Shifting-sand-textured glass ceramic tile preparation device

A preparation device and texture technology, which is applied in the field of quicksand texture vitrified tile preparation devices, can solve the problems of low production efficiency, unevenness, texture breakage, etc., and achieve soft transition between color and powder sand, strong controllability, and texture Layered effects for realistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

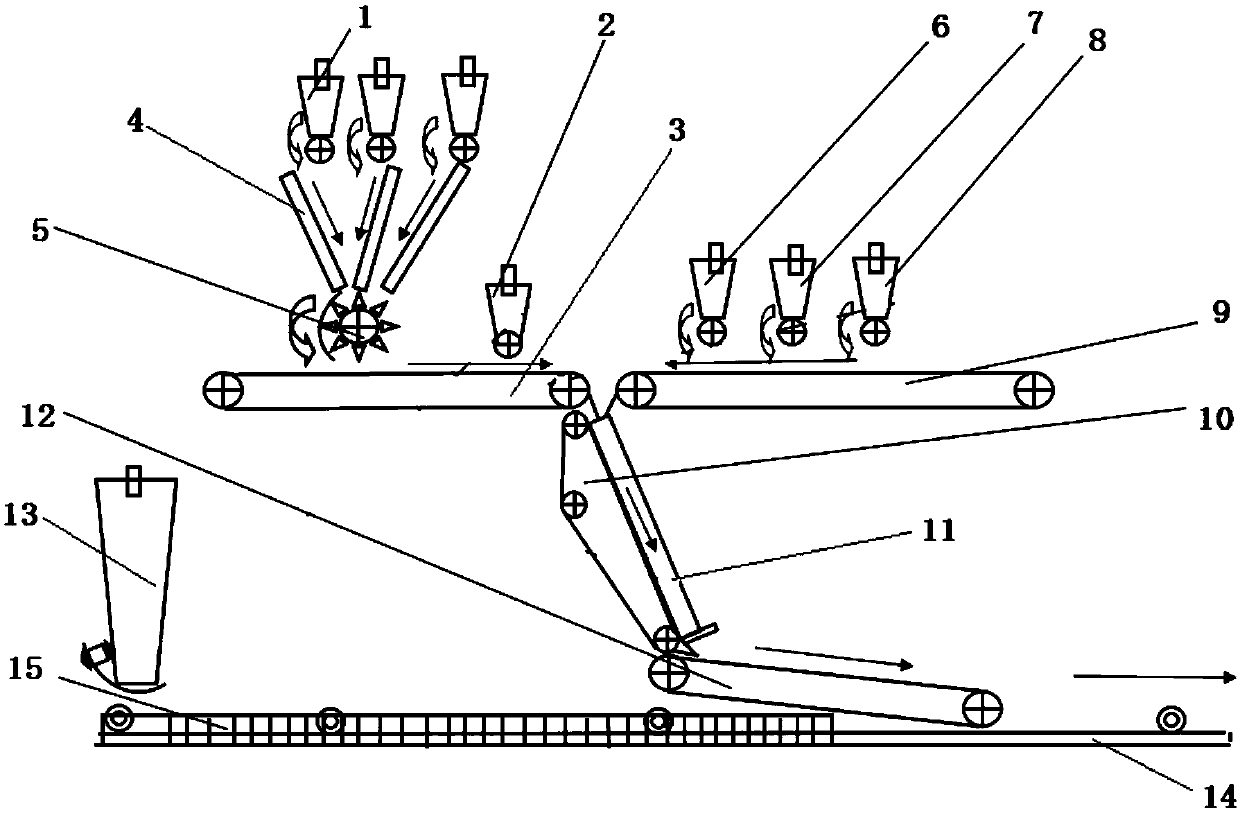

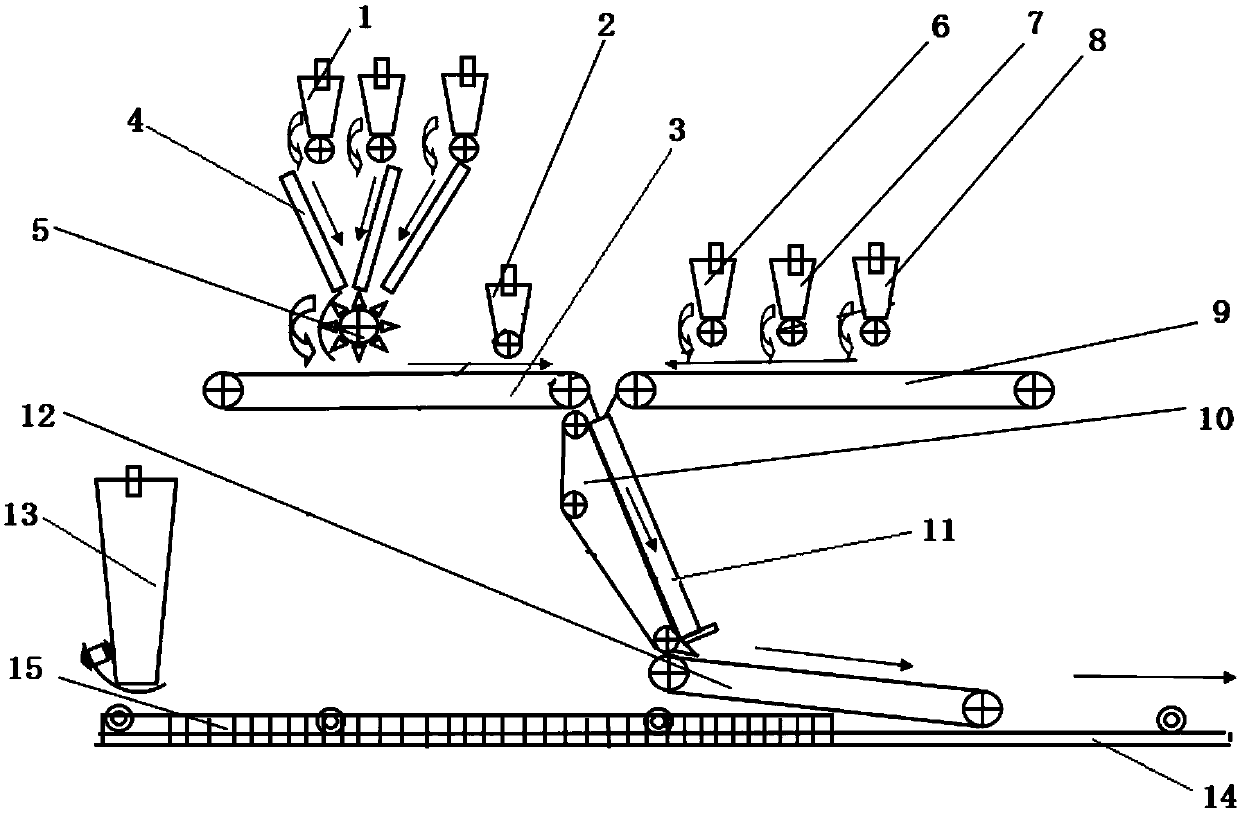

[0023] A device for preparing vitrified ceramic tiles with quicksand texture, the device includes a feeding cart 14, a base material unloading unit 13 arranged at the rear of the feeding cart 14, an aggregate transfer unit arranged at the front middle of the feeding cart 14, The color powder blanking unit and the line texture powder blanking unit at the entrance of the transfer unit and the controller used to control the blanking sequence of each blanking unit. When working, the controller moves forward and backward by controlling the material trolley 14, and then controls The blanking sequence of the base material, the color powder and the line texture powder forms a quicksand texture on the flat plate on the upper surface of the feeding cart 14, and then the firing is completed.

[0024] The color powder feeding unit includes a plurality of colored powder barrels 1 arranged side by side, a main color powder barrel 2, and a color powder conveying belt arranged below the colore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com