Chip charging barrel for steel casting electric furnace

A technology for feeding barrels and electric furnaces, which is applied to furnaces, furnace components, charge control and other directions, can solve the problems of reduced economic benefits, increased costs, complex structures, etc., and achieves the effects of increased economic benefits, easy feeding, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

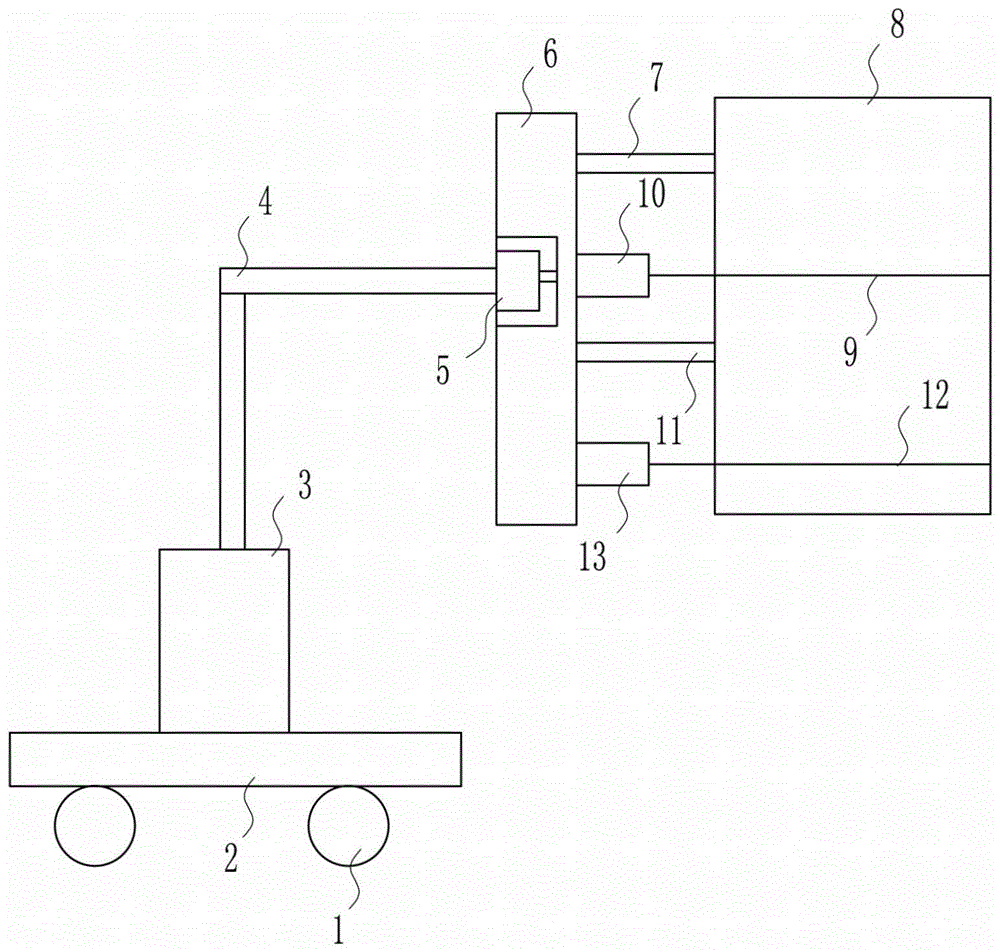

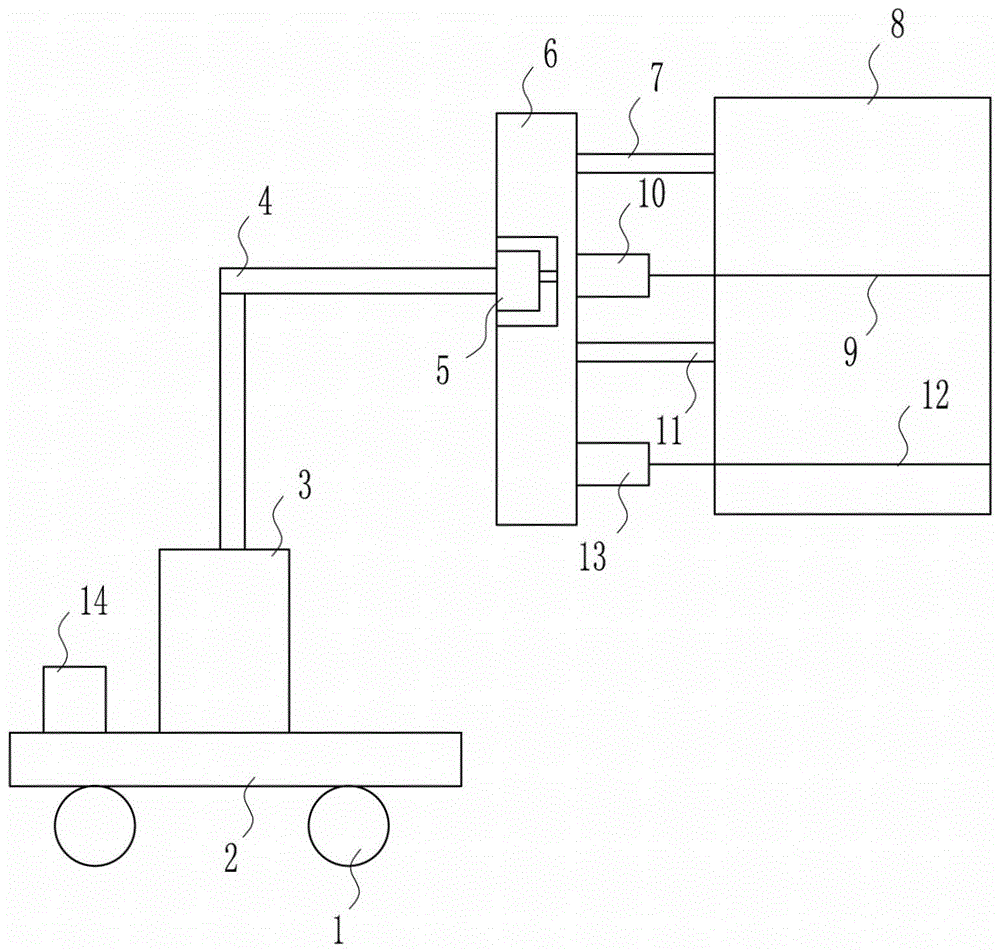

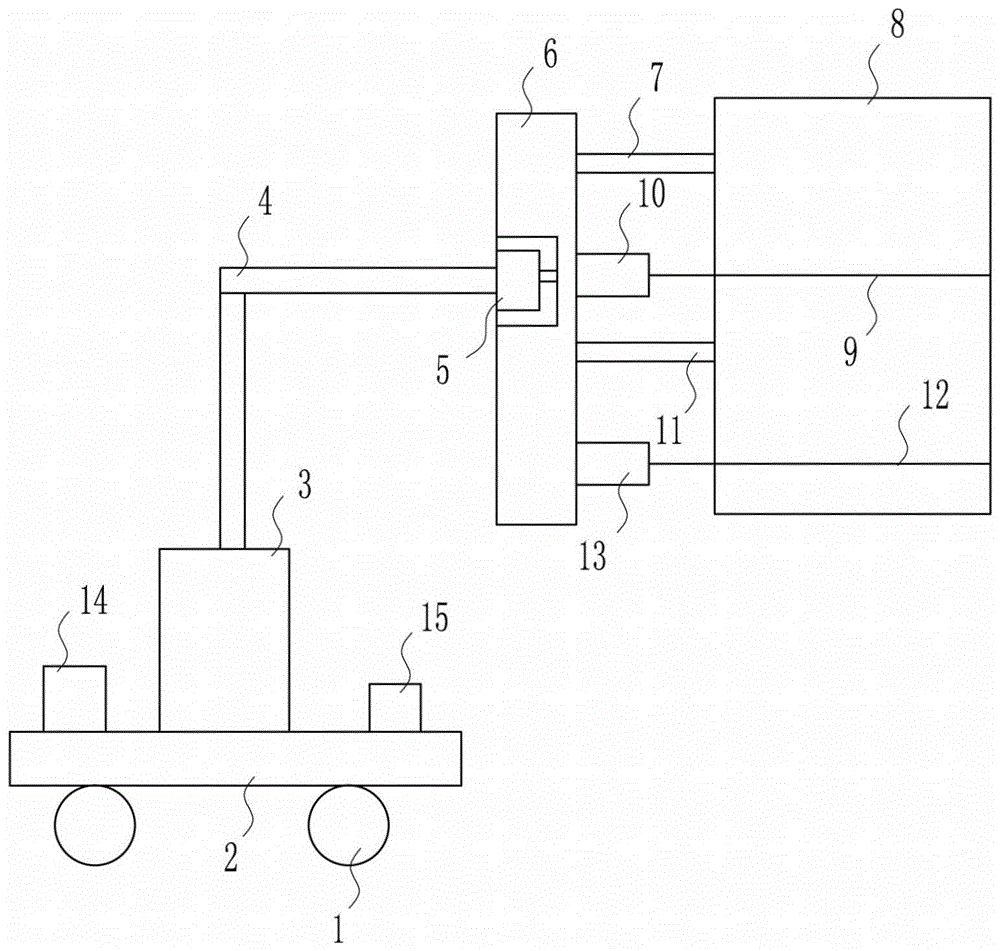

[0021] A kind of iron and steel electric furnace scrap feeding barrel, such as Figure 1-3 As shown, it includes wheel 1, plate Ⅰ2, cylinder 3, connecting rod Ⅰ4, motor 5, plate Ⅱ6, connecting rod Ⅱ7, feeding barrel 8, baffle Ⅱ6, electric push rod Ⅱ10, connecting rod Ⅲ11, baffle Ⅰ2 and electric Push rod Ⅰ13; wheel 1 is set at the bottom of plate Ⅰ2, cylinder 3 is set in the middle of the top of plate Ⅰ2, connecting rod Ⅰ4 is connected above cylinder 3, plate Ⅱ6 is set on the right side of connecting rod Ⅰ4, and motor 5 is embedded in plate Ⅱ6 Inside, the right side of the plate II6 is provided with connecting rod II7, electric push rod II10, connecting rod III11 and electric push rod I13 from top to bottom, and the right side of connecting rod II7 and connecting rod III11 is connected with a feeding barrel 8, electric The right side of the push rod I13 is connected with the baffle plate I2, and the right side of the electric push rod II10 is connected with the baffle plate II6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com