A pre-vibration double-station automatic feeding refractory brick forming method

A technology of automatic feeding and molding method, applied in ceramic molding machines, manufacturing tools, supplying devices, etc., can solve the problems of no automatic feeding function, unreasonable process, poor firmness, etc., and achieve easy control of feeding amount and structure. Simple and ingenious, the effect of improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

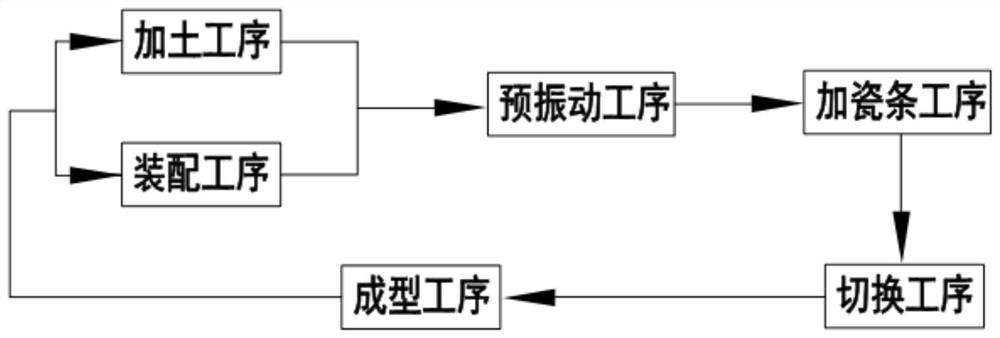

[0062] Such as figure 1 As shown, a pre-vibration double-station automatic feeding refractory brick forming method includes the following forming steps:

[0063] Step 1, soil adding process, the die a14 to be fed is moved to the feeding station on one side, and the blanking mechanism located at the feeding station adds a certain amount of sand and soil into the die a14;

[0064] Step 2, the assembly process, the blanking mechanism in the step 1 is in the process of adding sand, and the porcelain strip pushing mechanism located at the feeding station inserts the introduction block a2443 on one side into the die a14;

[0065] Step 3, the pre-vibration process, the die a14 in the step 2 is pre-vibrated under the drive of the press 1 after adding sand and inserting the introduction block a2443;

[0066] Step 4: Adding porcelain strips. After the pre-vibration of the die a14 in the step 3 is completed, the porcelain strip pushing mechanism is reset and the porcelain strip 10 is in...

Embodiment 2

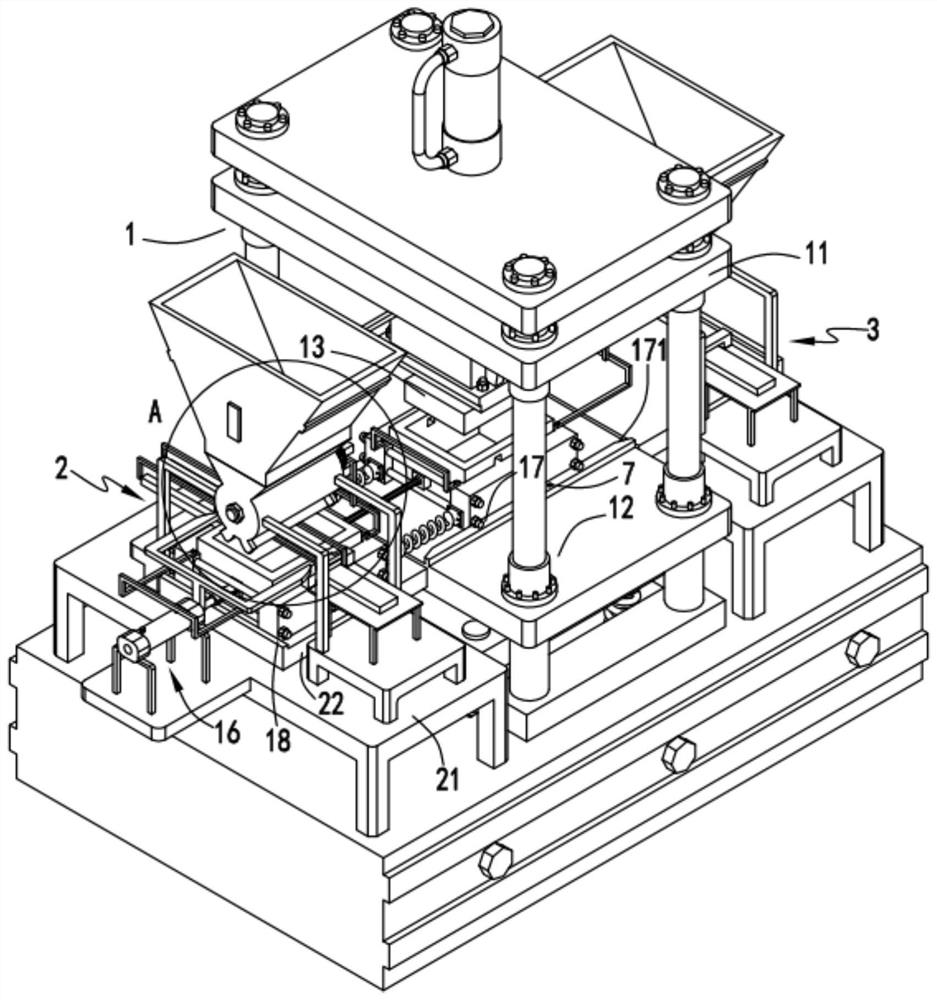

[0078] Such as Figure 2 to Figure 11 As shown, a pre-vibration dual-station automatic feeding refractory brick forming equipment includes a press 1, and the press 1 includes an upper mold base 11, a lower mold base 12 and a punch fixed on the upper mold base 11 13. It also includes a die a14, a die b15 and a push-pull mechanism 16 for driving the die a14 and die b15 to slide back and forth along the lower die base 12 for switching;

[0079] Both sides of described press 1 are respectively provided with first feeding device 2 and second feeding device 3, and described first feeding device 2 and second feeding device 3 all comprise base 21 and be arranged on base 21 The support platform 22, the first feeding device 2 also includes a blanking mechanism a and a porcelain strip pushing mechanism a arranged on the base 21, the blanking mechanism a is used to transfer a certain amount of sand and soil to the In the concave mold a14 below, the porcelain strip pushing mechanism a is ...

Embodiment 3

[0100] Such as Figure 5 , Figure 6 and Figure 11 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is: further, the end of the central axis 2323 of the quantitative barrel 2322 is provided with a square part 2327, the gear 2324 is slidingly fitted with the square part 2327, and the gear 2324 One side is provided with a lever 2328 fixedly connected to the gear 2324, and correspondingly, a pull rod a142 and a pull rod b143 are respectively arranged on the front and rear sides of the die a14 and the die b15, and the die a14 or the die b15 When moving to the limit block 18, the pull rod b143 pushes the gear 2324 to the position corresponding to the rack 2325 through the lever 2328, and whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com