Patents

Literature

45results about How to "Soft transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sole

Owner:ADIDAS

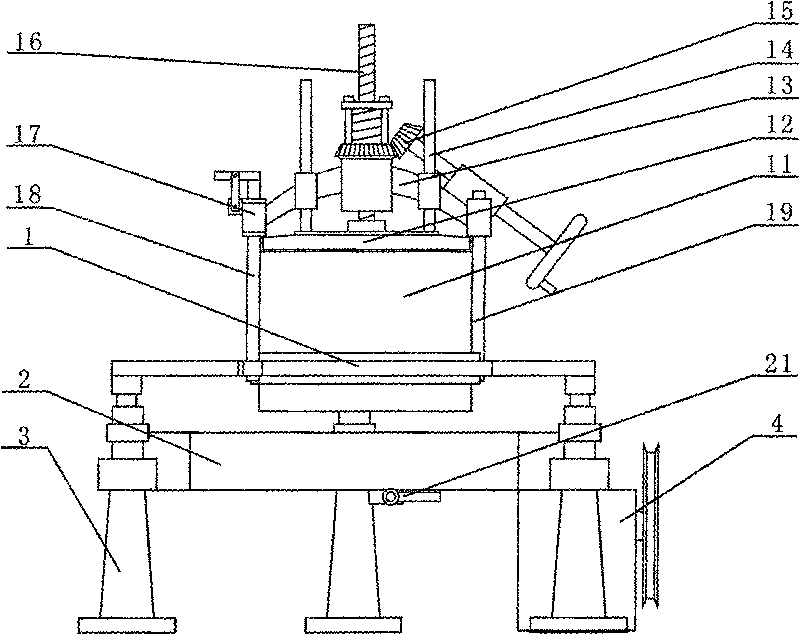

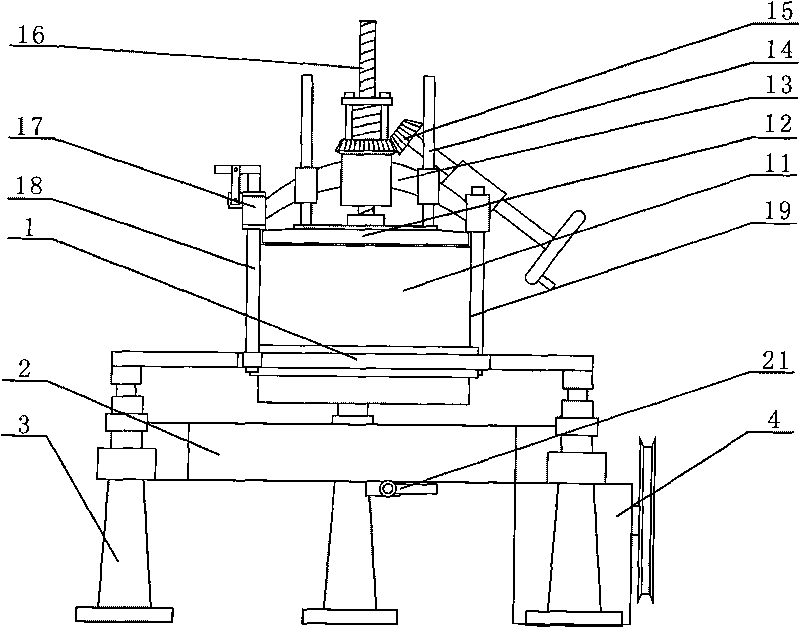

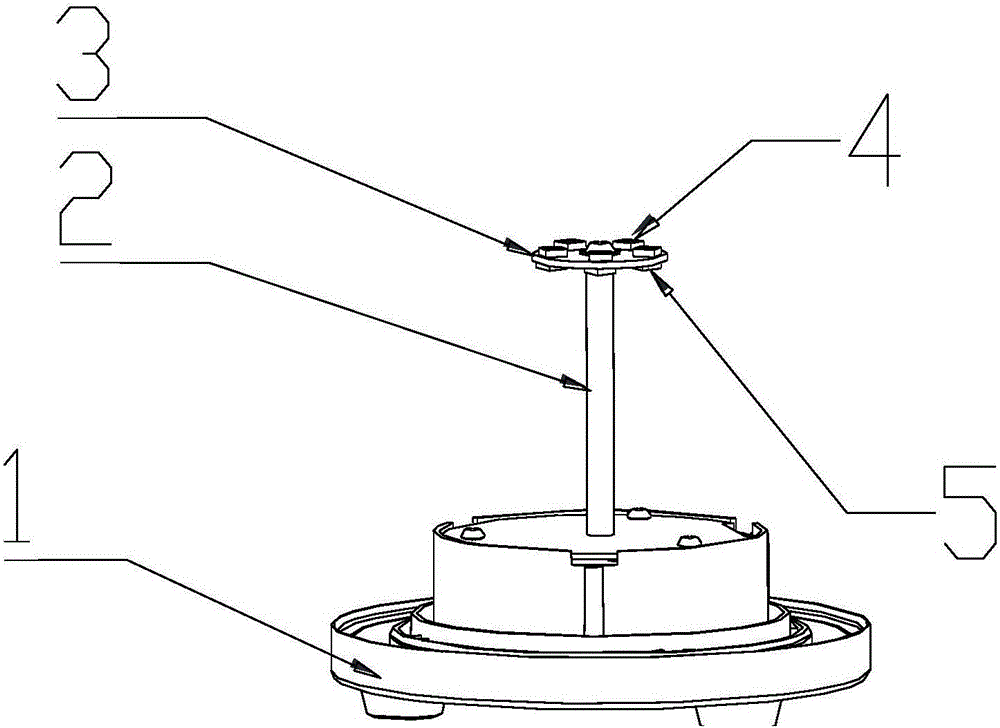

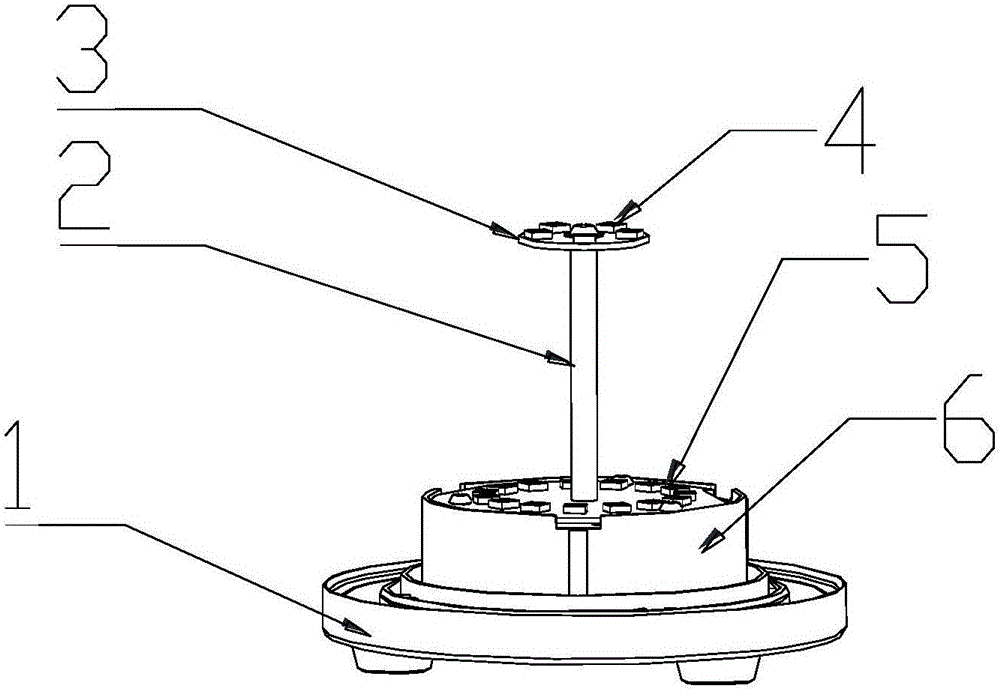

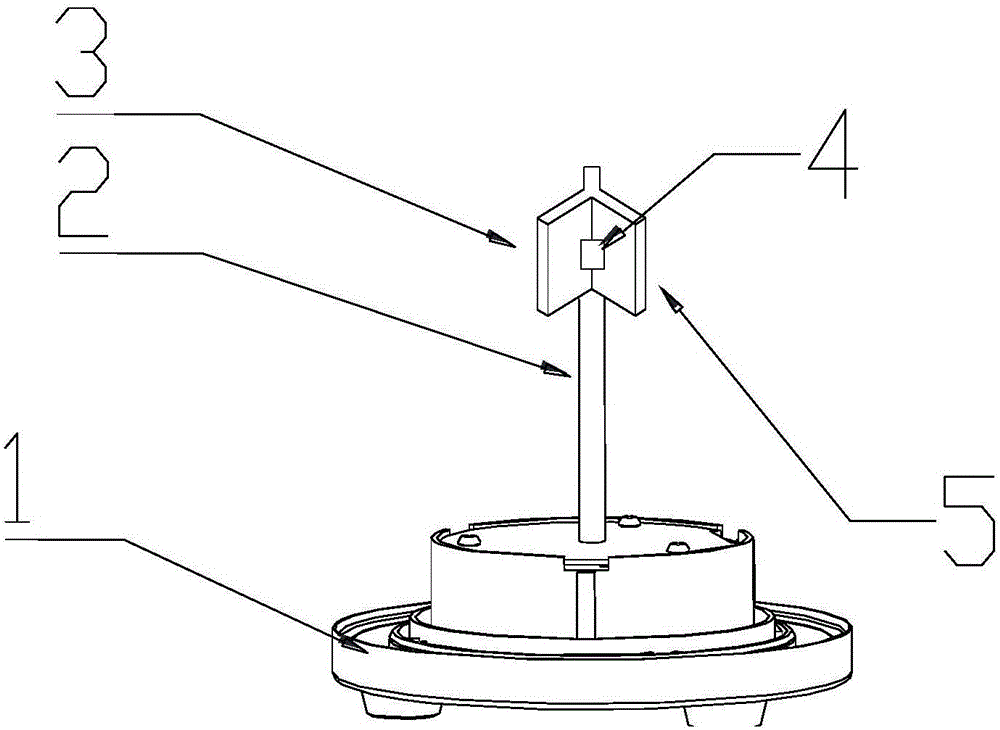

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

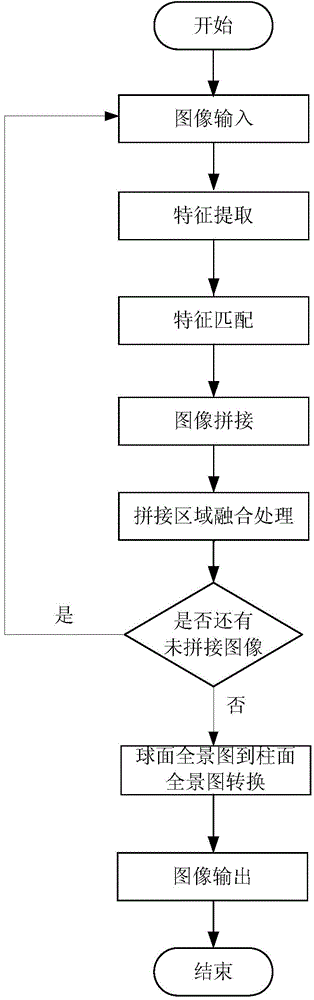

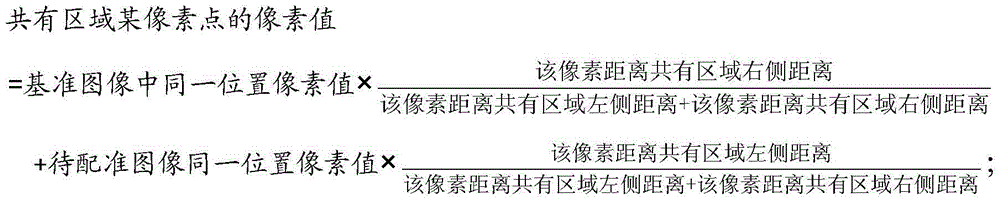

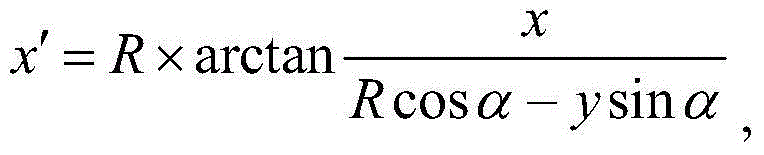

Panoramagram generation method

ActiveCN104463778AHigh precisionSmall distortionGeometric image transformationPoint pairSpherical coordinate system

The invention provides a panoramagram generation method which includes the steps that (1) for the same region, a benchmark image and an image to be registered are obtained; (2) pixel characteristic value sequences are generated for the two images respectively; (3) front M pixel points in the two sequences are selected to serve as characteristic points; (4) feature matching is conducted on the two sets of characteristic points, and a matching point pair sequence is obtained; (5) an affine mapping relation is built according to the matching point pair sequence, and a transformed image to be registered is obtained; (6) the shared regions on the two images are fused, and a spherical panoramagram for the same region is obtained; (7) the spherical panoramagram is converted to be an unfolded planar coordinate system from a spherical coordinate system, and a panoramagram is generated. The method is simple in overall procedure, high in speed and capable of generating the panoramagram with high accuracy and small deformation under the conditions that the lens pitch angle is unknown and the rotating angle is unknown and converting the spherical surface of the panoramagram to a plane, and watching is facilitated for users.

Owner:BEIJING INST OF CONTROL ENG

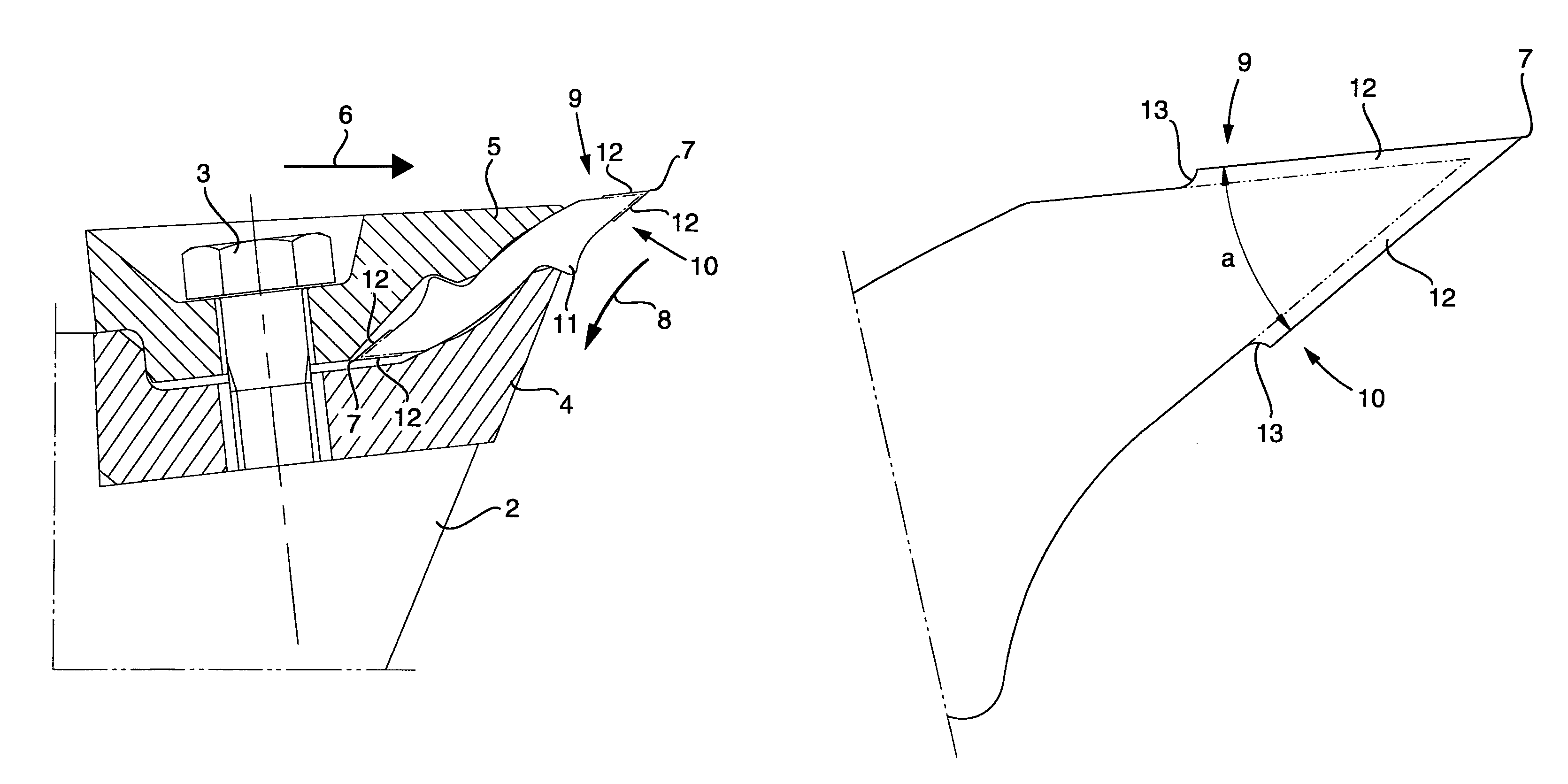

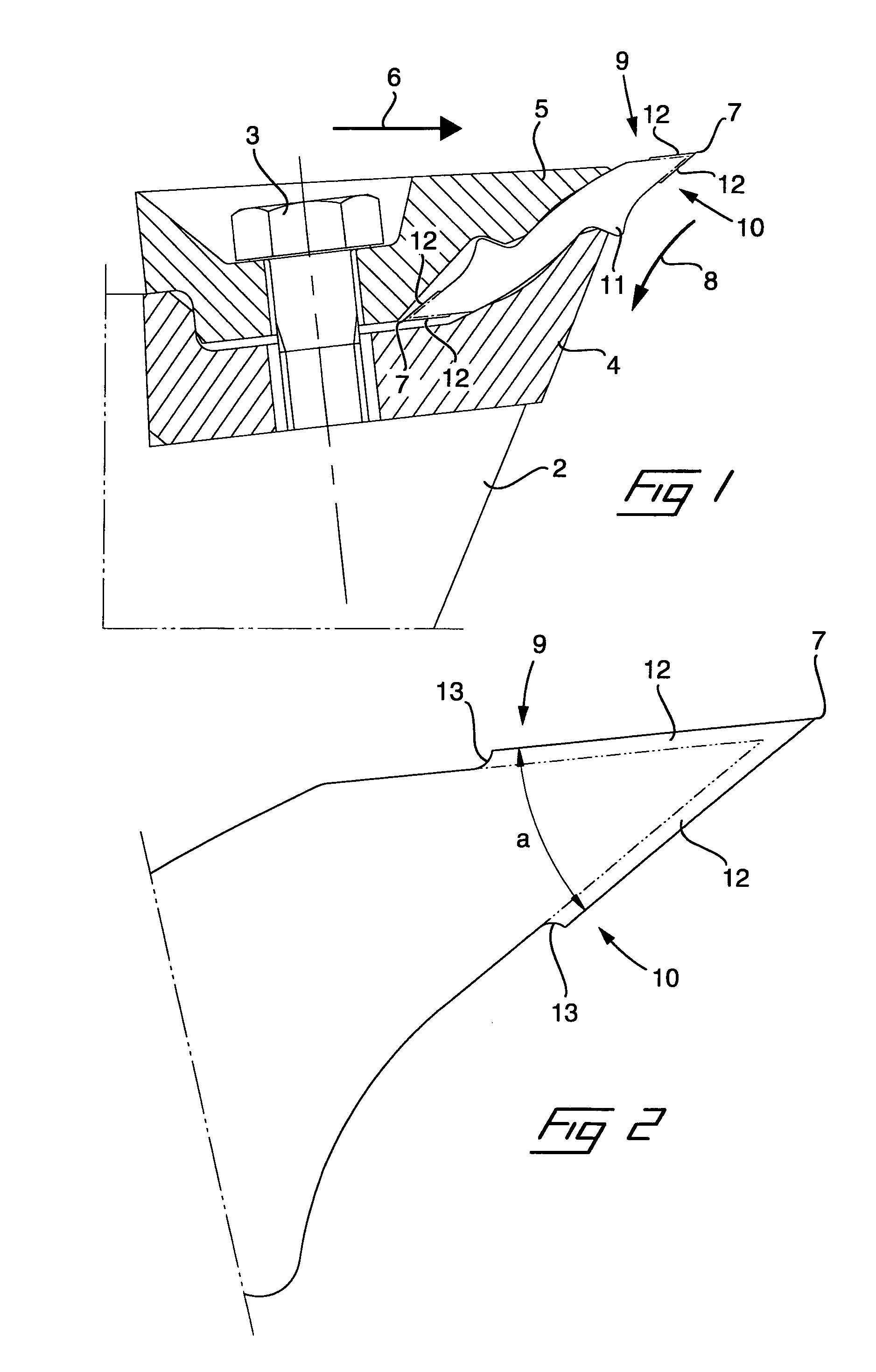

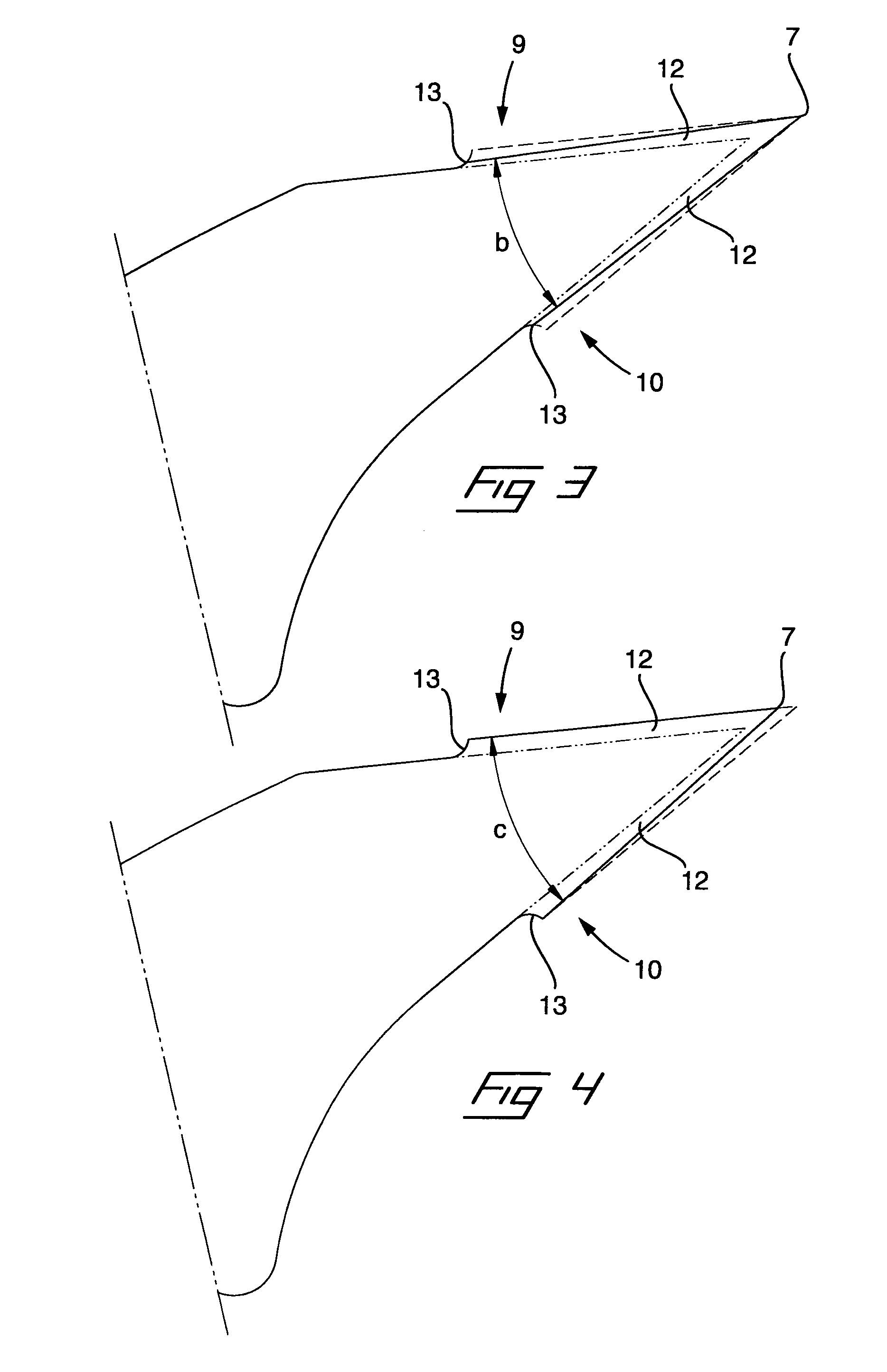

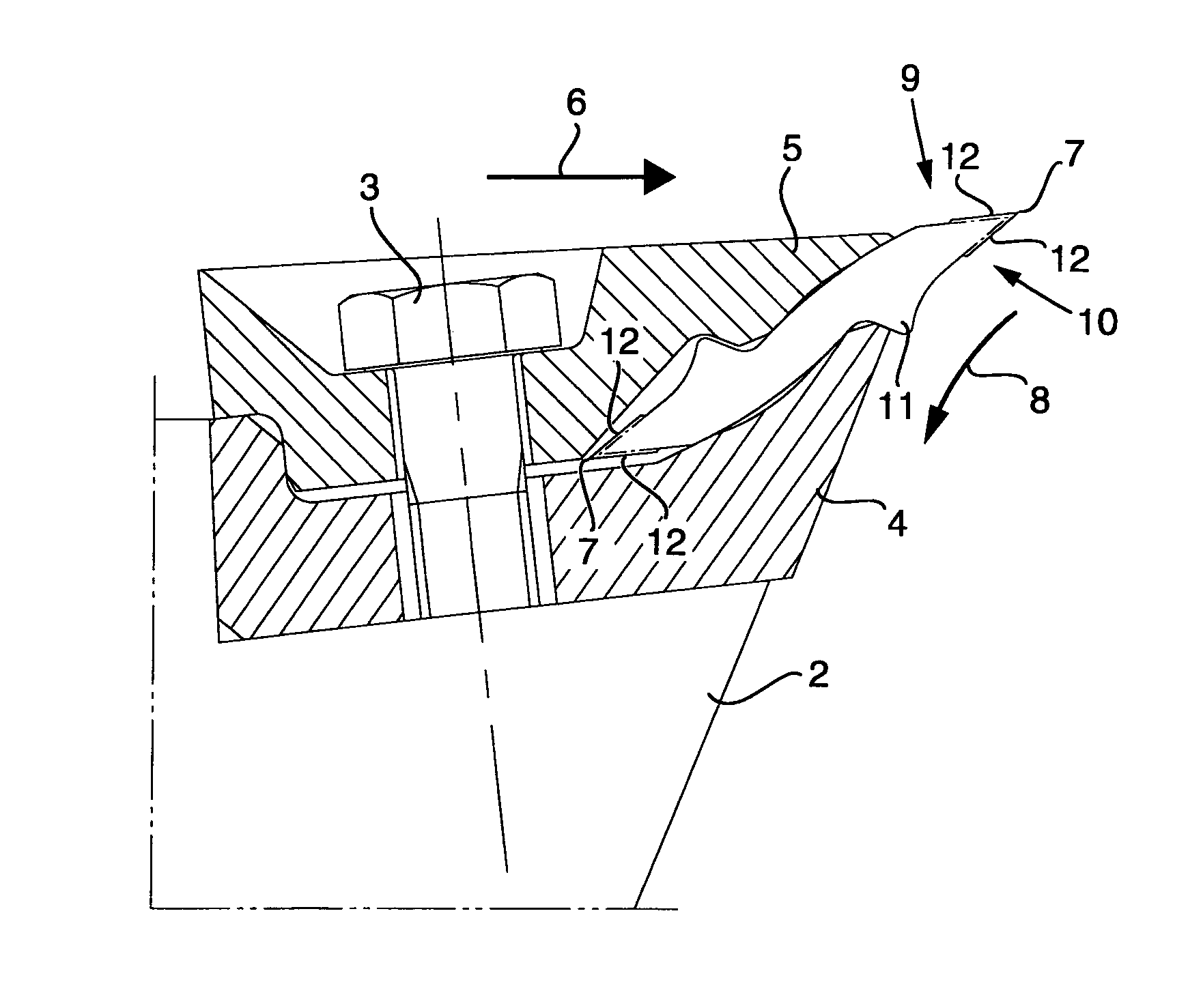

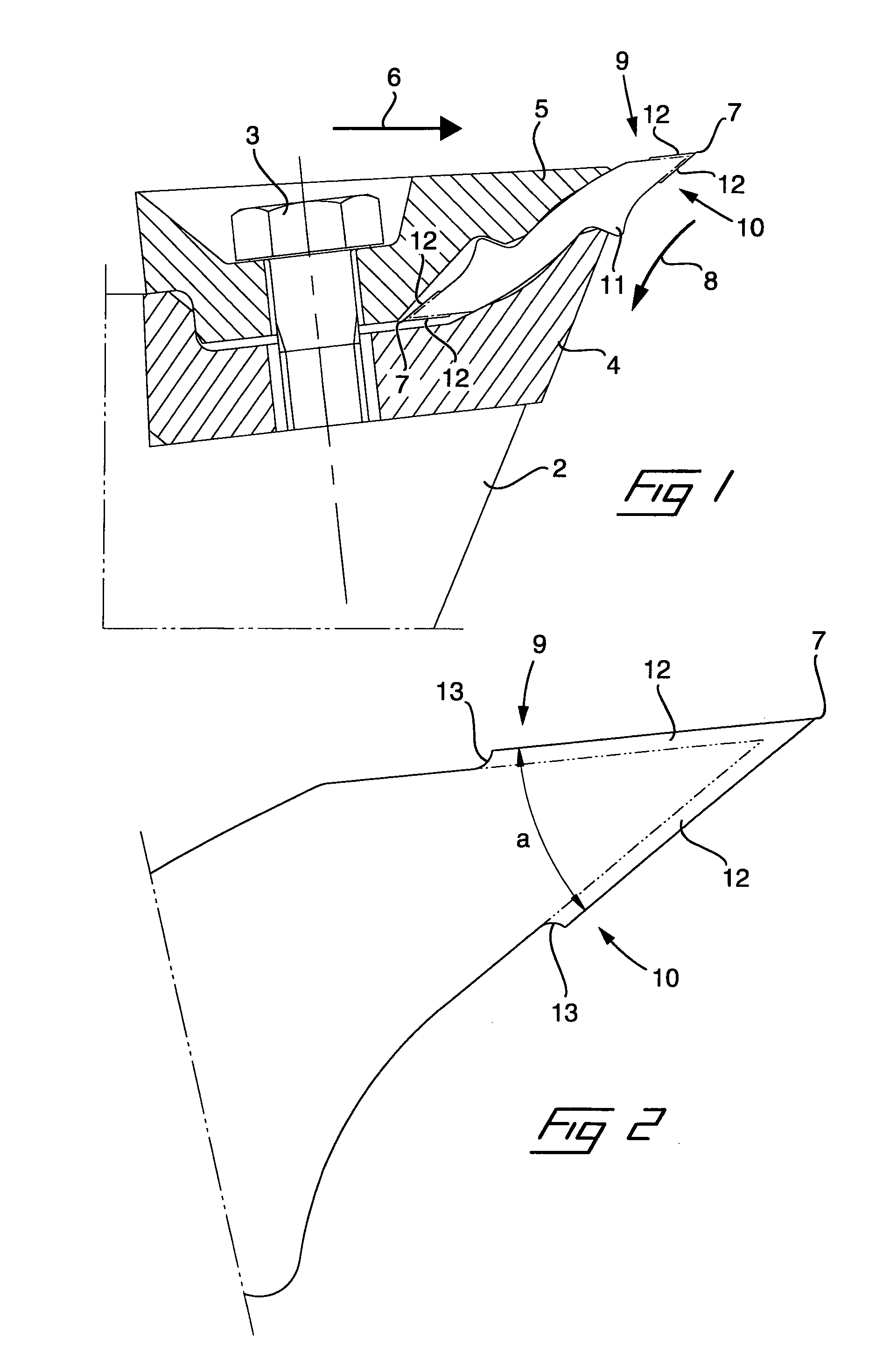

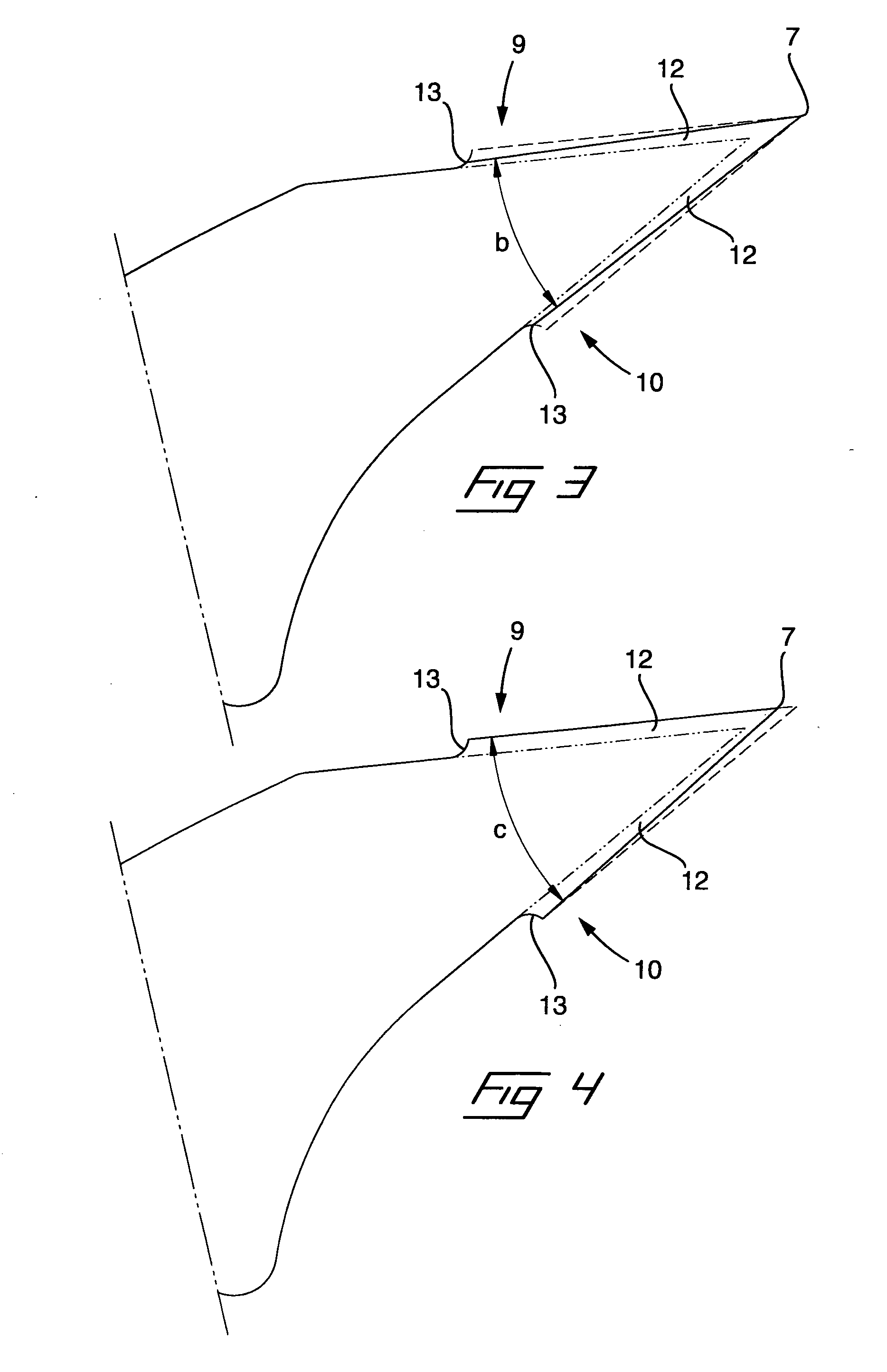

Chipper knife and method of manufacturing a chipper knife

A chipper knife adapted to be mounted in chippers which have a rotatable tool, in the form of a disc, drum or frustoconical member, on which a plurality of chipper knives are mounted has at least one cutting edge which is defined between two edge-forming surface portions of the knife at an acute angle to each other. At least one of the two edge-forming surface portions extends from the cutting edge inwardly to a shoulder extending parallel to and facing away from the cutting edge and defining a step surface on the knife behind the shoulder with respect to the rest of the adjacent knife surface and chipper knife.

Owner:IGGESUND TOOLS

3D panorama parking assistance system

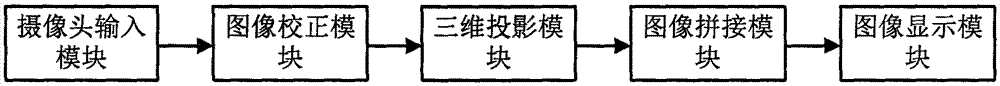

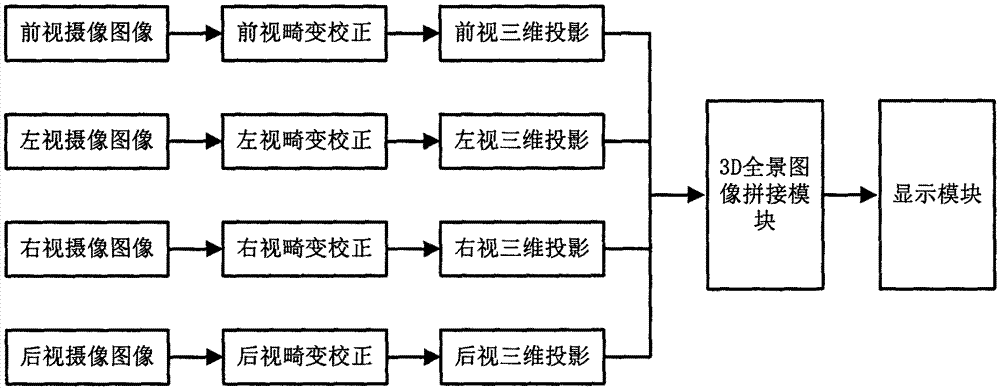

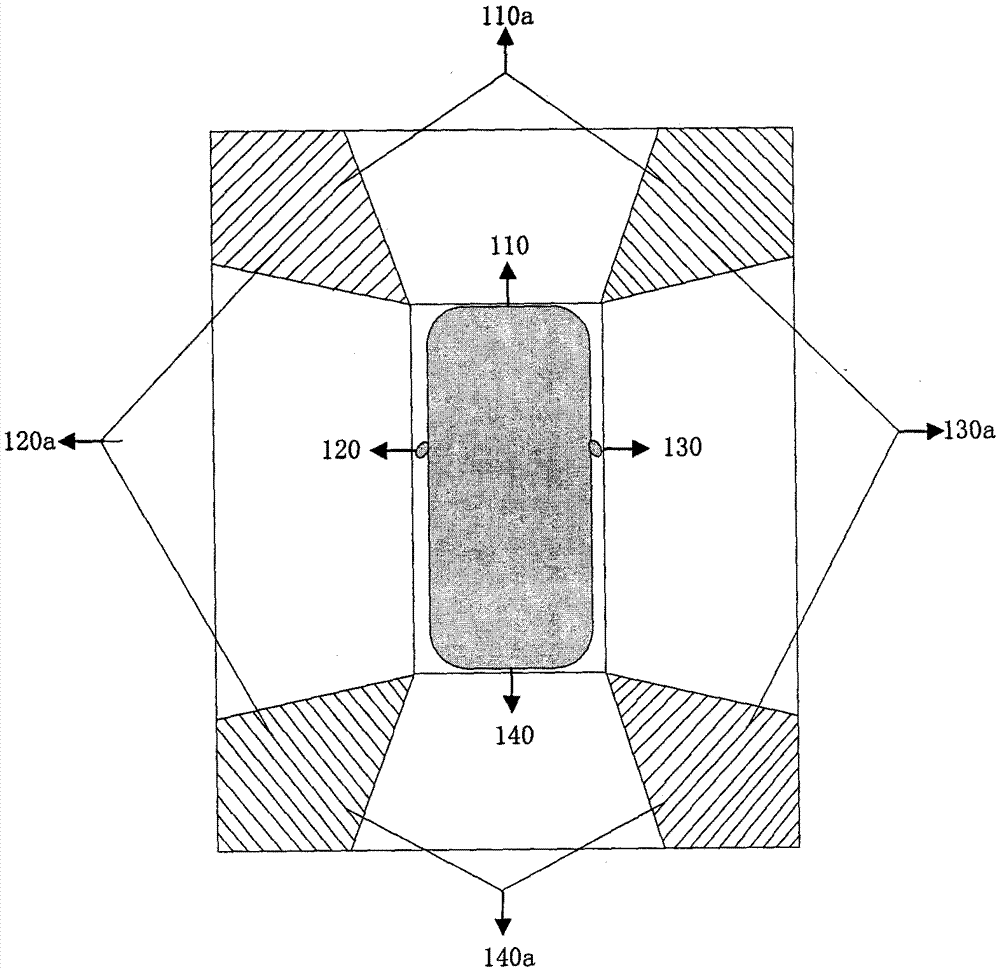

The invention discloses a 3D panorama parking assistance system and belongs to technologies applied to the field of automobile safety aided driving. The 3D panorama parking assistance system comprises a camera input module, an image correcting module, a three-dimensional projection module, an image splicing module and an image display module. The system shows the conditions around an automobile to a driver truly through a three-dimensional image, so that safety in the automobile parking process is improved. According to the system, a plurality of machine vision and digital image processing algorithms are integrated and combined with multiple advanced technologies of the machine vision field, so that the automobile parking process is higher in safety.

Owner:广州求远电子科技有限公司

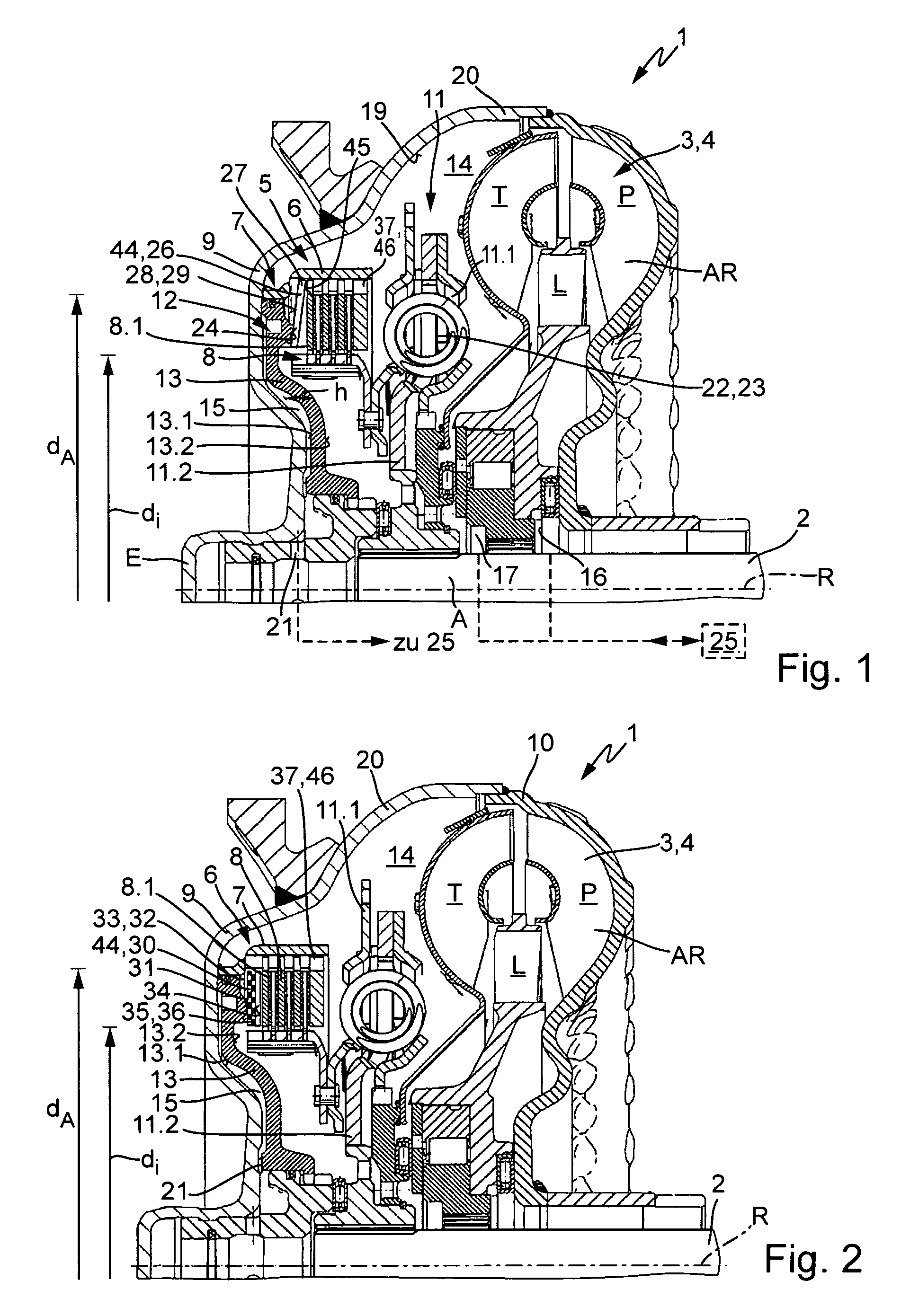

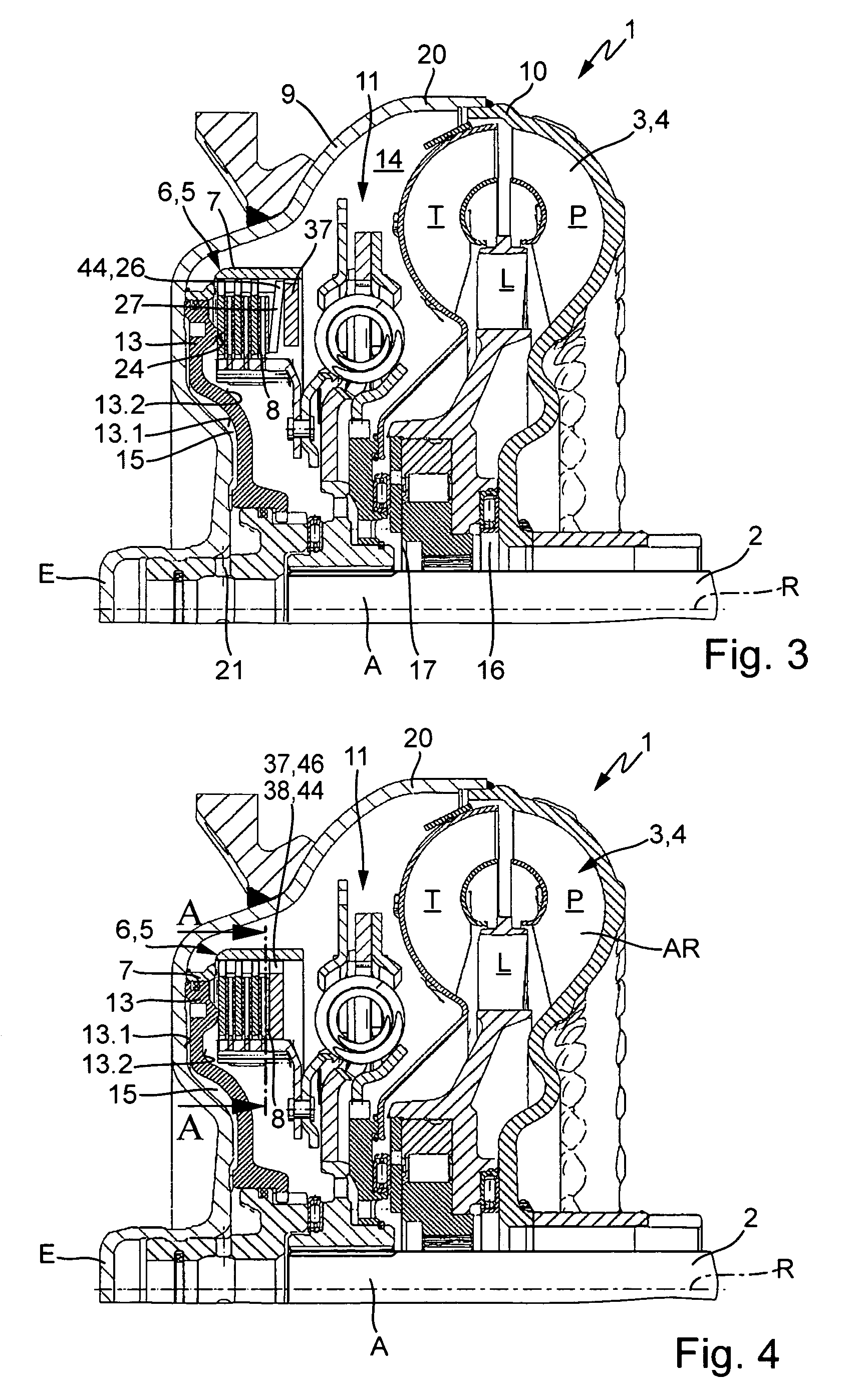

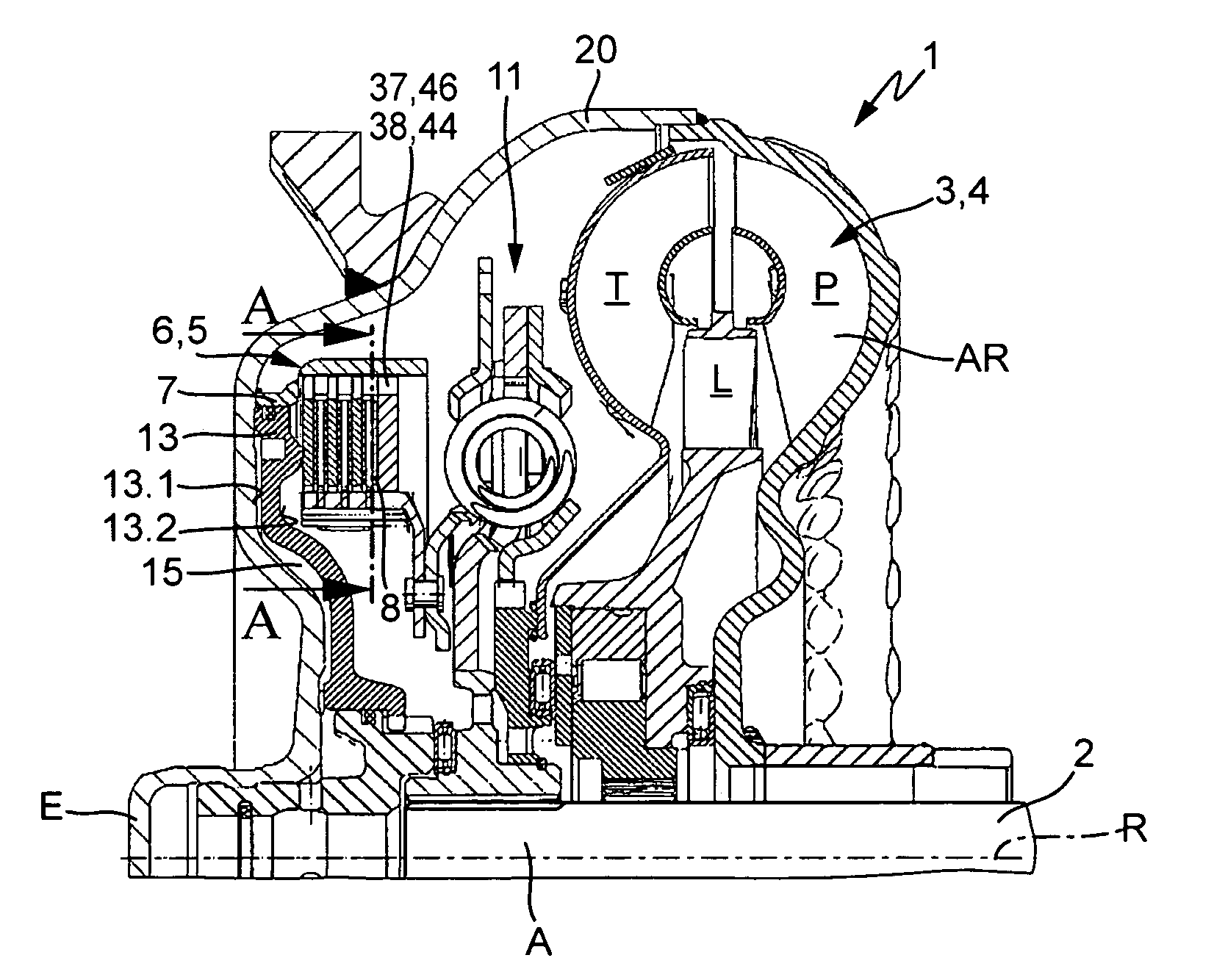

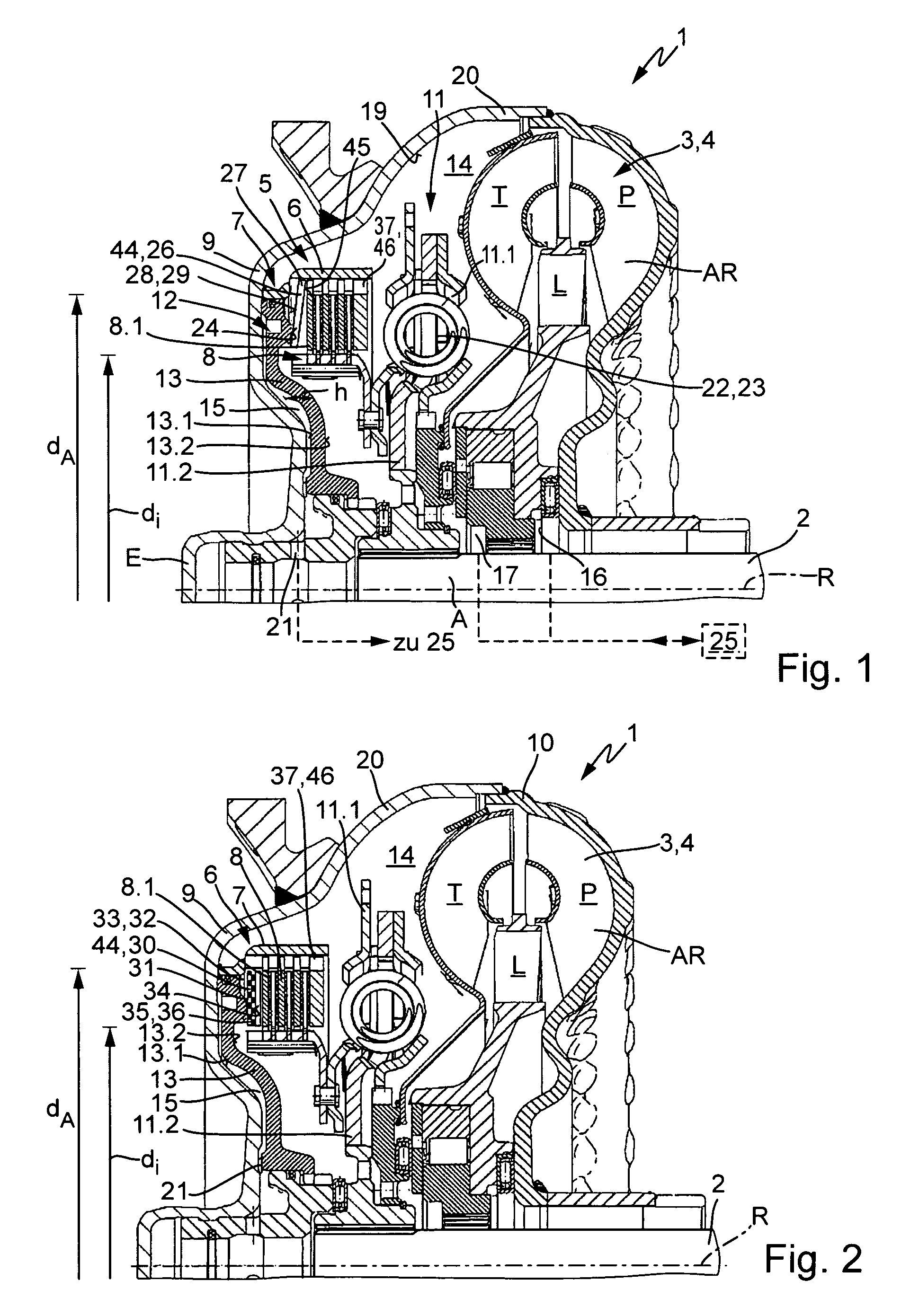

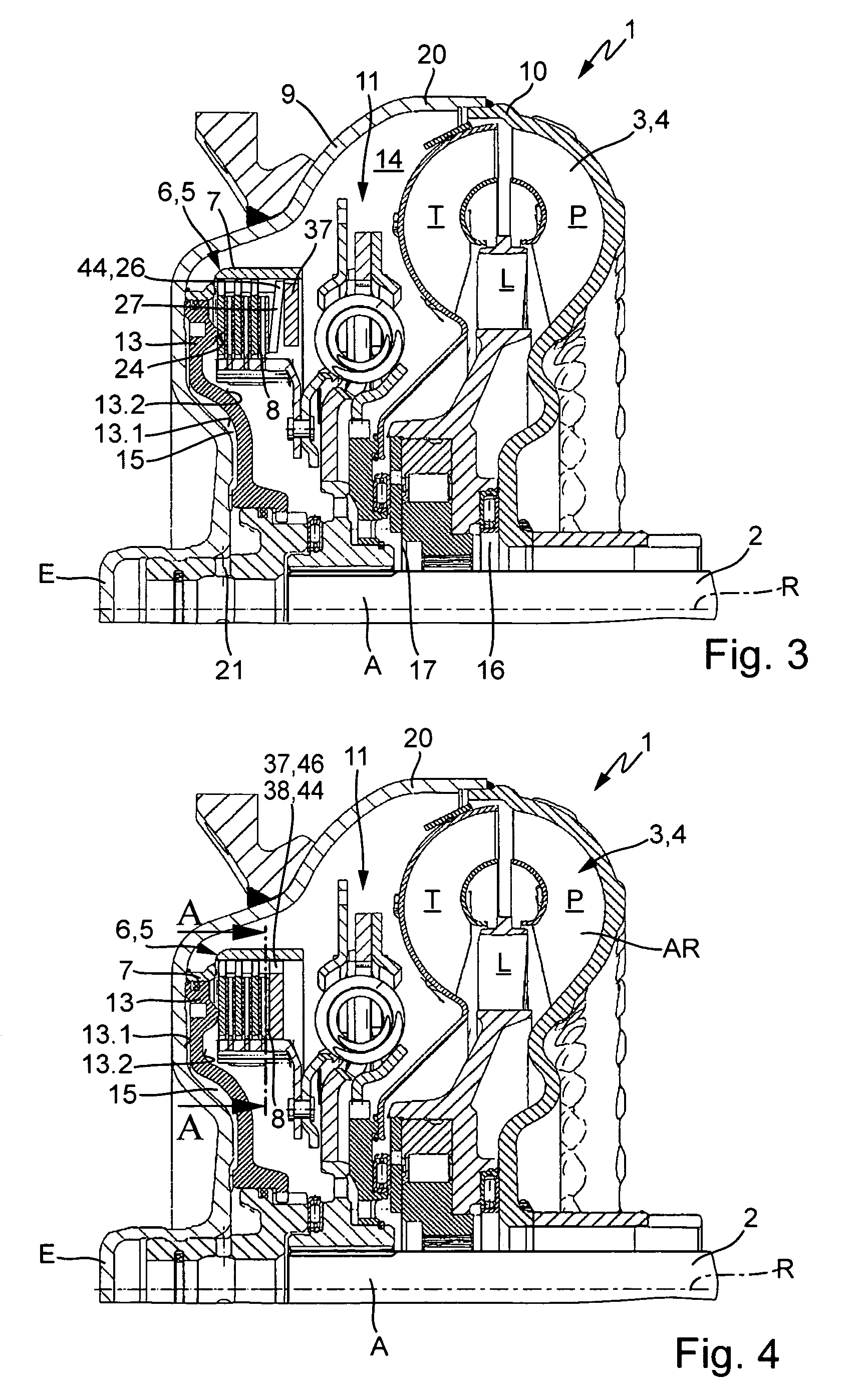

Power transmission mechanism

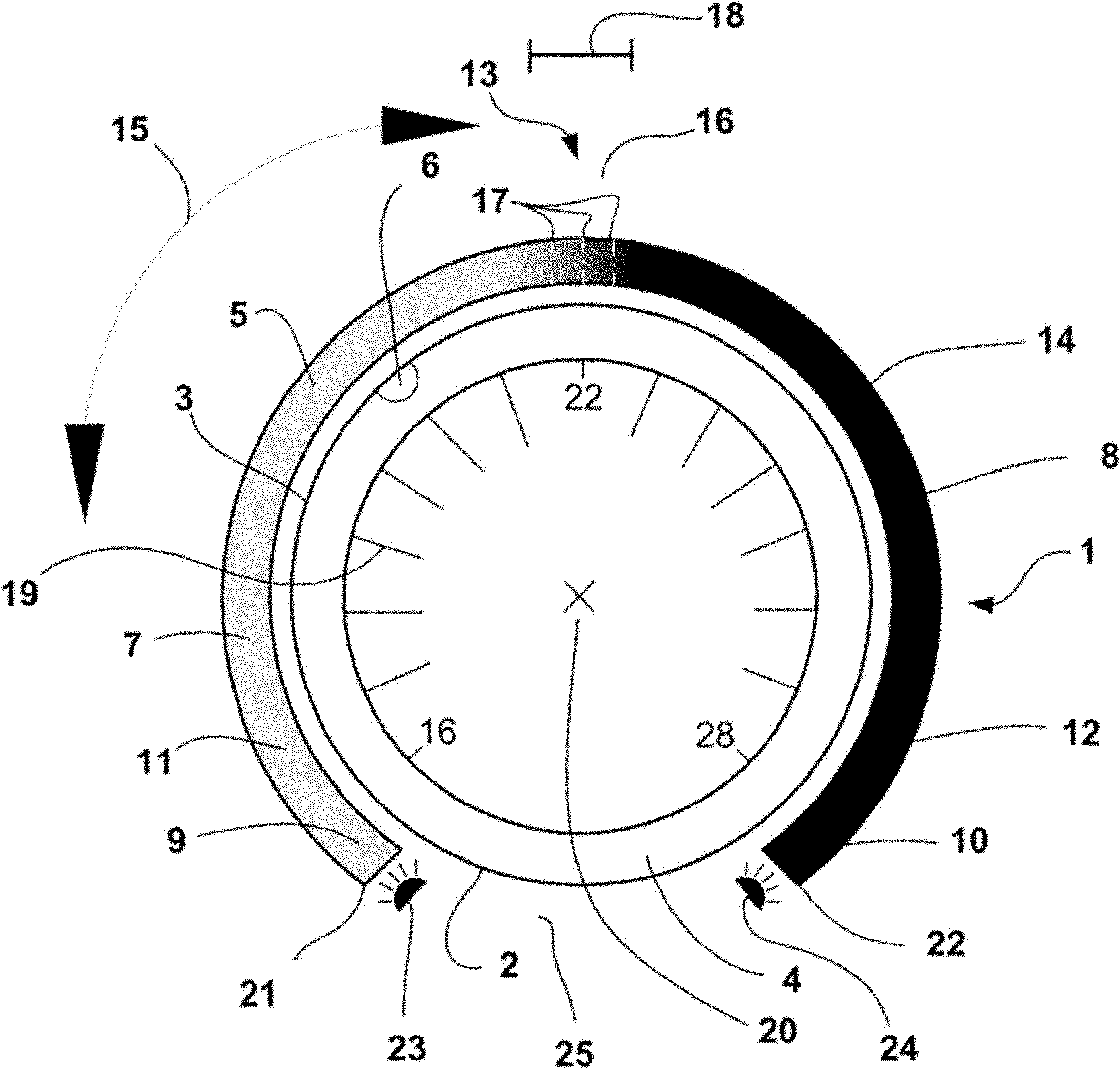

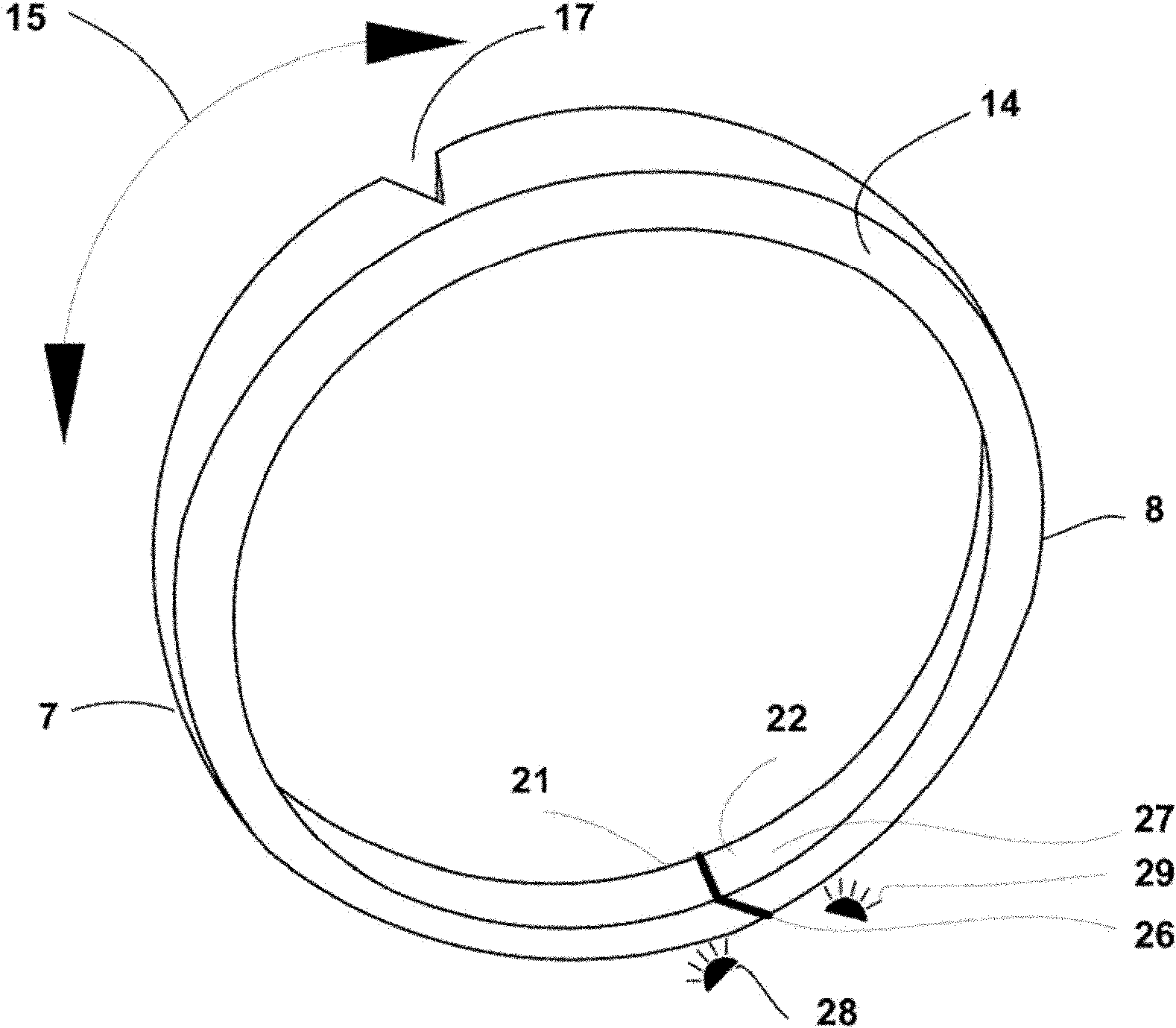

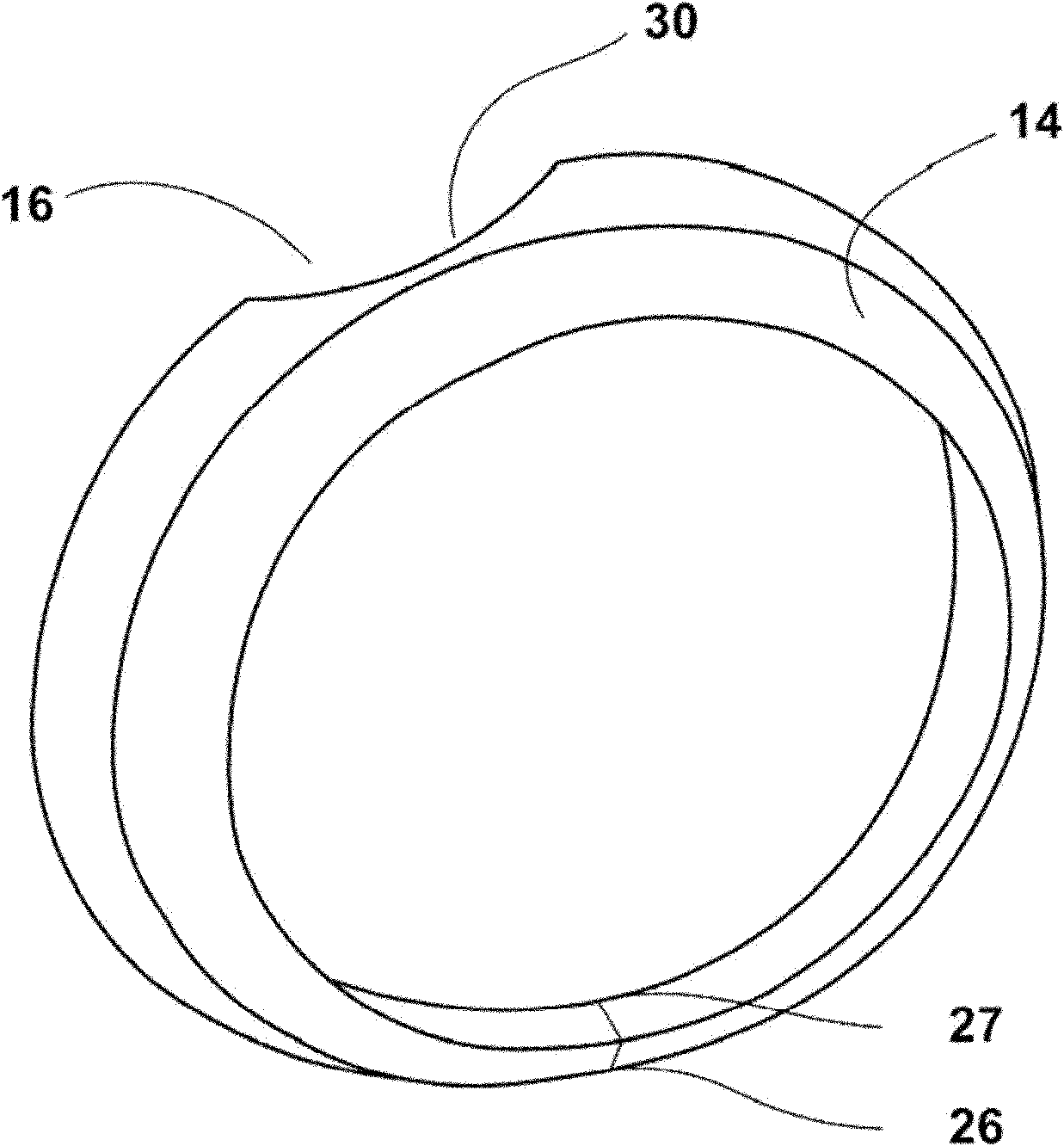

InactiveUS20090127049A1Feel goodHigh modulusRotary clutchesFluid gearingsElectrical and Electronics engineeringPower transmission

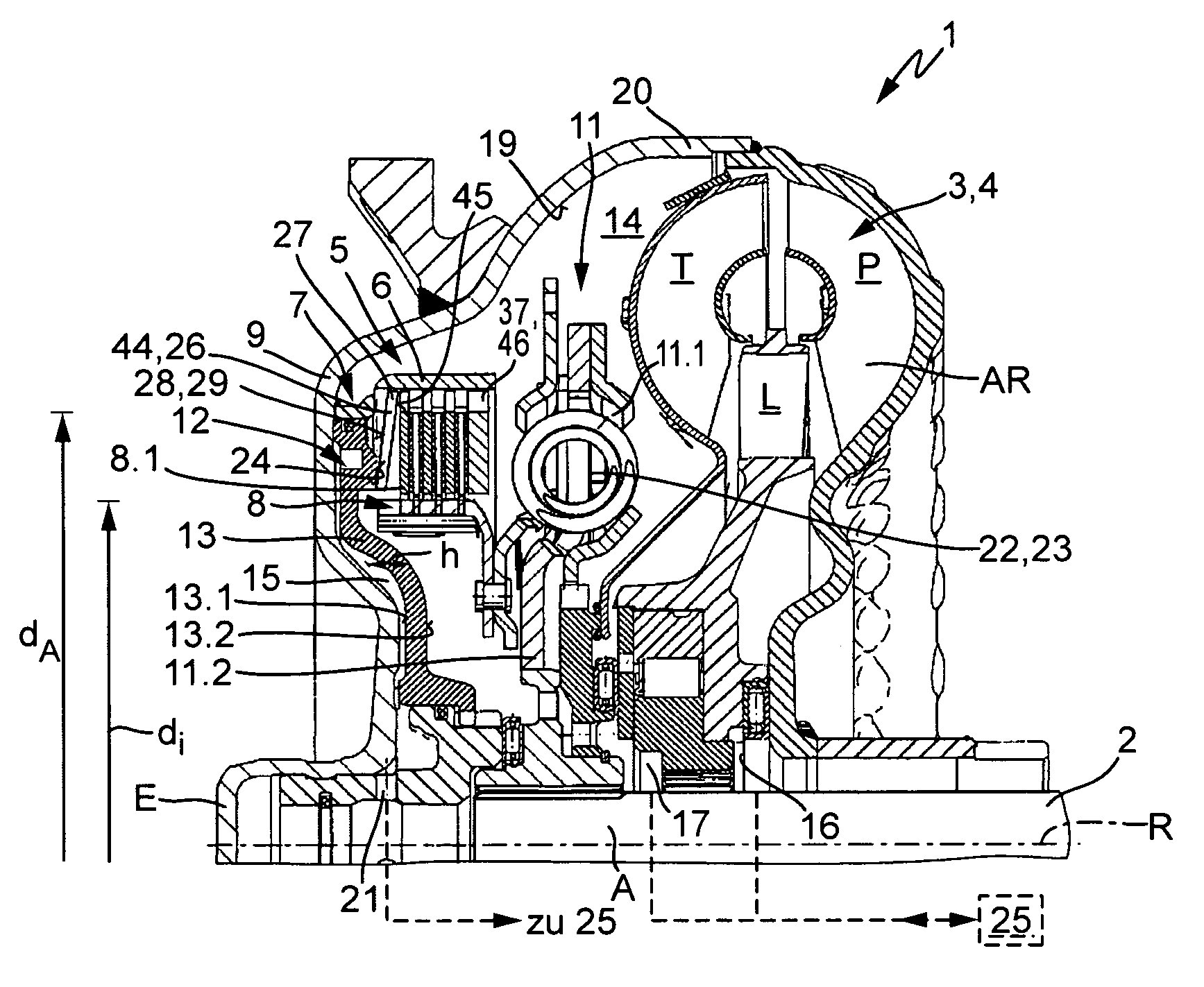

A power transmission mechanism including at least one hydrodynamic component and a device for at least partially bridging over the transmission of power through the hydrodynamic component by means of a control device, having an actuating mechanism that can be charged by way of a chamber that is chargeable with a pressurizing agent, and at least one spring unit is interposed between the actuating mechanism and the device for at least partially bridging over the hydrodynamic component.

Owner:SCHAEFFLER TECH AG & CO KG

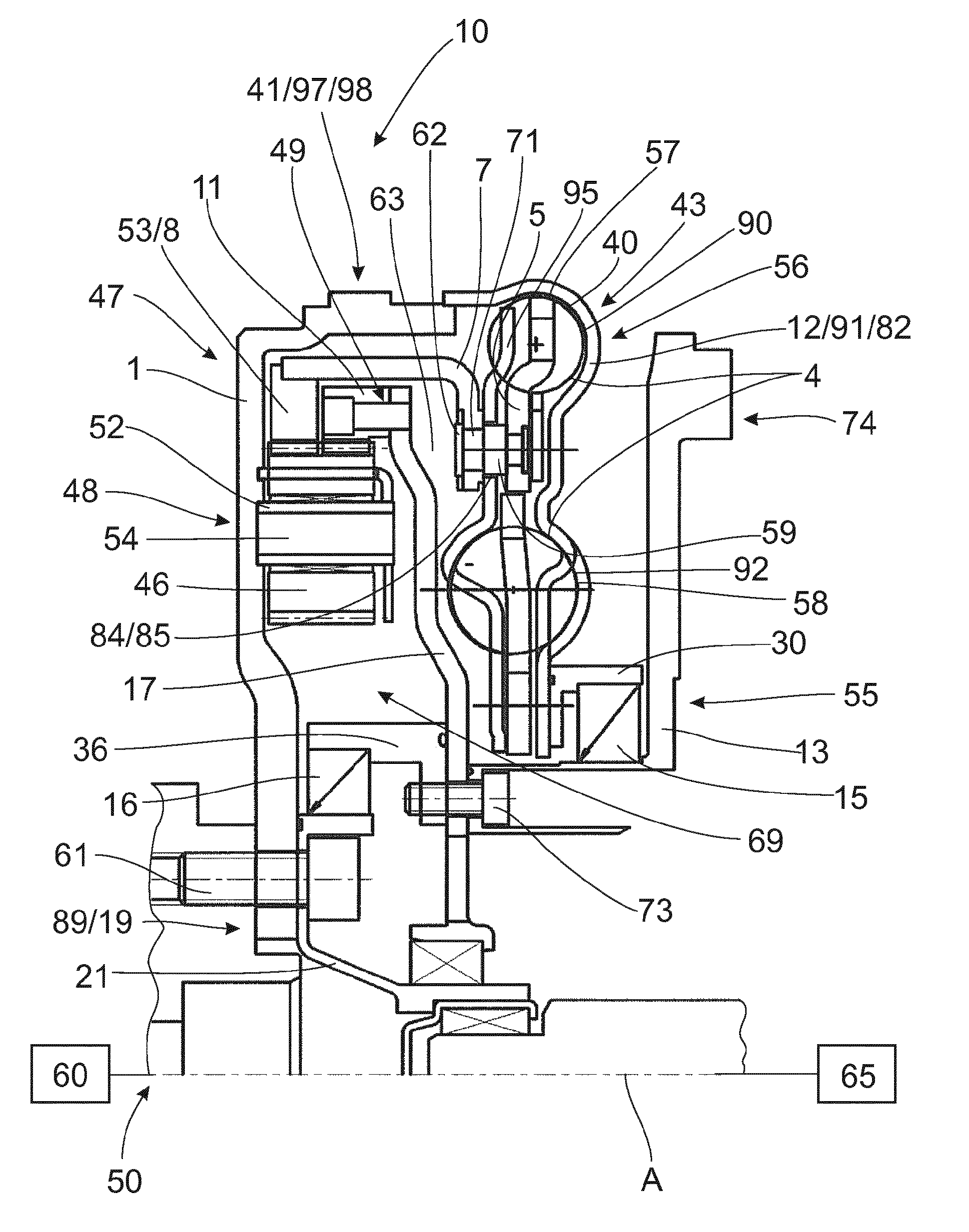

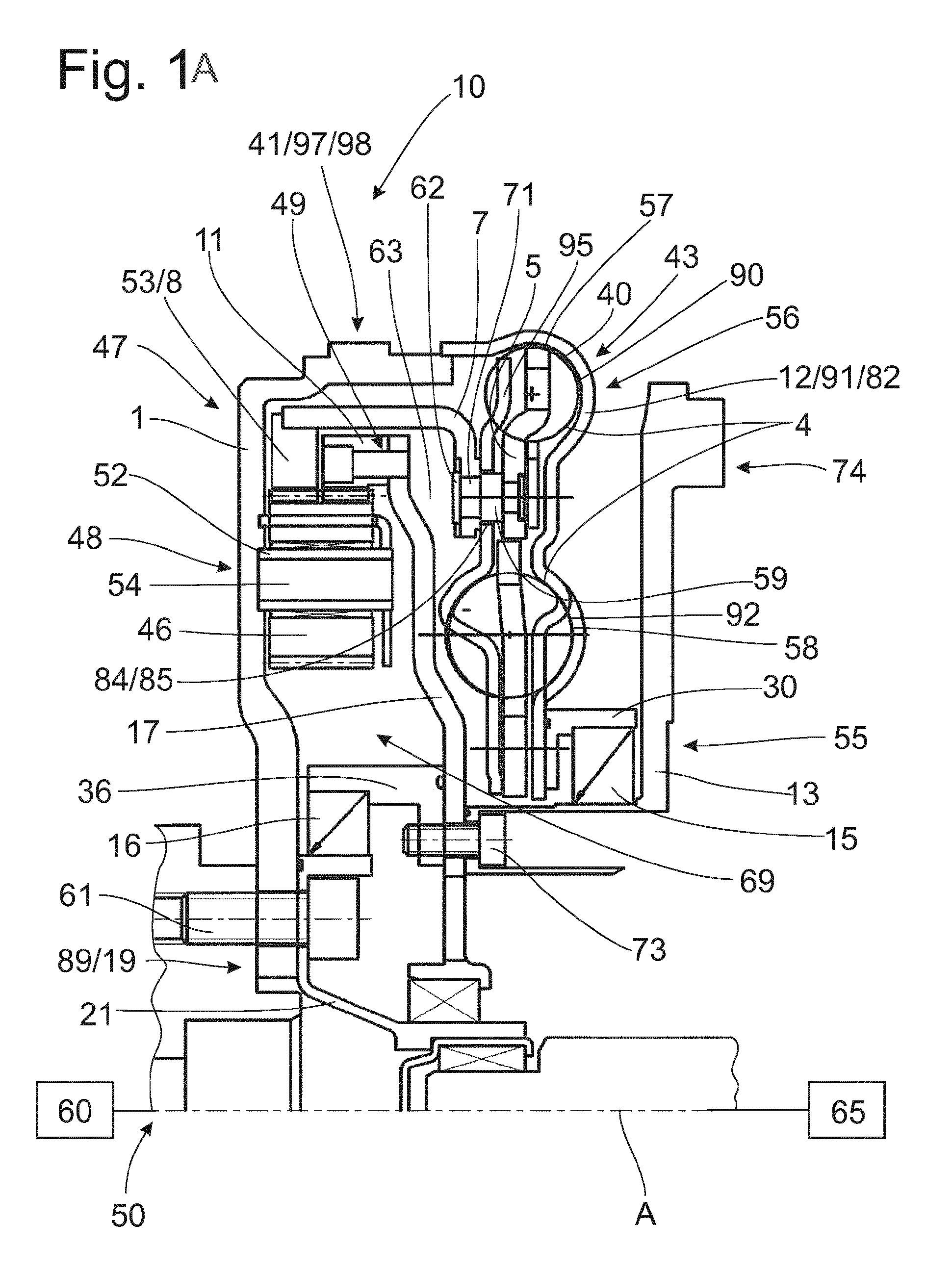

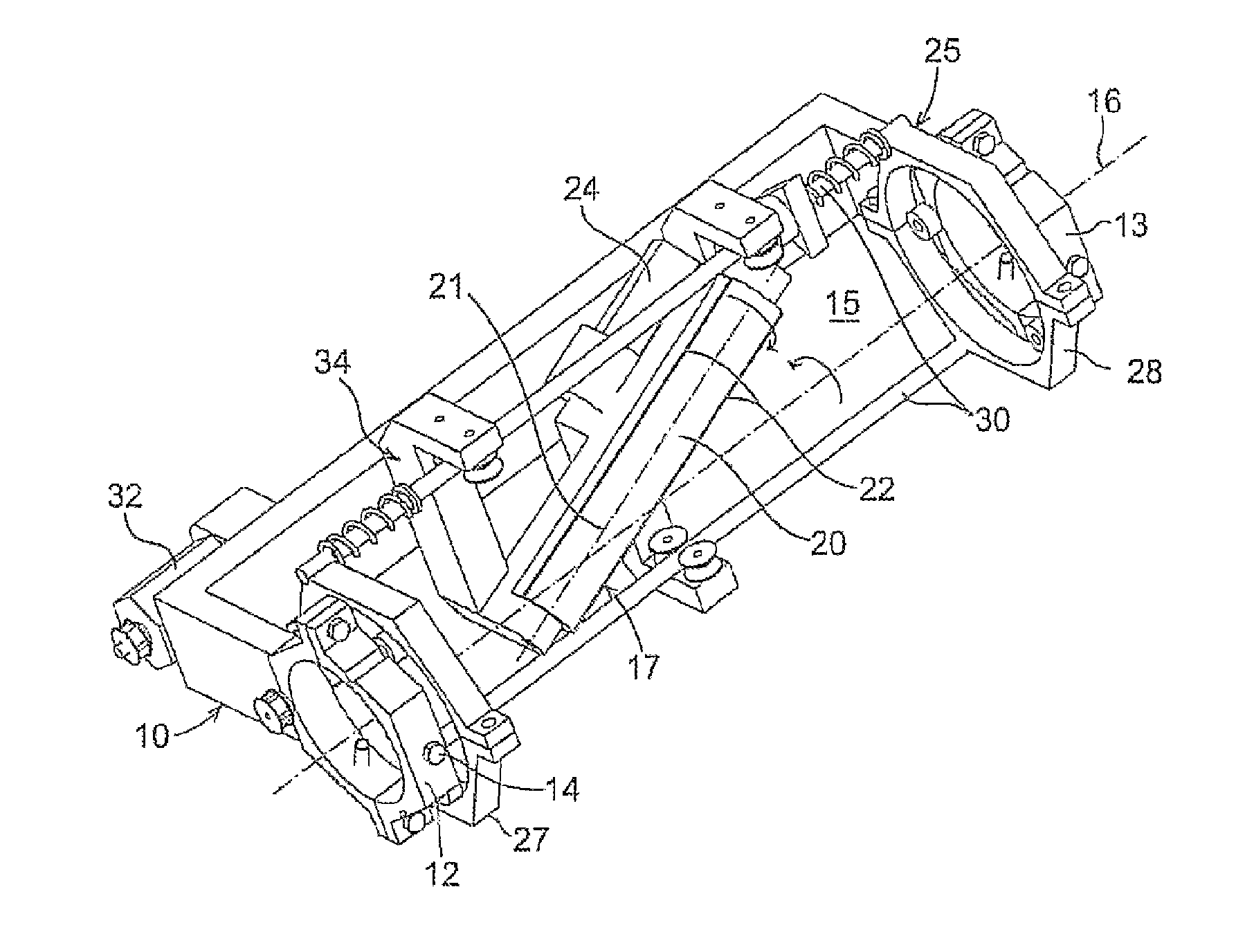

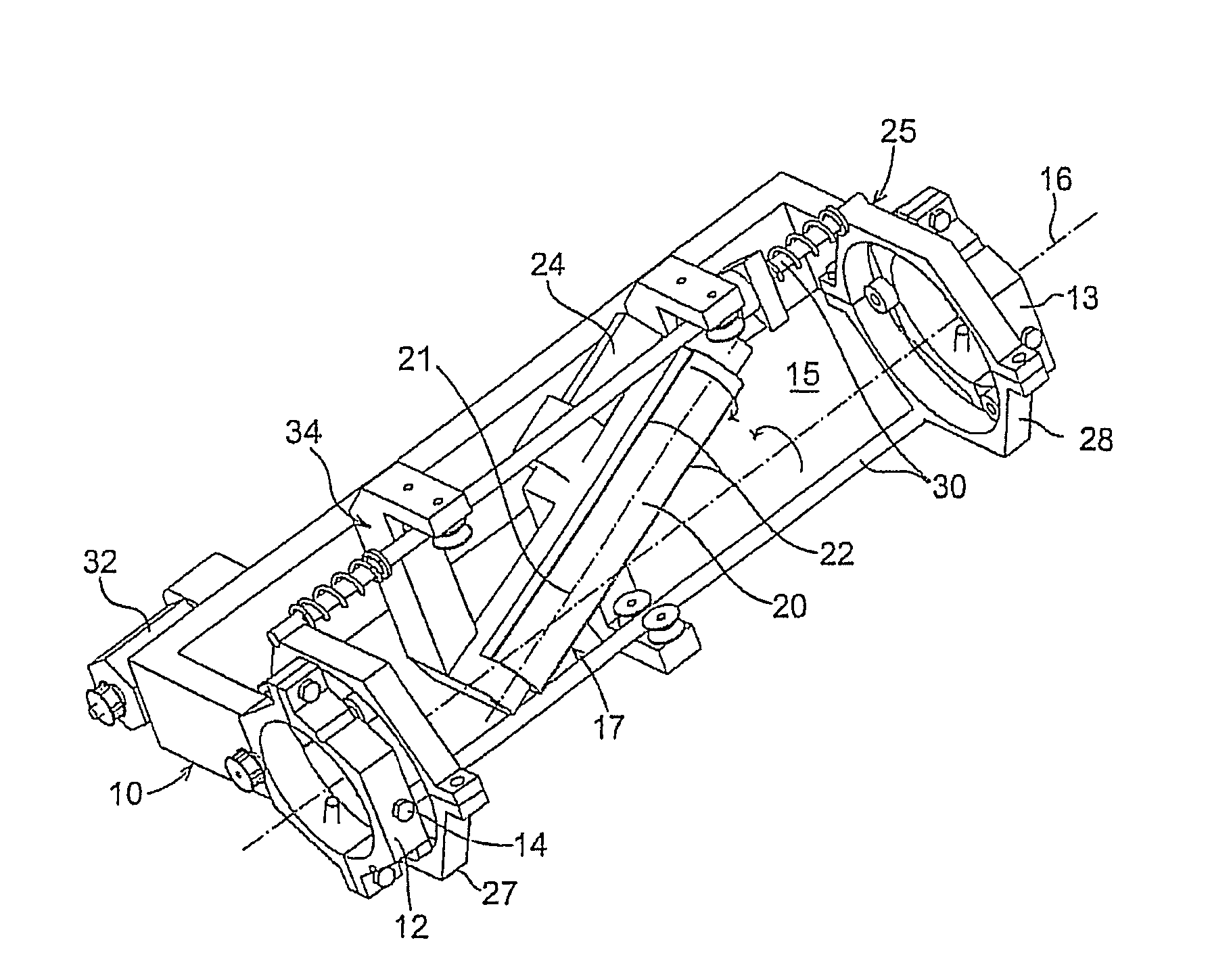

Torsional Vibration Damping Arrangement For Said Powertrain Of A Vehicle

A torsional vibration damping arrangement (10) for the drivetrain of a vehicle comprises an input region (50) to be driven in rotation around an axis of rotation A and an output region (55), and a first torque transmission path (47) and parallel thereto a second torque transmission path (48) which proceed from the input region, and a coupling arrangement (41) for superposing the torques guided via the two torque transmission paths, which coupling arrangement (41) communicates with the output region, and a phase shifter arrangement (43) for the first torque transmission path for generating a phase shift of rotational irregularities guided via the first torque transmission path relative to rotational irregularities guided via the second torque transmission path. The phase shifter arrangement comprises at least one spring set (40) with a curved spring (90).

Owner:ZF FRIEDRICHSHAFEN AG

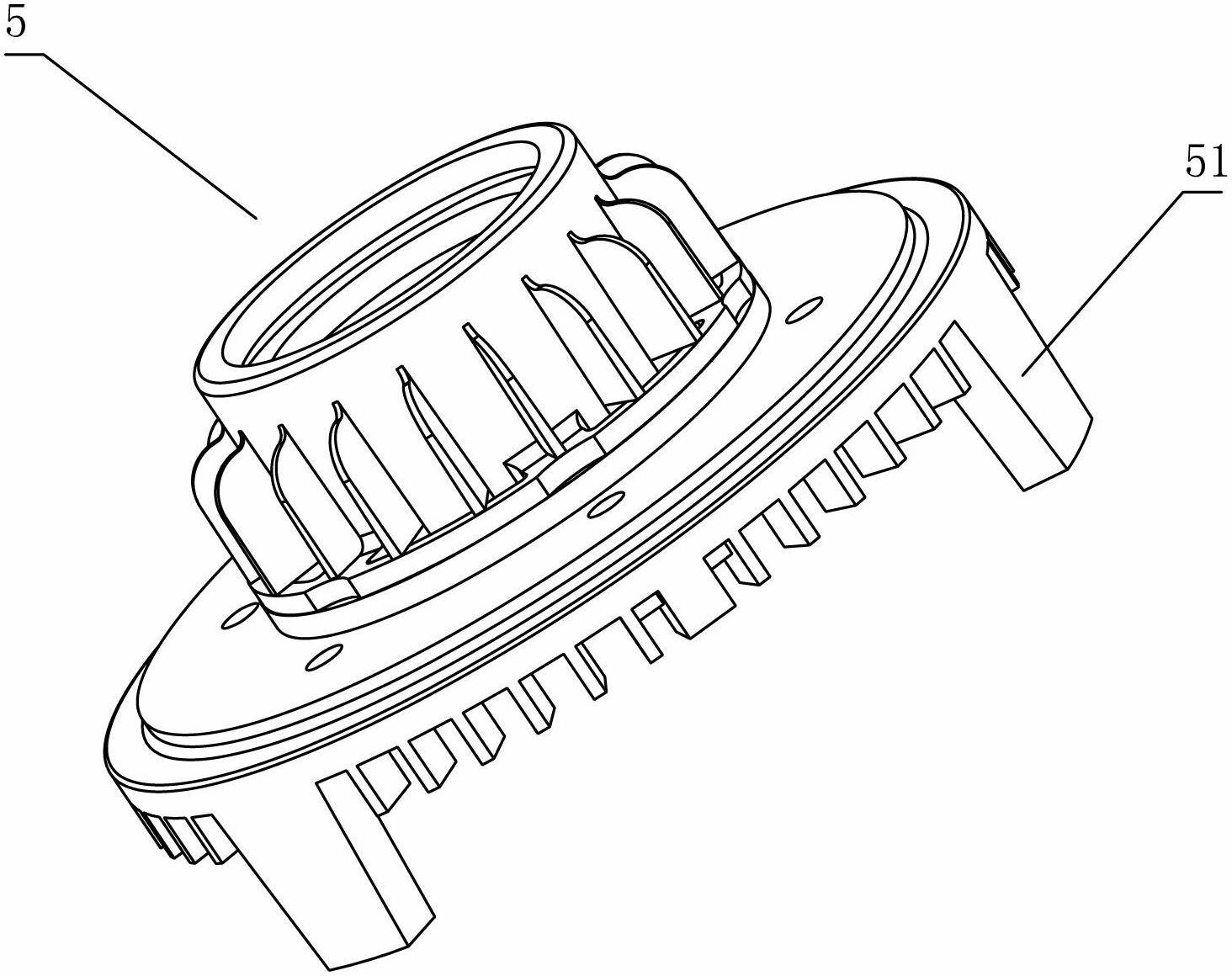

Novel tea knead entwist plate

InactiveCN101700085AReduce generationPrevent getting involvedPre-extraction tea treatmentSEMI-CIRCLESurface roughness

The invention discloses a novel tea knead entwist plate and relates to tea processing machinery parts. The knead entwist plate, an unloading plate and an edge bone are manufactured by adopting a casting method with the purposes of not only lowering the complexity of the technology, but also being convenient for molding, in particular to the molding of the broken tea terrace and the knead entwist area with an inclined angle. The knead entwist area with an inclined angle is in match with the edge bones which are arranged in a radiation shape, and the shape that the end of the edge bone close to the knead entwist plate is higher and the end close to the edge thereof is lower is beneficial for the separation of broken tea and mature tea, can improve stripping tea rate and can also reduce the generation of broken tea; the casting pieces have higher surface roughness and greater friction force, thus being beneficial for the improvement of knead entwist stripping tea rate. The section of the edge bone is approximately a semi circle, then in the processing of kneading and entwisting tea, the force transits smoothly, the kneading and entwisting and rolling speed of tea is even, and broken tea is not easy to generate, and the effect is particularly obvious in the central area in which the edge bone is higher and the tea rolls more frequently.

Owner:WUFENG TIANCHI TEA MACHINERY

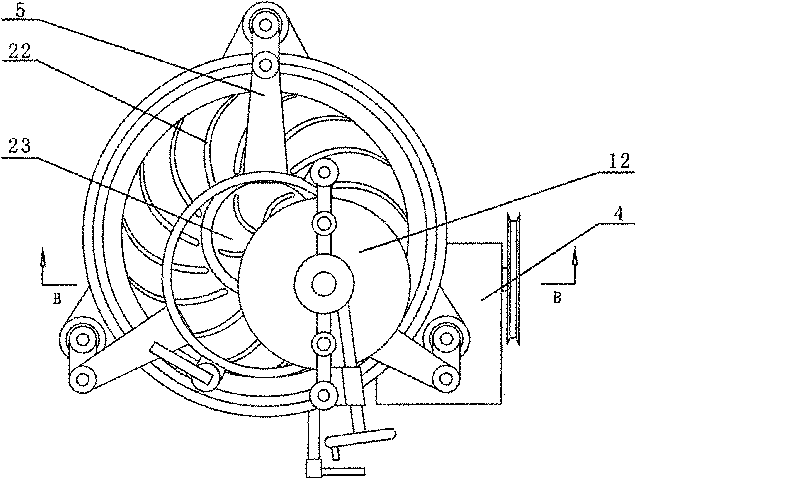

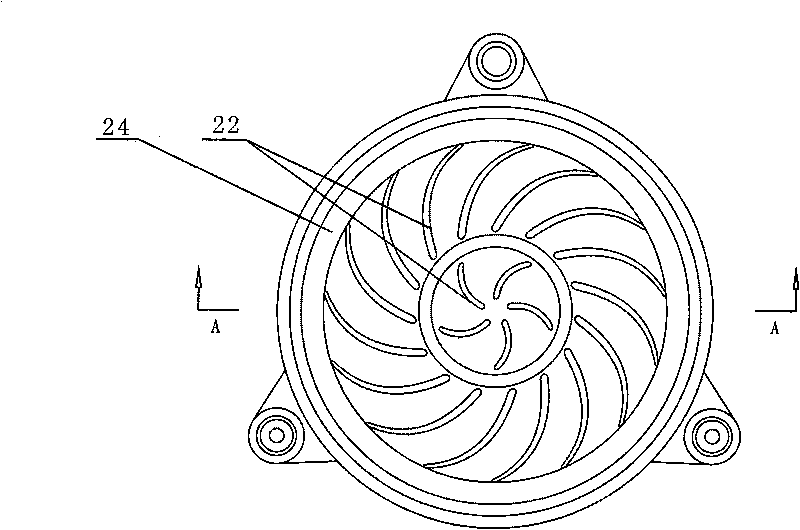

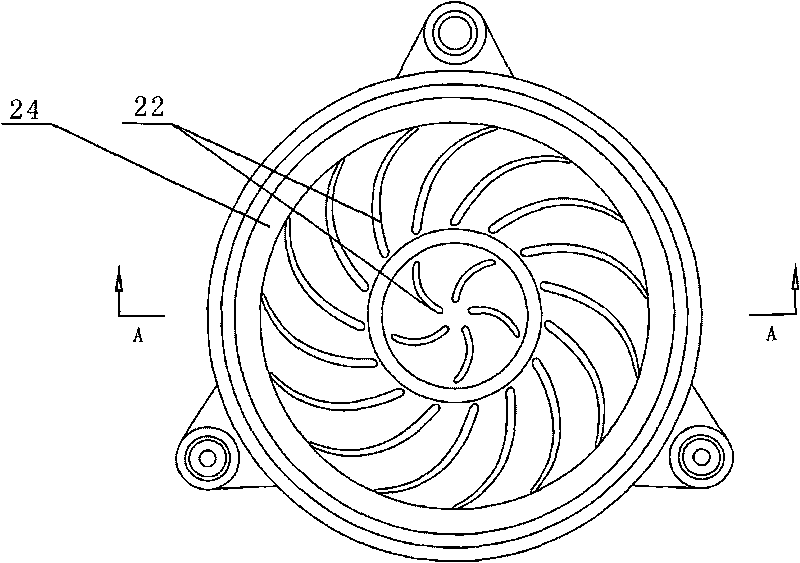

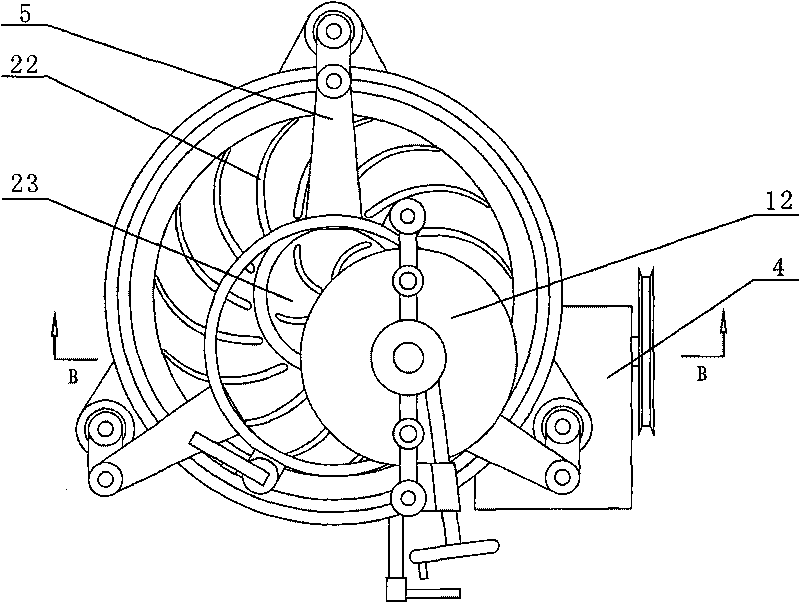

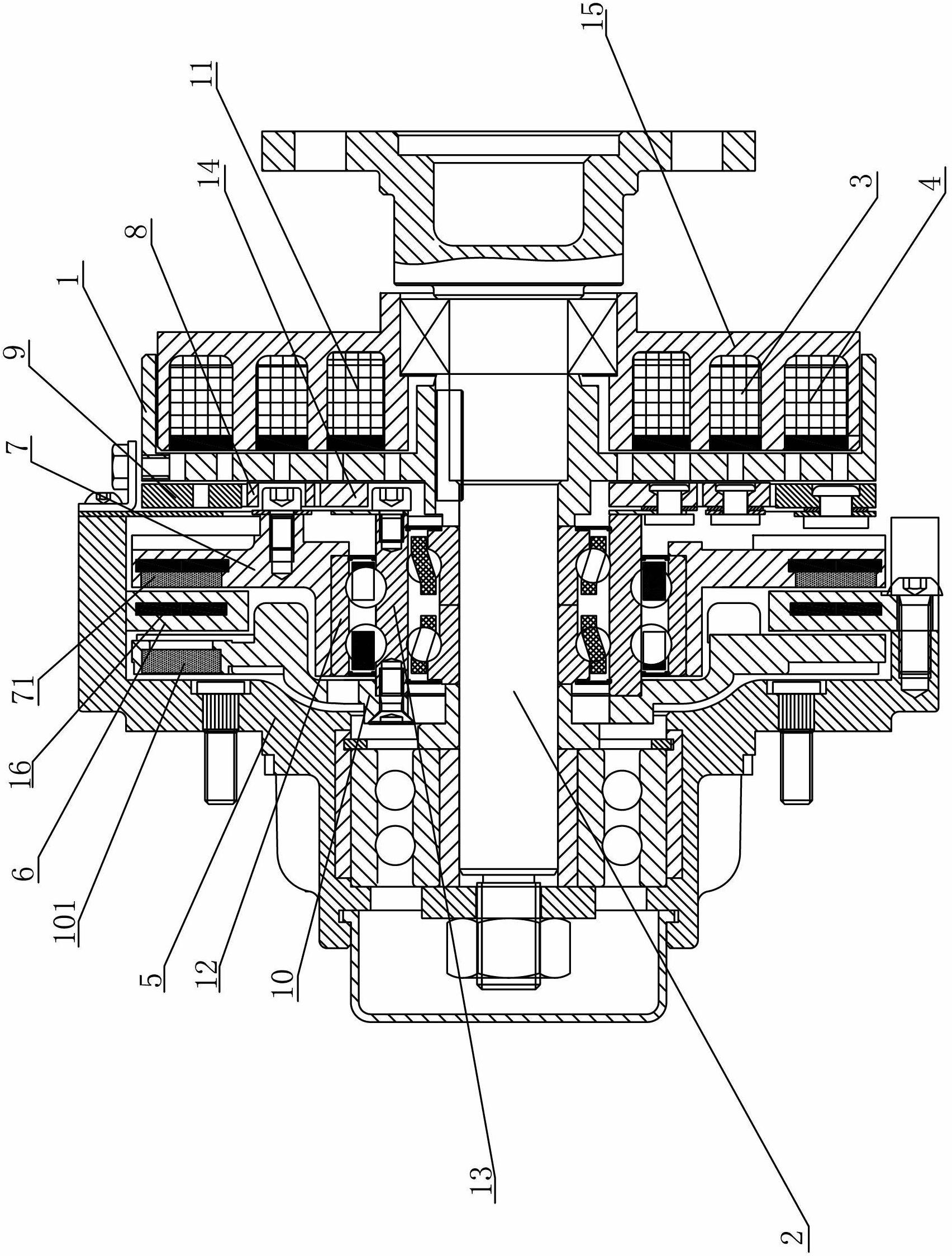

Four-speed electromagnetic fan clutch

ActiveCN102678258AReduce the temperatureEasy to fixCoolant flow controlMagnetically actuated clutchesFistEngineering

The invention discloses a four-speed electromagnetic fan clutch. A driving disc is connected to one side of a main shaft; an electromagnetic iron core is embedded into the driving disc; a fist coil and a second coil are arranged in the electromagnetic iron core; a fan fixing disk is arranged on the other side of the main shaft; a first magnetic fixing disk in which a first permanent magnet is embedded is arranged between the fan fixing disk and the driving disc; the first magnet fixing disk and the fan fixing disk are respectively connected with a first sucking disk and a second sucking disk through elastic sheets; a third sucking disk is also arranged on the four-speed electromagnetic fan clutch; the centers of the first sucking disk, the second sucking disk and the third sucking disk are superposed; a second magnet fixing disk in which a second permanent magnet is embedded and a drive disc are sequentially arranged between the fan fixing disk and the first magnet fixing disk; the drive disc is fixedly connected onto the fan fixing disk; iron parts are arranged at the positions, which correspond to the first permanent magnet and the second permanent magnet, of the drive disc; the first magnet fixing disk and the second magnet fixing disk are sleeved on the main shaft through a composite bearing and are respectively and fixedly connected with an outer ring and an intermediate ring of the composite bearing; the third sucking disk is connected with the intermediate ring of the composite bearing through an elastic sheet; and a third coil is also arranged in the electromagnetic iron core.

Owner:LONGKOU ZHONGYU AUTOMOBILE FAN CLUTCH

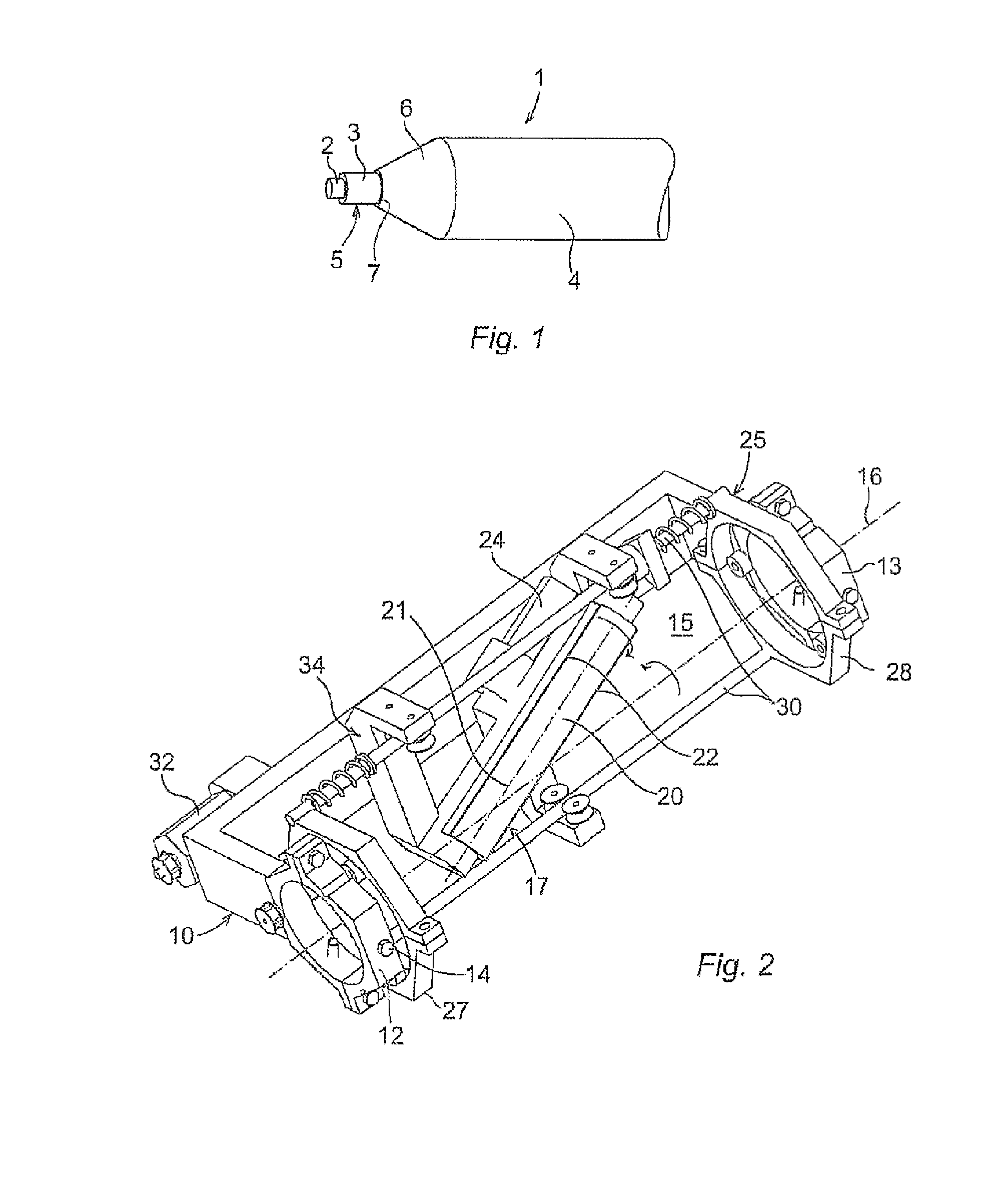

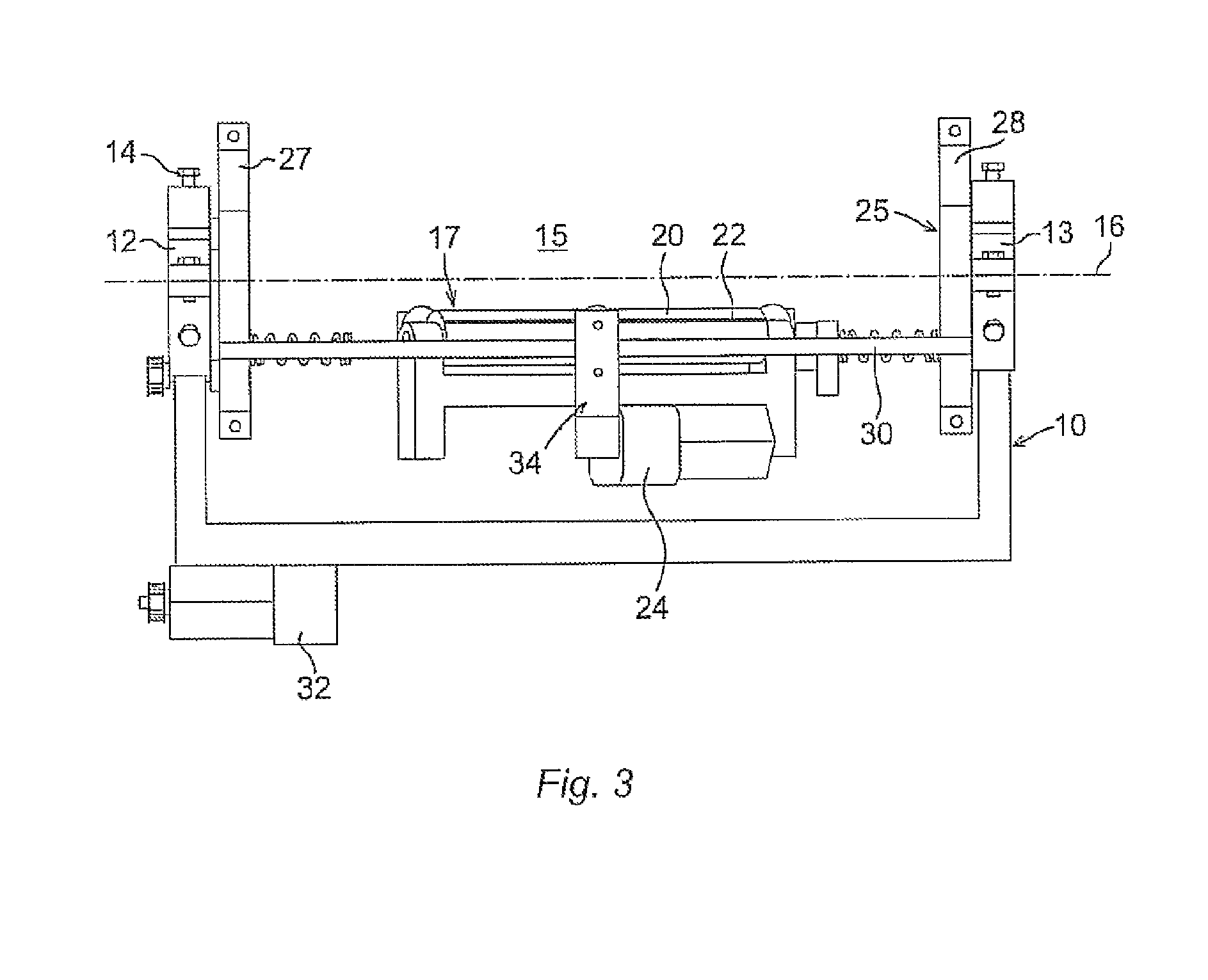

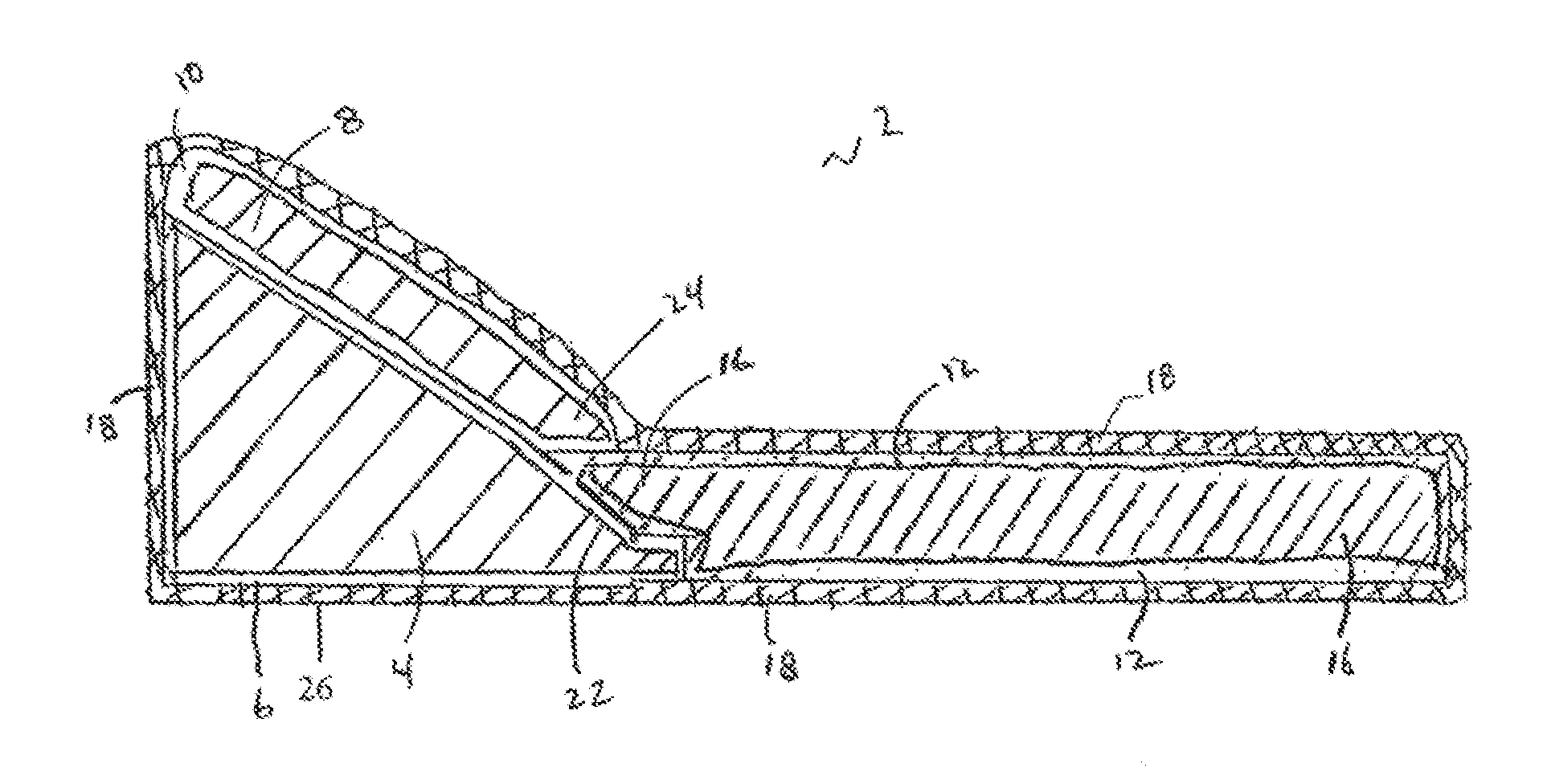

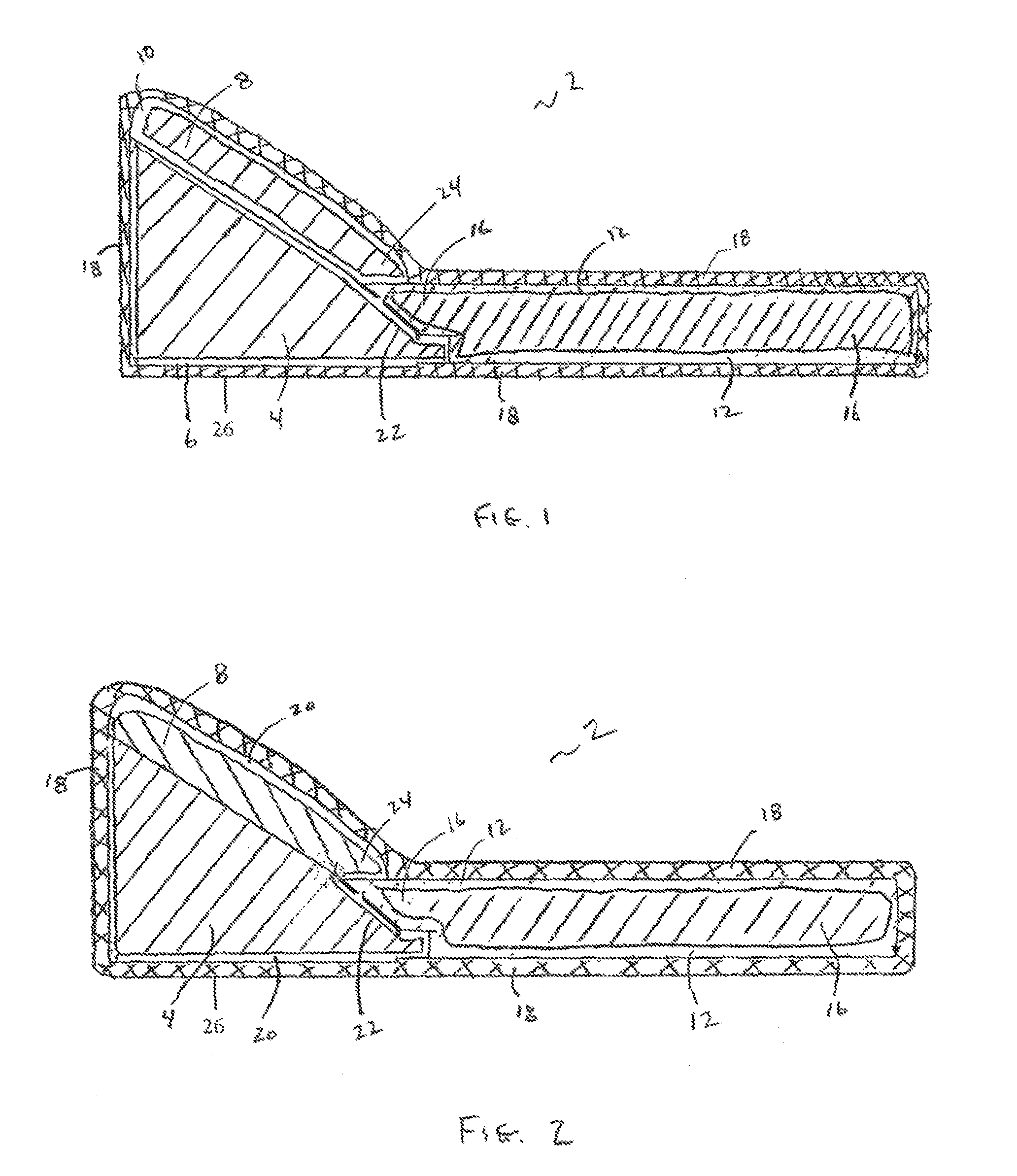

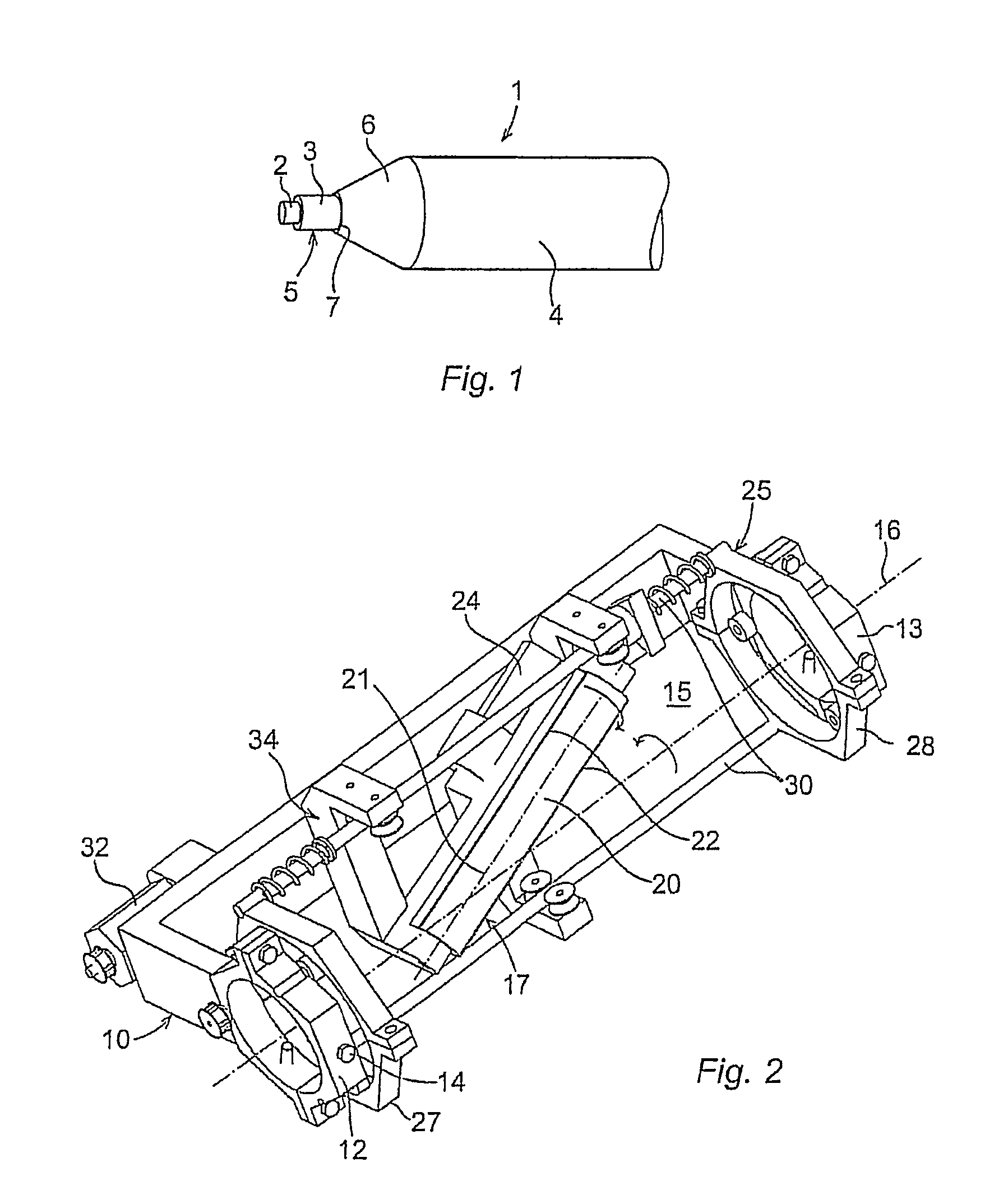

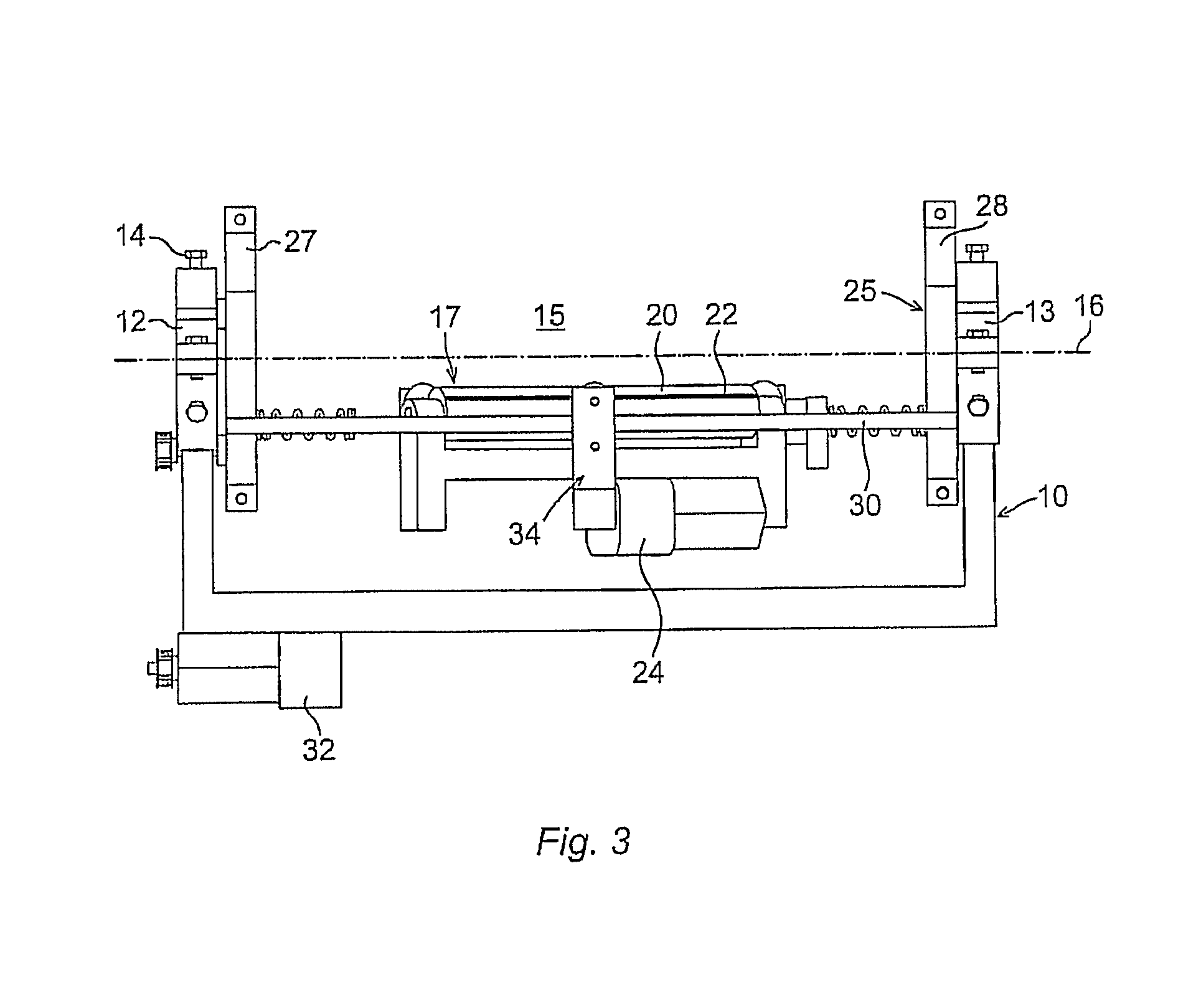

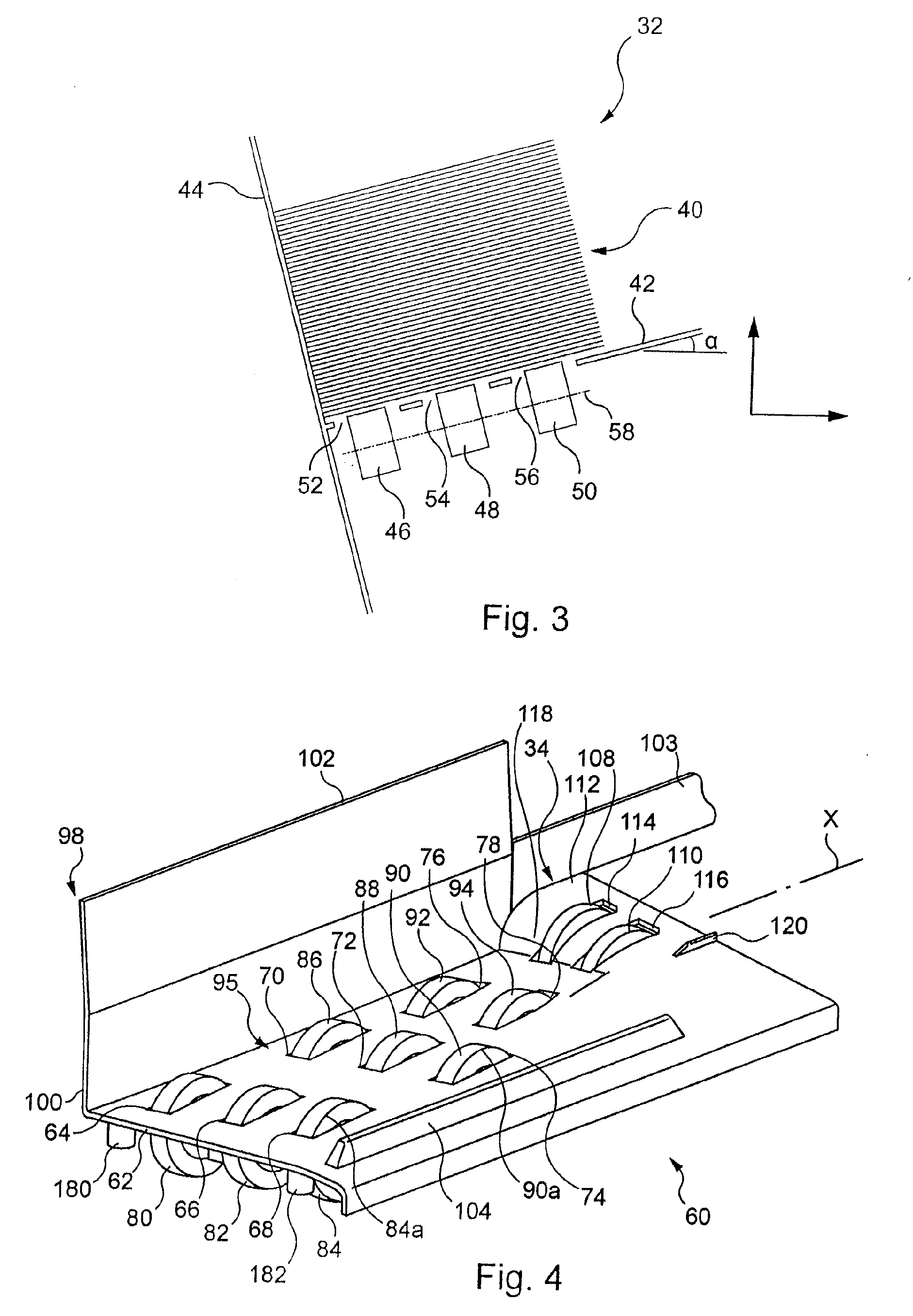

Device And Method For Machining An Electrical Cable

InactiveUS20130032011A1Quality improvementFast cutting speedLathesLine/current collector detailsRotational axisEngineering

A device for machining an electrical cable having a cylindrical part and a conical part adjoining the cylindrical part. The device includes a fixture arranged to receive the cable and to hold the cable in a fixed position, the fixture defines an elongated space for accommodating the cable, a tool for removing material from the cable including at least one cutter, and rotational guiding means for guiding a first rotation of the cutter about a longitudinal axis of the space. The cutter is elongated and the longitudinal axis of the cutter is arranged inclined with respect to the longitudinal axis of the space so that the angle between the longitudinal axes of the cutter and the space is between 10 and 80 degrees. The device further includes drive means for providing a second rotation of the cutter about a rotational axis through the tool in order to cause the machining.

Owner:NKT HV CABLES AB

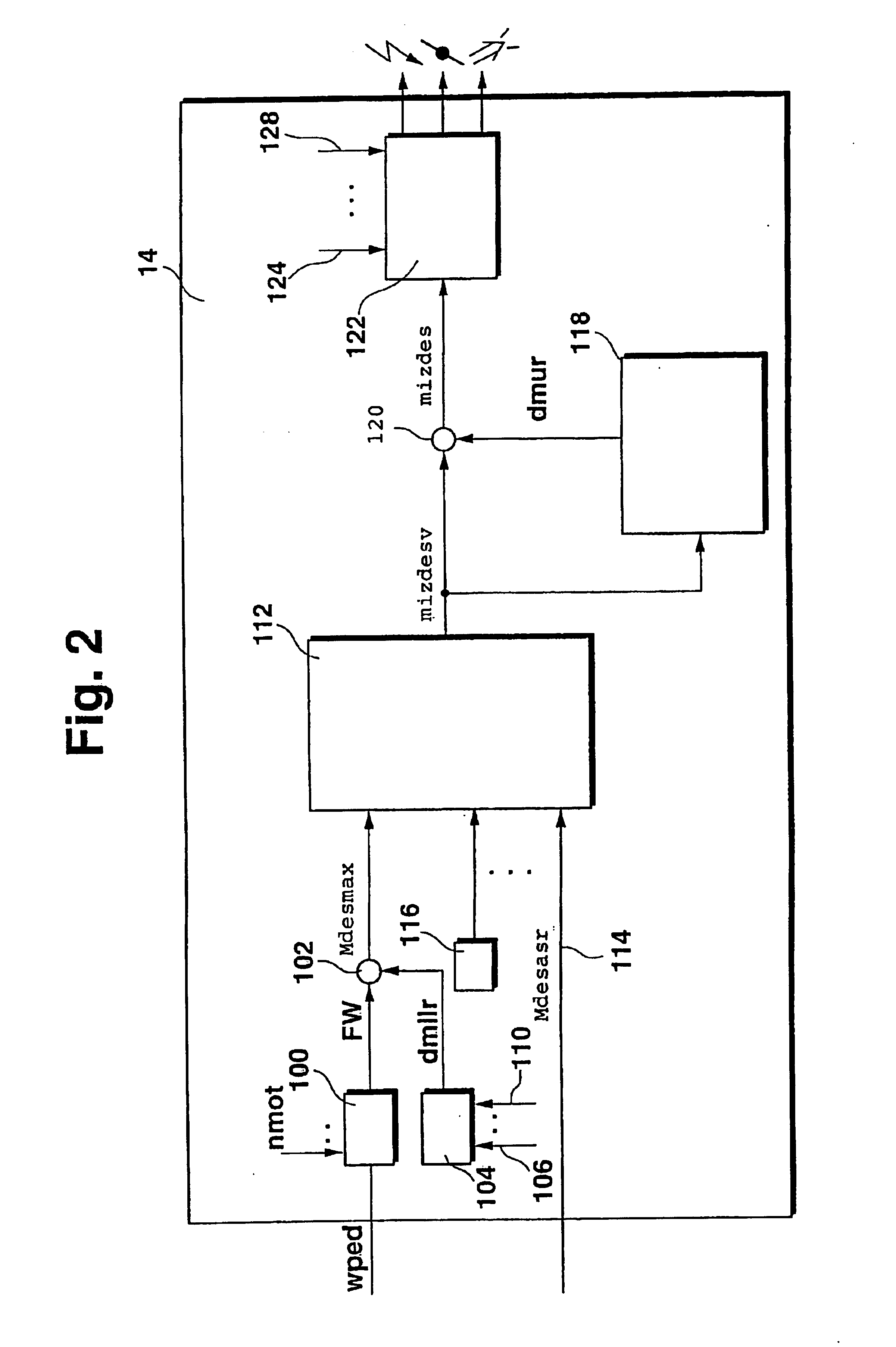

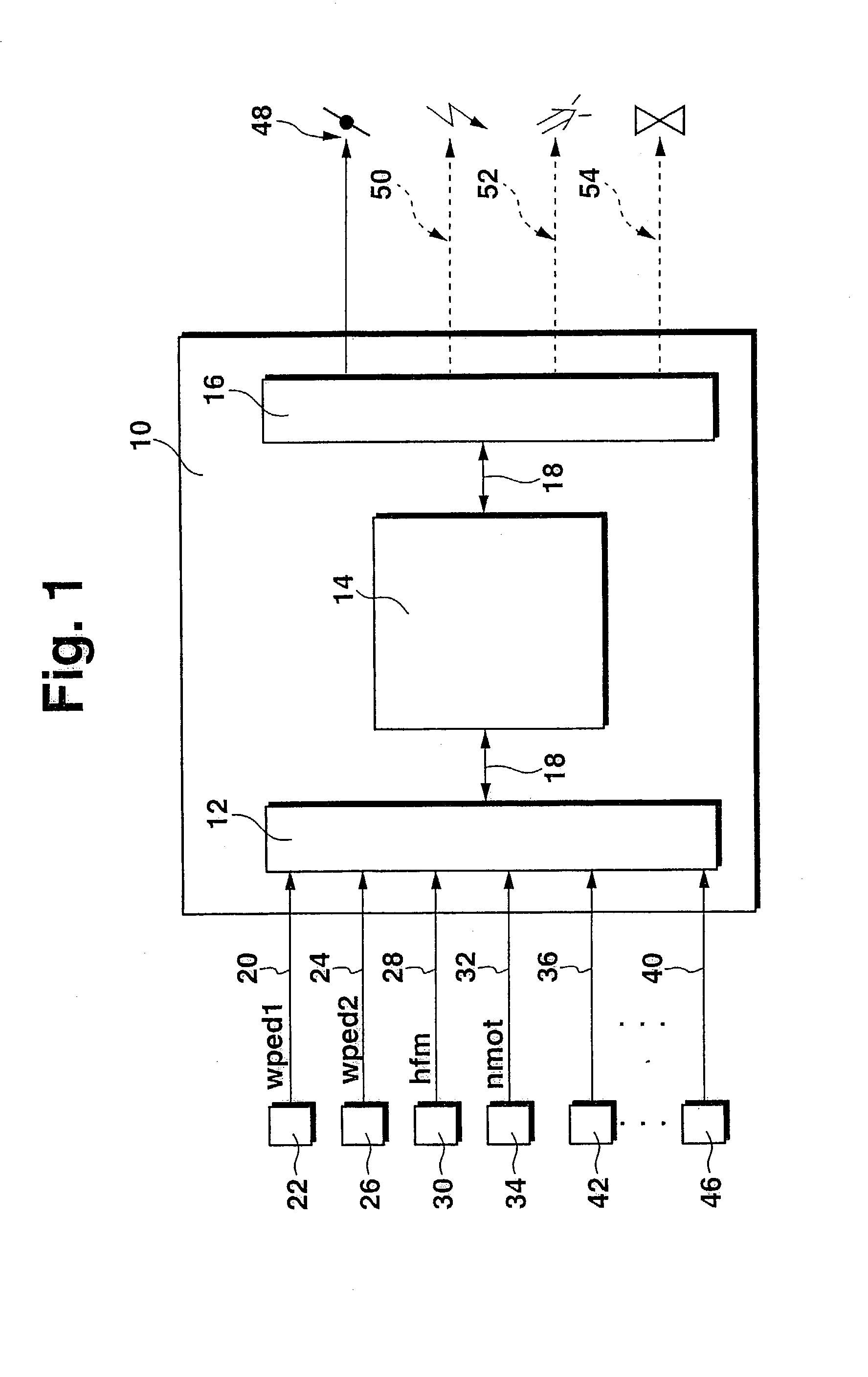

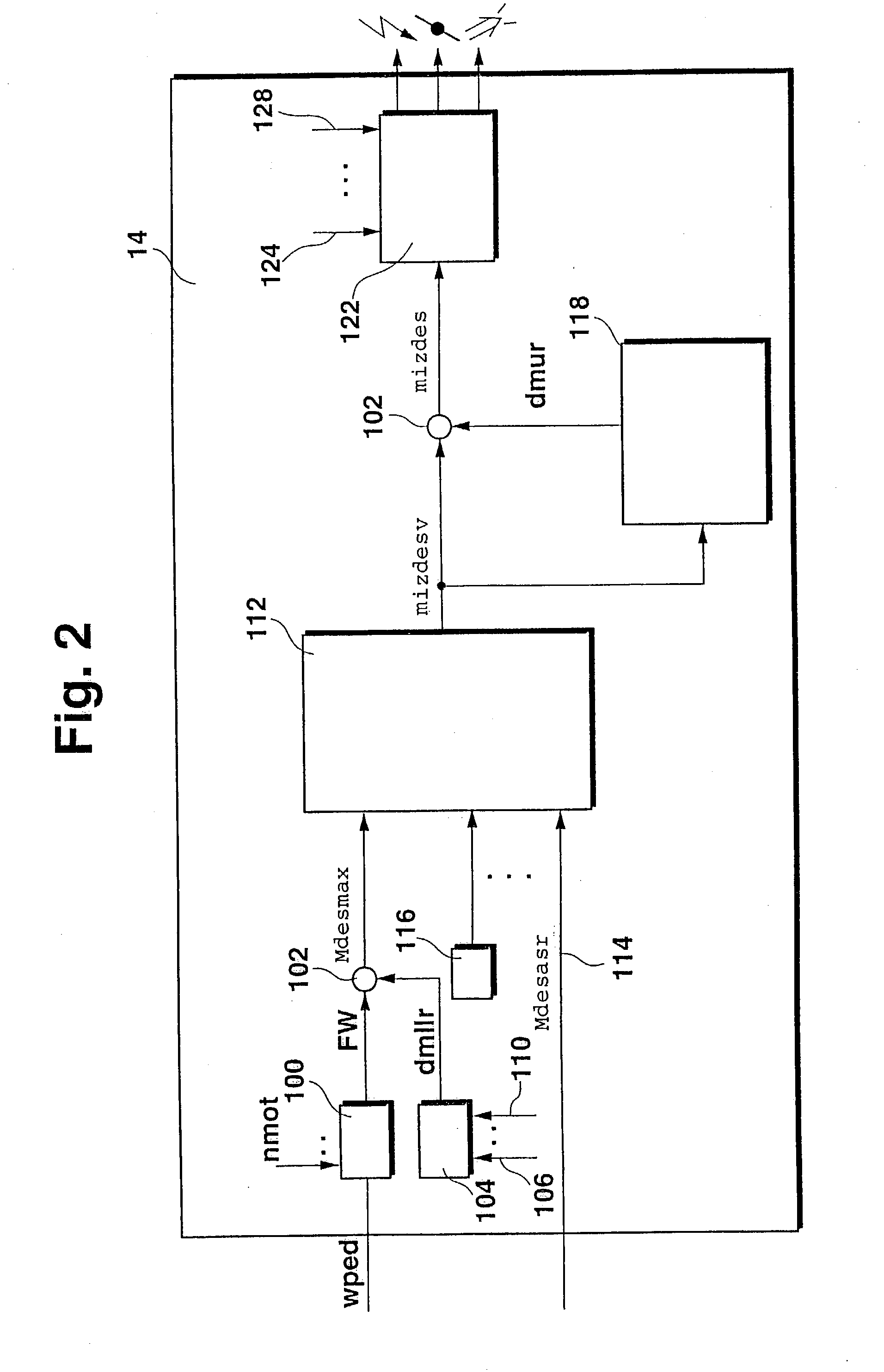

Method and device for controlling the drive unit of a motor vehicle

InactiveUS6938609B2Improve comfortAffect actionElectrical controlInternal combustion piston enginesMobile vehicleLimit value

Owner:ROBERT BOSCH GMBH

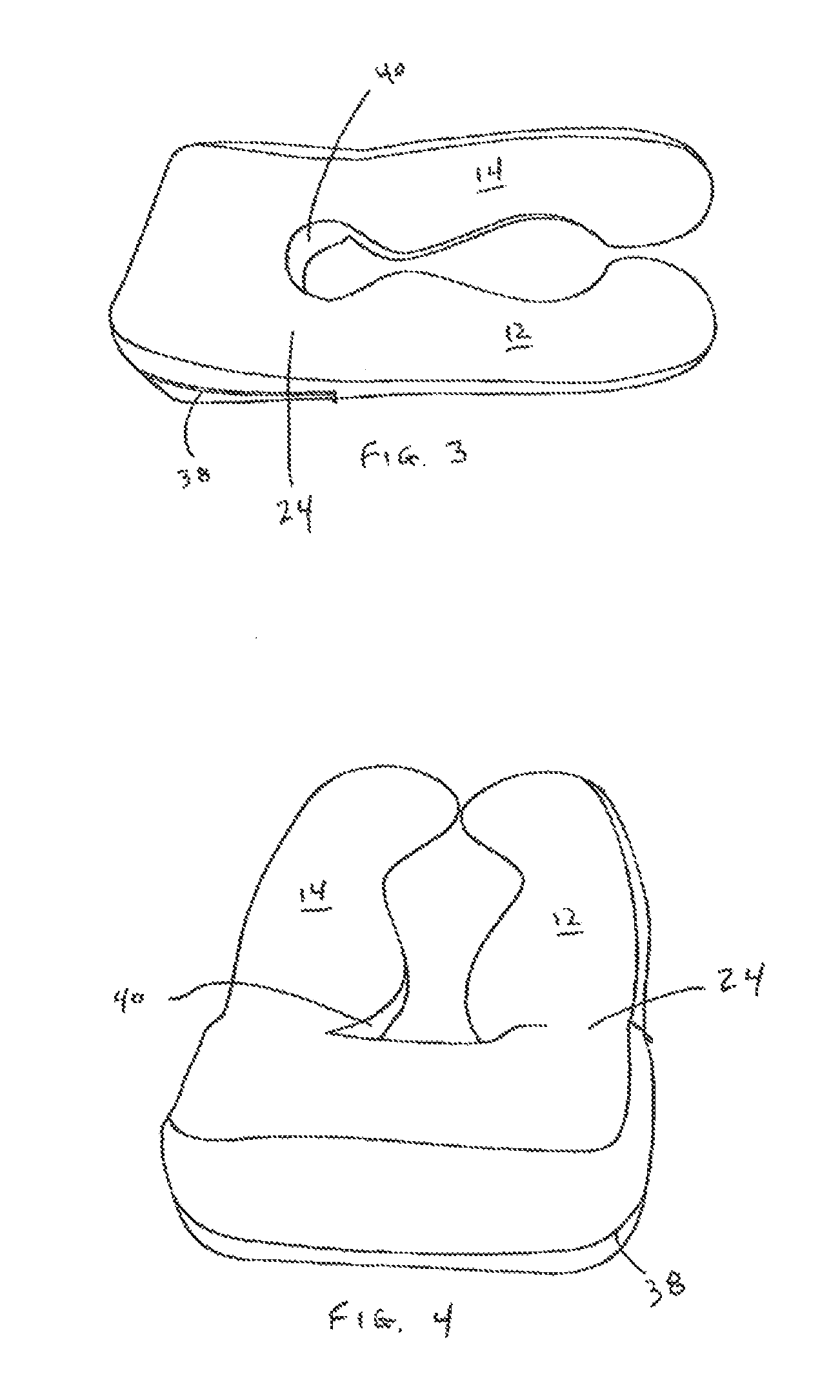

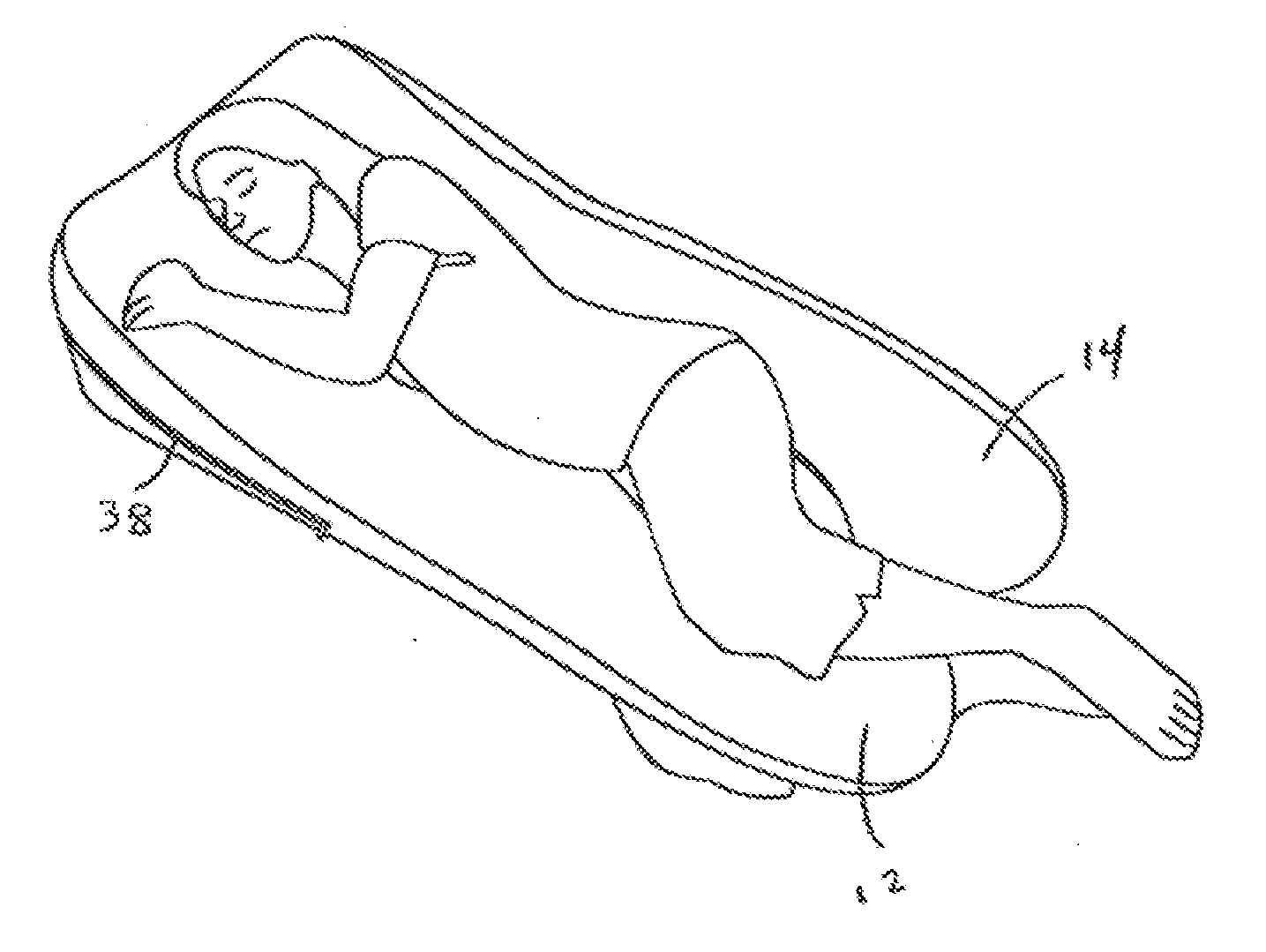

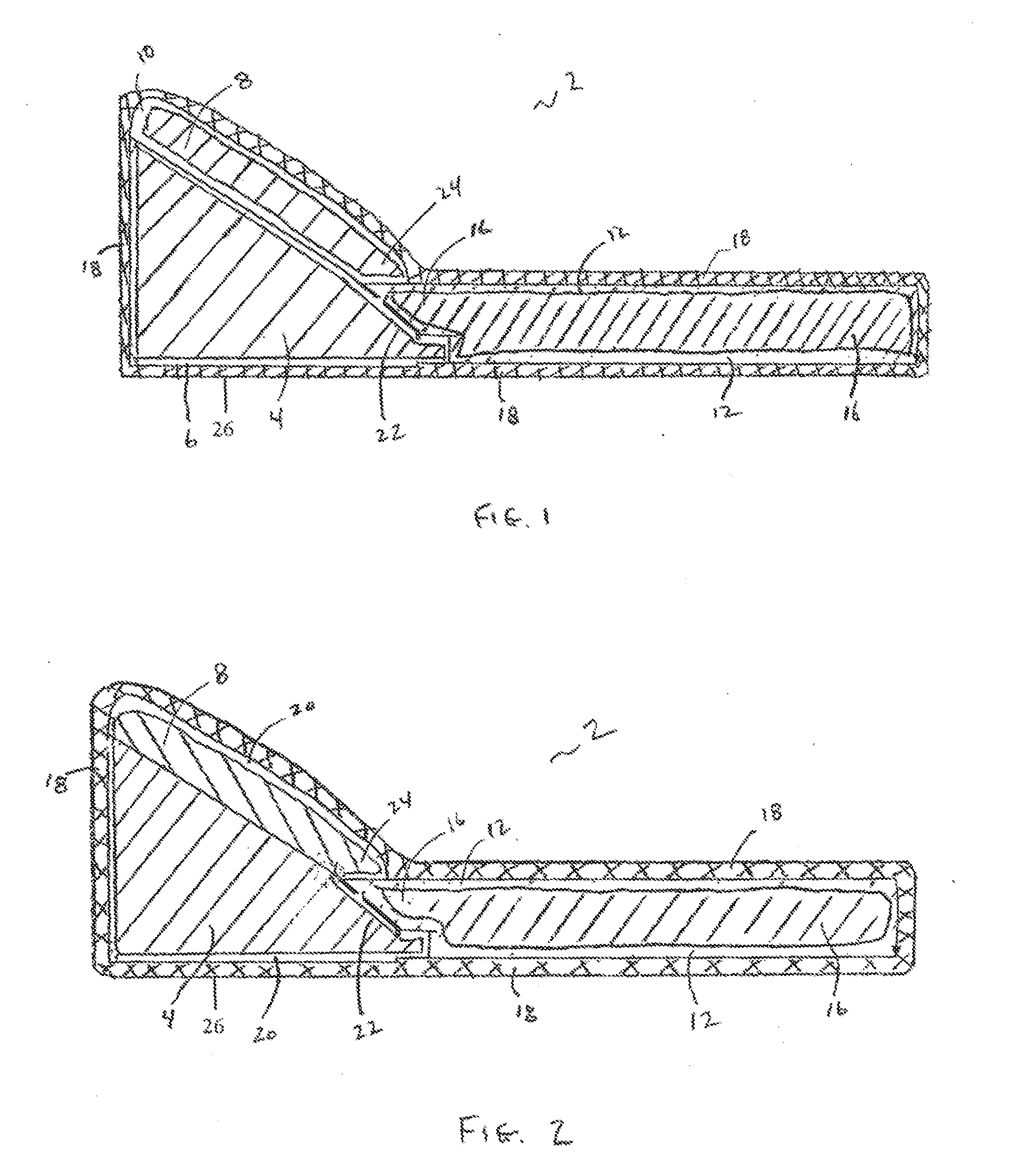

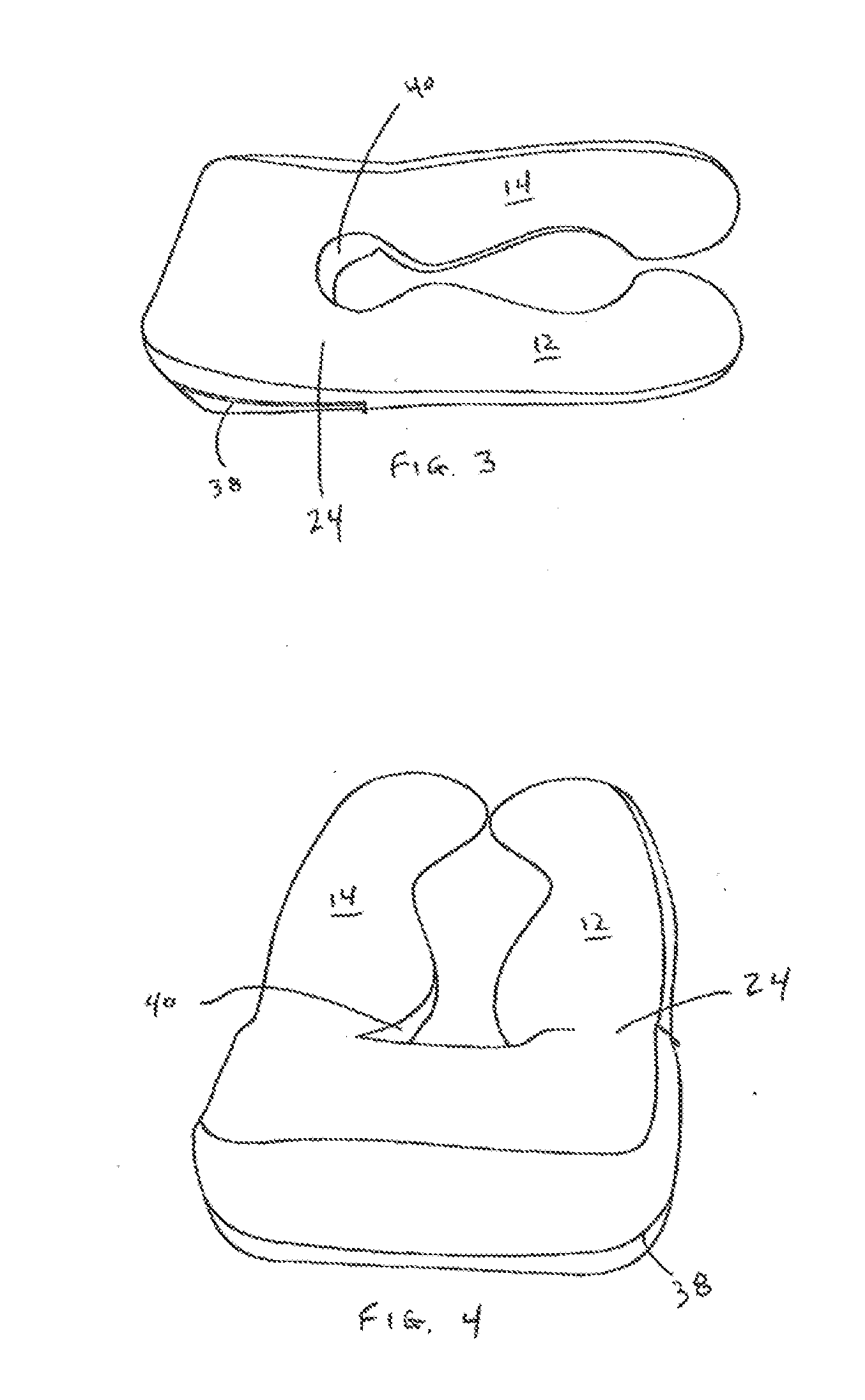

Inclined body positioning and support system

Owner:KIEFER JOHN

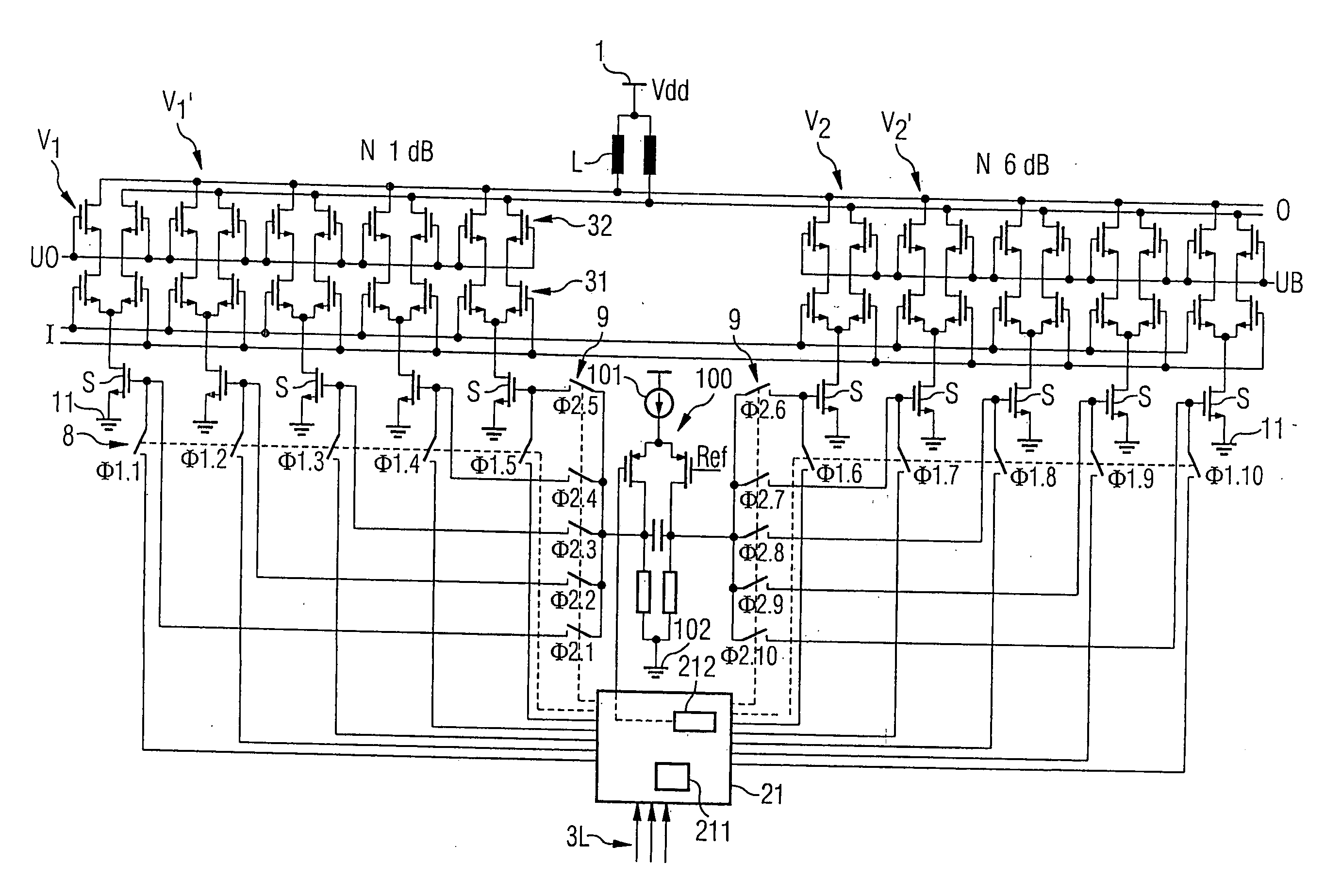

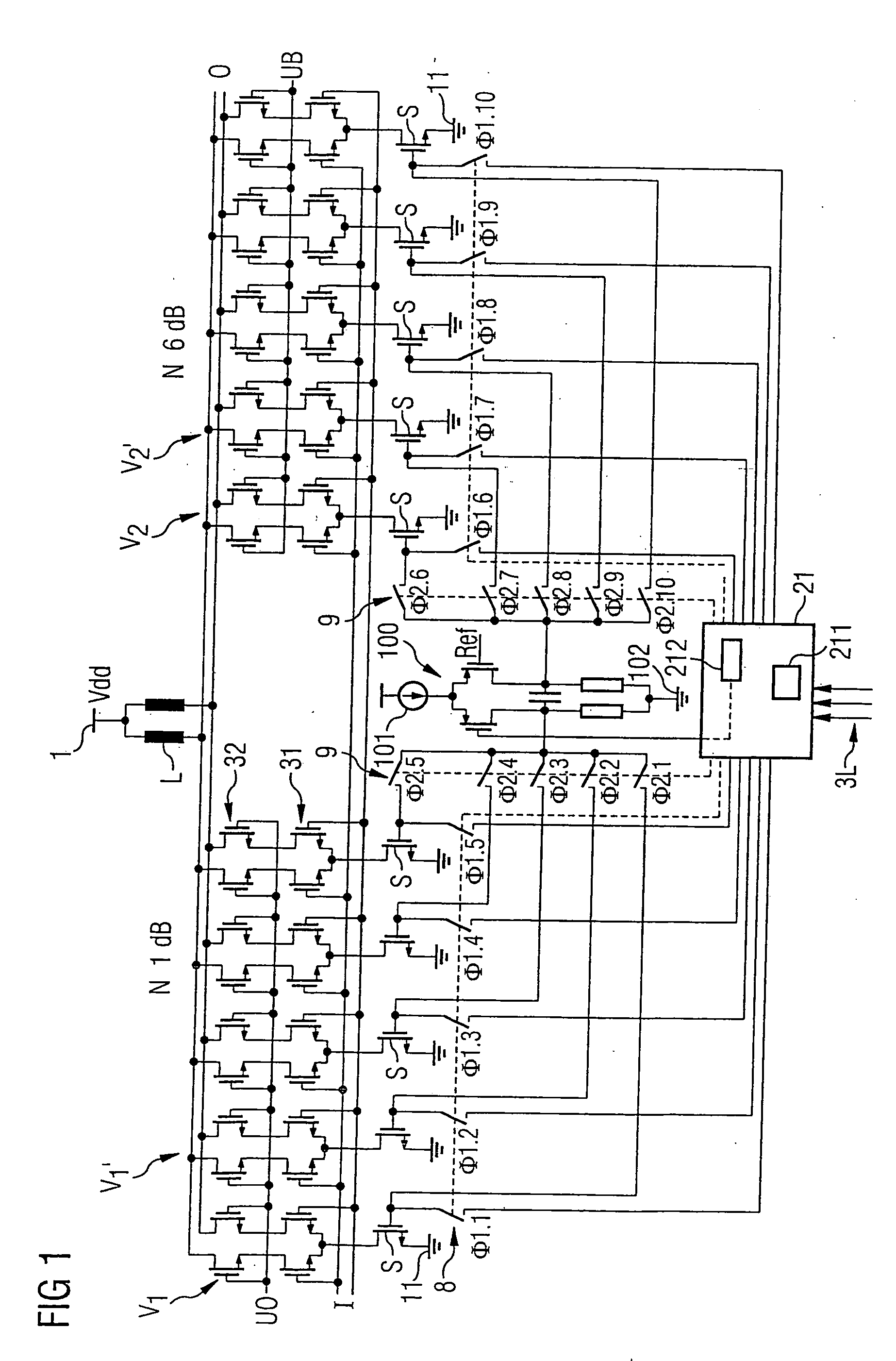

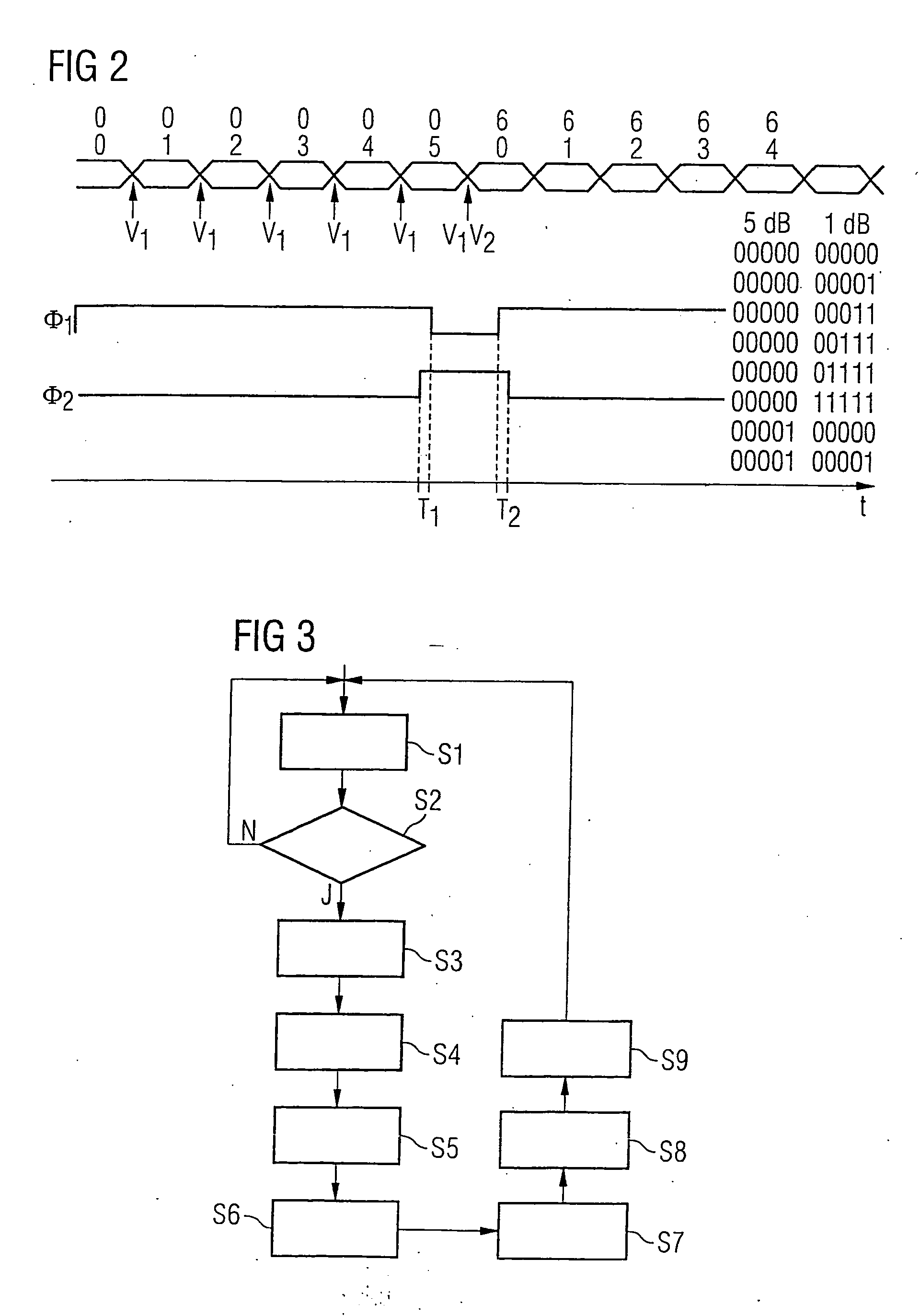

Controllable amplifier circuit with a variable discrete-value gain, use of the amplifier circuit and method for operation of an amplifier whose gain can be adjusted in discrete values

InactiveUS20060049875A1Soft transitionNot easy to make mistakesAnalog signal digital controlDifferential amplifiersAudio power amplifierControl signal

An amplifier circuit is disclosed in which a first amplifier stage and at least one second amplifier stage are each arranged between a signal input and a signal output. These amplifier stages are designed with a first gain factor and with a switching input. The amplifier circuit also has a third amplifier stage with a second gain factor, which is arranged between the signal input and the signal output. A control circuit is coupled to each amplifier stage for gain adjustment. The control circuit has a first control block designed for single-ended signal processing, and a second control block designed for push-pull signal processing. It is designed to supply control signals from the first control block to the amplifier stage when the gain of the first and at least one second amplifier stage is varied, and to supply control signals from the second control block to all of the amplifier stages when the gain of the at least one third amplifier stage is varied.

Owner:INTEL CORP

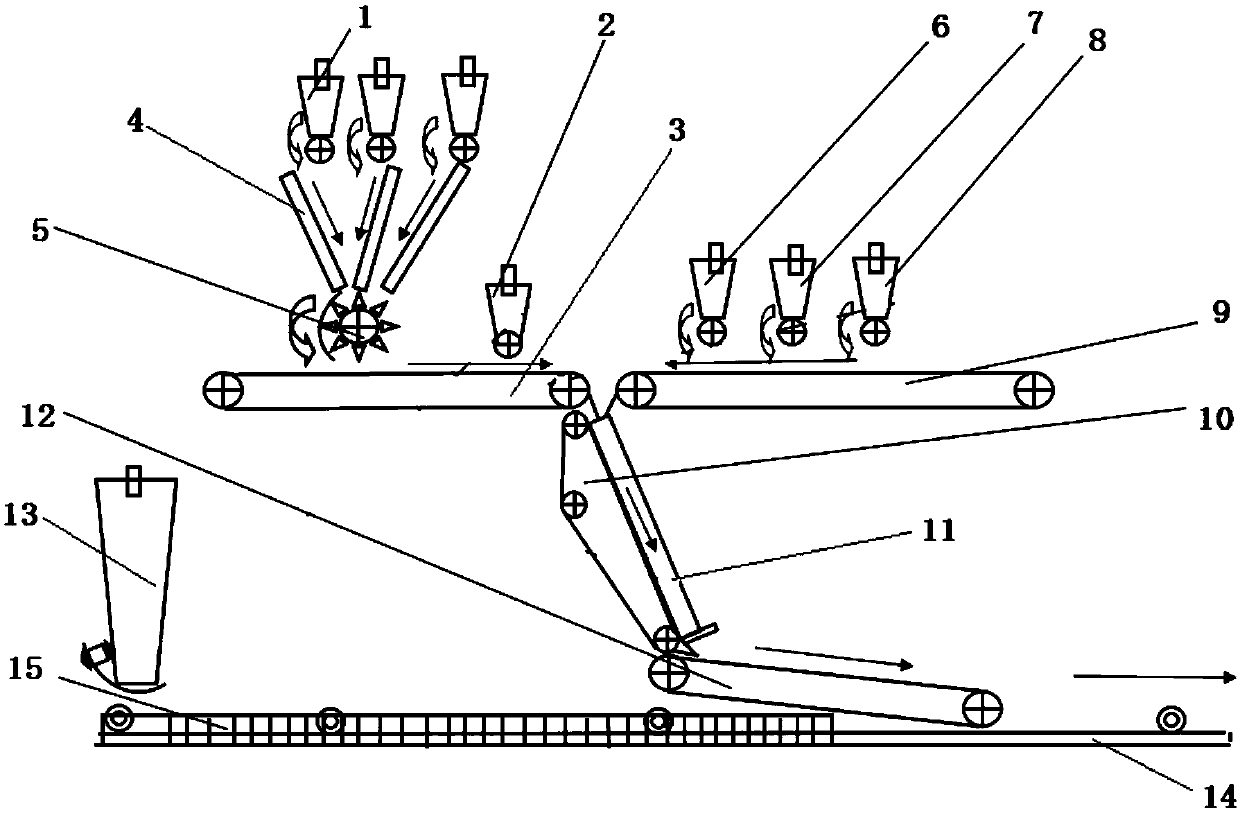

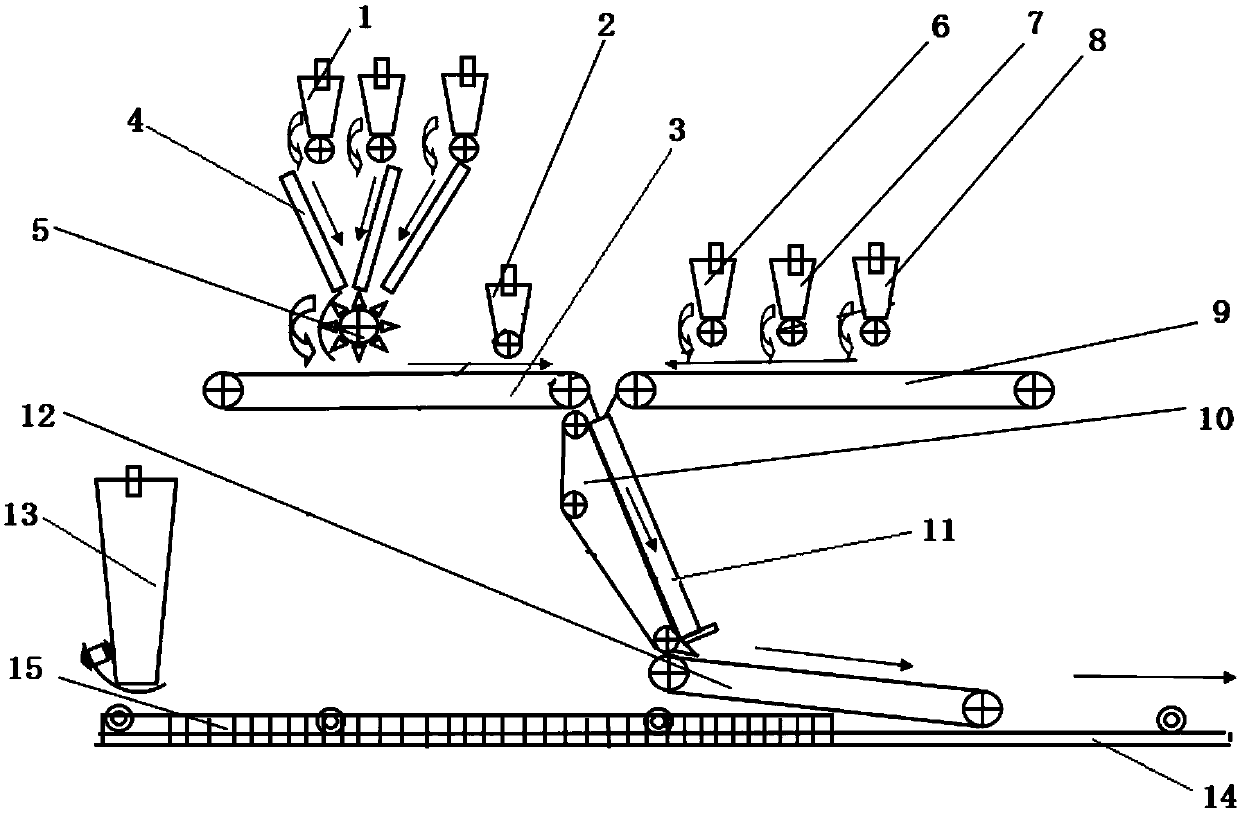

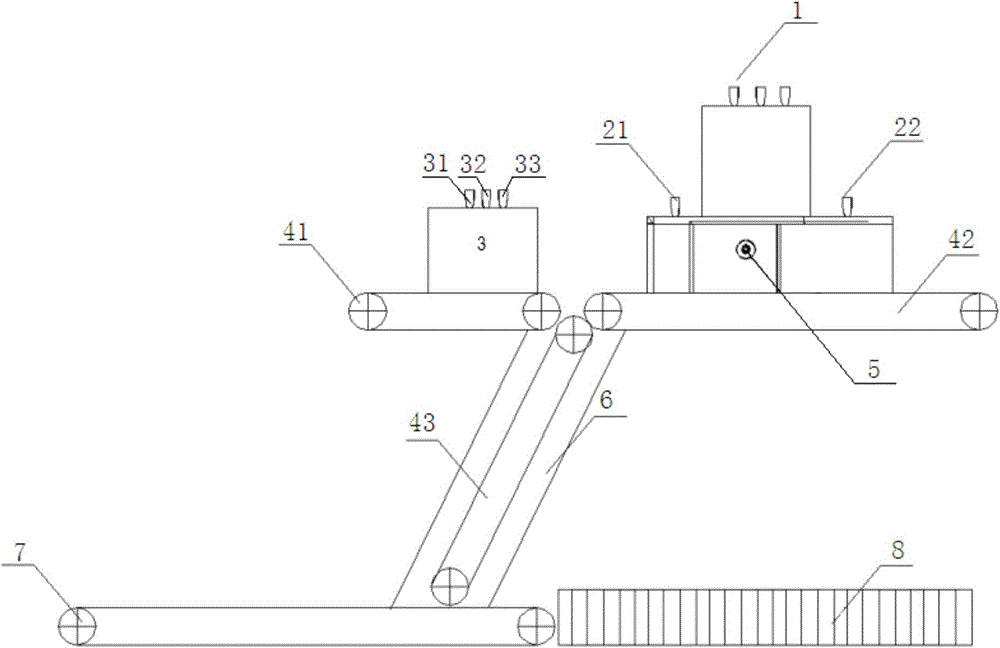

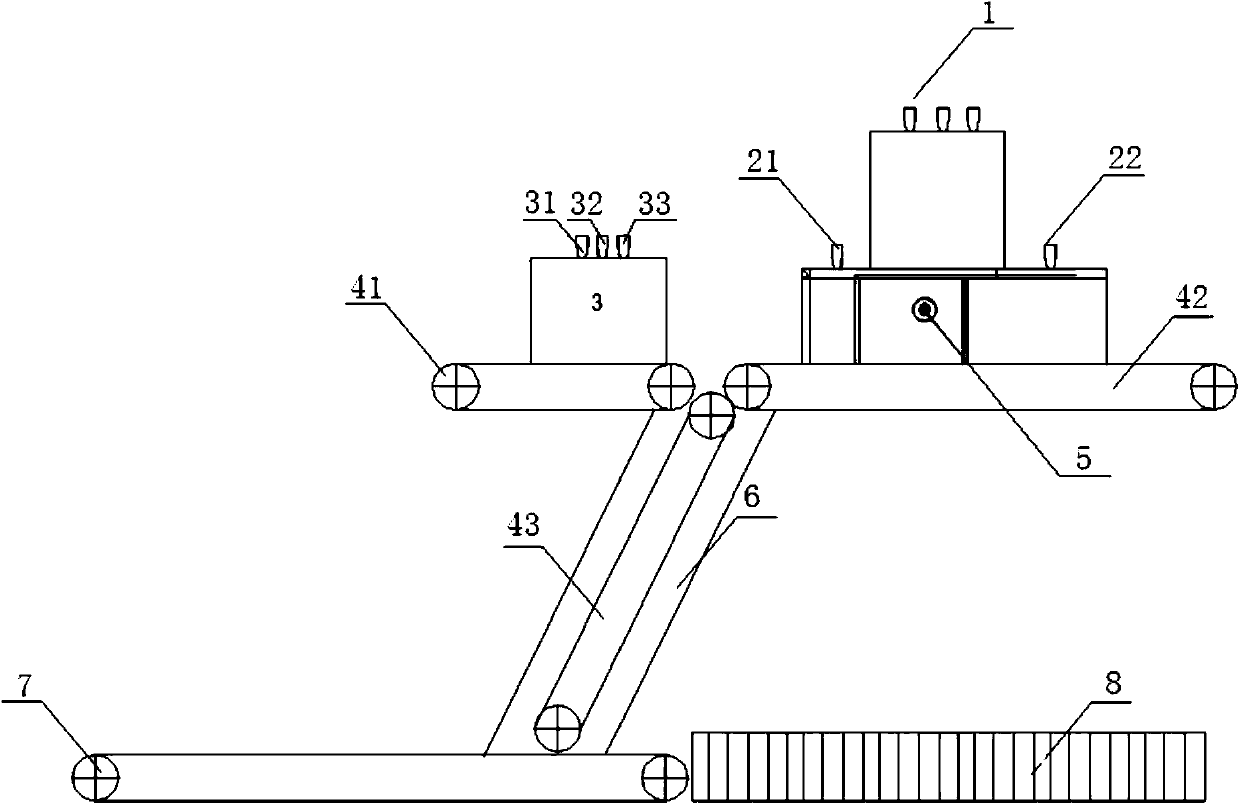

Shifting-sand-textured glass ceramic tile preparation device

InactiveCN109986689AControllable feeding timeThe feeding amount is easy to controlFeeding arrangmentsAuxillary shaping apparatusMetallurgyCascading effects

The invention relates to a shifting-sand-textured glass ceramic tile preparation device. The shifting-sand-textured glass ceramic tile preparation device comprises a material vehicle, a base materialfeeding unit arranged at the back part of the material vehicle, an aggregate and transfer printing unit arranged at the middle front part of the material vehicle, a color powder feeding unit and a line texture powder feeding unit arranged at an inlet of the aggregate and transfer printing unit, and a controller used for controlling the feeding order of each feeding unit. During working, the controller controls the front and back movement of the material vehicle, and then controls the feeding order of the base material, the color powder and the line texture powder, the shifting-sand texture isformed on a flat plate on the upper surface of the material vehicle, and then burning and completing are conducted. Compared with the prior art, the texture cascade effect of the product of the preparation device is imitation-stone, realistic, natural and smooth, the color and the powder sandiness are soft in transition, each texture is matched with the color by adjusting the technical parameters,the products of different color systems can be produced, the effect is ahead the effect of the similar product in the market, and the preparation process is high in controllability.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

Device and method for machining an electrical cable

InactiveUS8632284B2Quality improvementFast cutting speedLathesApparatus for cutting/splicing cablesRotational axisFixed position

Owner:NKT HV CABLES AB

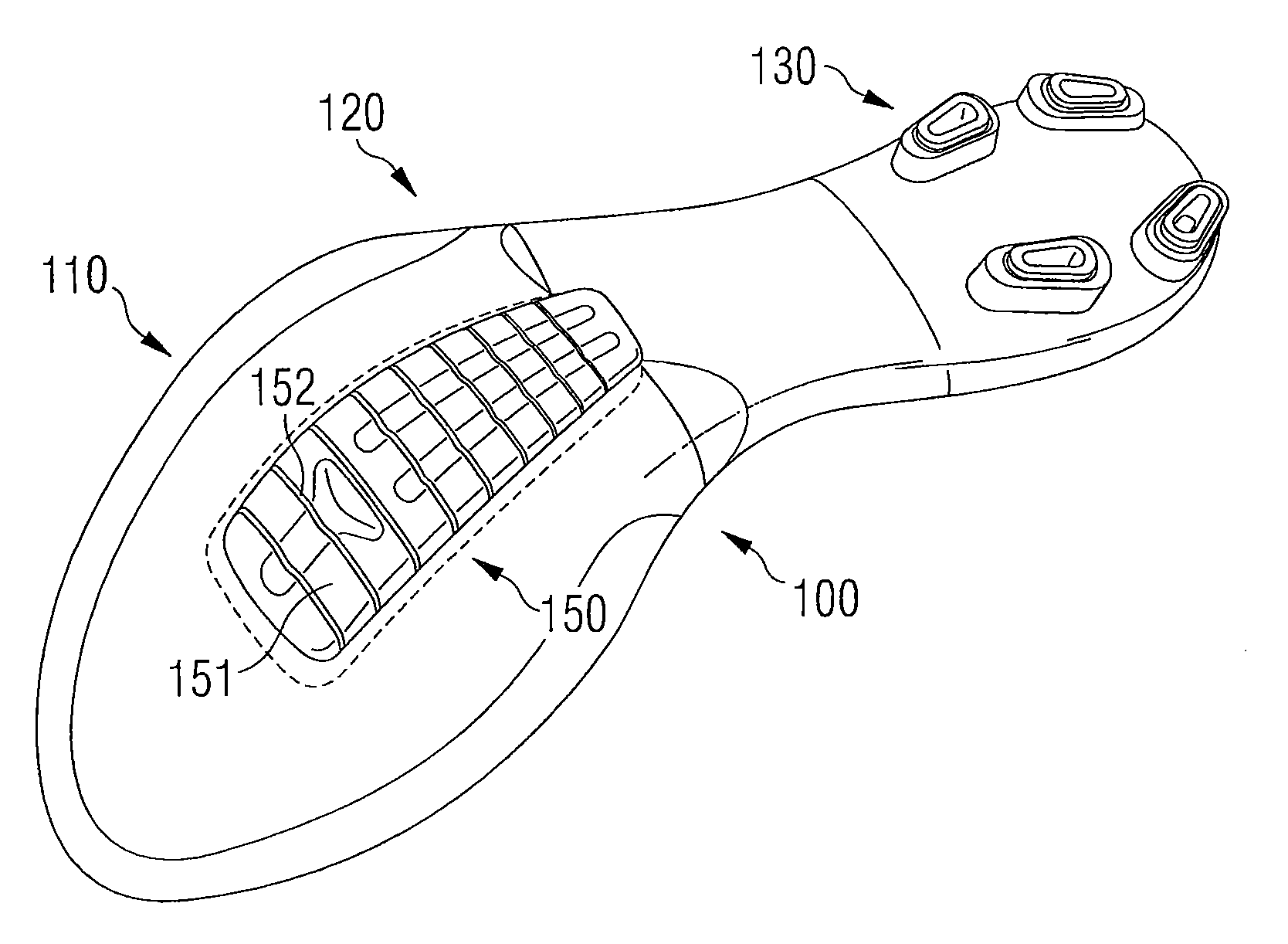

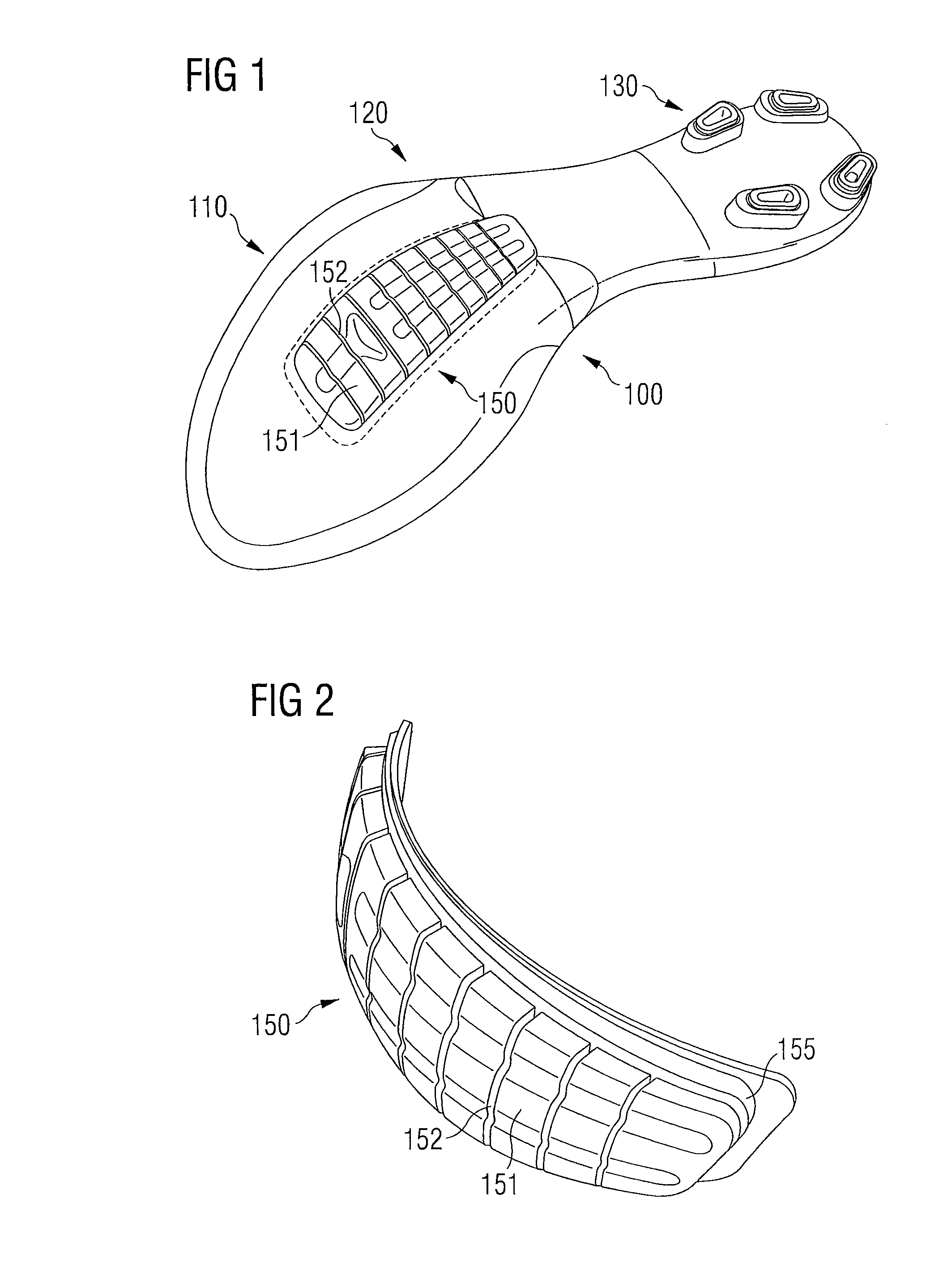

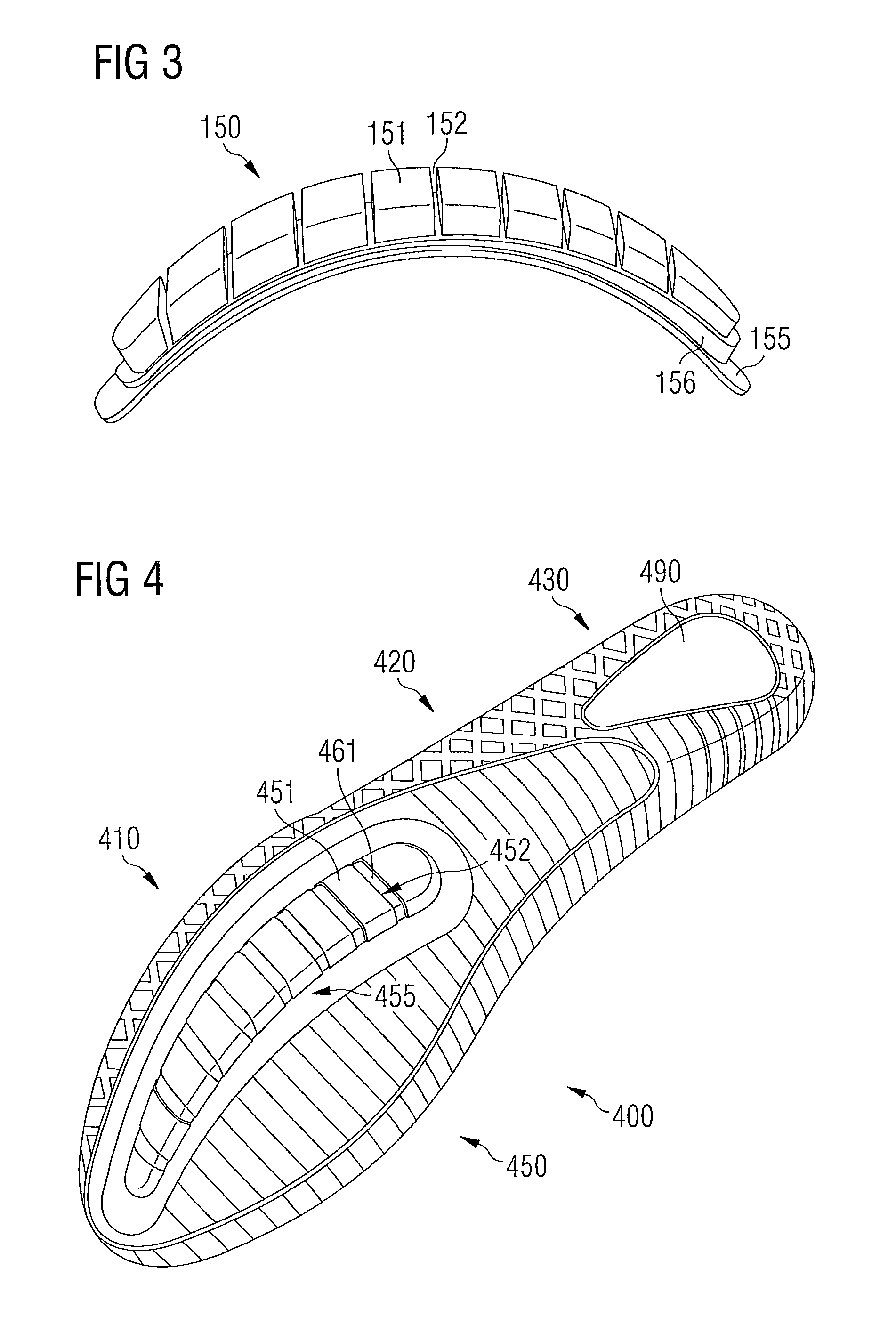

Inclined Body Positioning And Support System

InactiveUS20130291308A1Increase airflowSoft transitionPillowsSofasSupporting systemFilling materials

An inclined body positioning and support system is presented comprising an internal foundational wedged support encased in a chamber, an internal ventilation / comfort material encased in a chamber, first and second internal elongated positioning and support chambers each encasing a fill material, and an external cover. The foundational wedge chamber encases a respective first and second wedge plateau overlapped by the respective first and second elongated support material chamber to form a respective first and second transitional.

Owner:KIEFER JOHN

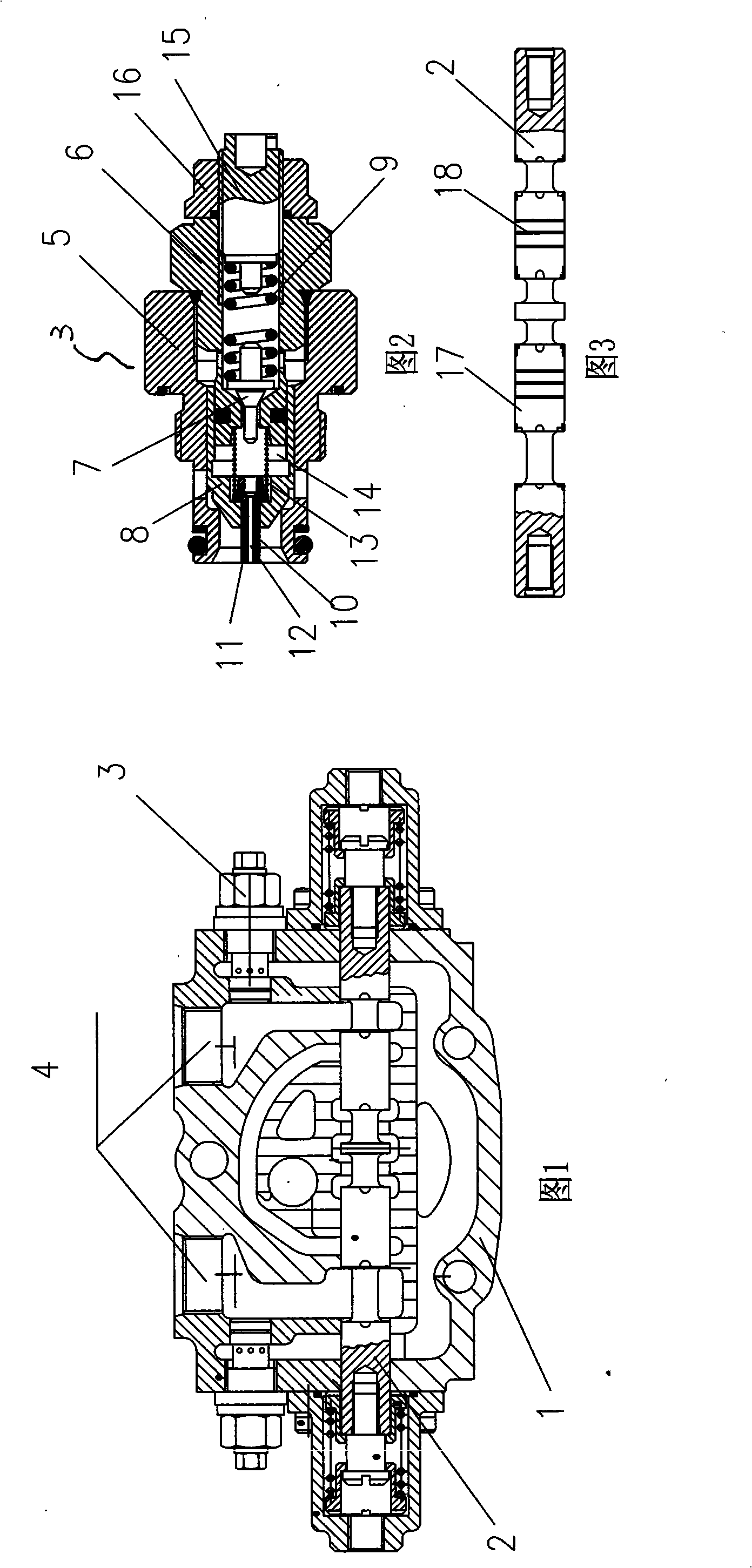

Hydraulic multichannel conversion valve

InactiveCN101403398APressure oil incremental transition is softProtected from damaging impactServomotor componentsSoil-shifting machines/dredgersRelief valveMicro motion

The invention relates to a hydraulic multi-channel conversion valve which consists of a left driving valve and a right driving valve; the driving valve comprises a driving valve body and a valve core, and is characterized in that: the driving valve body is provided with an overload protection valve which is connected with the oil inlet port and the oil outlet port of the valve body; the overload protection valve comprises a main valve body, an auxiliary valve body, a valve needle and a one-way valve core; the back end of the main valve body is connected with the auxiliary valve body by a screw; the valve needle is arranged in the inner cavity of the auxiliary valve body; the back end of the valve needle is sleeved with a reset spring; a cone valve needle is contacted with an oil hole at the front end of the auxiliary valve body; the front end of the one-way valve core is provided with a circular hole; the circular hole is matched with a throttle valve core in a sliding way; the back end of the throttle valve core provided with a throttle hole arranged in the center is provided with a spring; and a pressure release cavity is formed between the front end of the auxiliary valve body and the inner cavity of the one-way valve core. The conversion valve has the advantages that: the micro-motion effect is realized; as the overload protection valve is increased, the instant high pressure which is transmitted by working systems is opened before the relief valve of the system is unloaded, thereby removing the peak pressure, effectively protecting the hydraulic parts and structural parts from encountering destructive attack.

Owner:天津玖丰重工机械有限公司

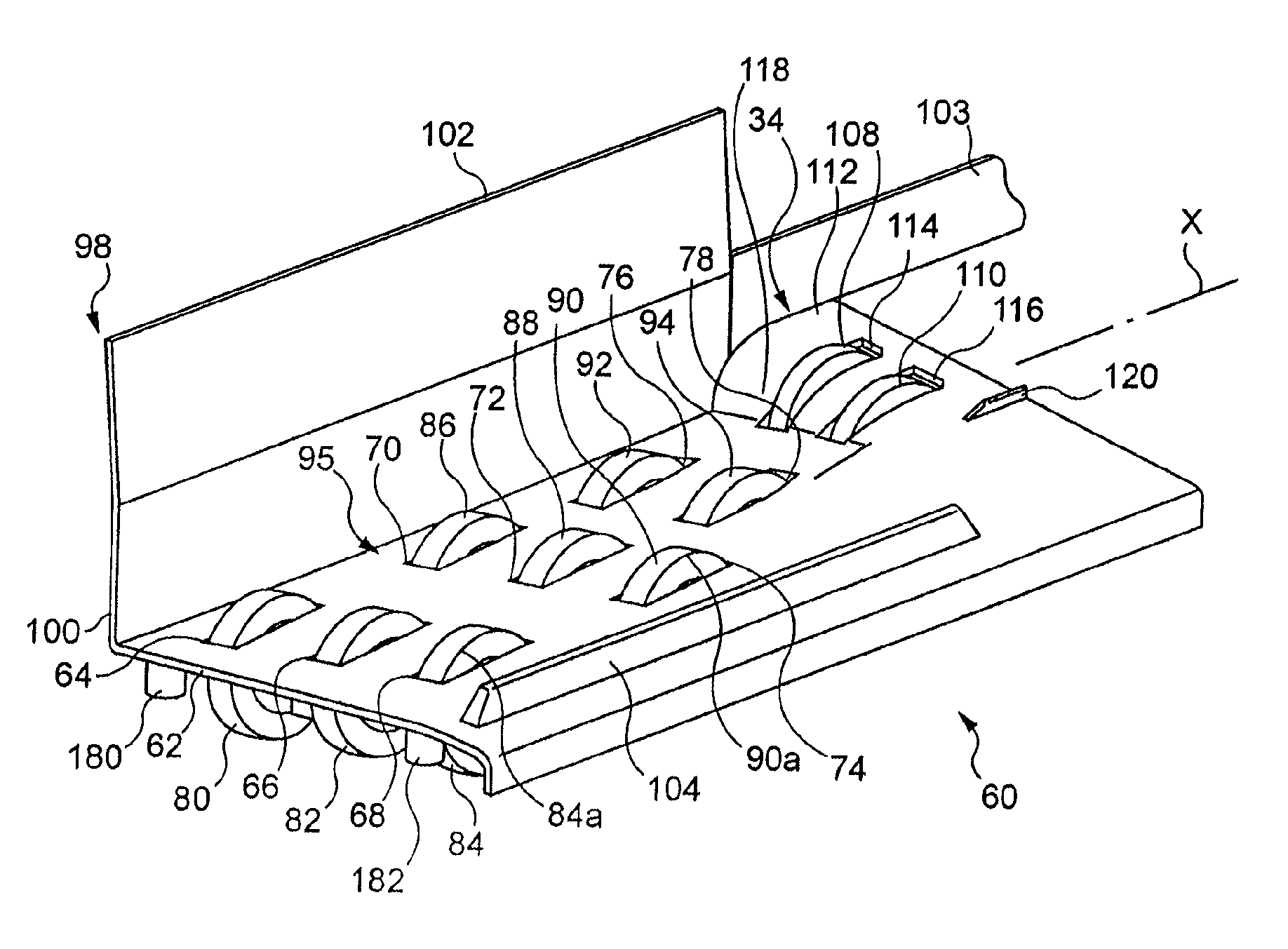

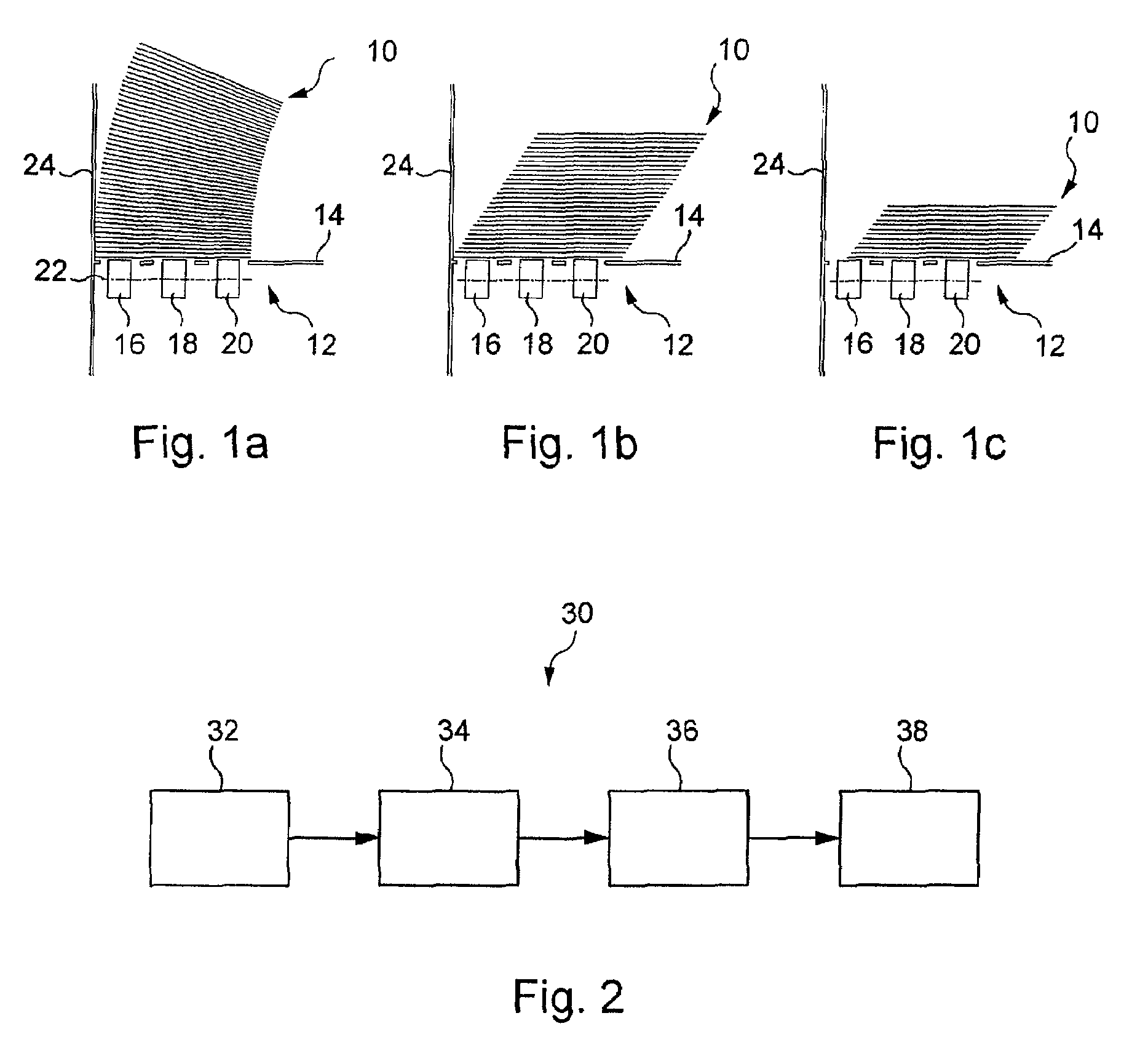

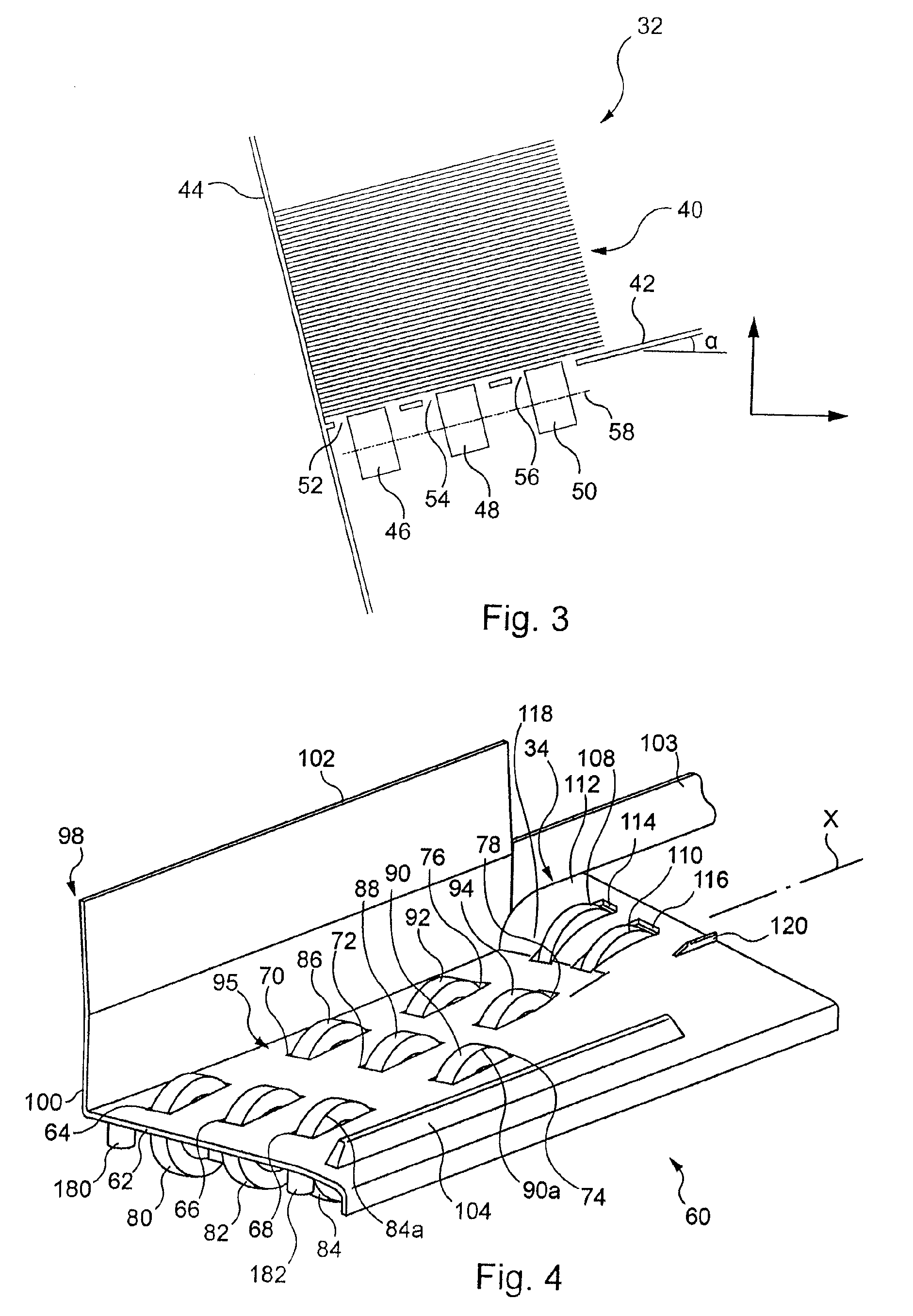

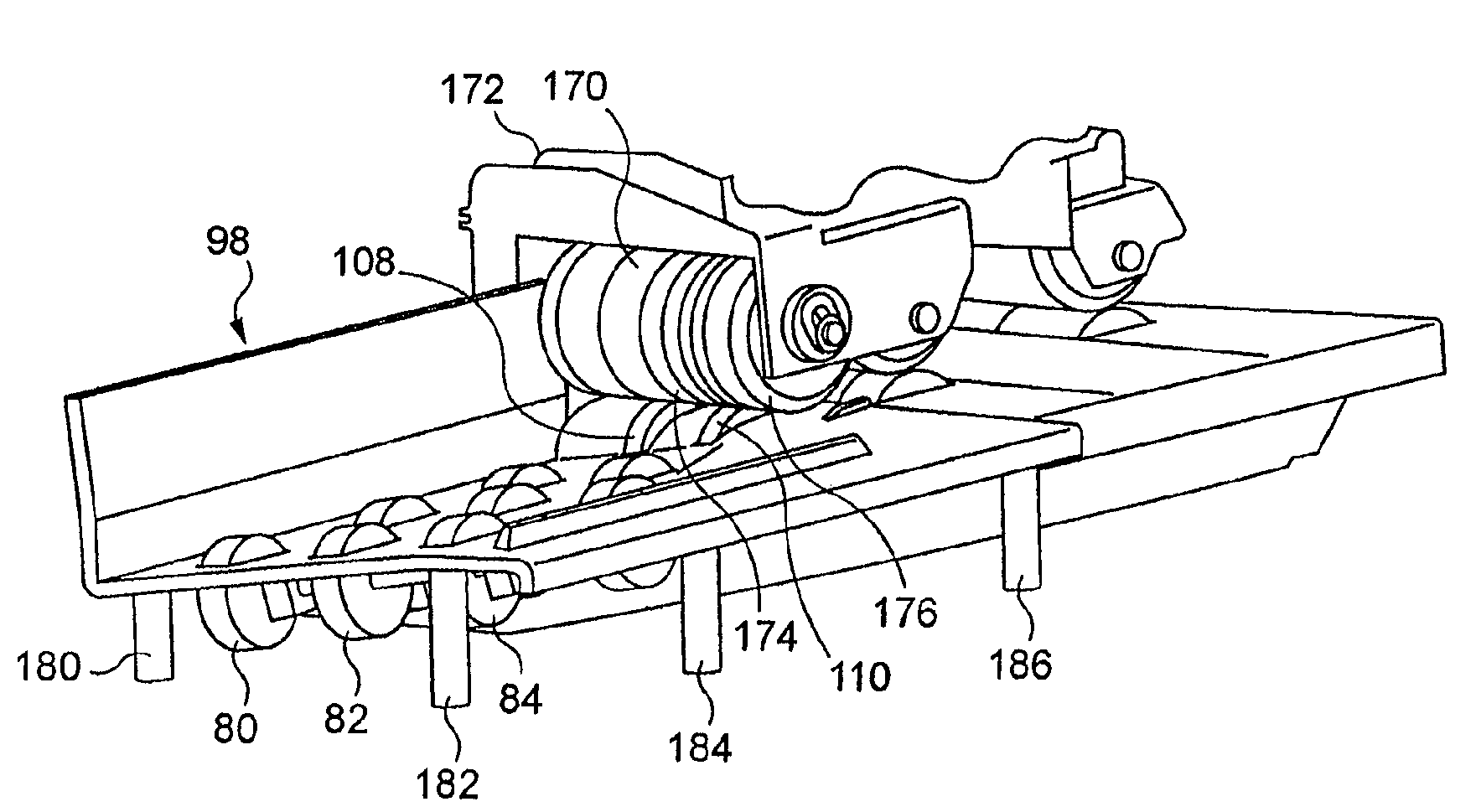

Document processing machine

InactiveUS7735818B2Certain effectivenessAvoid disadvantagesRegistering devicesArticle feedersDownstream processingPaper document

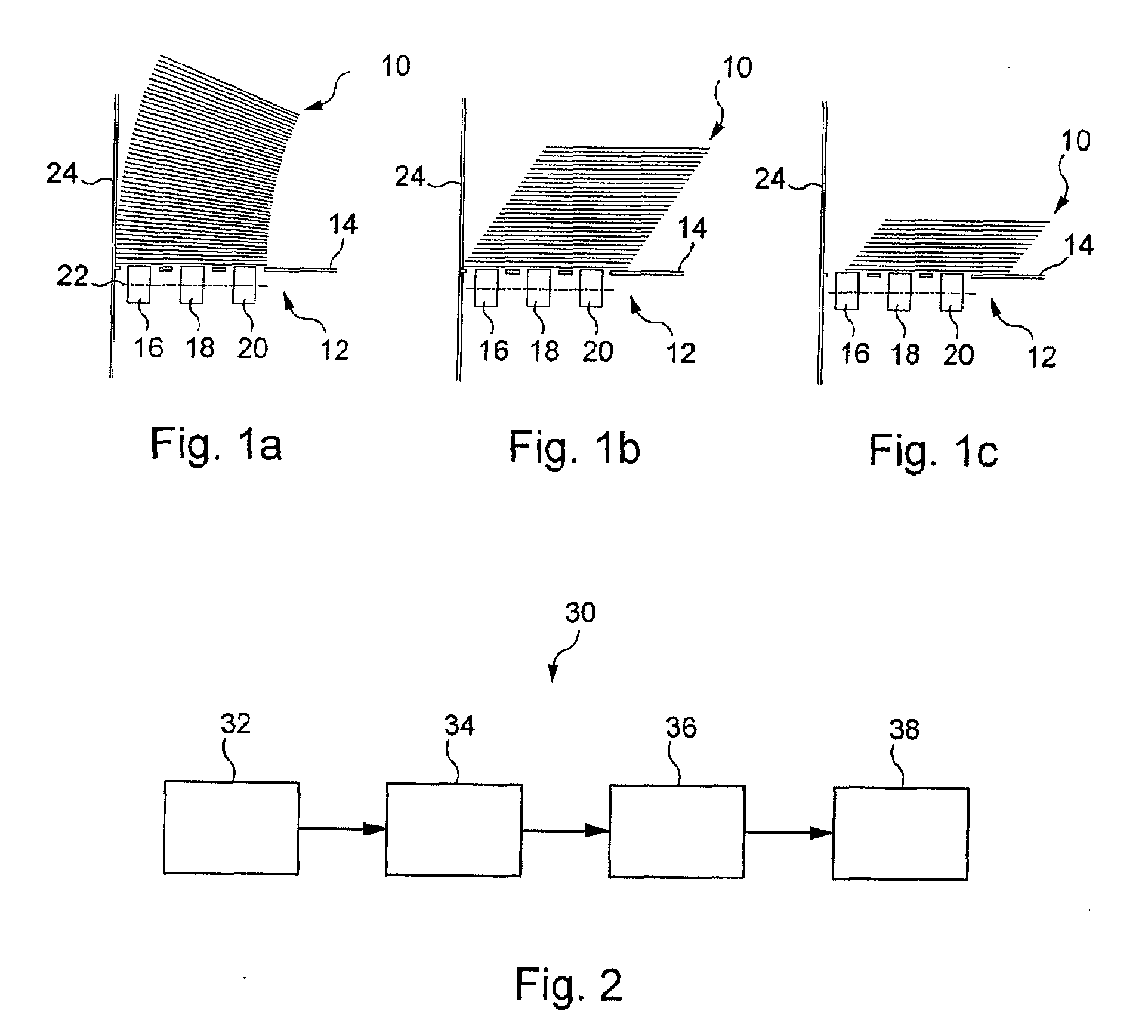

A document processing machine including a document feeder including a support intended to receive a stack of documents, and a unit for extracting documents from the stack of documents and transferring the extracted documents onto a horizontal support of a downstream processing unit, wherein the support of the document feeder is inclined relative to the horizontal is described.

Owner:SECAP GROUPE PITNEY BOWES S

Document processing machine

InactiveUS20090140488A1Easy to operateSoft transitionRegistering devicesArticle feedersDownstream processingPaper document

A document processing machine including a document feeder including a support intended to receive a stack of documents, and a unit for extracting documents from the stack of documents and transferring the extracted documents onto a horizontal support of a downstream processing unit, wherein the support of the document feeder is inclined relative to the horizontal is described.

Owner:SECAP GROUPE PITNEY BOWES S

Chipper Knife and Method of Manufacturing a Chipper Knife

ActiveUS20100123034A1Reduce frictionSoft transitionCutting toolsWood working apparatusAcute angleEngineering

The invention relates to a chipper knife of the type that is adapted to be mounted in chippers which have a rotatable tool, in the form of a disc, drum or frustoconical member, on which are mounted a plurality of such chipper knives to provide, during rotation of the tool and simultaneous feeding of pieces of wood to the same, material-cutting working or disintegrating of the pieces of wood into chips. The chipper knife comprises at least one cutting edge (7) which is defined between two edge-forming surfaces (9, 10) at an acute angle to each other. At least one of the two edgeforming surfaces is formed with a thickened cutting edge portion (12) in the area next to the cutting edge, said thickened cutting edge portion having a shoulder edge (13) toward the rest of the edge-forming surface and forming an angle to, or having a different centre of curvature to, the rest of the edgeforming surface. The invention also relates to a method of manufacturing such a chipper knife.

Owner:IGGESUND TOOLS

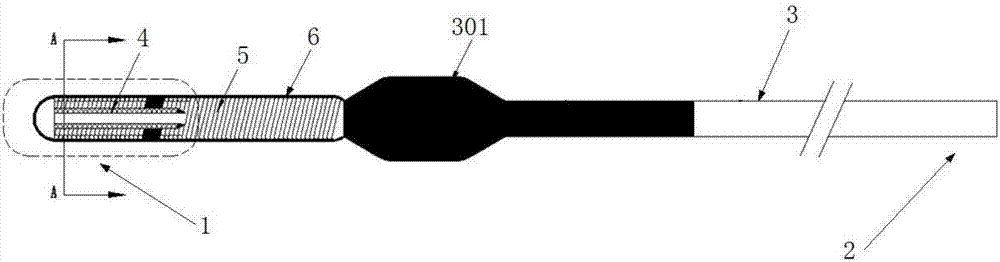

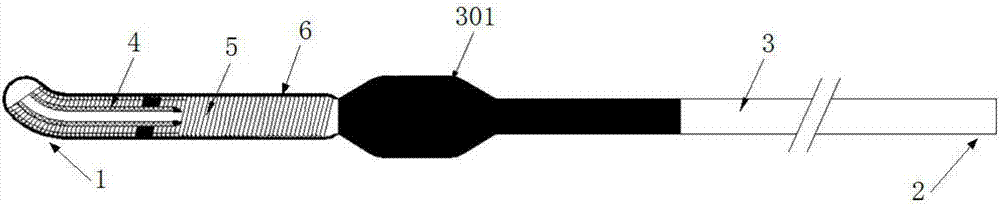

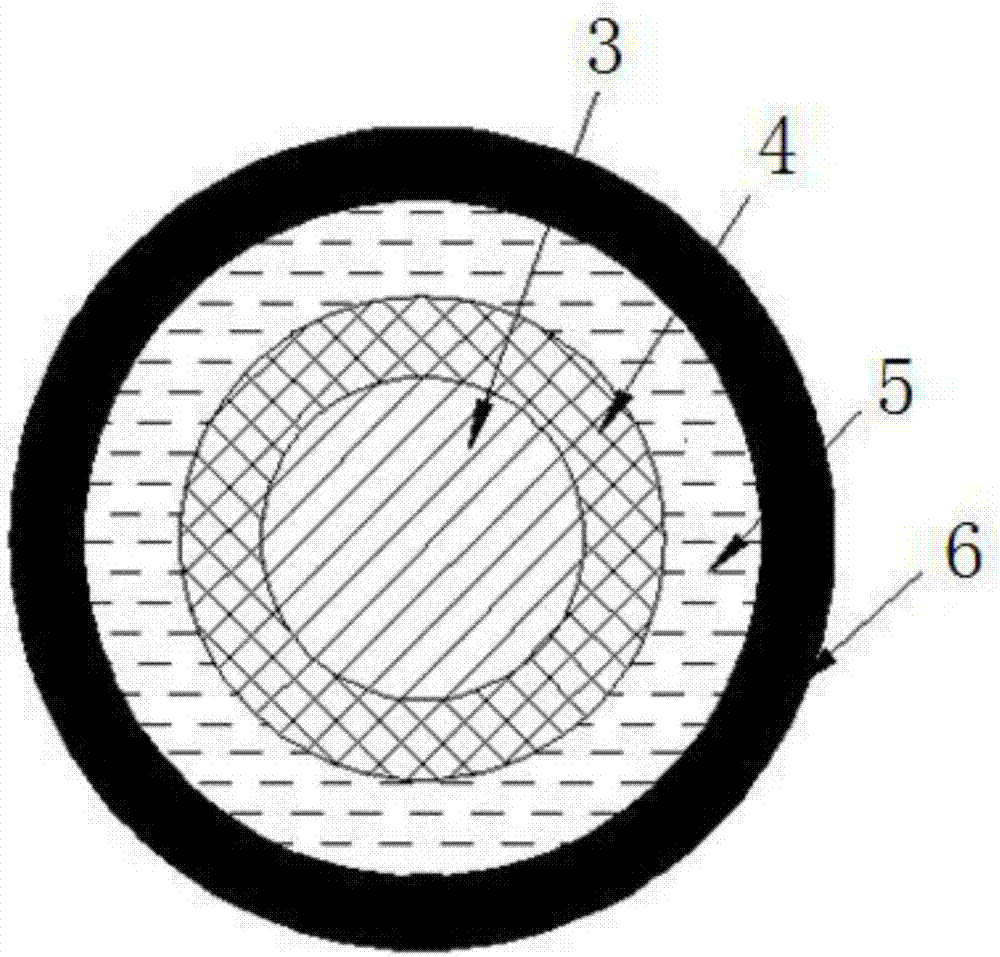

Pre-dilating guide wire and preparation method thereof

InactiveCN107362437AReduce torqueReduced torque lossGuide wiresSurgeryTorque transmissionEngineering

The invention discloses a guide wire. The guide wire comprises a far end, a near end and a core wire, the core wire is positioned in a guide wire body and extends from the near end to the far end, a dilating portion is arranged on the core wire, the diameter of the dilating portion is larger than that of the core wire, and a safety net is arranged at a head end, positioned at the far end, of the core wire and is fixedly connected with the head end. The invention further discloses a preparation method of the guide wire. By additionally arranging the safety net at the head end, positioned at the far end, of the core wire, loss of torsion / torque transmission of the guide wire is reduced, and softness and non-deformability of the far end of the guide wire are guaranteed while the phenomenon of 'tail whipping' is eliminated; by arranging the dilating portion on the guide wire, a narrow portion can be pre-dilated by a radial support effect, and an inner cavity of the narrow portion can be dilated to allow a balloon to pass through conveniently. The dilating portion of the pre-dilating guide wire is perfectly round, smooth and soft and cannot cause wounds to blood vessels.

Owner:APT MEDICAL HUNAN INC

Illuminating device for an adjusting mechanism in a vehicle

InactiveCN102097229AEnhanced authenticationImprove comfortControlling membersElectric switchesEngineeringElectrical and Electronics engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Powder distributing device for ceramic tile with extended fine sand texture effect

The invention relates to a powder distributing device for a ceramic tile with the extended fine sand texture effect. The device comprises a colored powder roller combination blanking device, a main-color powder blanking roller, a base material blanking roller, a line-texture powder control roller combination blanking device, a linear powder feeding belt, a texture and main powder feeding belt, a toothed roller, a powder collecting box, a transfer printing belt and a base material grid. With the adoption of the device in the production of the ceramic tile with the extended fine sand texture effect, the sense of motion and the change of the extended fine sand textures can be created. Compared with the prior art, the device has the advantages that extending and rolling textures are brought to the ceramic tile; the cascading and transition are natural and smooth; the color and sandiness of the powder are exquisite and soft; the products of different colors can be produced by adjusting the technical parameters and matching the color of each texture; the effect of the device is ahead of that of like products in the market, the controllability of the device is high, and a wide product design scope is provided.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

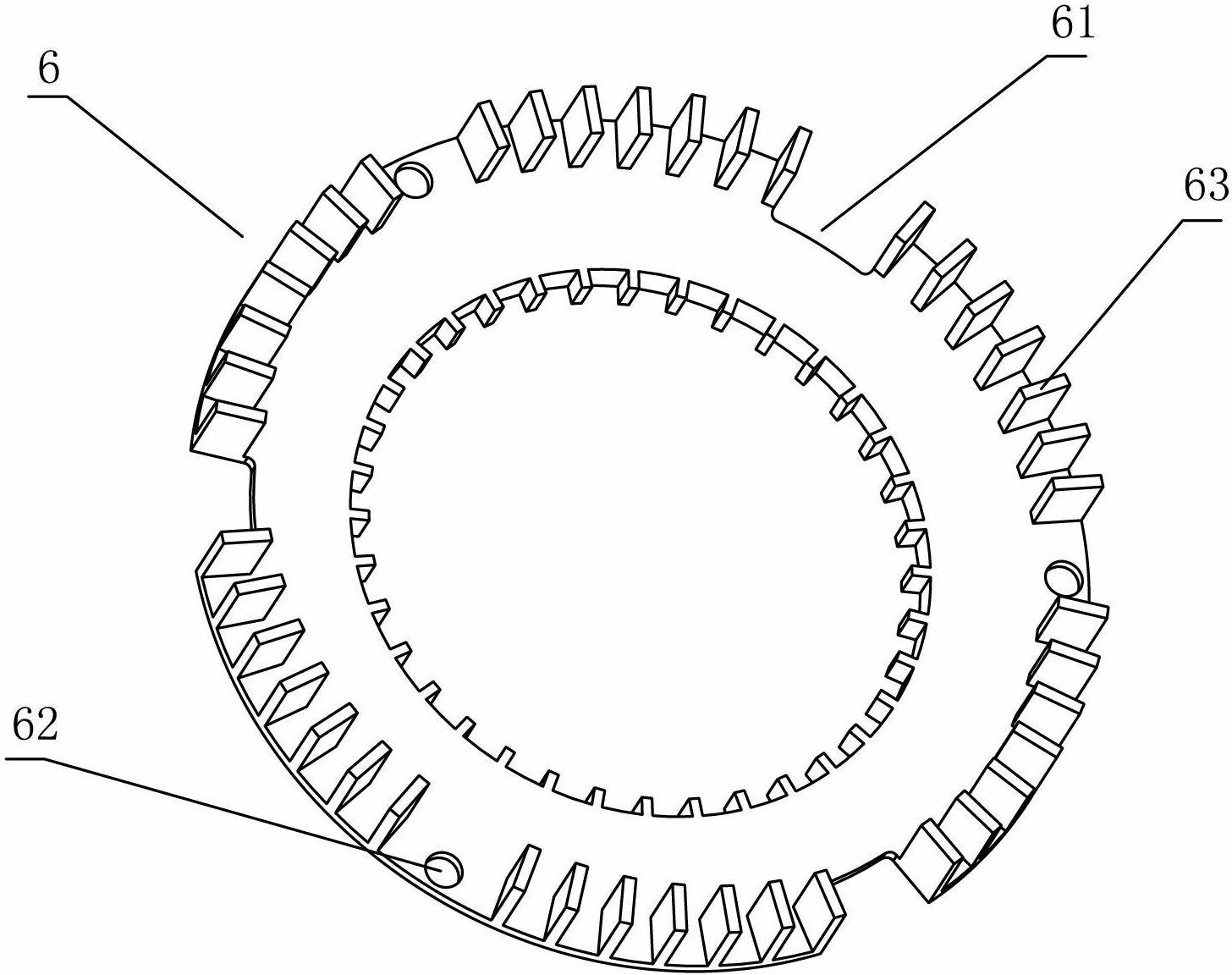

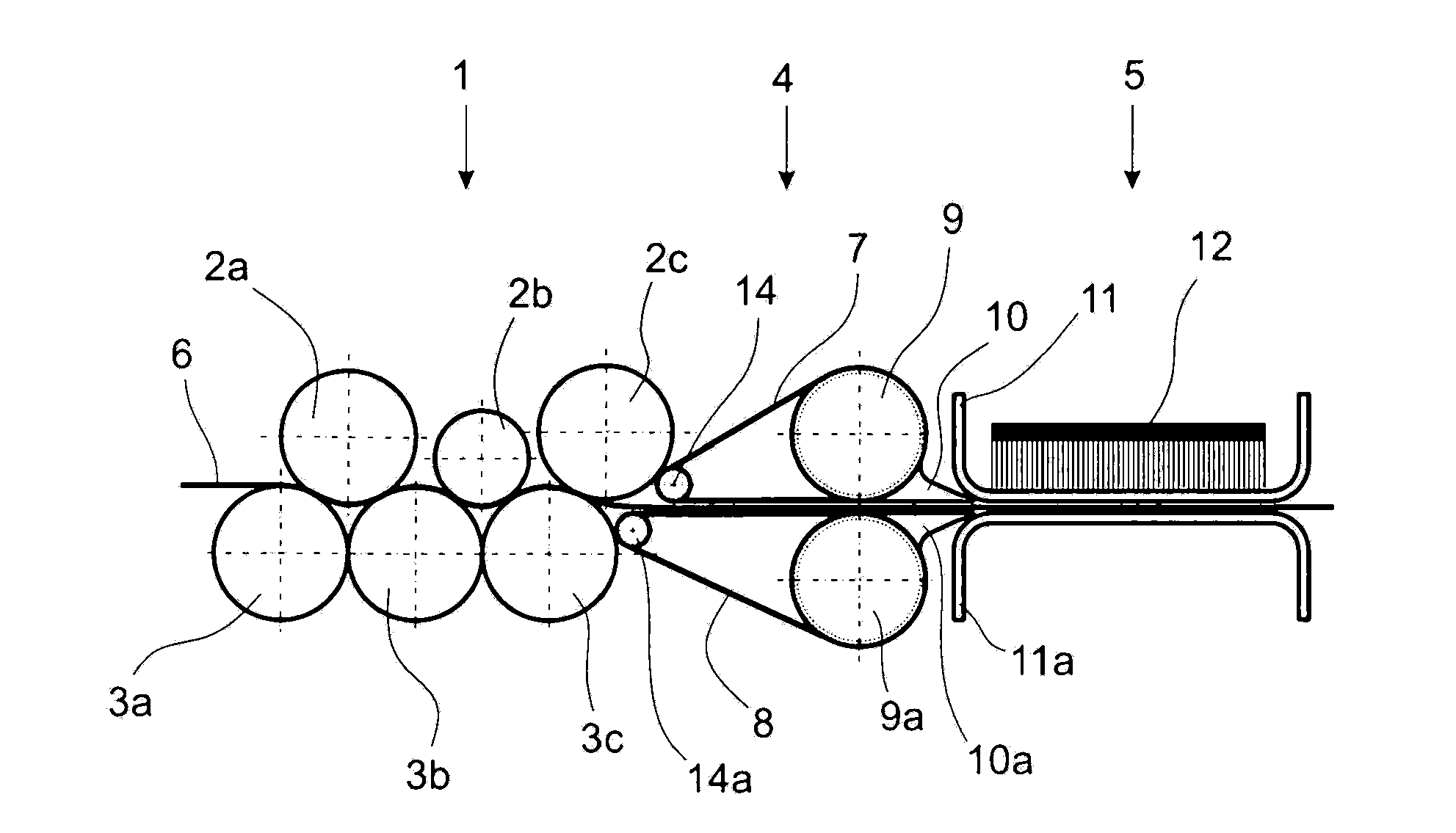

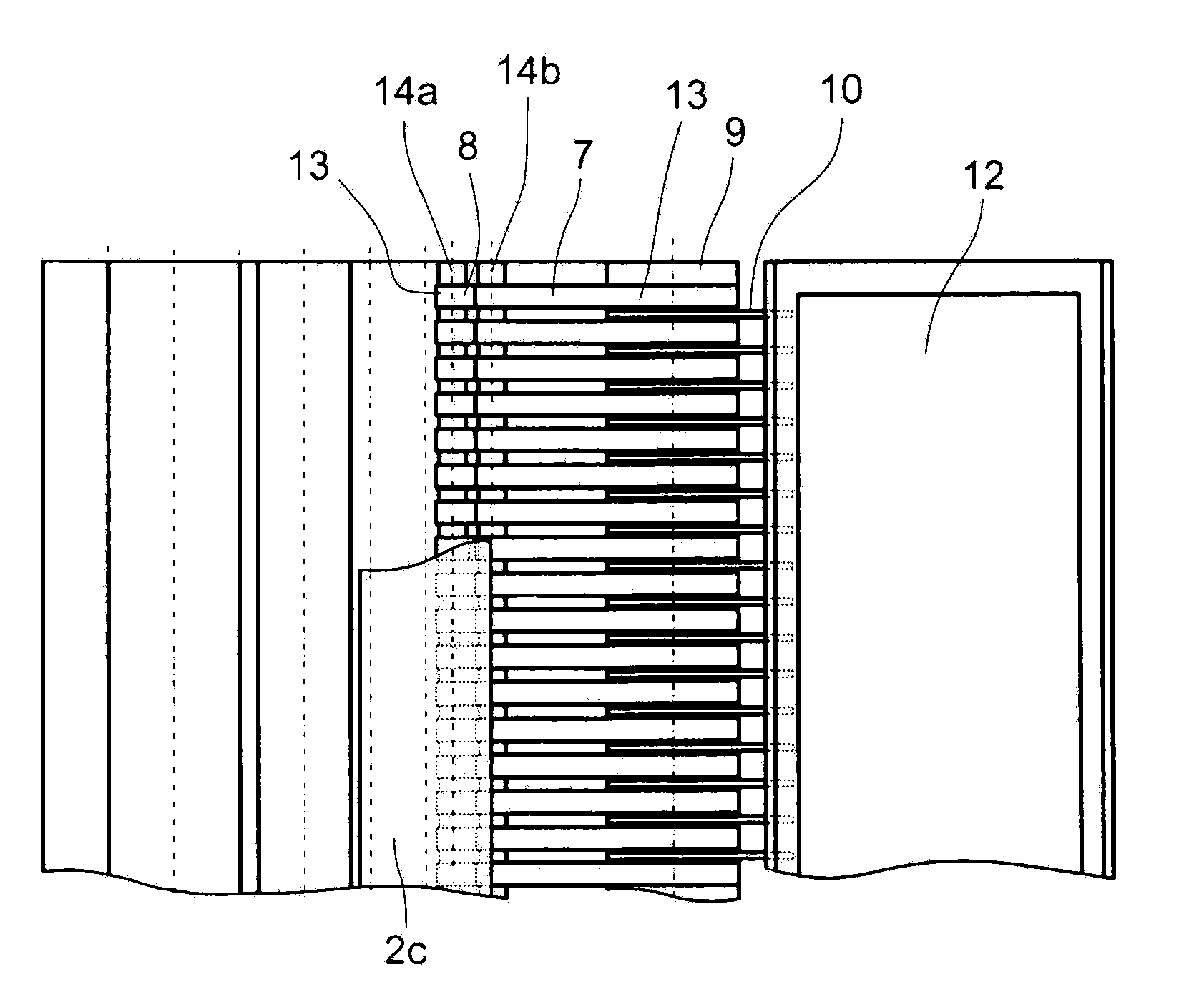

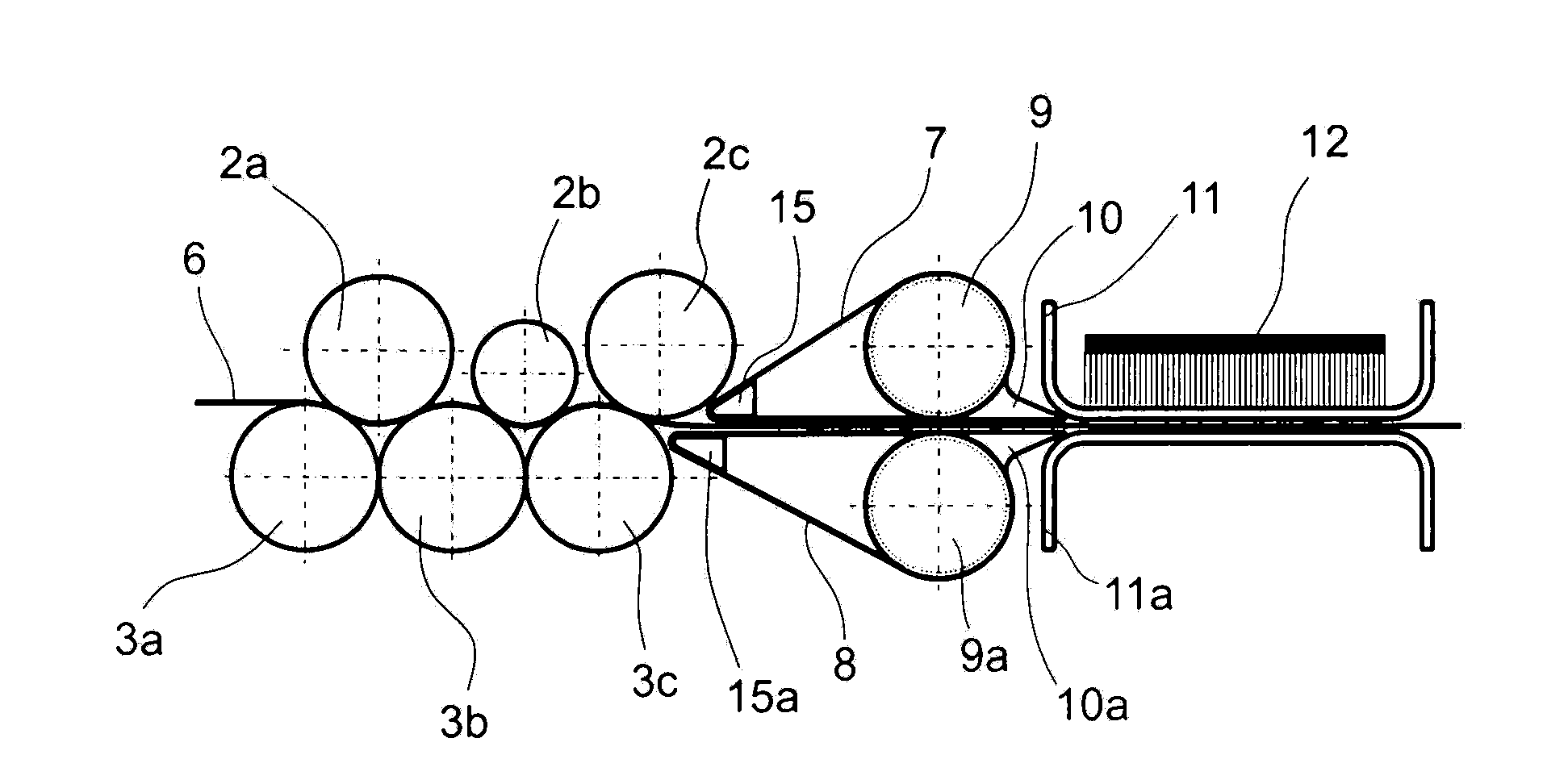

Feed system for textile processing machine

InactiveCN103668574AReliable deliveryReliable bootFibre feedersNeedling machinesYarnTextile processing

The invention relates to a feed system for a textile processing machine. The feed system includes at least one circling conveyer belt (8) and another conveying device, a non-woven fabric belt (6) is conveyed and guided between the conveyer belt and the other conveying device, and the feed system is characterized in that the conveyer belt (8) includes at least two belt strips, and a yarn guide (10a) is arranged between every adjacent belt strips.

Owner:TRUETZSCHLER GMBH & CO KG

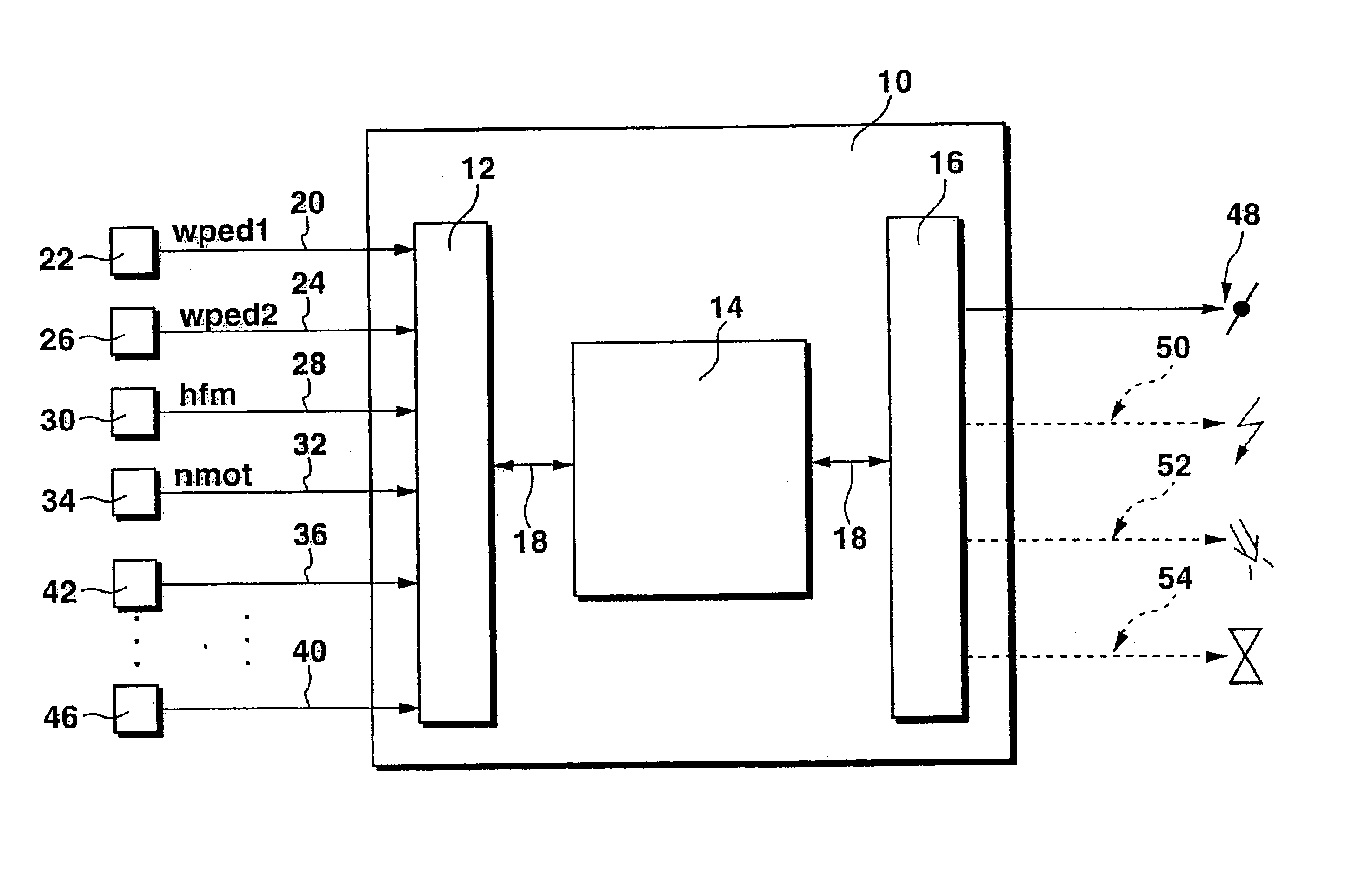

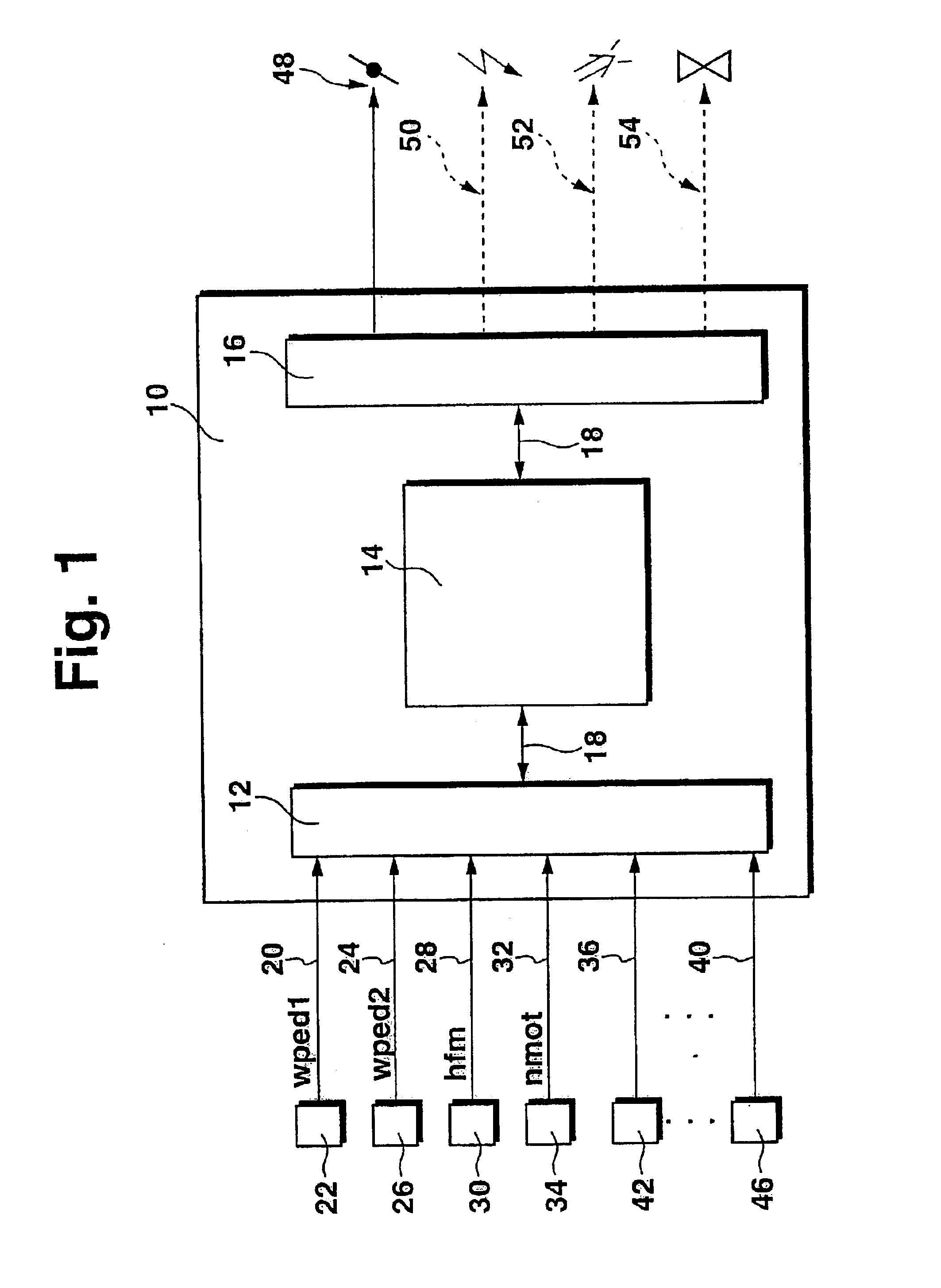

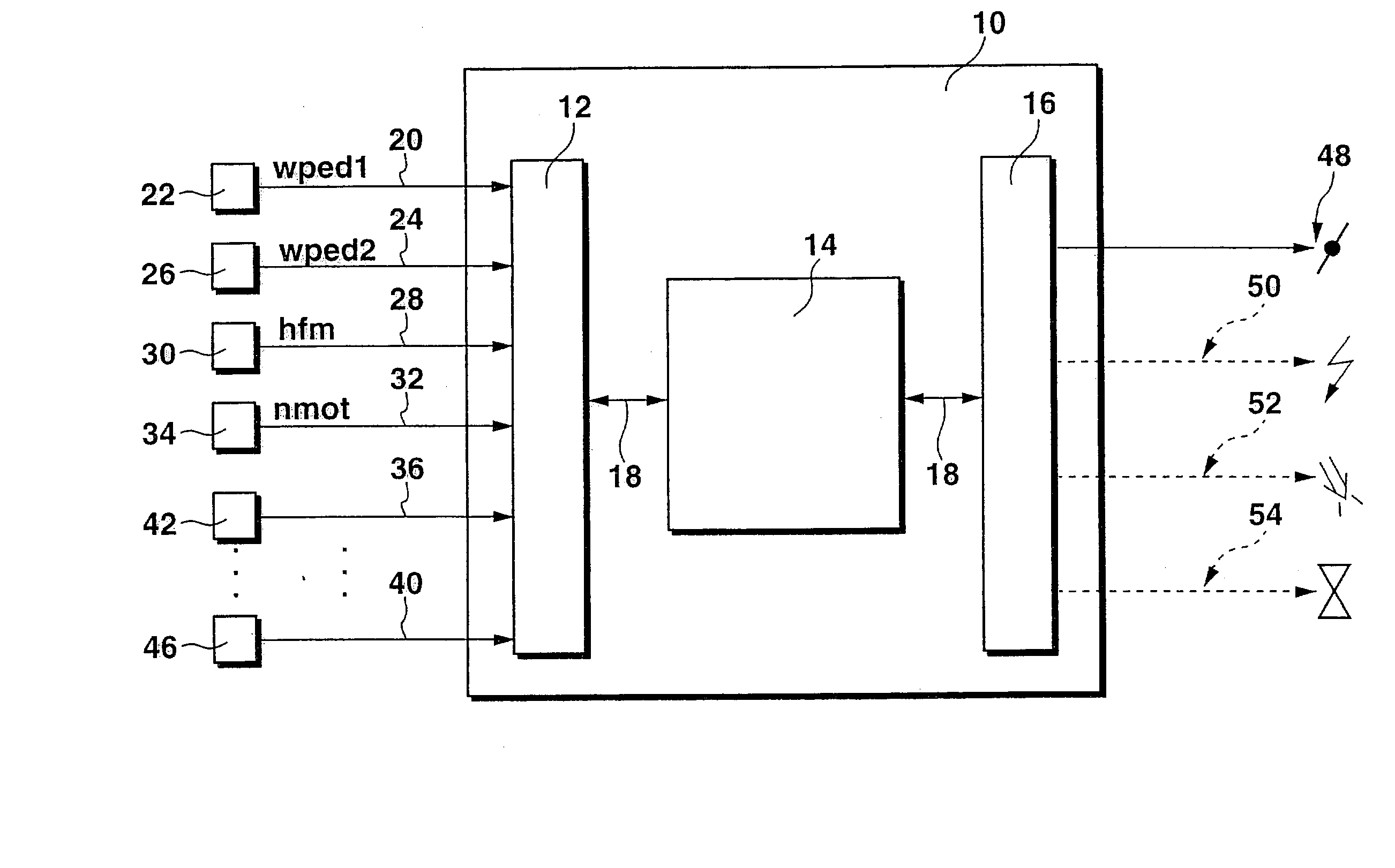

Method and device for controlling the drive unit of a motor vehicle

InactiveUS20030150421A1Improve comfortAffect actionElectrical controlInternal combustion piston enginesMobile vehicleLimit value

A method and arrangement for controlling the drive unit of a vehicle is suggested wherein a limiter is provided to limit the engine rpm to a pregiven limit value in at least one operating state. The limiter is controlled to be ineffective in this at least one operating state in dependence upon at least one additional operating variable.

Owner:ROBERT BOSCH GMBH

Power transmission mechanism

InactiveUS8220605B2Feel goodHigh modulusRotary clutchesFriction clutchesPower transmissionFluid power

A power transmission mechanism including at least one hydrodynamic component and a device for at least partially bridging over the transmission of power through the hydrodynamic component by means of a control device, having an actuating mechanism that can be charged by way of a chamber that is chargeable with a pressurizing agent, and at least one spring unit is interposed between the actuating mechanism and the device for at least partially bridging over the hydrodynamic component.

Owner:SCHAEFFLER TECH AG & CO KG

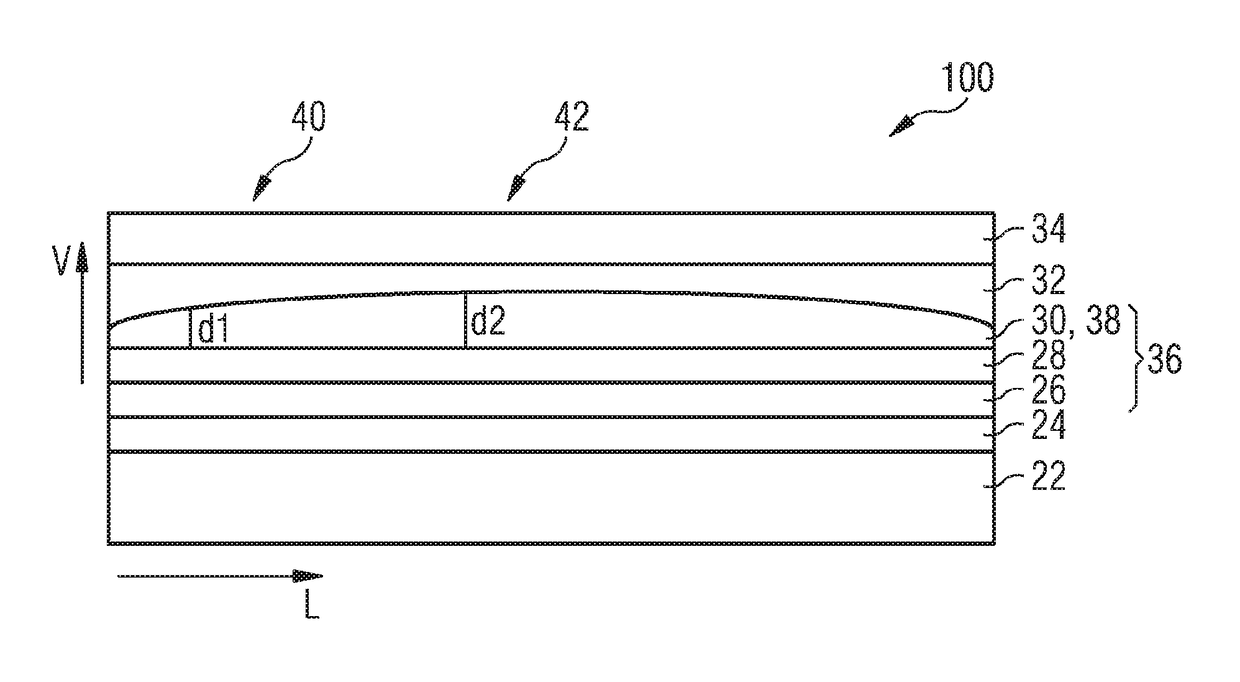

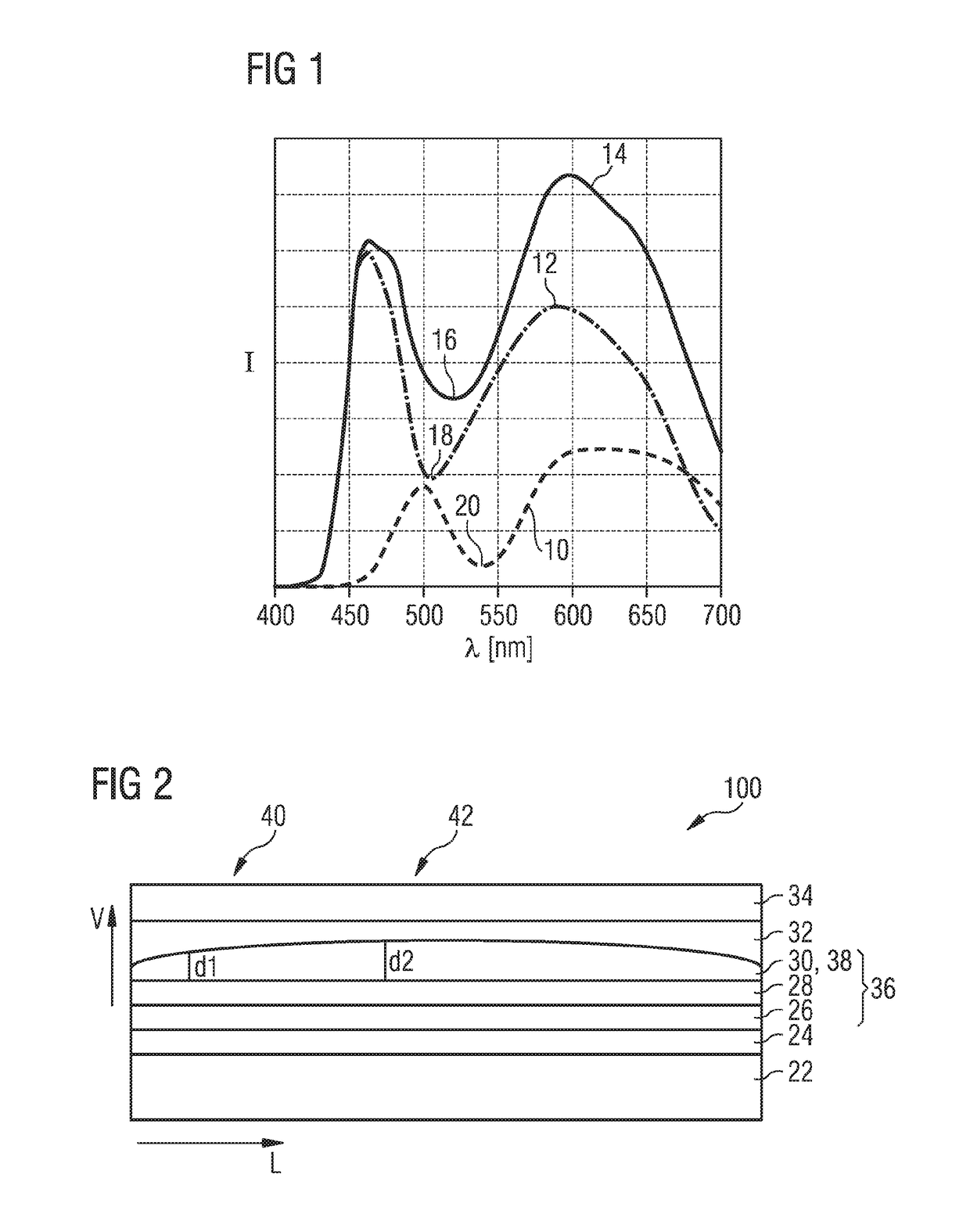

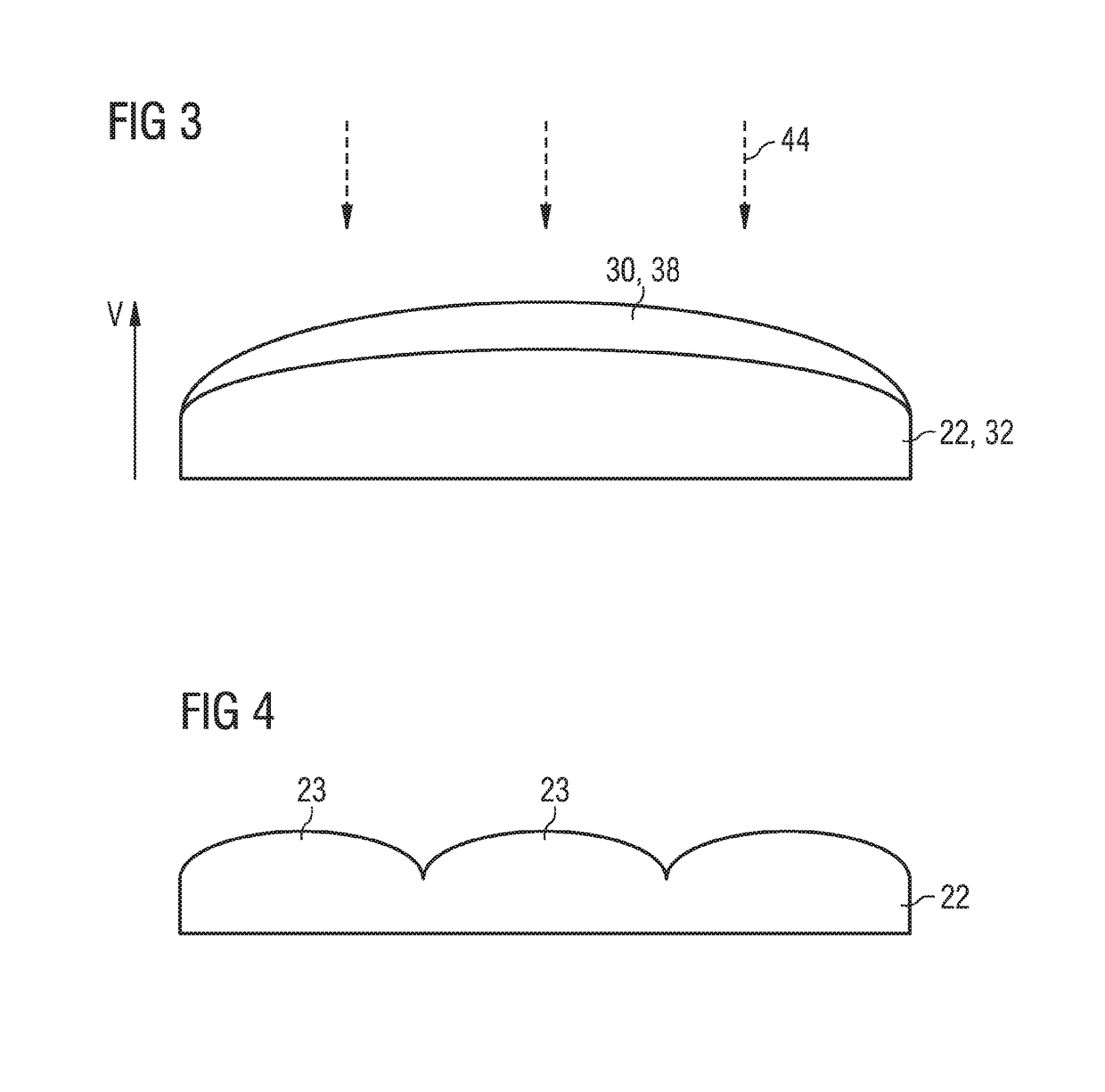

Organic Light-Emitting Device

ActiveUS20170229675A1Soft transitionAvoid distractionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceElectromagnetic radiation

An organic light-emitting device and a method for producing an organic light emitting device are disclosed. In an embodiment the device includes a substrate and at least one layer sequence arranged on the substrate and suitable for generating electromagnetic radiation. The at least one layer sequence includes at least one first electrode surface arranged on the substrate, at least one second electrode surface arranged on the first electrode surface and an organic functional layer stack having organic functional layers between the first electrode surface and the second electrode surface. The organic functional layer stack includes at least one organic light-emitting layer, wherein the at least one organic light-emitting layer is configured to emit light, wherein the organic functional layer stack includes at least one inhomogeneity layer, and wherein a thickness of the at least one inhomogeneity layer varies in a lateral direction.

Owner:DOLYA HOLDCO 5 LTD

LED lamp bracket and lamp comprising same

InactiveCN105953160ASoft light structureMovable light structureLight source combinationsLighting support devicesEngineeringLED lamp

The present invention relates to an LED lamp bracket and a lamp including the bracket. The bracket includes a base and a plurality of lamp beads, and at least one isolation structure, the isolation structure divides the light-emitting structure into several groups, so that the Lamp beads have different lighting areas. The beneficial effects of the present invention are: the bracket isolates several lamp beads, so each lamp bead can illuminate different areas; the isolation plate is combined with the motor to create a soft and movable light structure; The lamp, with the bracket applied, can form multiple layers of different color layers on the lampshade under the action of the bracket, and there is a very soft and smooth transition between the color layers.

Owner:SHENZHEN BASON TECH CO LTD

Novel embossing roller manufacturing process

InactiveCN110653978AAvoid lossAvoid distortionLaser beam welding apparatusSurface patternLaser engraving

The invention relates to a novel embossing roller manufacturing process. The manufacturing process comprises the following process operation steps: S1, sampling by laser scanning; S2, carrying out pattern processing on scanned patterns by a computer to generate a 3D seamless spliced file; S3, carrying out digital processing on the 3D file to enable the 3D file to be used for laser engraving; S4, selecting rubber capable of being engraved by laser, and engraving and reducing the patterns to the surface of the rubber; S5, casting liquid silica gel on the surface of an engraved rubber mold, drying and curing, and reducing the rubber surface patterns to the surface of the silica gel; and S6, removing a silicon gel sleeve, and sleeving the surface of a steel roller with the silicon gel sleeve for embossing operation. According to the novel embossing roller manufacturing process, the silicon gel sleeve is arranged on the surface of the steel roller in a sleeving mode to be used for carryingout embossing process treatment, so that the grains on the surface of a pressed object achieve a series of effects of matting, clear pattern layer, no seam, soft pattern edge transition and the like.An embossing roller manufactured by the process is lower than a prior embossing roller in manufacturing cost, and the grains are adjusted conveniently.

Owner:CHANGZHOU YUDONG ROLLER MFG CO LTD

A ceramic tile powder distributing device with the effect of continuous fine sand texture

The invention relates to a powder distributing device for a ceramic tile with the extended fine sand texture effect. The device comprises a colored powder roller combination blanking device, a main-color powder blanking roller, a base material blanking roller, a line-texture powder control roller combination blanking device, a linear powder feeding belt, a texture and main powder feeding belt, a toothed roller, a powder collecting box, a transfer printing belt and a base material grid. With the adoption of the device in the production of the ceramic tile with the extended fine sand texture effect, the sense of motion and the change of the extended fine sand textures can be created. Compared with the prior art, the device has the advantages that extending and rolling textures are brought to the ceramic tile; the cascading and transition are natural and smooth; the color and sandiness of the powder are exquisite and soft; the products of different colors can be produced by adjusting the technical parameters and matching the color of each texture; the effect of the device is ahead of that of like products in the market, the controllability of the device is high, and a wide product design scope is provided.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com