Partially prestressed and partially non-prestressed concrete hollow pile

A hollow square pile, non-prestressed technology, used in sheet pile walls, buildings, infrastructure engineering and other directions, can solve the problems of low reinforcement ratio, integrity, and difficulty in meeting high requirements for shear, bending and tensile properties. , to achieve the effect of improving the pile formation rate, the construction pile formation rate and the shear resistance capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

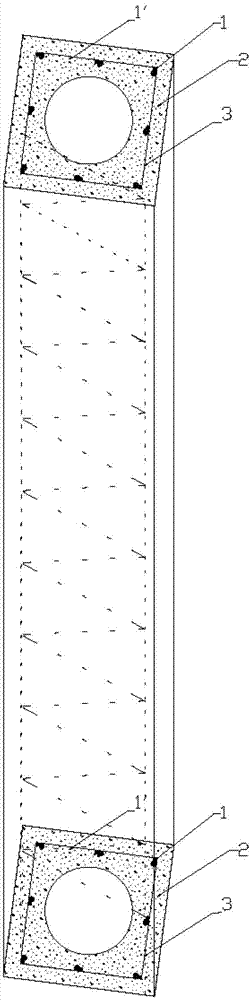

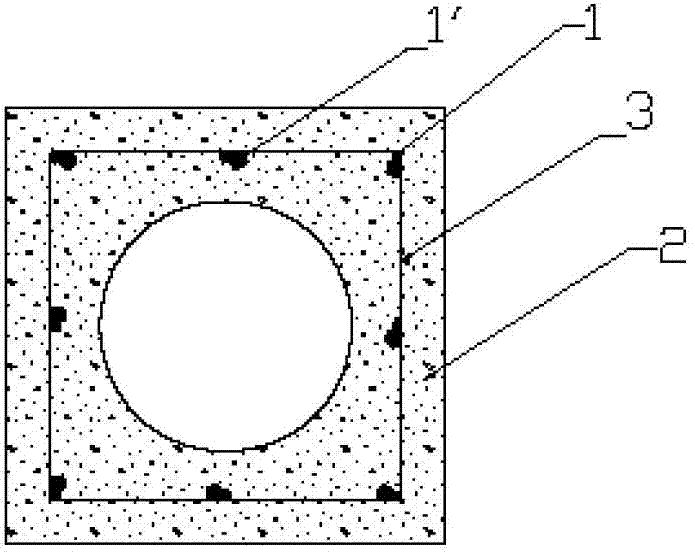

[0026] figure 1 is a perspective view of the present invention, figure 2 It is a sectional view of the present invention.

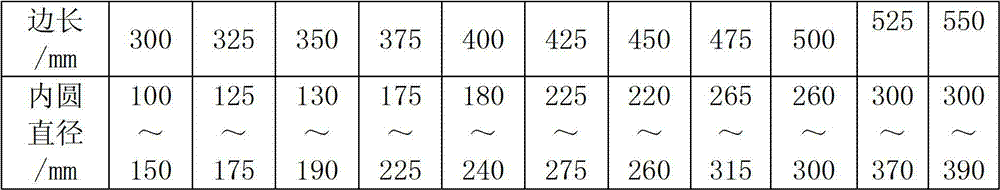

[0027] Such as figure 1 and 2 Shown: the partially prestressed and partially non-prestressed concrete hollow square pile provided by the present invention, the longitudinal axis direction of the partially prestressed and partially non-prestressed concrete hollow square pile is provided with a hollow square pile that runs through the entire partially prestressed and partially non-prestressed concrete The central through hole of the part of the prestressed part of the non-prestressed concrete hollow square pile, the outer circumference of the cross section is a rounded square or rectangle, and the inner circumference is a circle, and the part of the prestressed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com