Large coiling device for covering yarns

A technology of core-spun yarn and roll-forming, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. The effect of shedding short fibers and improving work efficiency

Inactive Publication Date: 2022-06-21

XUZHOU YUTU TEXTILE

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When core-spun yarn is rolled, most of the yarn rolls can only be rolled individually when the traditional roll-forming device is used, and it is impossible to use a single power to achieve uniform and compact formation of the yarn rolls

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

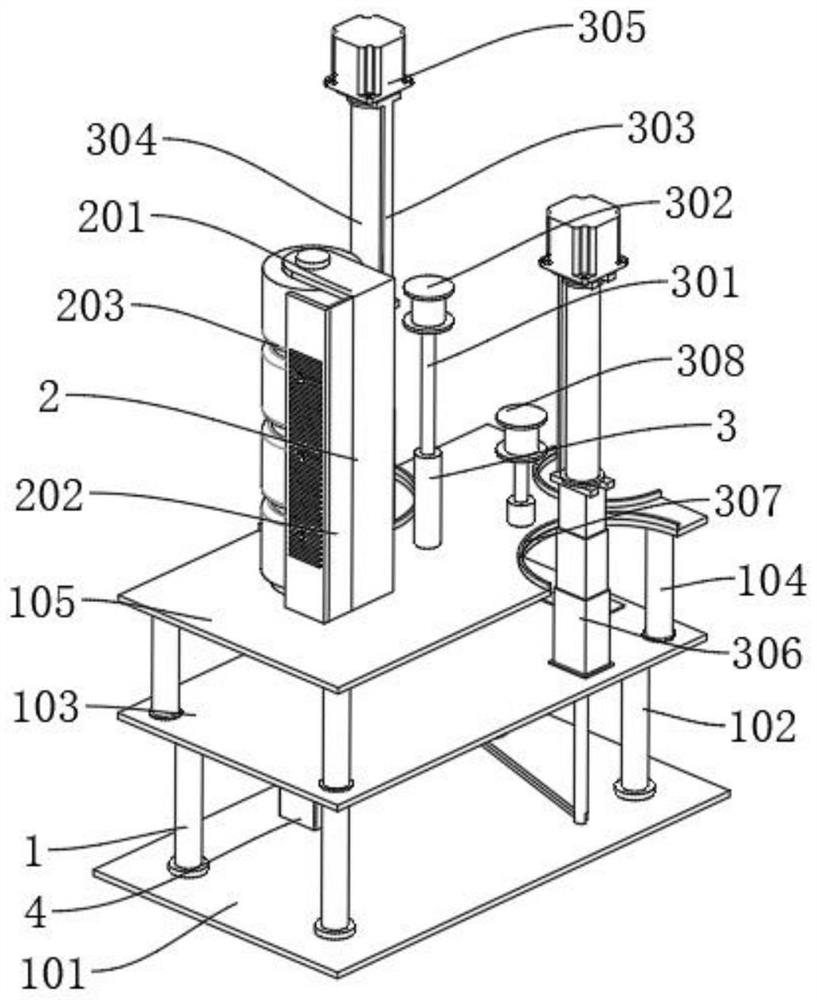

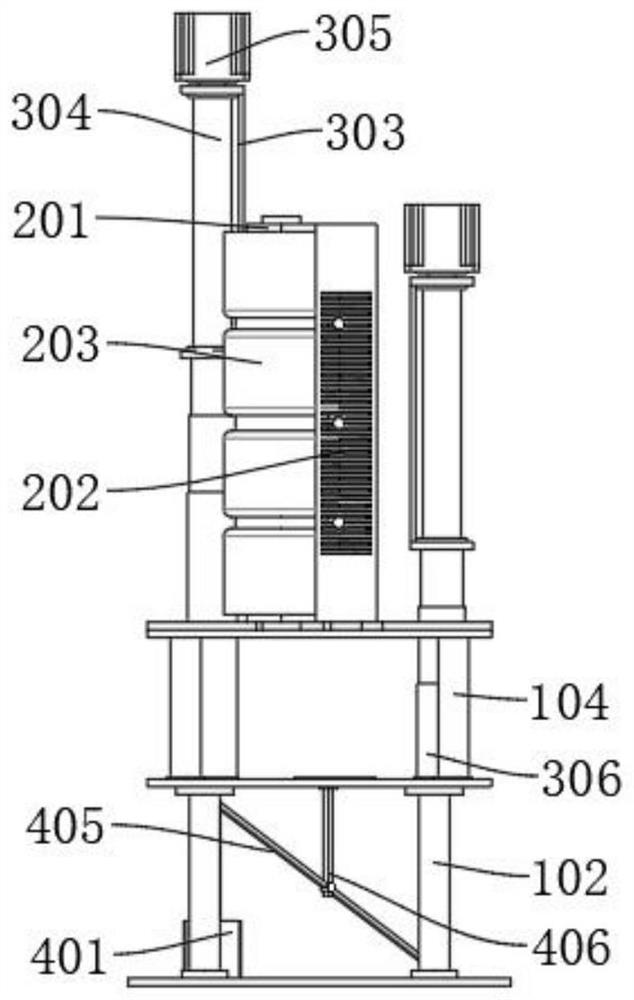

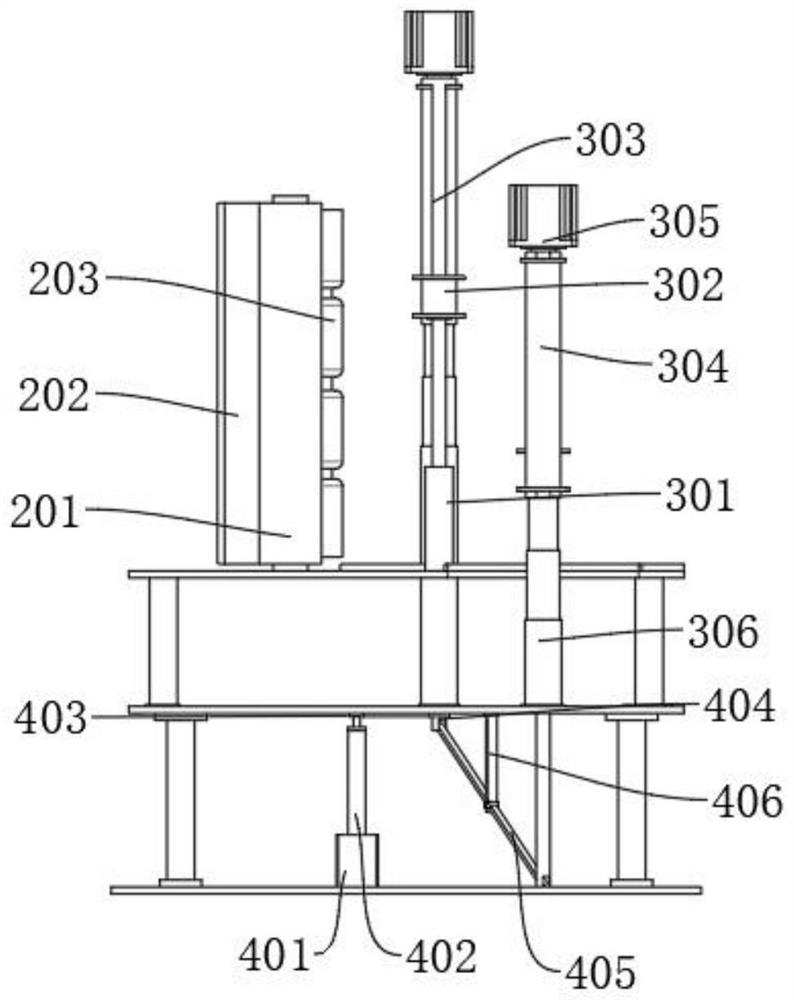

The invention belongs to the technical field of core-spun yarn production devices, and particularly relates to a large core-spun yarn coiling device which comprises a bearing mechanism, a yarn feeding mechanism and a driving mechanism, the yarn feeding mechanism is installed on one side of the upper surface of the bearing mechanism, and the driving mechanism is installed on the rear portion of the upper surface of one layer of the bearing mechanism; the device further comprises a rolling mechanism capable of rolling at the same time. According to the large coiling device for the covering yarn, through the arrangement of the two layers of rectification space, all components can be evenly arranged, and stable work can be guaranteed in the running process; by means of the arrangement of the carding panel, when the covering yarn is fed, the uniform orientation of short fibers can be kept, and the short fibers are prevented from falling off due to disorder; and finally, under the action of a driving air cylinder, linkage of a connecting rod and a bearing rod can be utilized, so that it is guaranteed that the collecting rollers can move in different directions, and simultaneous coiling is achieved.

Description

technical field [0001] The invention belongs to the technical field of core-spun yarn production devices, and in particular relates to a large-scale roll-forming device for core-spun yarns. Background technique [0002] Core-spun yarn, also known as composite yarn or covered yarn, is a new type of yarn composed of two or more fibers. The original core-spun yarn is short fiber and short-fiber core-spun yarn developed with cotton fiber as the skin and polyester spun yarn as the core. New bead thread with polyester coated polyester cored thread. Core-spun yarn is generally a yarn made of synthetic fiber filaments with good strength and elasticity as the core yarn, and short fibers such as cotton, wool, and viscose fibers are twisted and spun together. The core-spun yarn combines the excellent properties of the filament core yarn and the outer staple fiber. The more common core-spun yarn is polyester-cotton core-spun yarn, which uses polyester filament as the core yarn and ou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H57/06B65H57/14B65H54/70

CPCB65H57/06B65H57/14B65H54/70B65H2701/174B65H2701/31

Inventor 王俊杰

Owner XUZHOU YUTU TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com