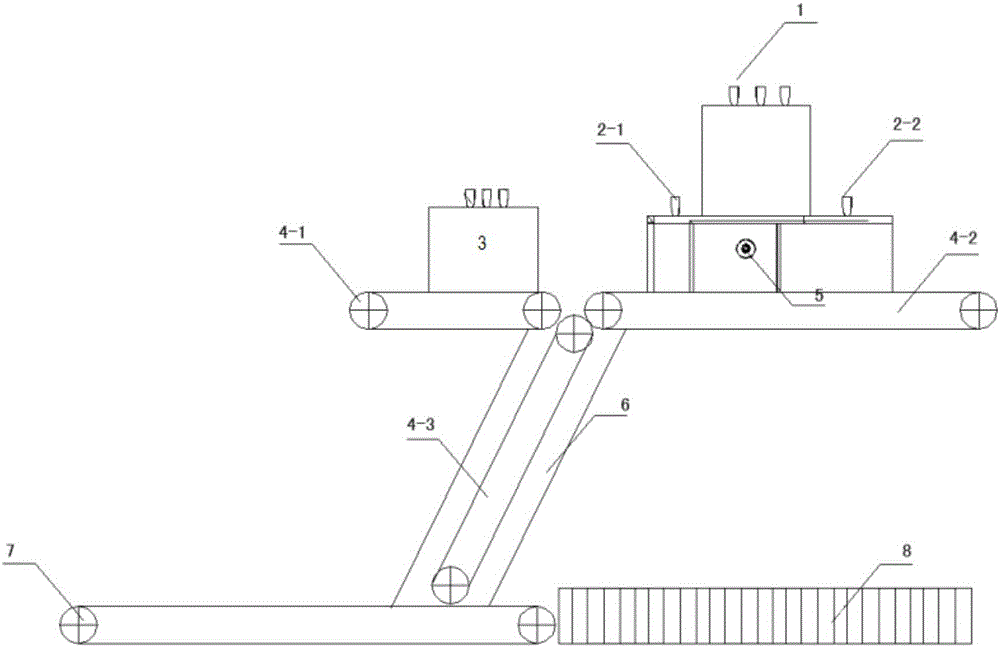

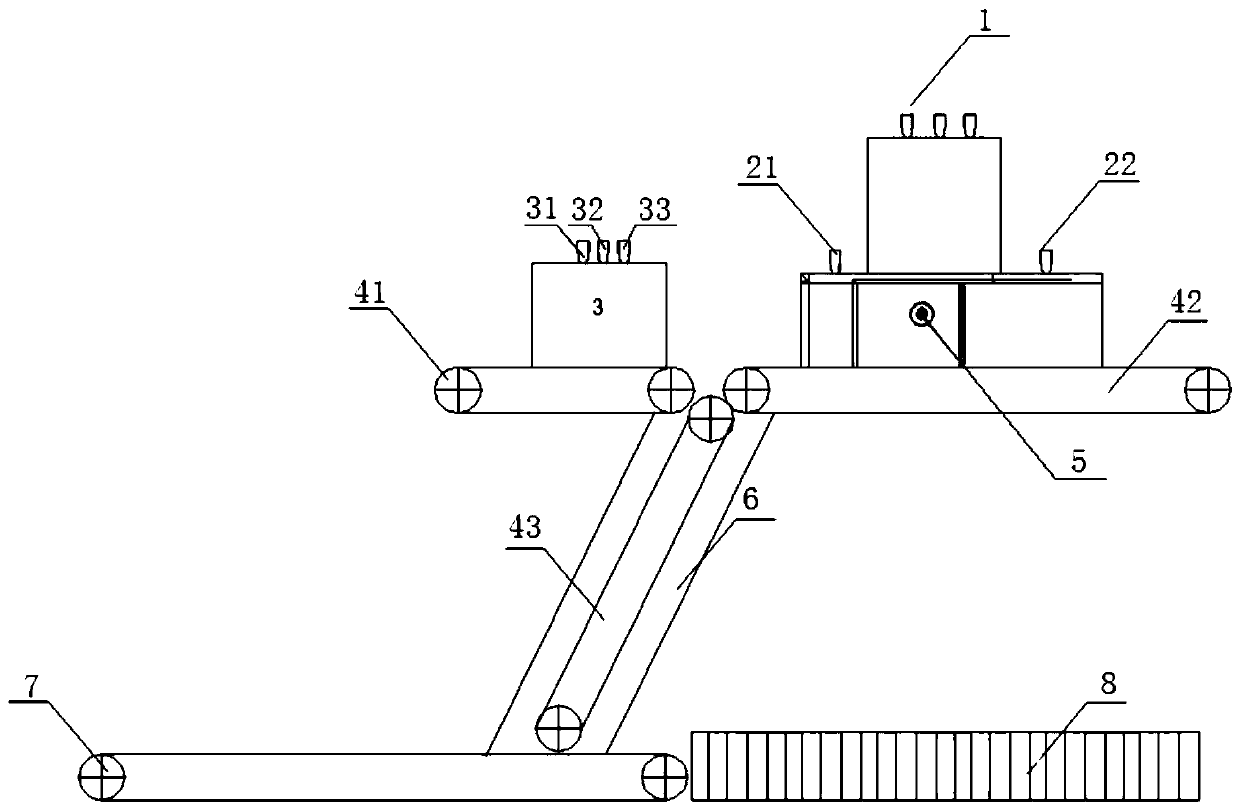

A preparation device and process for ceramic tiles imitating Australian sandstone texture

The invention relates to a device and process for preparing a ceramic tile simulating Austrian sandstone textures. The device comprises a color control roller combined discharging device (1), a main material discharging roller (2-1), a base material discharging roller (2-2), a texture control roller combined discharging device (3), a conveyor belt assembly (4), a toothed roller (5), a powder collecting box (6), a transfer printing belt (7) and a grid (8). Compared with the prior art, the device has the advantages that the texture cascading effect of the product is stone-like, vivid, natural and fluent, the transition of color and powdery sand is soft, products of different color systems can be produced through carrying out technical parameter adjustment and color assortment on the textures, the effect is superior to that of the like product on the market, the controllability is high, and the design range of the product is wide.

Owner:JIANGXI CIMIC CERAMICS +1

A tile powder cloth transfer printing process with the effect of continuous fine sand texture

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

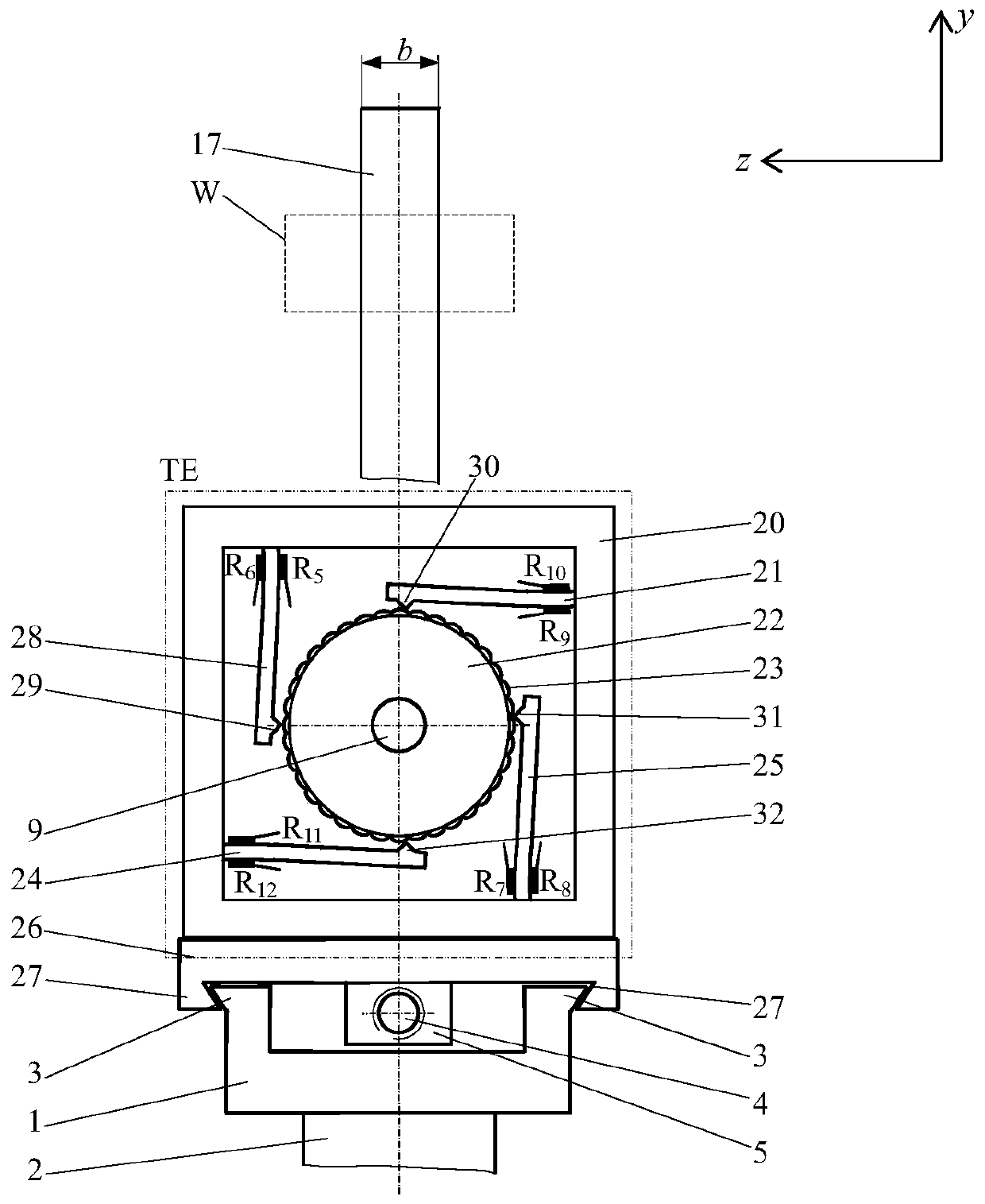

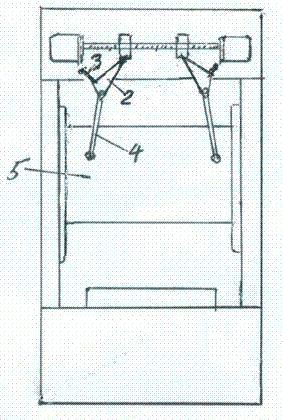

Manipulator to control clamping deformation

ActiveCN110744577BWide range of designsImprove design flexibilityProgramme-controlled manipulatorGripping headsCantilevered beamControl signal

The invention discloses a manipulator for controlling clamping deformation, which is used for a robot. The device consists of a frame, an encoding screw, a holder, a driver and a numerical control. The coding screw consists of a micrometer screw and a three-state encoder, and the three-state encoder includes a toothed disc and four pairs of cantilever beam sensors. The gripper includes two gripping arms. The coding screw and the holder form a force-deformation-displacement composite sensing mechanism, which is installed on the frame and connected with the driver. When the device is working, the CNC controls the rotation of the driver and the coding screw, the gripper clamps the object, and the composite sensing mechanism interacts with the CNC to transmit measurement and control signals to measure the clamping force and the distance between clamping points in real time to control the deformation of the object.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com