A process and equipment for making vitrified tiles imitating the Roman non-porous stone texture

A technology of vitrified bricks and textures, applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve strong controllability, wide range of product design, and realistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

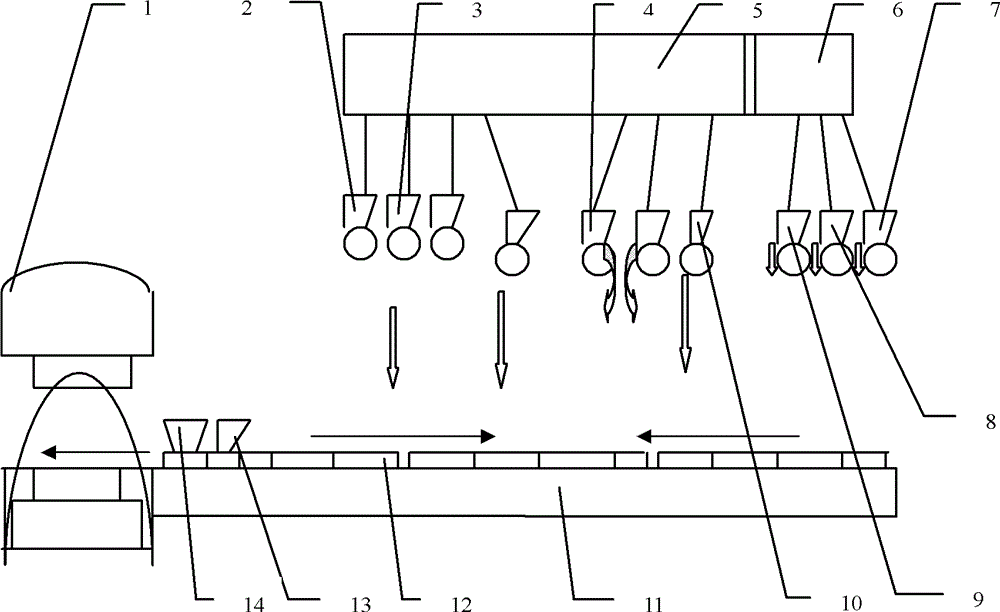

[0019] A process for making vitrified tiles imitating the texture of Roman stone without holes, the equipment used in it is as follows figure 1 As shown, it includes a press 1, a micropowder line blanking combination structure 2, a micropowder blanking structure 3, a hedge micropowder blanking structure 4, a pulverizing mechanism micropowder system 5, a micropowder tablet mechanism granule mechanism 6, a granule K1 blanking mechanism 7, Particle K2 feeding mechanism 8, particle K3 feeding mechanism 9, line X2 stacking overall conveying belt 10, fixed flat glass 11, first filling micro powder conveying grid 12, second filling hopper 13, third filling Hopper 14, in addition, is also provided with texture grid conveying device, powder material pulverization making micropowder device, micropowder unloading device, micropowder particle unloading device. All operating devices are installed above the fixed flat glass 11, and the textured grid 12 is above the fixed flat glass 11. Driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com