Patents

Literature

66results about How to "Realize the whole process automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data processing method, device and system

ActiveCN104462121AImprove processing efficiencyRealize the whole process automationMultiprogramming arrangementsSpecial data processing applicationsData stream processingData element

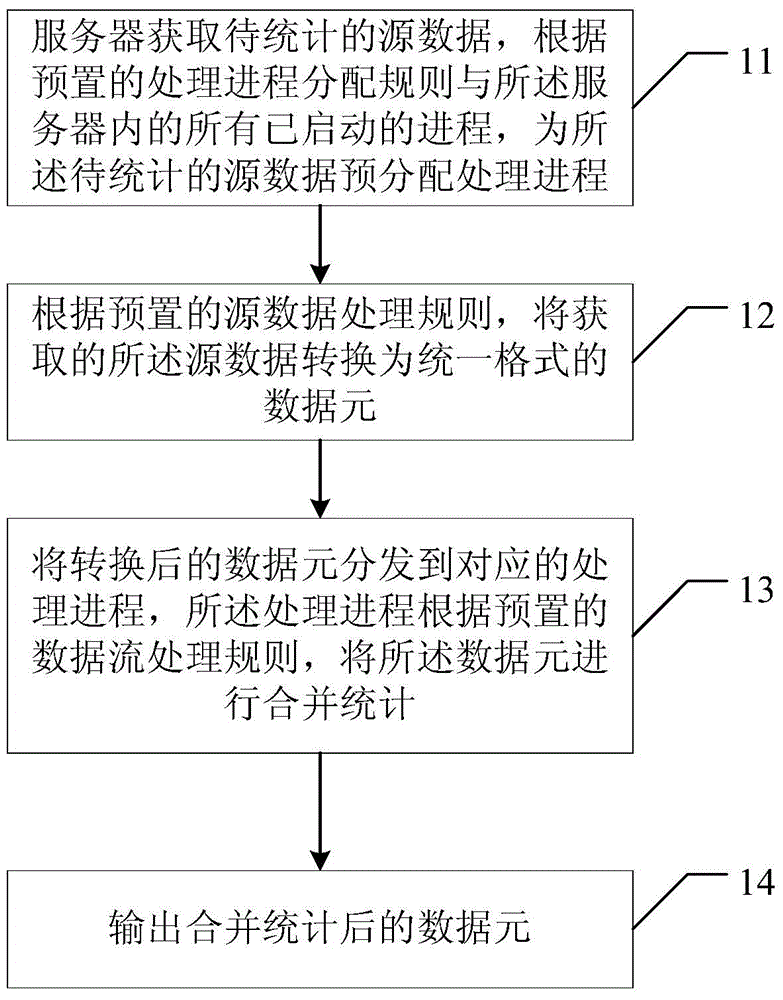

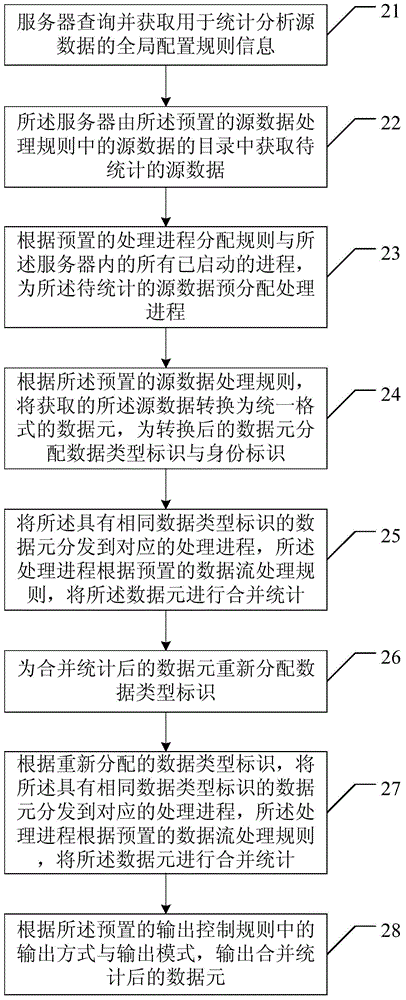

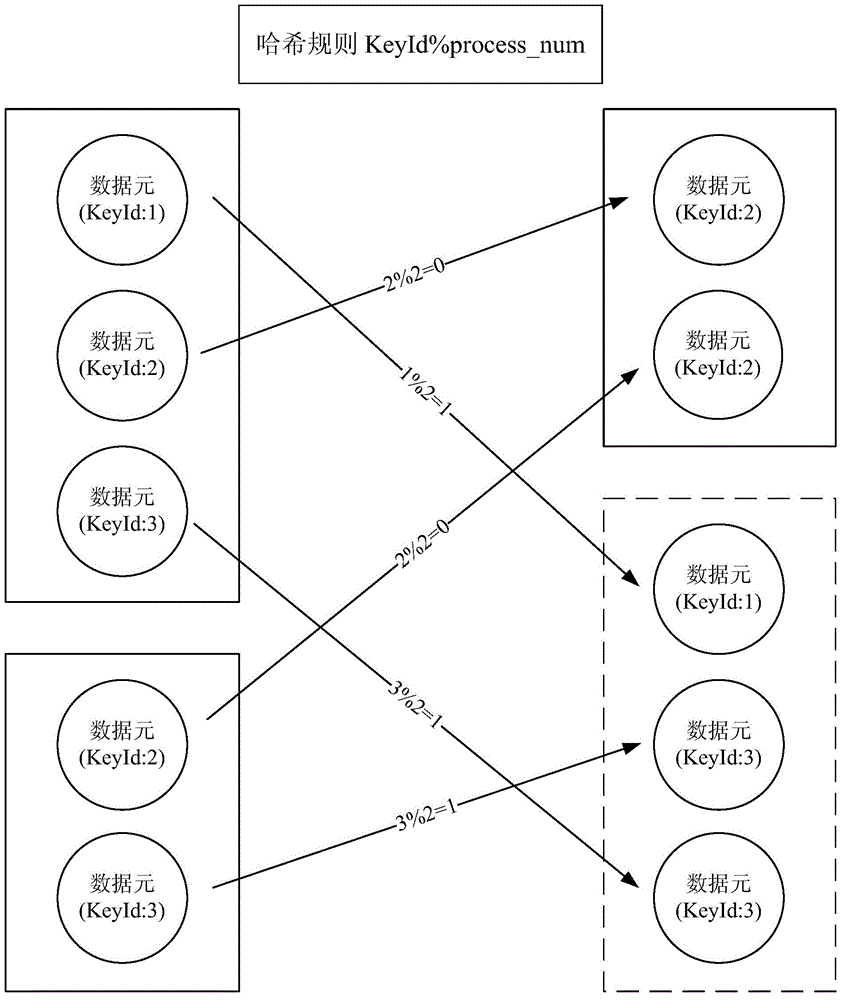

The invention provides a data processing method. The method includes the steps that a server acquires source data to be subjected to statistics, and a processing course is pre-allocated for the source data to be subjected to statistics according to a preset processing course allocation rule and all courses having been started in the server; the obtained source data are converted into data elements in a uniform format according to a preset source data processing rule; the converted data elements are distributed to the corresponding processing courses, and the data elements are combined and subjected to statistics by the processing courses according to a preset dataflow processing rule; the combined data elements having been subjected to statistics are output. The invention further provides a data processing device and system. Through the data processing method, device and system, the data processing efficiency can be greatly improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

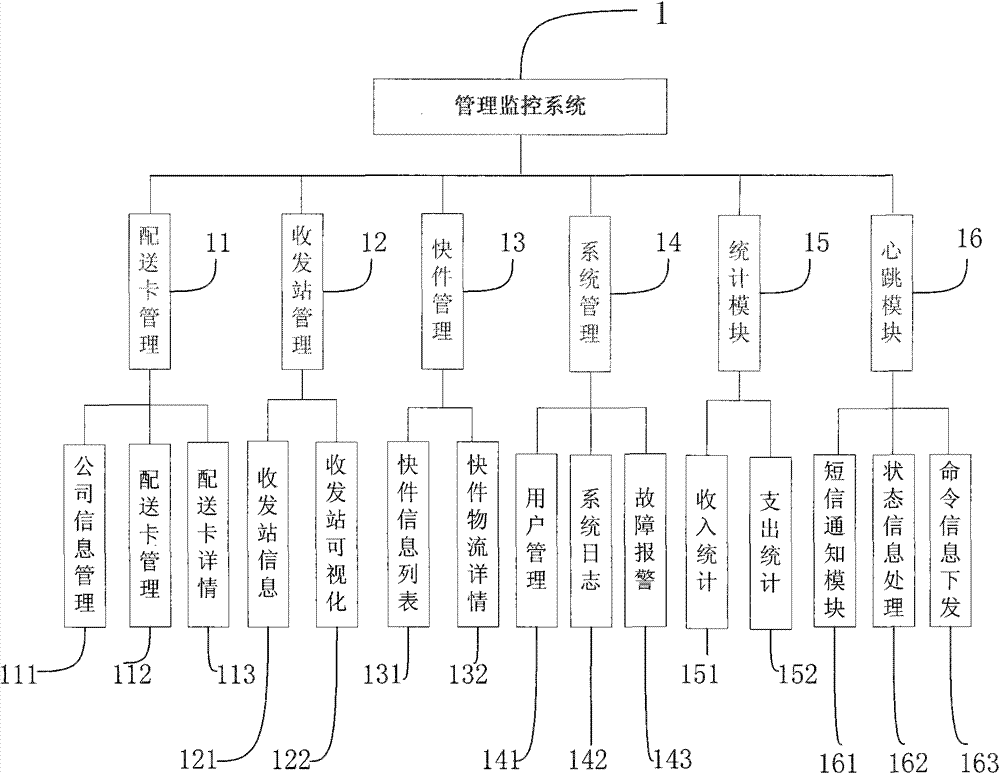

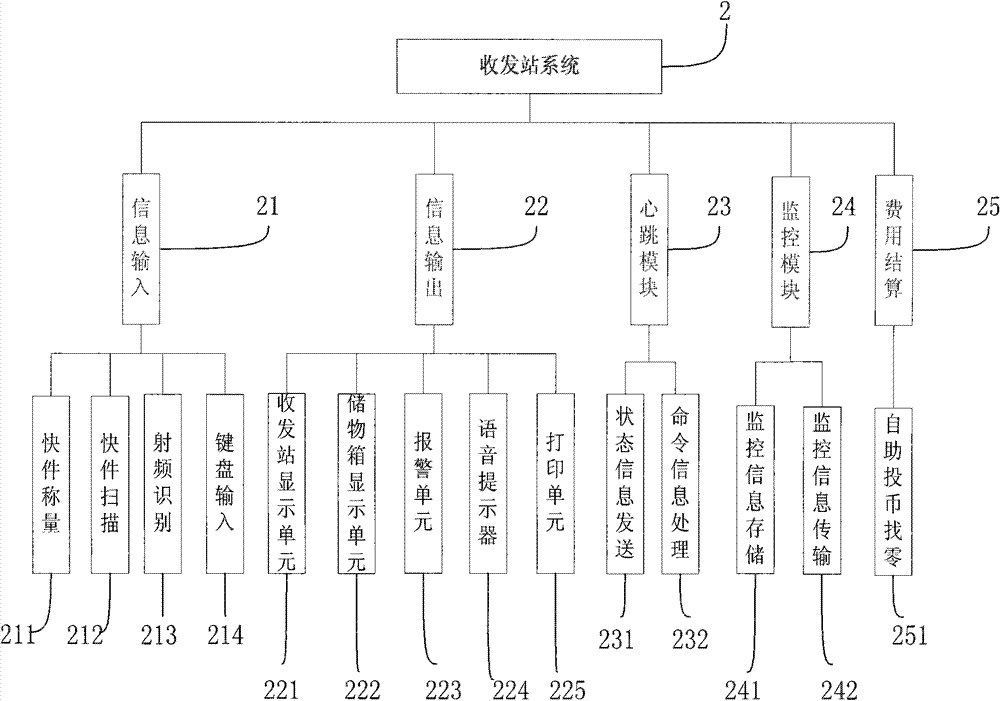

Automatic express pick-up and delivery system, and business processes and system integration method thereof

InactiveCN103679414ARealize the whole process automationAchieve a win-win situationLogisticsSocial benefitsSystem integration

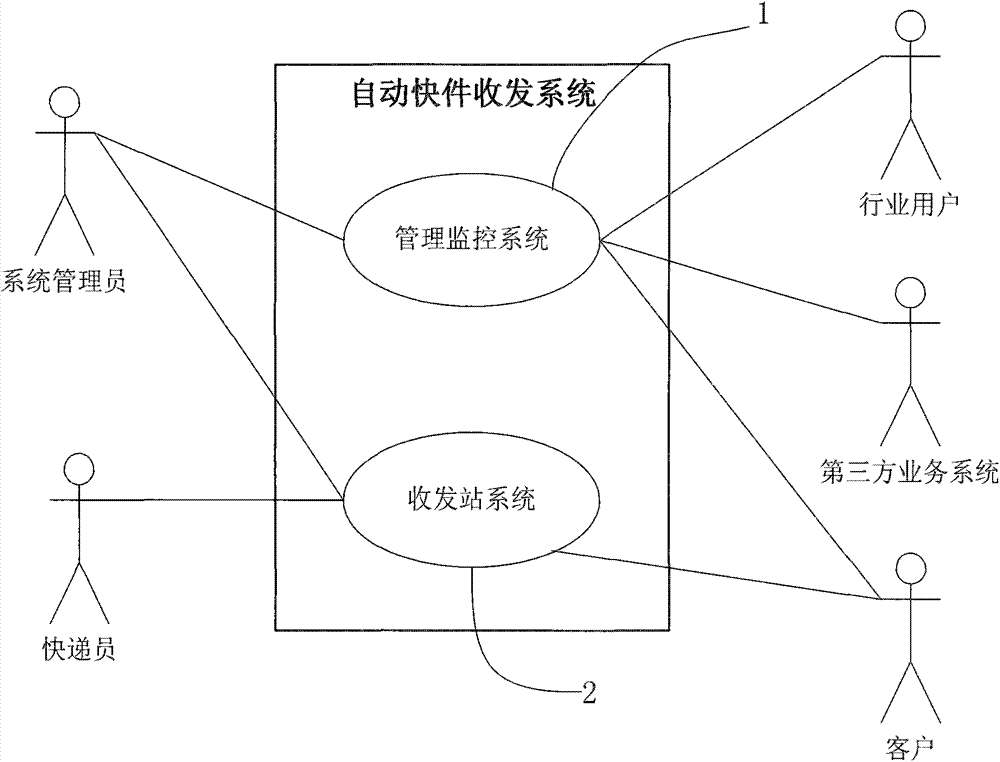

The invention discloses an automatic express pick-up and delivery system, and business processes and a system integration method thereof, belonging to the technical field of computer software and system integration. The automatic express pick-up and delivery system comprises a management monitoring system and a pick-up and delivery station system; and the business processes include an expressman express delivery process, an expressman express pick-up process, a client express sending process, and a client express receiving process. According to the invention, the working efficiency of the whole express delivery and logistics industry is improved, the operation cost is effectively reduced, good economical and social benefits are provided for express delivery companies, a win-win effect is achieved between the express delivery companies and the clients, and development of the whole express delivery and logistics industry is prompted.

Owner:黄长杰 +1

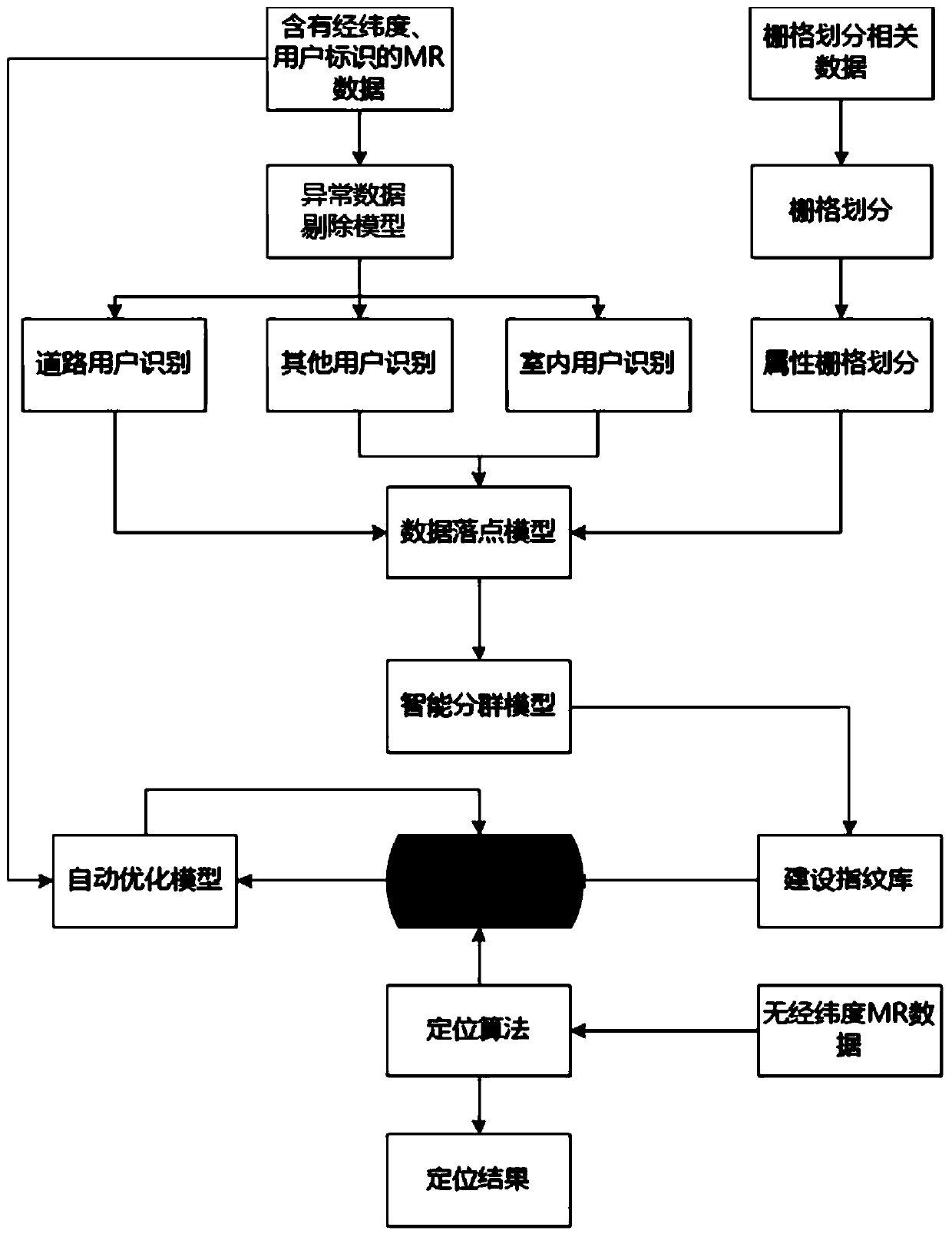

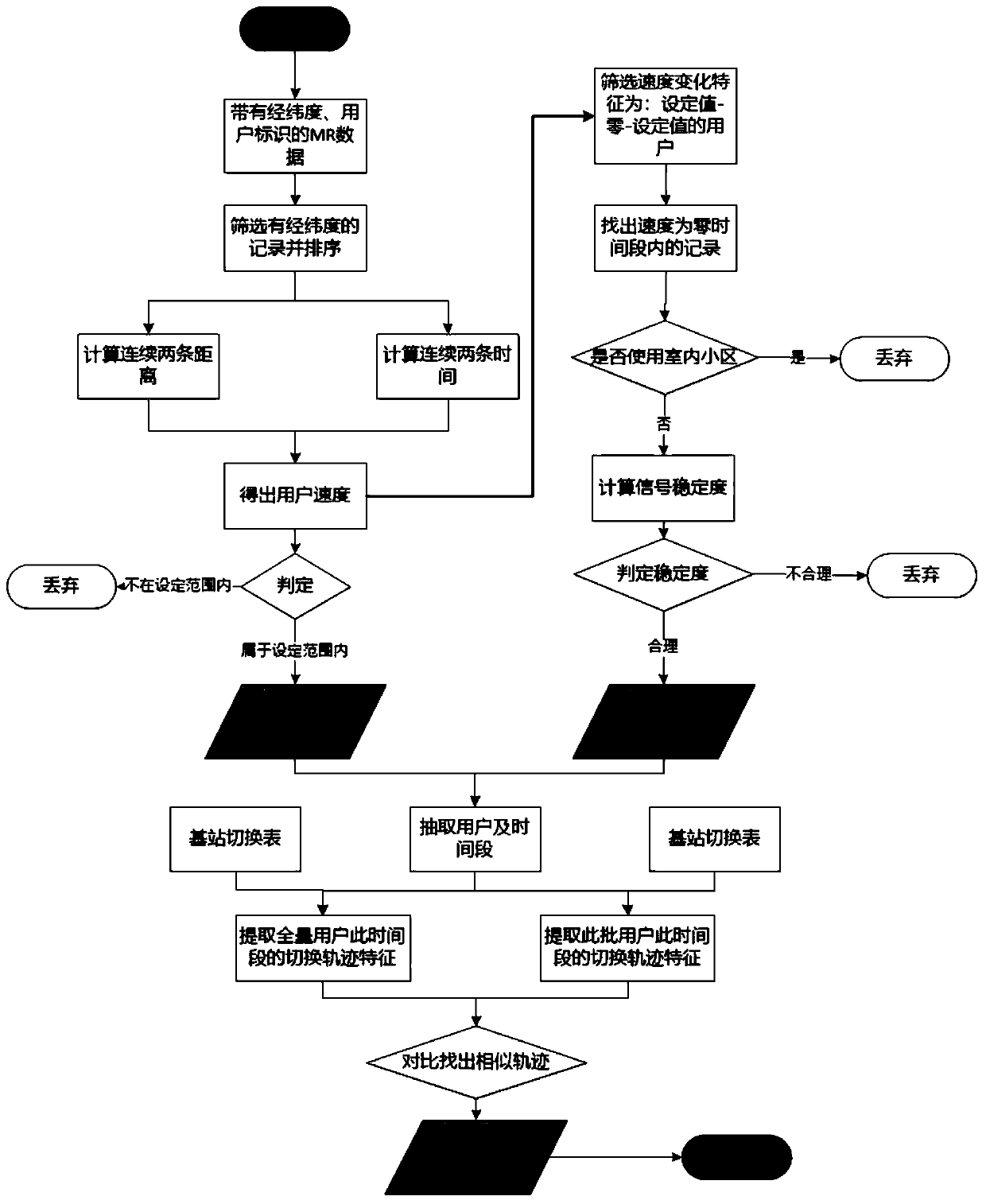

Smart city management platform for realizing accurate positioning of a user

ActiveCN109769201ASolve the problem of data placement difficultiesAccurate removalCharacter and pattern recognitionLocation information based serviceOriginal dataRoad user

The invention discloses a smart city management platform for realizing accurate positioning of a user. The smart city management platform includes eliminating abnormal data; identifying road users asfast-speed users, users waiting for traffic lights, and users with similar tracks on roads; identifying an indoor user; determining a range of grids required to be divided, and dividing the grids according to a set size; dividing sub-grids of all indoor attributes and sub-grids of road attributes; matching the data points with the attributes with the grids, and enabling the data points to fall into the corresponding grids; classifying users with user groups and similar signal characteristics into one class according to the signal characteristics; extracting features in each area and corresponding feature values; the fingerprint database is automatically updated in real time; and carrying out matching calculation on the characteristics and the corresponding characteristic values of the MR original data points and the characteristics and the characteristic values of the uniquely identified area in the fingerprint database, and returning corresponding longitude and latitude information inthe fingerprint database. Accurate positioning can be realized, and a basis is provided for subsequent decision making.

Owner:USTC SINOVATE SOFTWARE

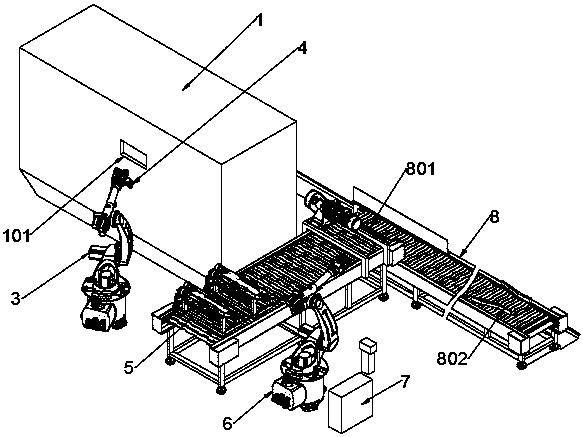

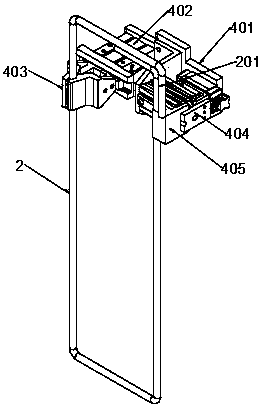

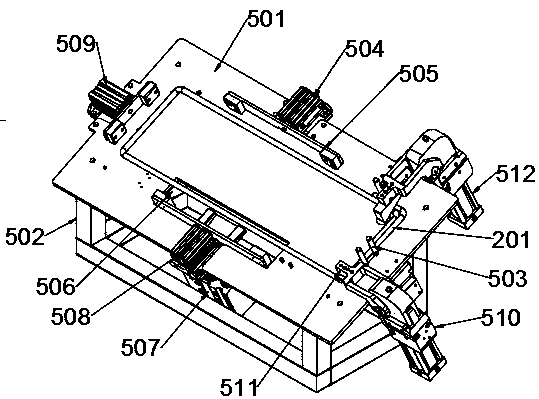

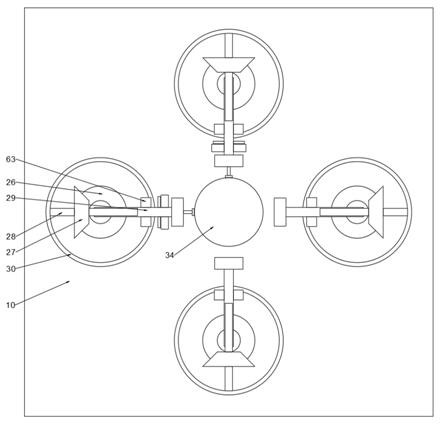

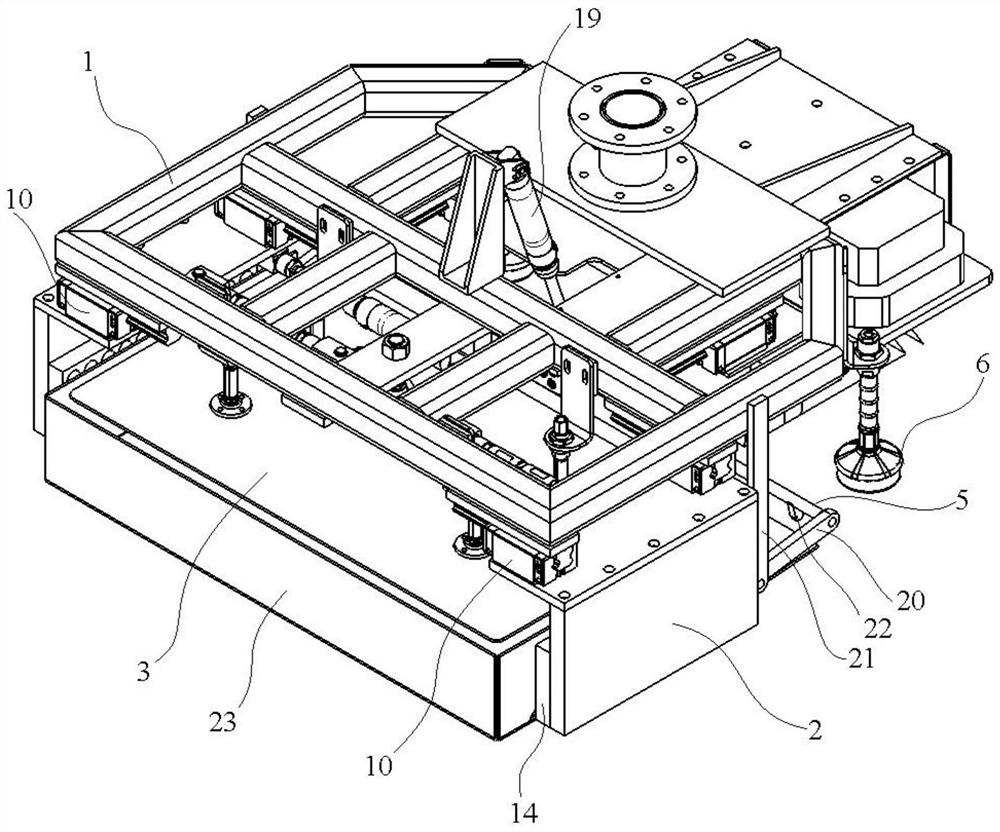

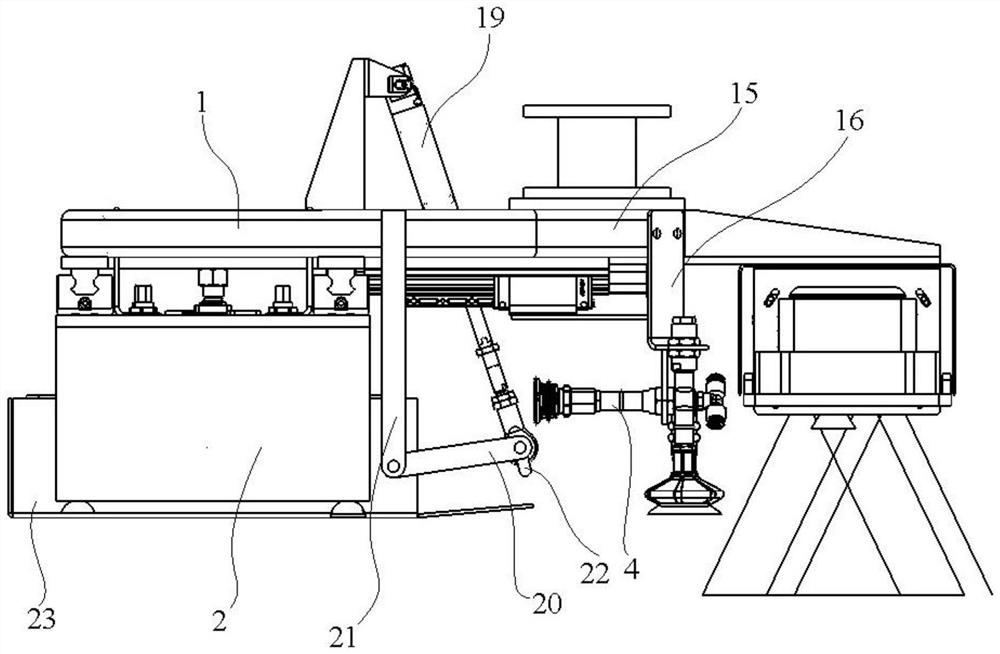

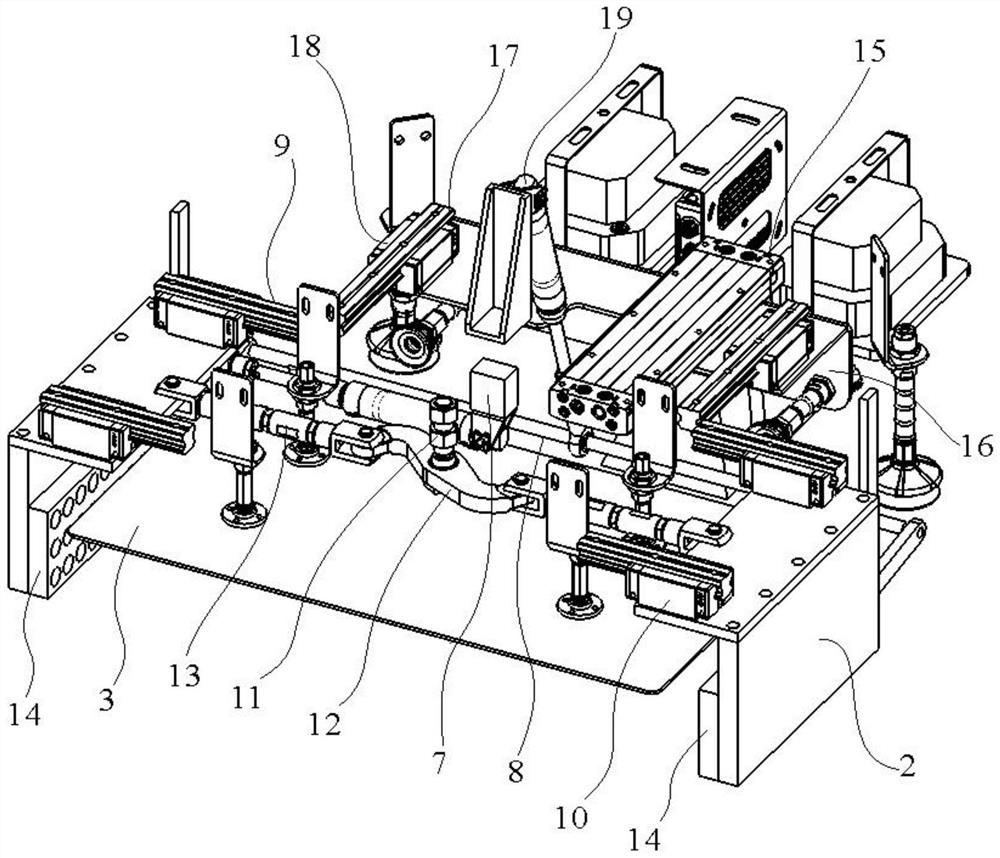

Automatic production line of G-series high-speed train sleeper stirrup

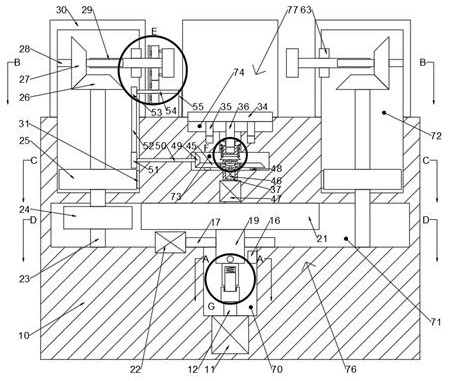

PendingCN109014923AFast and accurate welding processingRealize the whole process automationGripping headsWelding/cutting auxillary devicesProduction lineLap joint

The invention discloses an automatic production line of a G-series high-speed train sleeper stirrup. The automatic production line comprises a bending machine, a taking robot, a grabbing tool, a welding workbench, a welding robot and a welding machine and a plate chain conveying line. The bending machine is used for bending a rebar to be rectangular. The grabbing tool is mounted at the tail end ofthe taking robot and used for grabbing the stirrup machined by the bending machine and placing the stirrup on the welding workbench. The welding robot is connected with the welding machine, the welding robot is arranged on one side of the welding robot, and welding of a stirrup lap joint opening is completed. The plate chain conveying line is arranged below the welding workbench, and the welded stirrup automatically falls onto the plate chain conveying line and is transported to an output position. The automatic production line is used for replacing manpower to complete welding of the sleepertruss stirrup, the robot automatically grabs the bent stirrup output by the bending machine, the stirrup is placed on the welding workbench, and automatic locating and compressing are carried out; and welding is fast and accurately completed by the welding robot, automation of the whole process is achieved, the work efficiency is high, and the automatic production line is in seamless connection with a automatic sleeper production line.

Owner:北京好运达智创科技有限公司

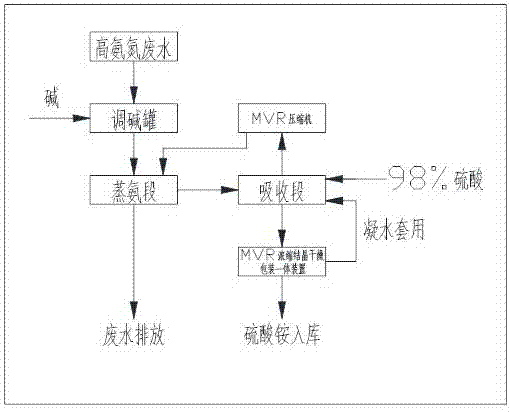

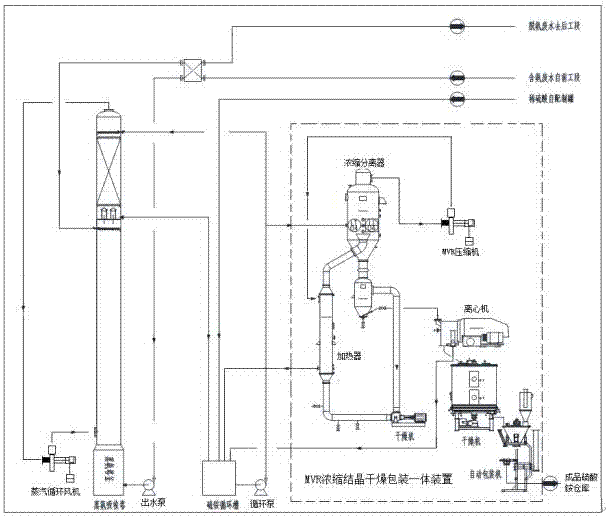

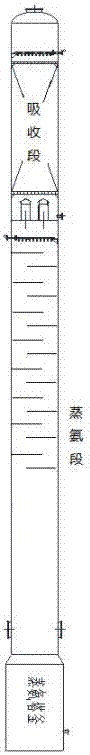

Technique for treating high-ammonia-nitrogen wastewater by recycling ammonium sulfate through MVR (Mechanical Vapor Recompression) ammonia distillation

InactiveCN107352726ALow resistance dropImprove separation efficiencyWater treatment parameter controlSpecific water treatment objectivesAmmonium sulfateChemistry

The invention discloses a technique for treating high-ammonia-nitrogen wastewater by recycling ammonium sulfate through MVR ammonia distillation. A steam closed cycle ammonia distillation technique is realized by virtue of alkali adjustment of high-ammonia-nitrogen wastewater and a mechanical vapor recompression (MVR) technique, ammonia nitrogen in treated wastewater is less than 10mg / L, and industrial product ammonium sulfate is recycled by carrying out MVR concentration and crystallization on a produced 25% ammonium sulfate solution.

Owner:陈雪薇

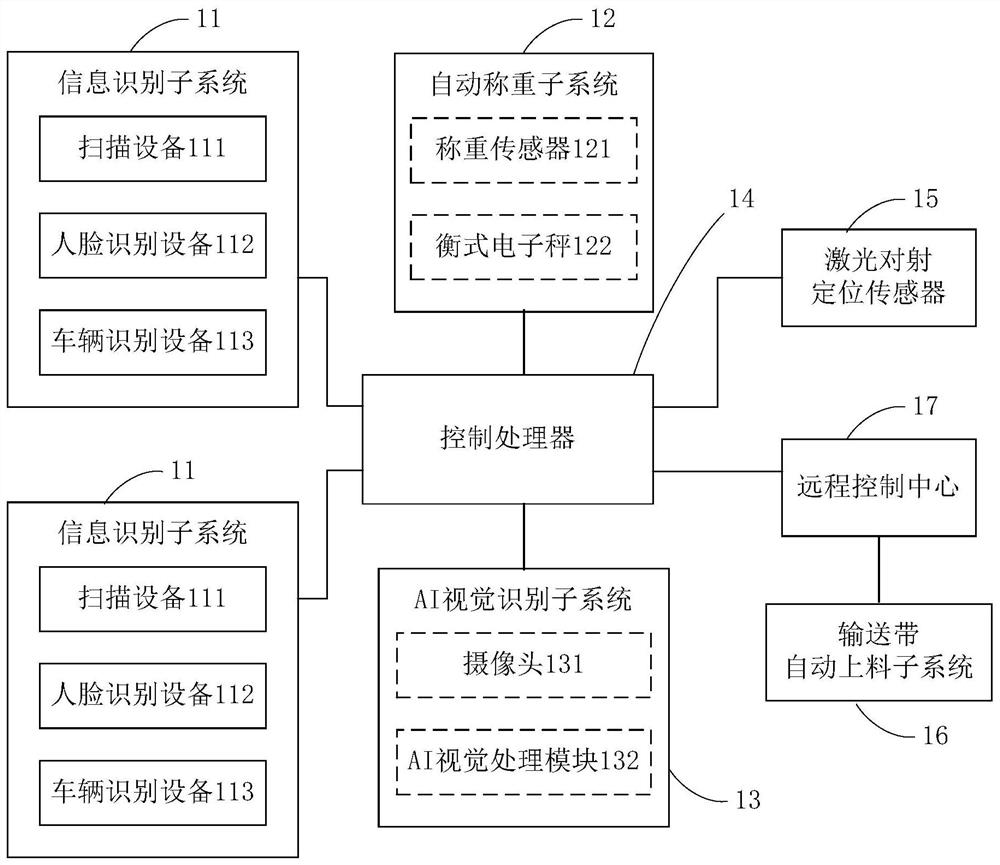

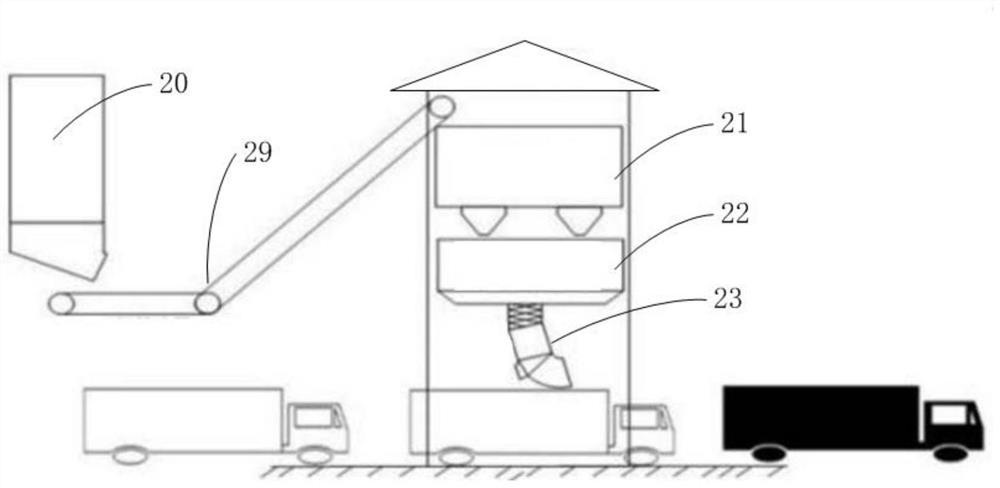

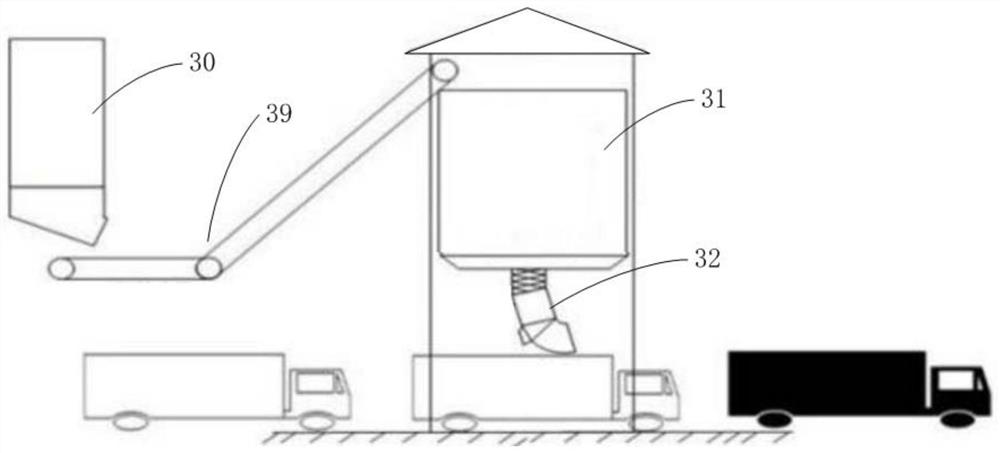

Intelligent loading control system and method

InactiveCN112299049ARealize the whole process automationGo onlineLoading/unloadingControl systemControl engineering

The invention discloses an intelligent loading control system and method. The system comprises a plurality of information identification subsystems, an automatic weighing subsystem, an AI visual identification subsystem and a control processor. Accurate positioning of a parking position and an unloading position of a transport vehicle and accurate measurement of a unloading weight can be achieved,unmanned, intelligent and scenarized loading is achieved, an unloading speed can be increased, the continuity of automatic unloading is ensured, the unloading time is controllable, and the unloadingprecision and a loading full load rate are improved.

Owner:上海平奥供应链管理有限公司

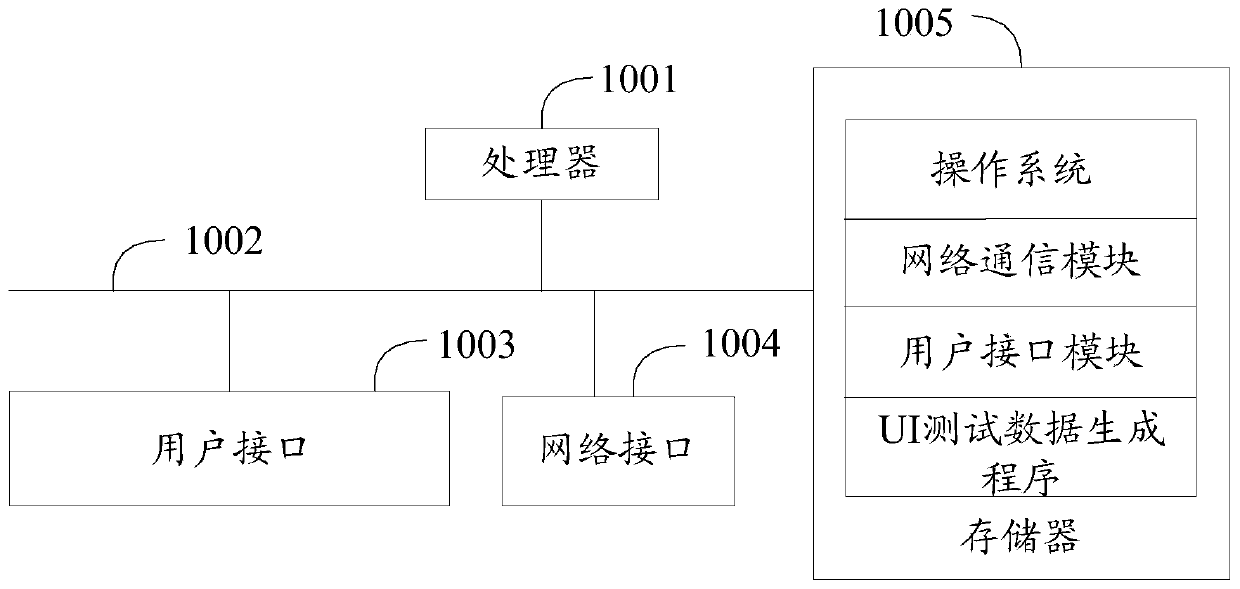

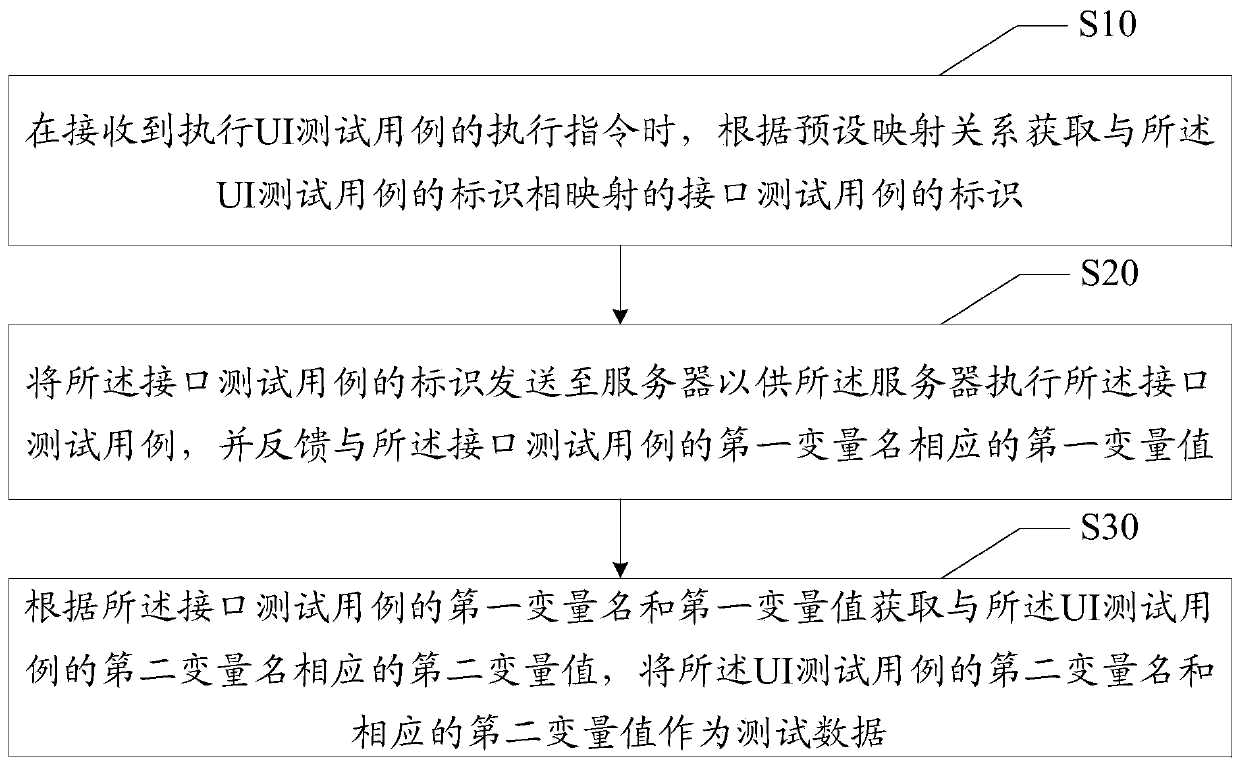

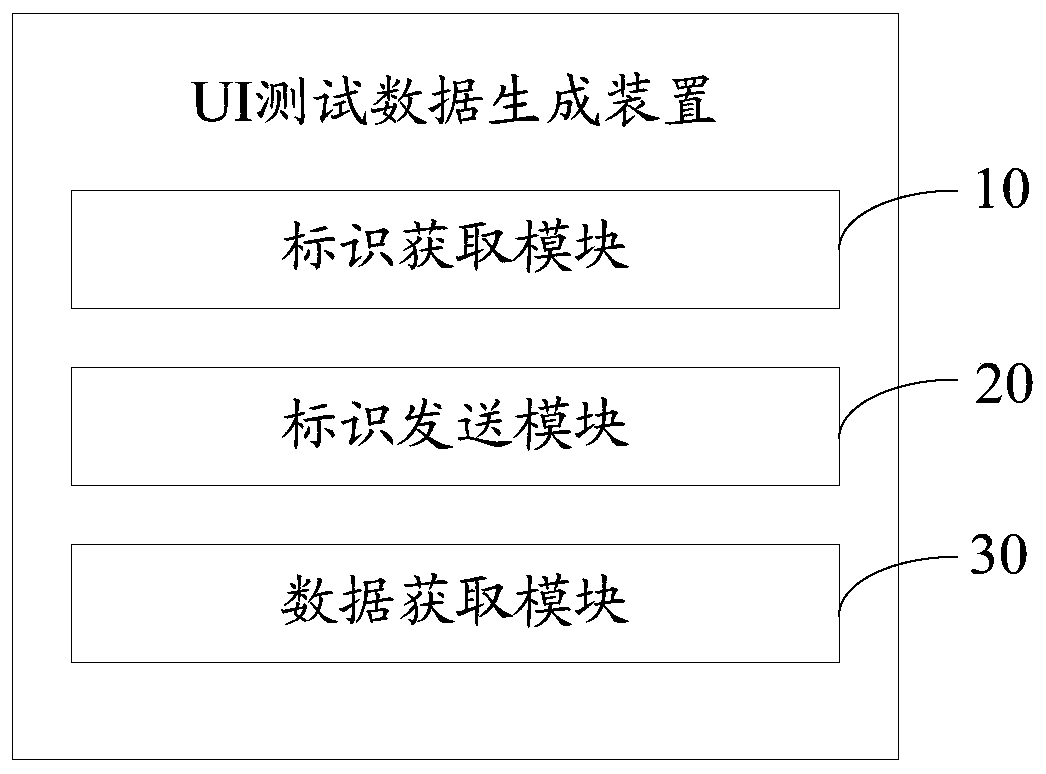

UI test data generation method, apparatus and device, and readable storage medium

PendingCN110134612AImprove efficiencyImprove accuracySoftware testing/debuggingComputer hardwareTest efficiency

The invention discloses a UI test data generation method, apparatus and device, and a readable storage medium and the method comprises the following steps: obtaining an identifier of an interface testcase mapped with the identifier of the UI test case according to a preset mapping relation when an execution instruction for executing the UI test case is received; sending the identifier of the interface test case to a server to enable the server to execute the interface test case, and feeding back a first variable value corresponding to a first variable name of the interface test case; and obtaining a second variable value corresponding to a second variable name of the UI test case according to the first variable name and the first variable value of the interface test case, and taking the second variable name of the UI test case and the corresponding second variable value as test data. Full-process automation of UI test case execution is realized, so that the UI test efficiency, accuracy and maintainability are improved.

Owner:WEBANK (CHINA)

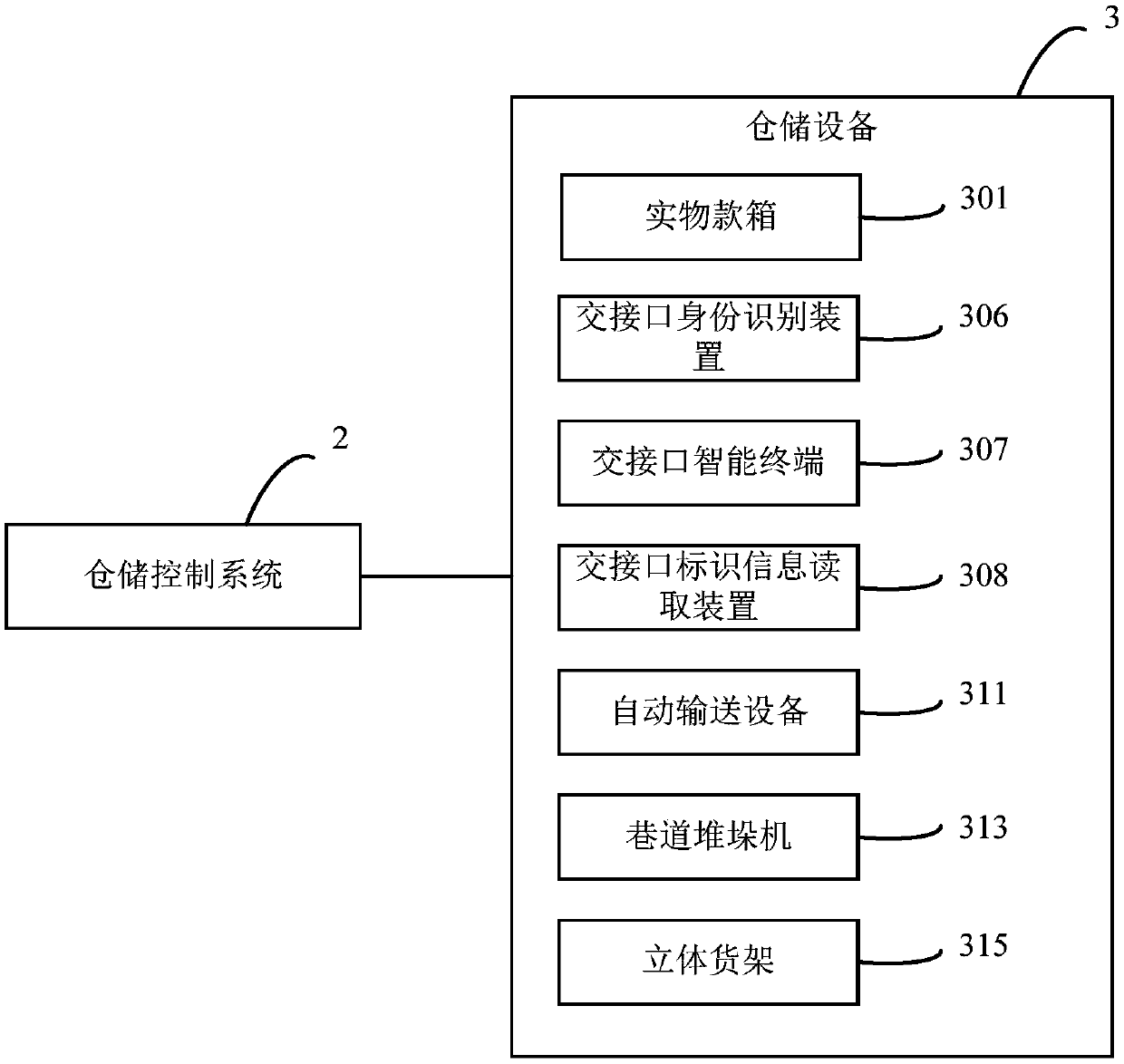

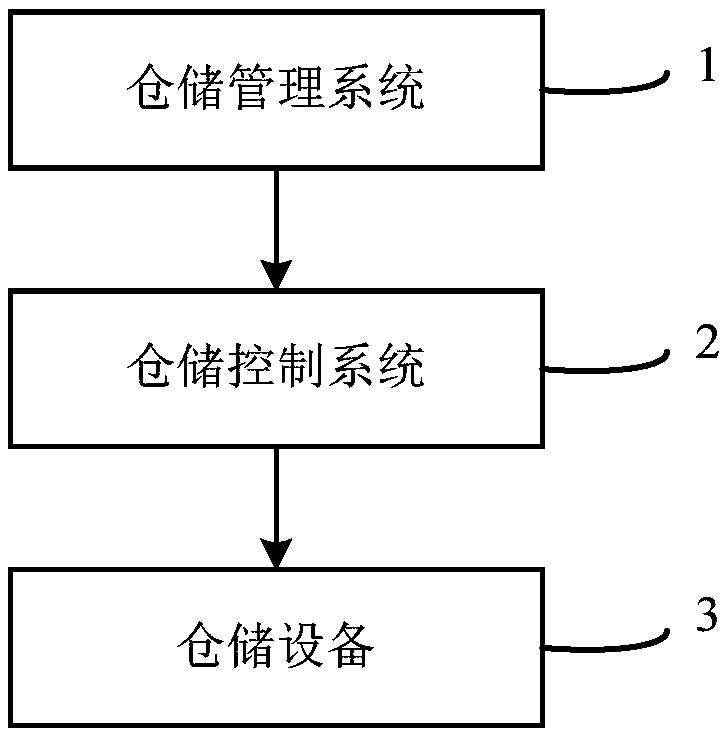

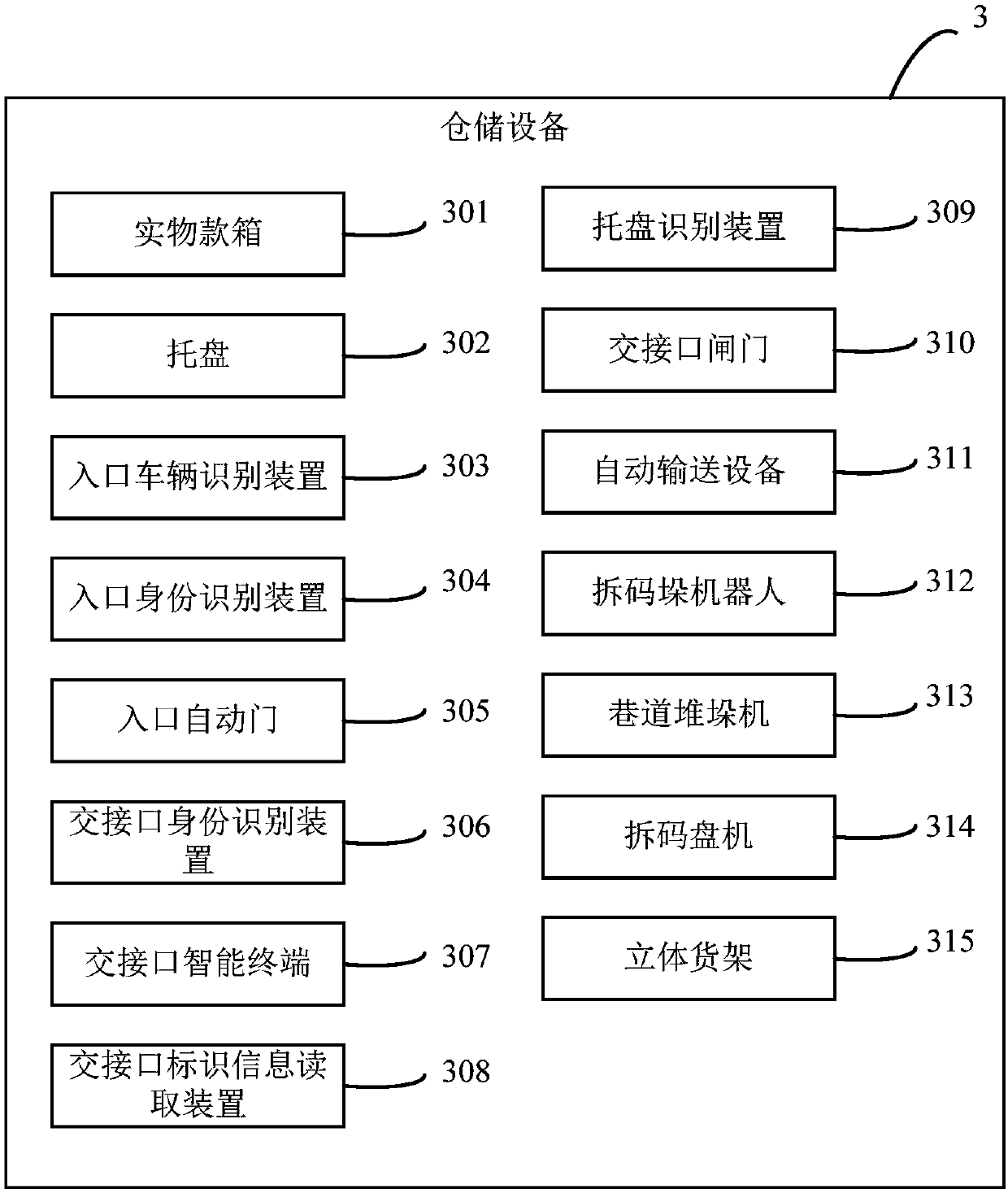

Cash operation center intelligent warehousing system and method

ActiveCN109516049AImprove physical management efficiencyRealize the whole process automationLogisticsStorage devicesControl systemIdentification device

The invention discloses a cash operation center intelligent warehousing system and method. The cash operation center intelligent warehousing system comprises a warehousing management system, a warehousing control system, an entrance vehicle recognizing device, an entrance identity recognizing device, an entrance automatic door, a handover port identity recognizing device, a handover port intelligent terminal, a handover port identifying information reading device, trays, a tray recognizing device, a handover port gate, automatic conveying equipment, an unstacking-stacking robot, a roadway stacker, a tray stacking-unstacking machine and vertical storage racks. According to the cash operation center intelligent warehousing system and method, the problems that on the material object management aspect, a traditional cash operation center is low in business operation automation degree, mainly relies on manpower participation, and is high in labor intensity and moral hazard probability, lowin business operation efficiency and the like are solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

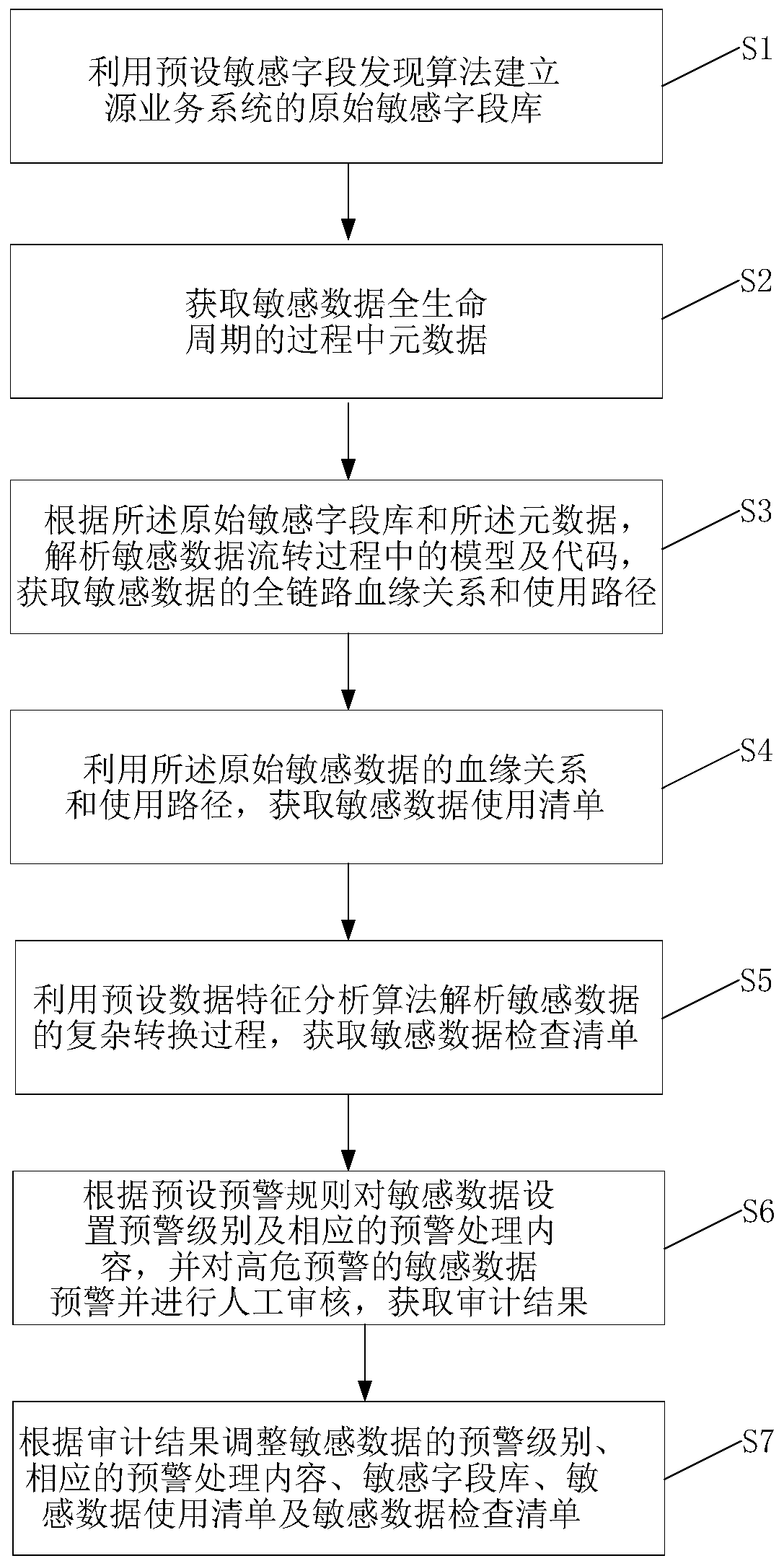

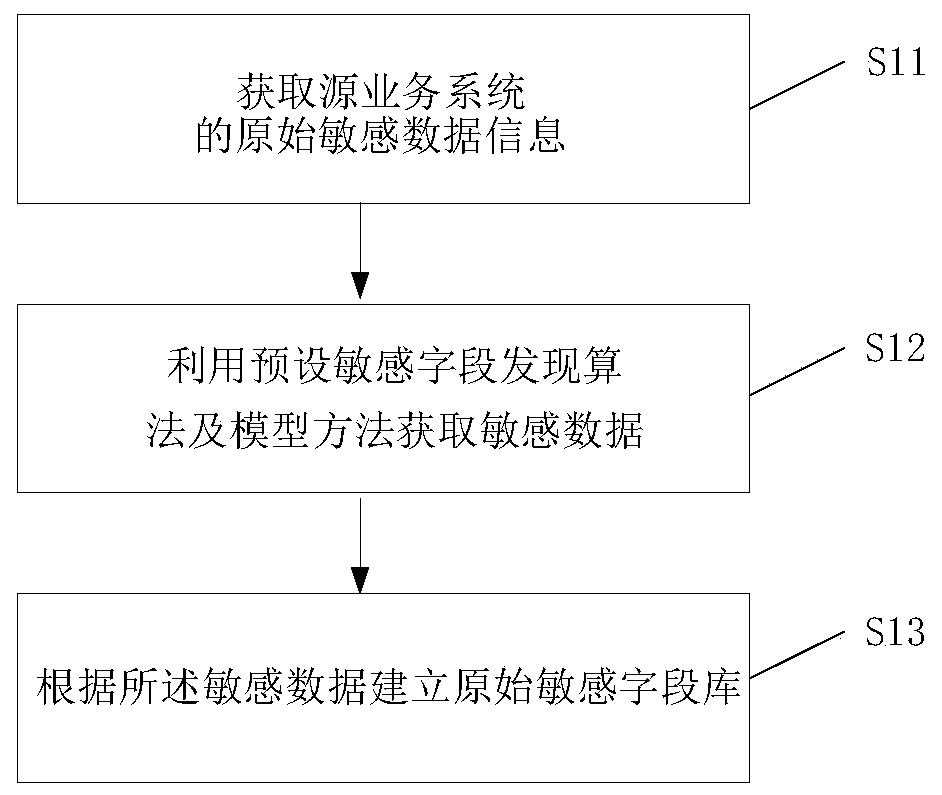

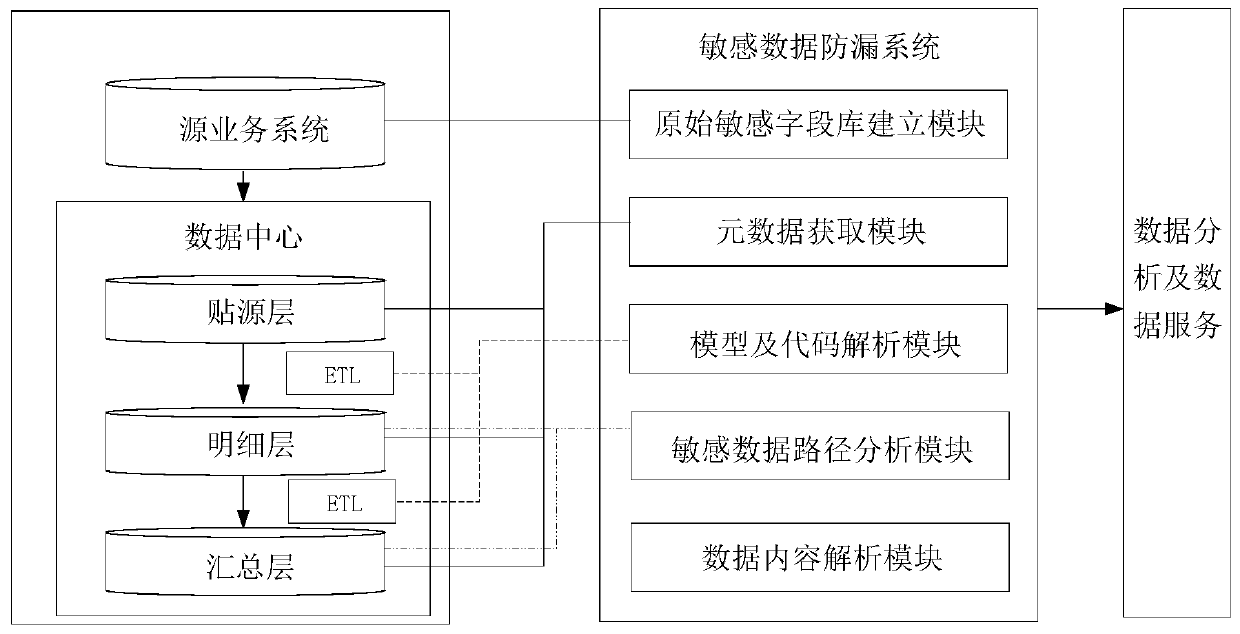

Method and system for preventing sensitive data leakage

ActiveCN110704873AThe transfer process is clearThe effect is clearData processing applicationsDigital data protectionMetadata managementData management

The invention discloses a method and a system for preventing sensitive data leakage. The method comprises the following steps: establishing an original sensitive field library by utilizing a preset sensitive field discovery algorithm; obtaining metadata in the whole life cycle process of the sensitive data; according to the original sensitive field library and the metadata, analyzing a model and acode in a sensitive data circulation process, and obtaining a blood relationship and a use path of sensitive data in a full link; obtaining a sensitive data use list by utilizing the blood relationship and the use path of the sensitive data; analyzing the sensitive data conversion process by using a preset data feature analysis algorithm to obtain a sensitive data check list; performing early warning and auditing sensitive data. According to the method, the original sensitive field library, metadata management, model and code analysis, sensitive data blood relationship, sensitive data contentfeature analysis and early warning audit are combined, so that the transfer and use process of the sensitive data is more intuitive and clearer, and the risk of sensitive data leakage in each link inthe full life cycle of the data is effectively reduced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

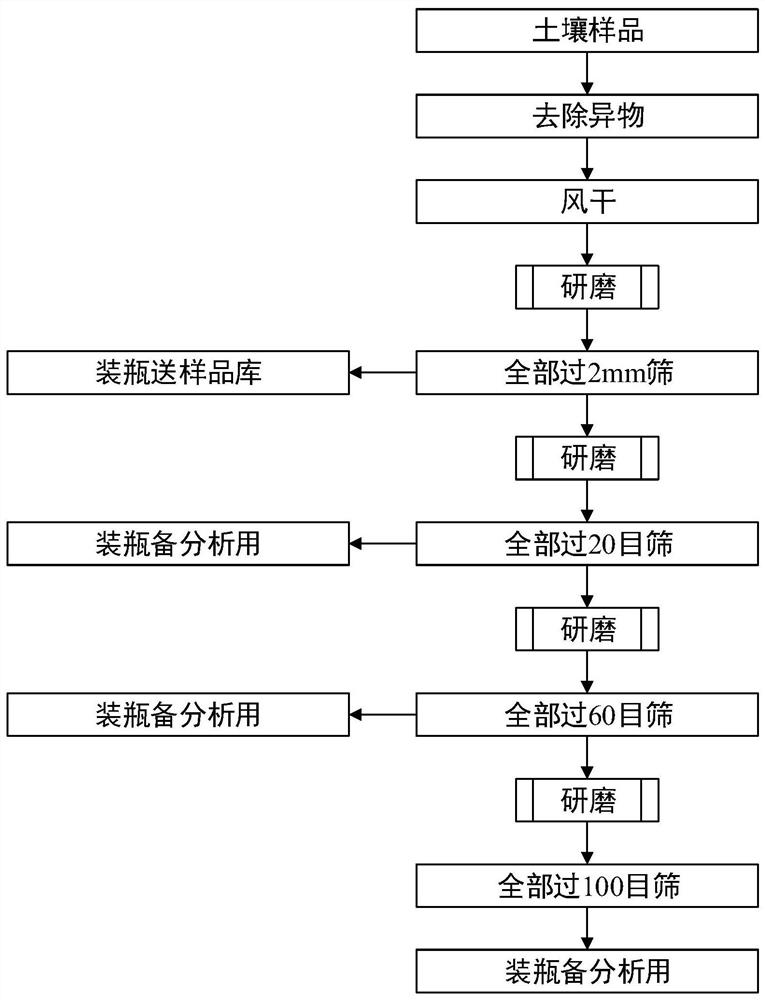

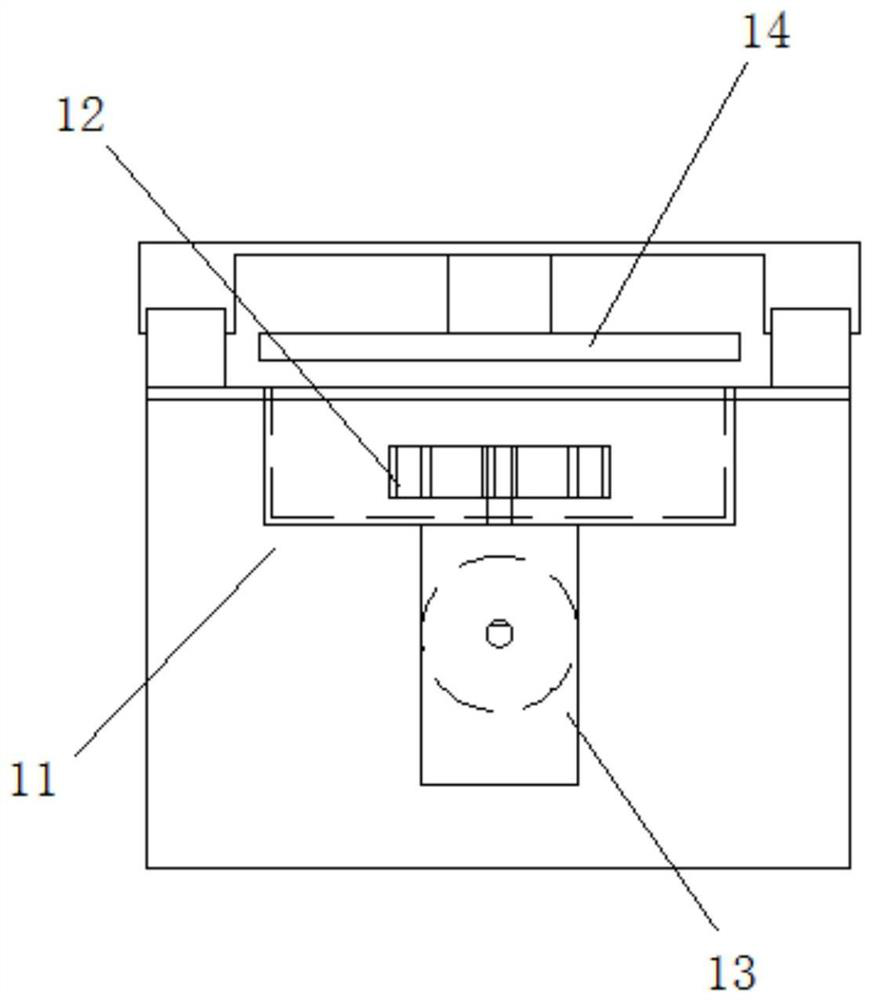

Full-automatic soil sample preparation system

PendingCN111855336AAvoid cross contaminationRealize the whole process automationPreparing sample for investigationSoil scienceEngineering

The invention relates to the technical field of soil sample preparation, in particular to a soil sample preparation system. The full-automatic soil sample preparation system comprises a crushing and grinding mechanism, a screening mechanism, a sample loading mechanism, a manipulator and a cleaning assembly, wherein the crushing and grinding mechanism is used for grinding a soil sample; the screening mechanism is used for screening the ground soil sample; the sample loading mechanism is used for carrying out quartering sample loading on the screened soil sample; the manipulator is used for transferring the soil sample; and the cleaning assembly is used for cleaning a container accommodating the soil sample. The full-automatic soil sample preparation system realizes automation of the soil sample preparation process, effectively avoids the cross contamination of samples, improves the sample preparation environment, reduces the labor intensity, and improves the sample preparation efficiency; and the process operation of the full-automatic soil sample preparation system has compliance consistency, and full-process automation of soil sample preparation is realized.

Owner:北京兰友科技有限公司

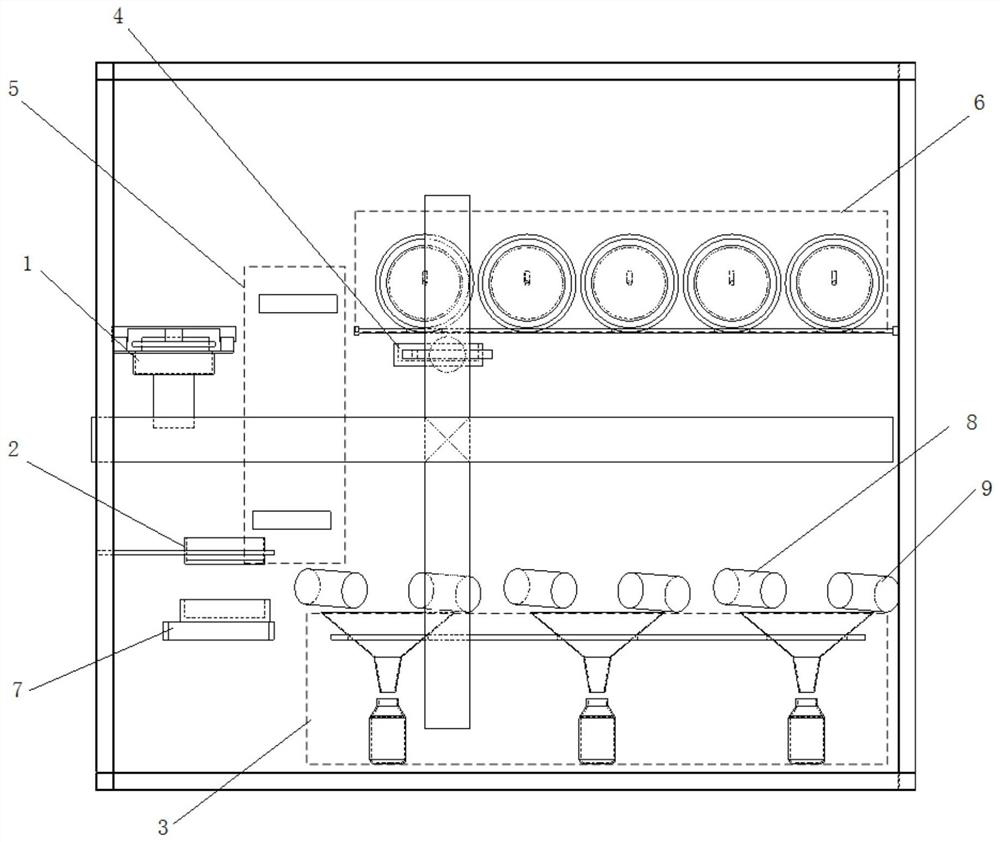

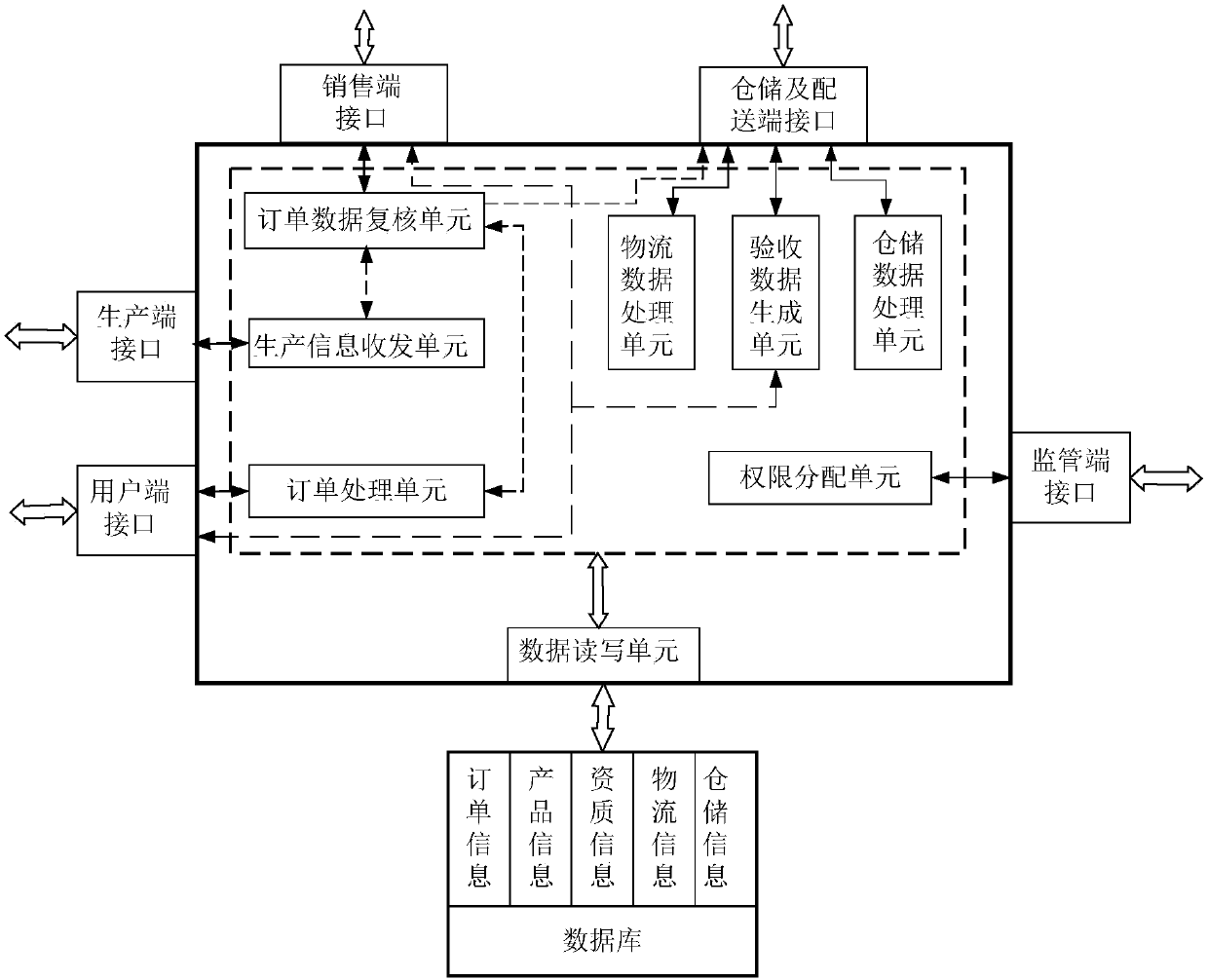

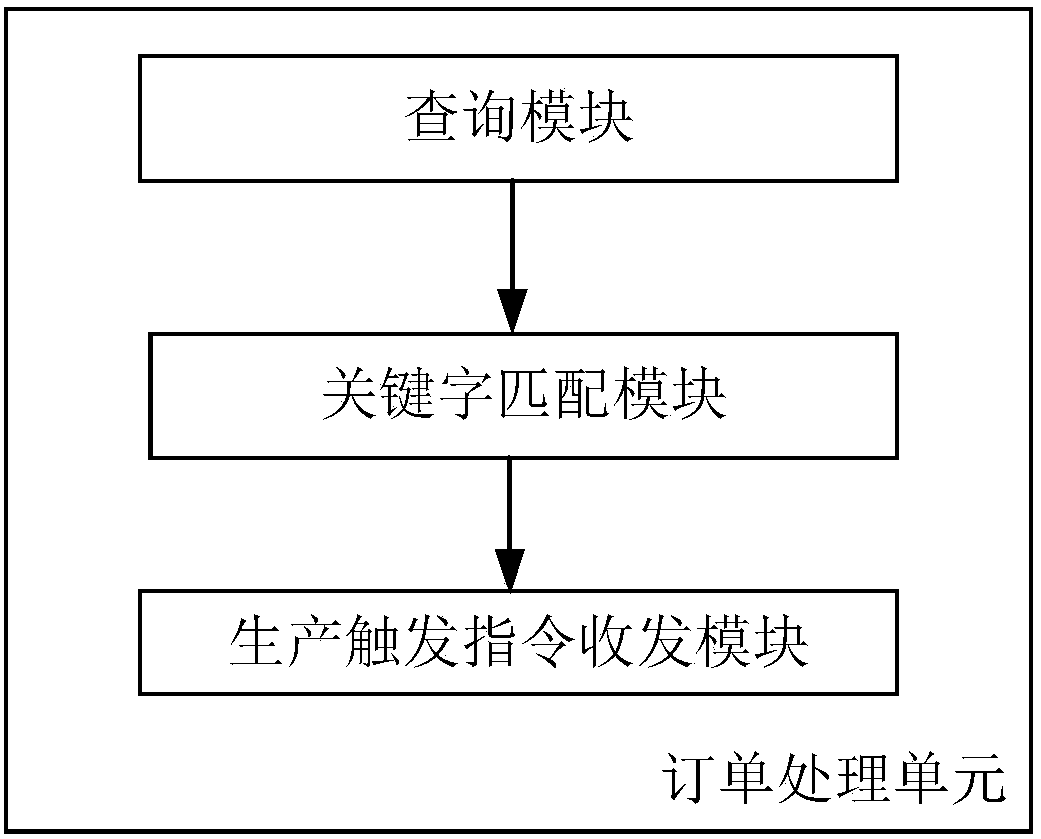

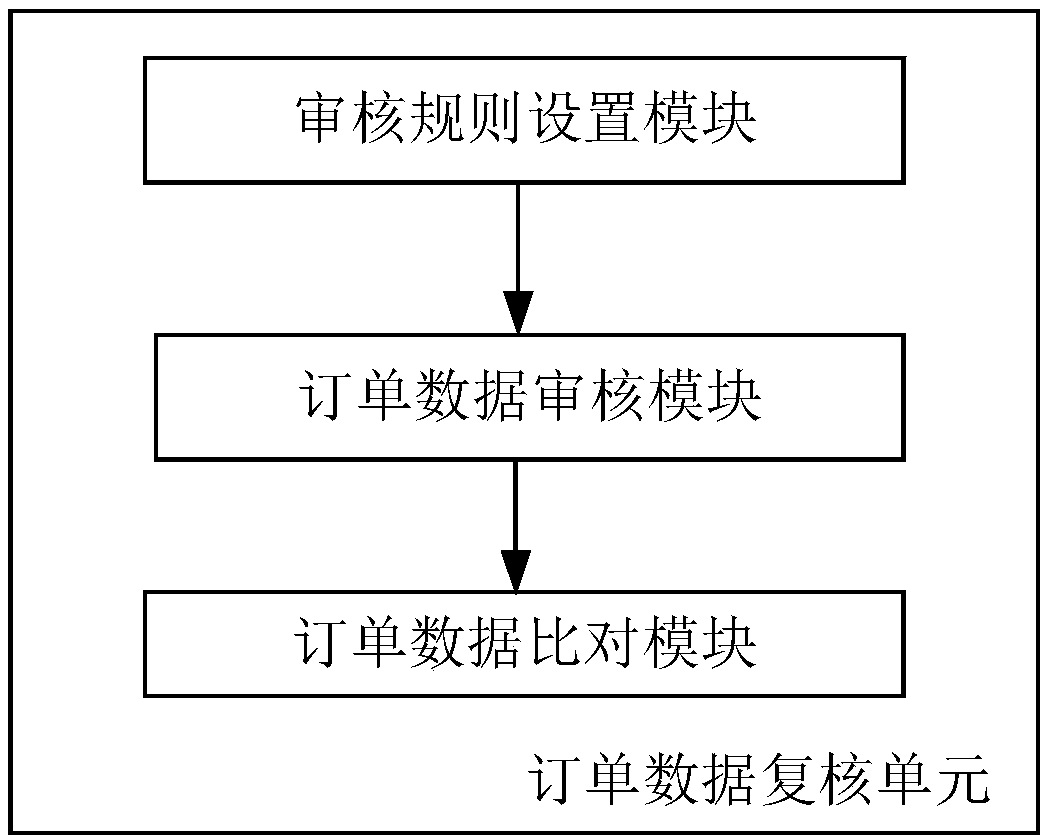

Vitro-diagnostic-reagent supply chain information integrated-management platform realizing full-chain monitoring

ActiveCN107862494ALow costReduce manufacturing costHealthcare managementLogisticsLogistics managementInformation processor

The invention discloses a vitro-diagnostic-reagent supply chain information integrated-management platform realizing full-chain monitoring. The platform includes an information processor and a memoryused for storing a database. The information processor has a user-oriented interface, a production-oriented interface, a sales-oriented interface, a warehousing and distribution-oriented interface anda supervision-oriented interface, and an order processing unit, an order data rechecking unit, a warehousing data processing unit, a logistics data processing unit, a checking and acceptance data generation unit, an authority allocation unit and a data reading and writing unit are internally integrated. The order processing unit is connected with the order data rechecking unit. The order data rechecking unit is connected with the warehousing and distribution end interface. The checking and acceptance data generation unit is connected with the sales end interface, the user end interface and the warehousing and distribution end interface. All the order processing unit, the order data rechecking unit, the logistics data processing unit, the checking and acceptance data generation unit, the warehousing data processing unit and the authority allocation unit read data from the database in the memory and write data to the database through the data reading and writing unit. The platform realizes full-chain monitoring and full-chain information integrated-sharing.

Owner:李泽昊

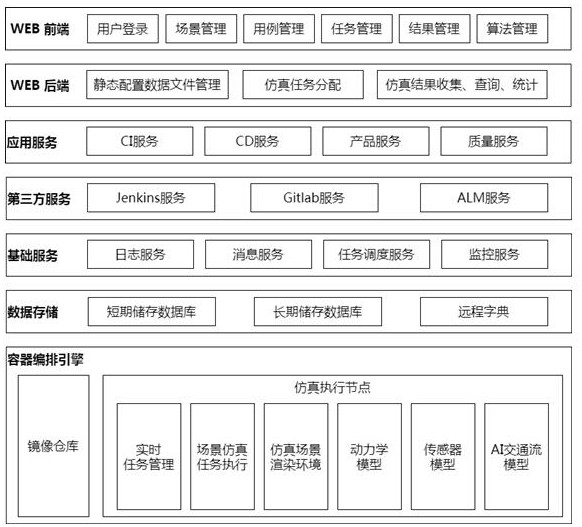

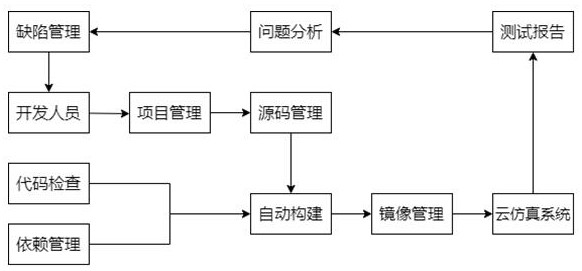

Intelligent networking vehicle intelligent driving function cloud simulation test system and method based on DevOps

PendingCN114647585ARealize the whole process automationSolve the problem of duplication of capacity buildingVersion controlSoftware testing/debuggingIntelligent NetworkThird party

The invention discloses an intelligent networked vehicle intelligent driving function cloud simulation test system and method based on DevOps. The system comprises a WEB front end subsystem, a WEB rear end subsystem, an application service subsystem, a third-party service subsystem, a basic service subsystem, a data storage subsystem and a container arrangement engine subsystem. The WEB front end is used for providing an interactive interface for a user; the WEB back end responds to the front-end user operation; the third party service comprises a Jenkins service, a Gitlab service and an ALM service; and the container arrangement engine comprises a mirror image warehouse and a simulation execution node, and the mirror image warehouse is used for storing container mirror images developed based on the application of the container and mirror images prepared for various users in advance in the simulation execution node. According to the test system, a developer submits software to the project management platform, issues and automatically constructs platform integration and releases the platform integration to the mirror image management platform, issues the platform integration to the mirror image management platform, tests and issues a test report, a tester analyzes problems and submits a problem list to the defect management platform in a closed loop mode to the developer, and automation of the whole process is achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

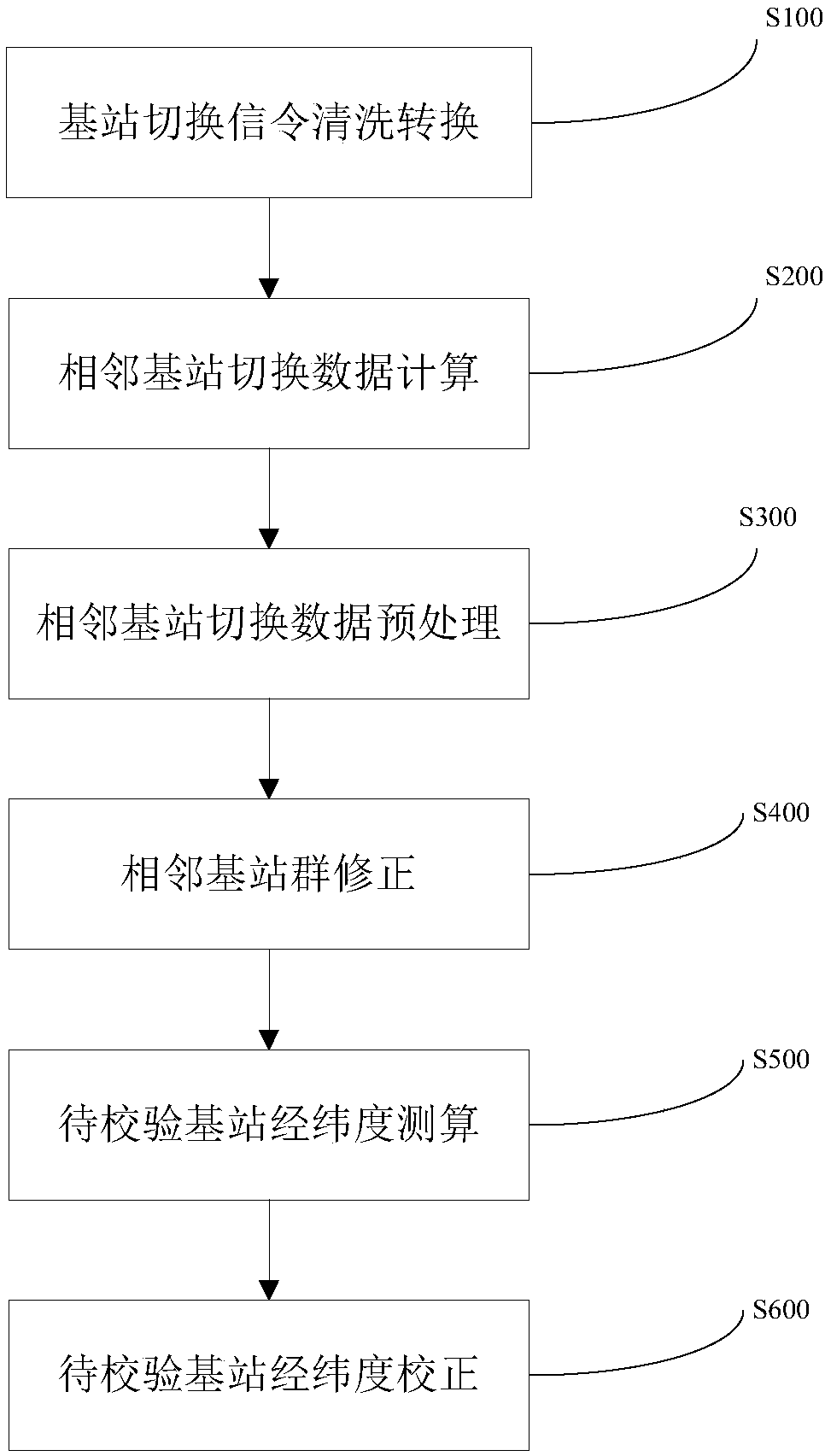

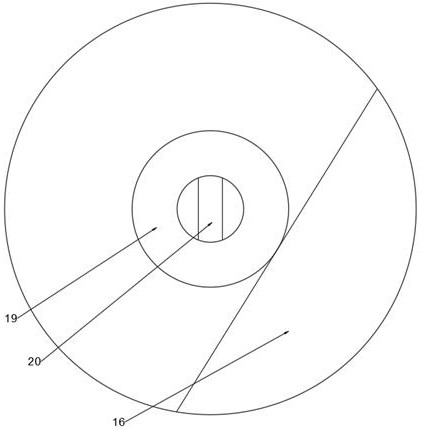

Cell base station longitude and latitude data correction method based on KNN (K Nearest Neighbor)

ActiveCN109548139AConvenient manual correctionEasy to fixWireless communicationLongitudeNear neighbor

The invention discloses a cell base station longitude and latitude data correction method based on a KNN (K Nearest Neighbor), which comprises the steps of: carrying out base station switching signaling cleaning conversion, carrying out cleaning, conversion and serialization on mobile phone signaling data, and constructing a mobile phone user base station switching sequence; calculating neighbor base station switching data; preprocessing the neighbor base station switching data; correcting a neighbor base station group; measuring and calculating a longitude and a latitude of a to-be-verified base station; and correcting the longitude and the latitude of the to-be-verified base station. By the method, automatic verification on a longitude and a latitude of a to-be-verified base station cellis implemented; meanwhile, by the method, the measured and calculated values of the longitude and the latitude of the to-be-verified base station cell can be output so as to facilitate carrying out manual correction on the base station cell with an longitude and latitude abnormality by network optimization personnel. The method adopts a big data processing technology; by regularly executing a background task, the base station cell with the longitude and latitude abnormality is regularly output; and the method provides a front-end base station cell application management function and is convenient for operation and maintenance personnel to carry out abnormal longitude and latitude base station query and abnormal longitude and latitude correction.

Owner:FUJIAN NEWLAND SOFTWARE ENGINEERING CO LTD

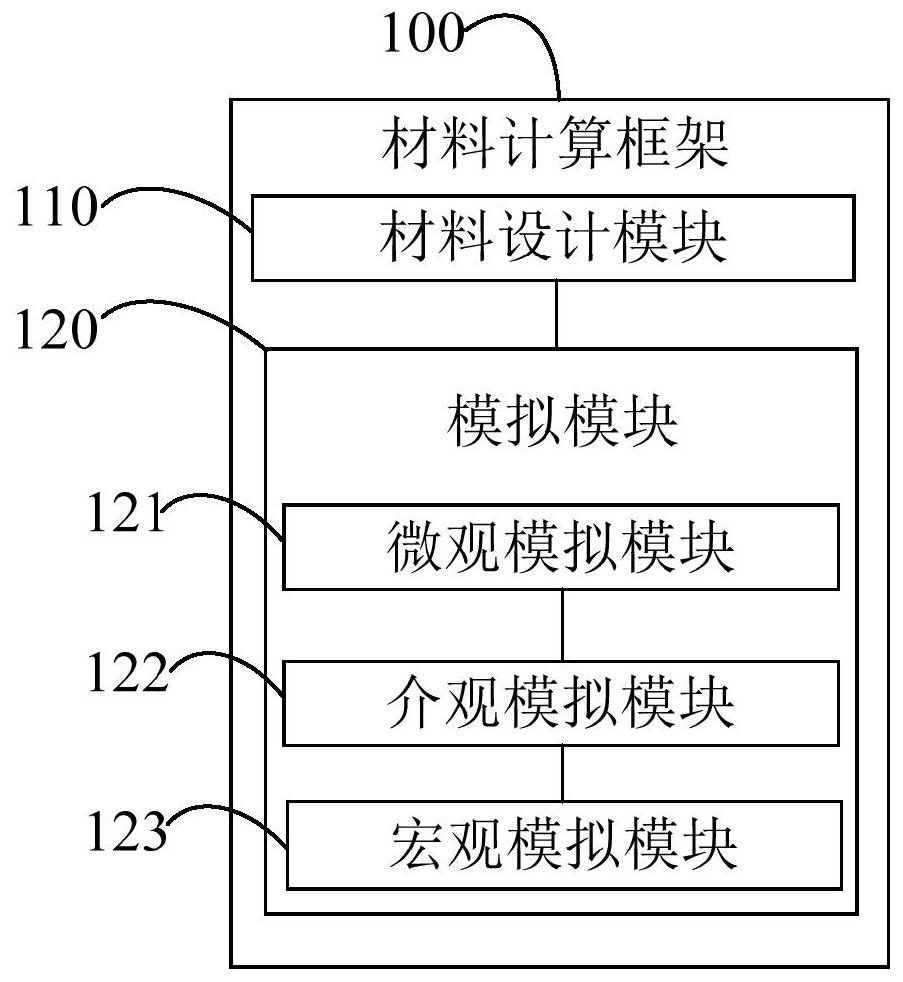

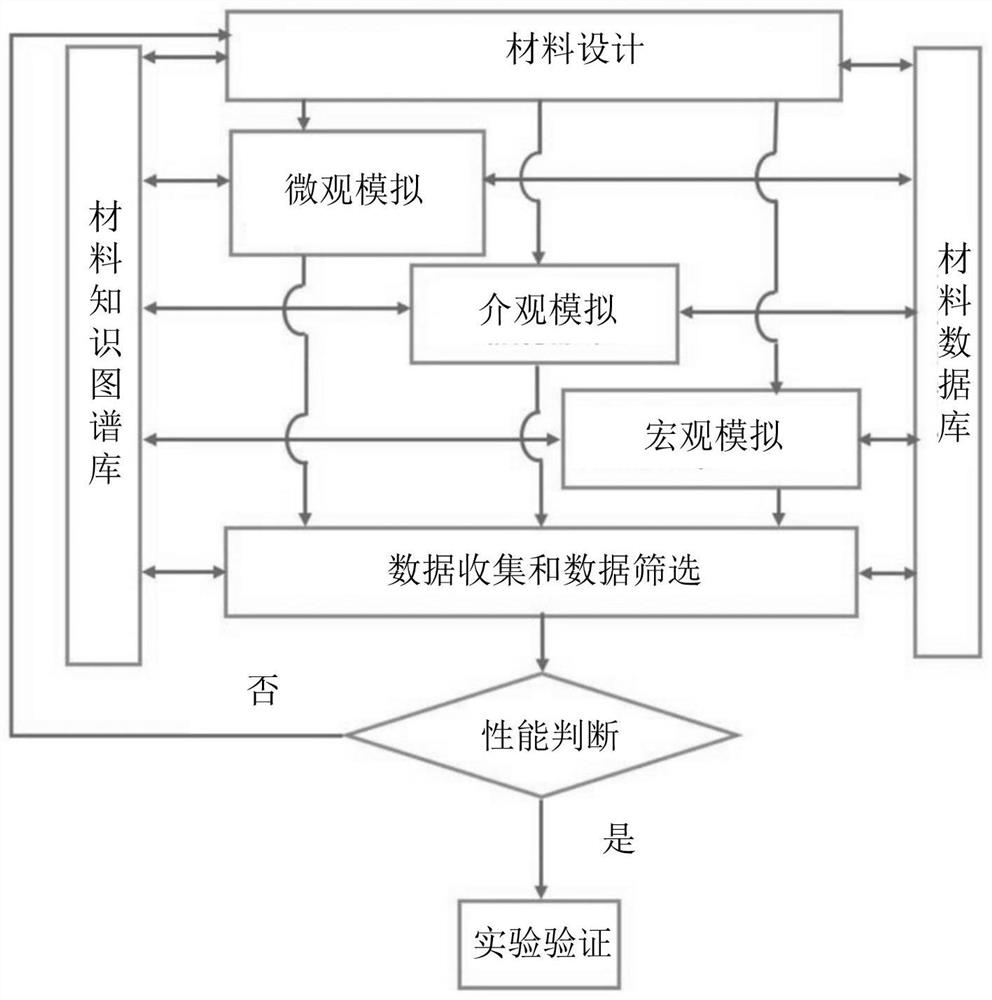

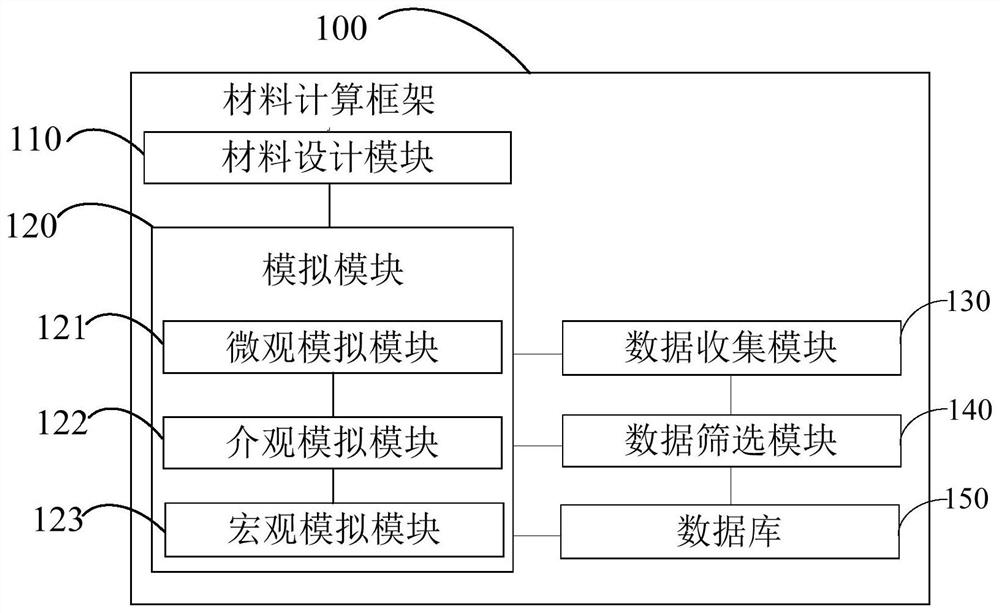

Material computing framework, method and system and computer equipment

PendingCN112685911AShorten the development cycleRealize the whole process automationDesign optimisation/simulationMaterial DesignAnalogue computation

The embodiment of the invention provides a material calculation framework, method and system and computer equipment, and relates to the field of material science. The frame comprises a material design module and a simulation module. The material design module is used for modeling the received target material to obtain a material model; the simulation module comprises a microscopic simulation module, a mesoscopic simulation module and a macroscopic simulation module; the microcosmic simulation module is used for carrying out simulation calculation on the microcosmic performance of the material model to obtain microcosmic performance parameters; the mesoscopic simulation module is used for performing simulation calculation on mesoscopic performance of the material model to obtain mesoscopic performance parameters; and the macroscopic simulation module is used for carrying out simulation calculation on the macroscopic performance of the material model to obtain macroscopic performance parameters. Based on a material calculation framework, material calculation of properties of a target material under different scales is realized, so that the calculation efficiency of material development is improved, and the material development period is effectively shortened.

Owner:HUNAN UNIV

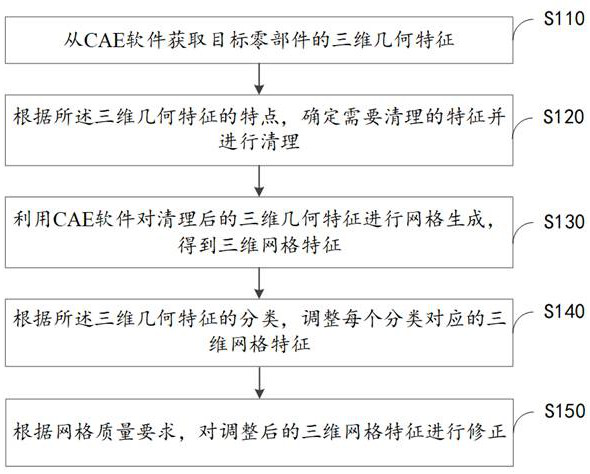

Finite element grid automatic division method and device and storage medium

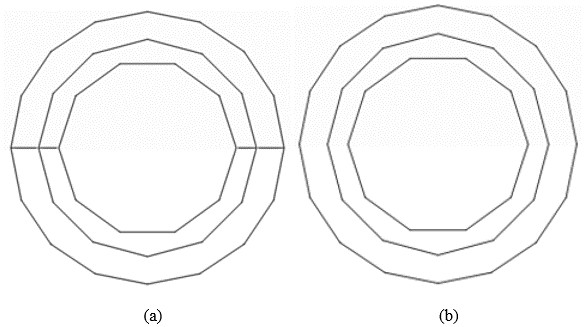

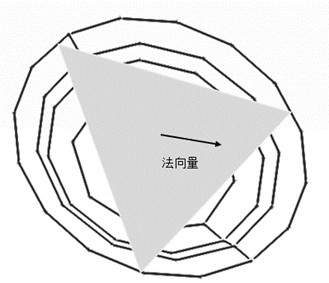

ActiveCN114491824AMeet the requirements of the generatedImprove chemical efficiencyGeometric CADDesign optimisation/simulationComputational scienceAlgorithm

The embodiment of the invention discloses a finite element grid automatic division method and device and a storage medium. The method comprises the following steps: acquiring three-dimensional geometrical characteristics of a target part from CAE software; according to the characteristics of the three-dimensional geometric features, determining features needing to be cleaned and cleaning the features; performing grid generation on the cleaned three-dimensional geometric features by using CAE software to obtain three-dimensional grid features; according to the classification of the three-dimensional geometric features, adjusting the three-dimensional grid features corresponding to each classification; and according to the grid quality requirement, correcting the adjusted three-dimensional grid characteristics. According to the embodiment of the invention, an automatic finite element grid division process is realized, and the grid division efficiency is improved.

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD +1

Clamping base for automatically turning over workpiece during milling

InactiveCN111993130ARealize the whole process automationReduce processing timePositioning apparatusMetal-working holdersUniversal jointElectric machinery

The invention discloses a clamping base for automatically turning over a workpiece during milling. The clamping base comprises a machine body, wherein a power cavity is formed in the lower side of themachine body; a moving cavity is formed in the upper side of the power cavity; a rotating cavity is formed in the upper side of the moving cavity; a supporting cavity is formed in the upper side of the rotating cavity; four shells which are circumferentially distributed are fixedly arranged on the upper side surface of the machine body; clamping cavities are formed in the machine body and each shell; a clamping device for clamping the workpiece is arranged on the lower side of the machine body; the clamping device comprises a main motor which is fixedly installed on the lower side wall of thepower cavity; the main motor is in power connection with a motor shaft; a universal joint is fixedly arranged on the motor shaft; and a turning-over device for turning over the workpiece is arrangedbetween the shells. According to the clamping base, the machining surface of the workpiece in the machining process can be automatically turned over, the machine does not need to be stopped, the workpiece does not need to be manually taken out and fixed, so that the automation of the whole machining process is realized, the machining time can be shortened, the machining efficiency is improved, andthe machining amount is increased.

Owner:台州市天枢机械科技有限公司

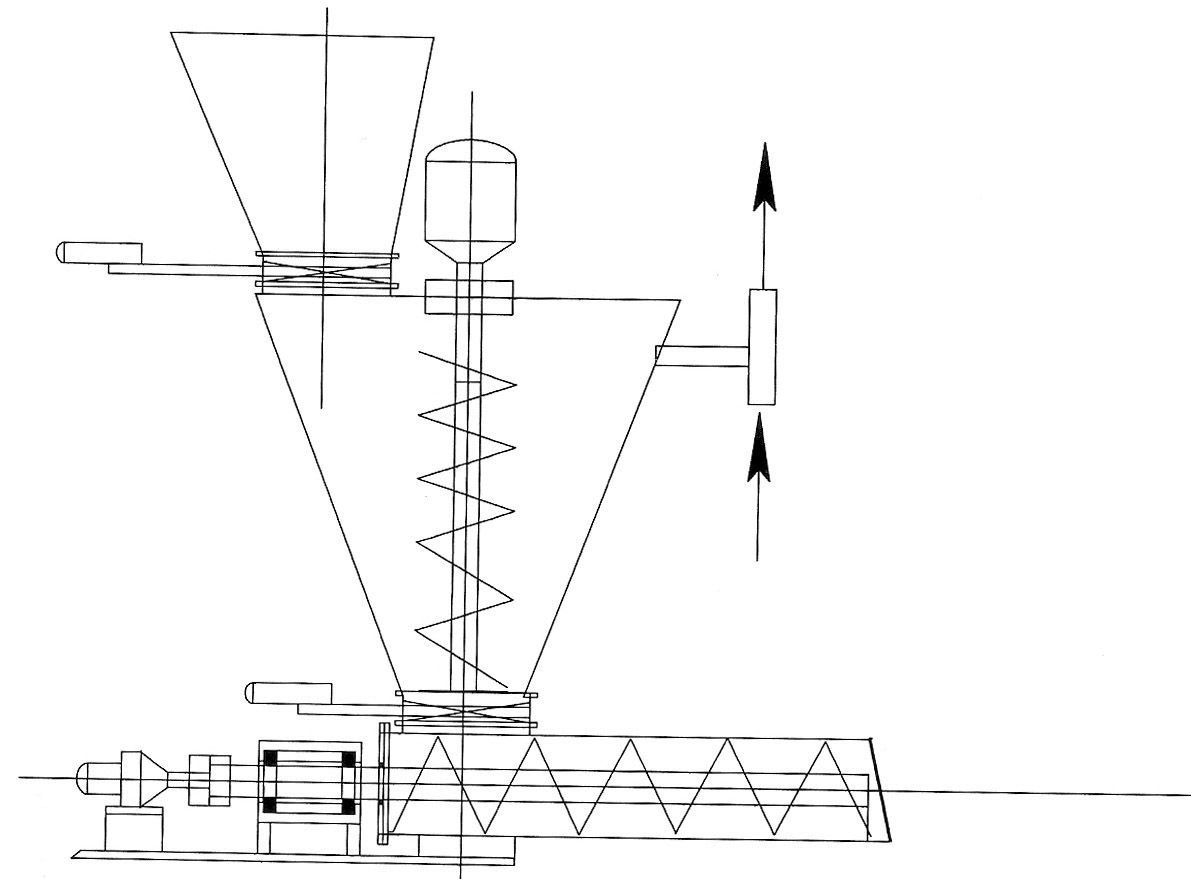

Waste pyrolysis screw feed pump for household garbage and waste tires

InactiveCN102618305AReasonable structureRealize the whole process automationProductsReagentsWaste tiresPyrolysis

The invention discloses a waste pyrolysis screw feed pump for household garbage and waste tires. A first-stage screw feeder is provided with a hopper; a first threaded rod driven by a first motor is arranged in the hopper; the first threaded rod is provided with a first screw blade; the upper end of the hoper is connected with a feed hopper through a feeding hole; the bottom part of the hopper is a discharge hole communicated with a second-stage screw feeder; the inner space of the hopper is an air exchange chamber; the air exchange chamber is communicated with a negative-pressure generator; the feeding hole is provided with an inlet knife-type valve for opening and closing the feeding hole; the discharge hole is provided with an outlet knife-type valve for opening and closing the discharge hole; a second threaded rod driven by a second motor is arranged in a barrel of the second-stage screw feeder; and the second threaded rod is provided with a second threaded rod blade. The waste pyrolysis screw feed pump for the household garbage and the waste tires has the advantages that the structure is reasonable; the feed process is safe and controllable; and the environment cannot be polluted.

Owner:赵旭荣 +1

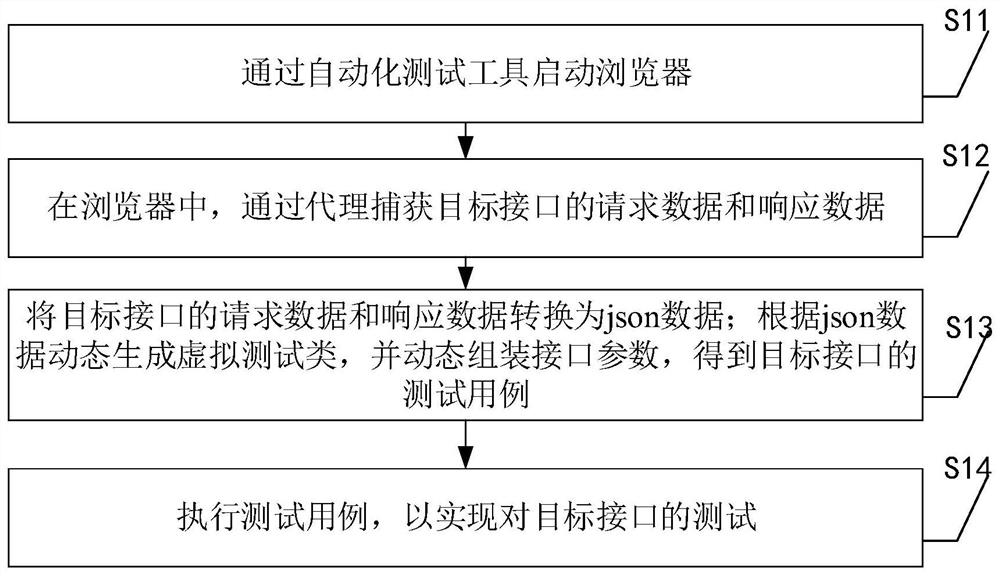

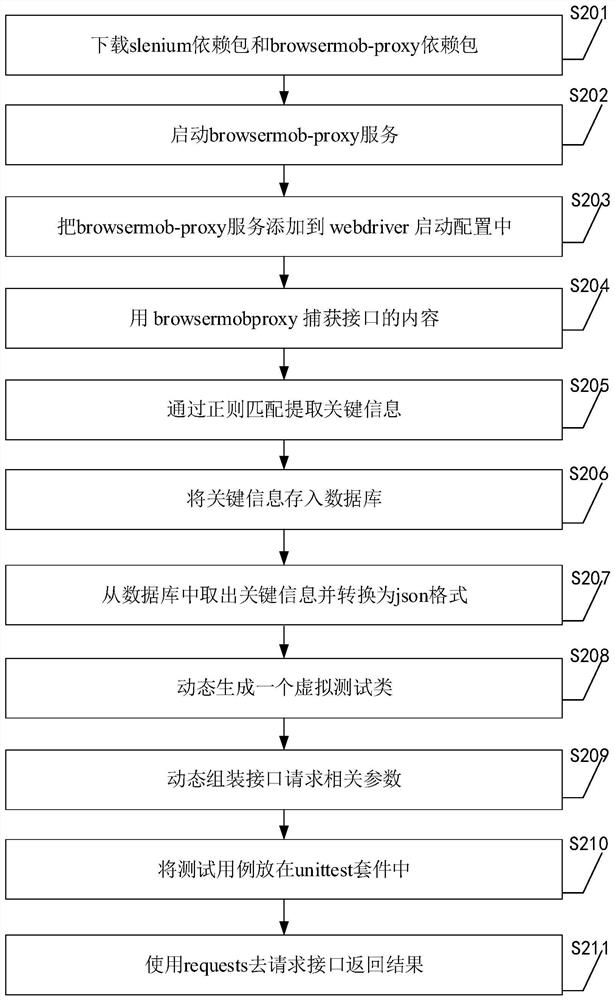

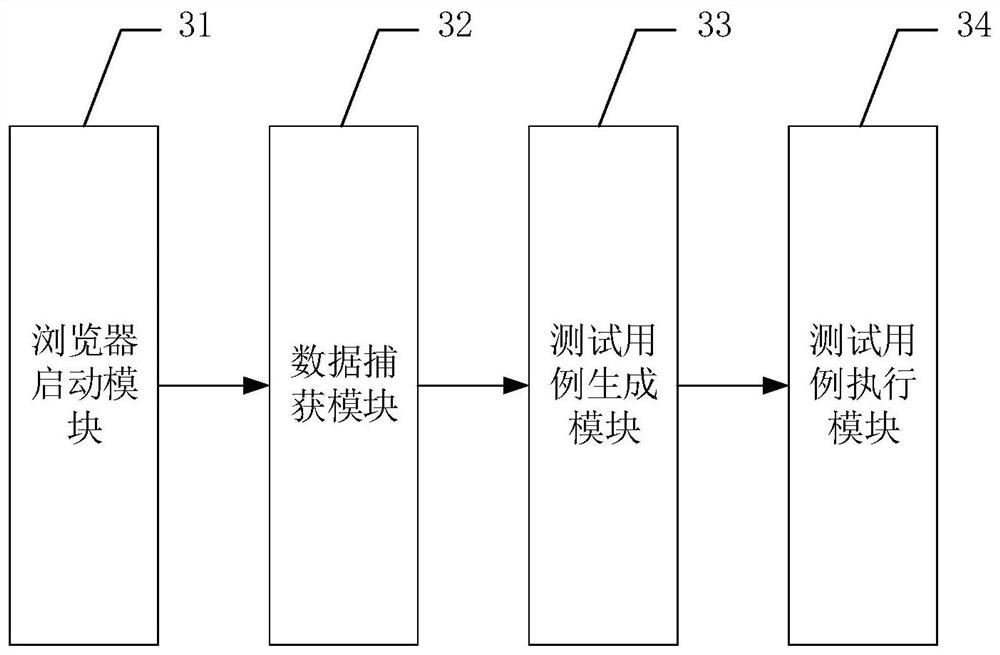

HTTP interface automatic test method and device, equipment and storage medium

PendingCN113505068ARealize the whole process automationSave time and costSoftware testing/debuggingTransmissionData transformationAutomatic testing

The invention discloses an HTTP interface automatic test method. The method includes starting a browser through an automatic test tool; in the browser, capturing request data and response data of the target interface through the proxy; converting the request data and the response data of the target interface into json data; dynamically generating a virtual test class according to the json data, and dynamically assembling interface parameters to obtain a test case of the target interface; and finally executing the test case to test the target interface. Therefore, according to the method, the corresponding parameters of the interface can be automatically obtained, then the test case is automatically generated, the interface test is executed, full-process automation of the interface test is achieved, and a large amount of time cost and labor cost are saved. In addition, the invention further provides an HTTP interface automatic test device and equipment and a readable storage medium, and the technical effects of the HTTP interface automatic testing device and equipment and the readable storage medium correspond to the technical effects of the method.

Owner:杭州遥望网络科技有限公司

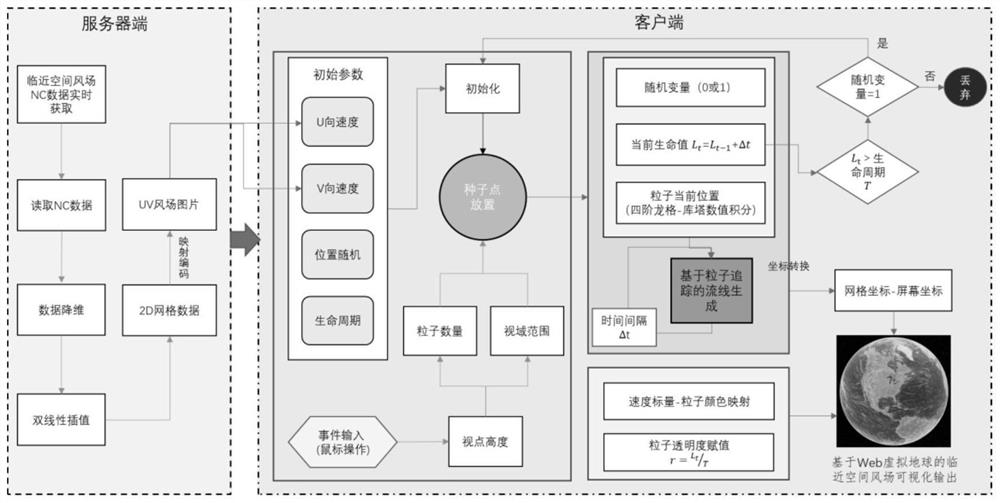

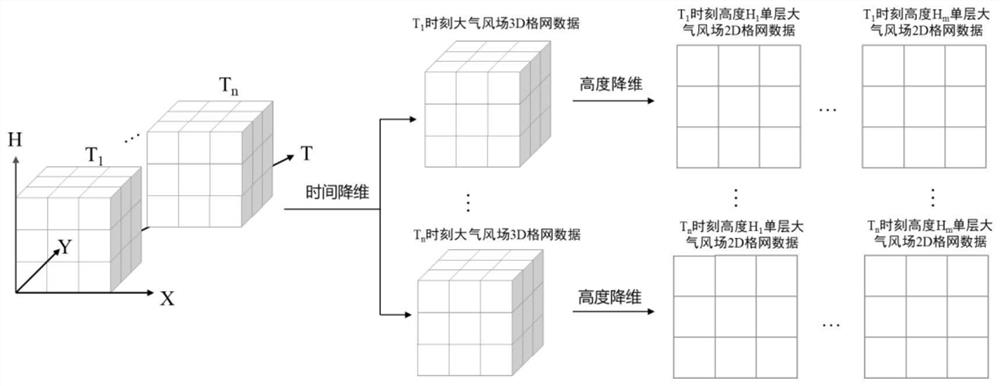

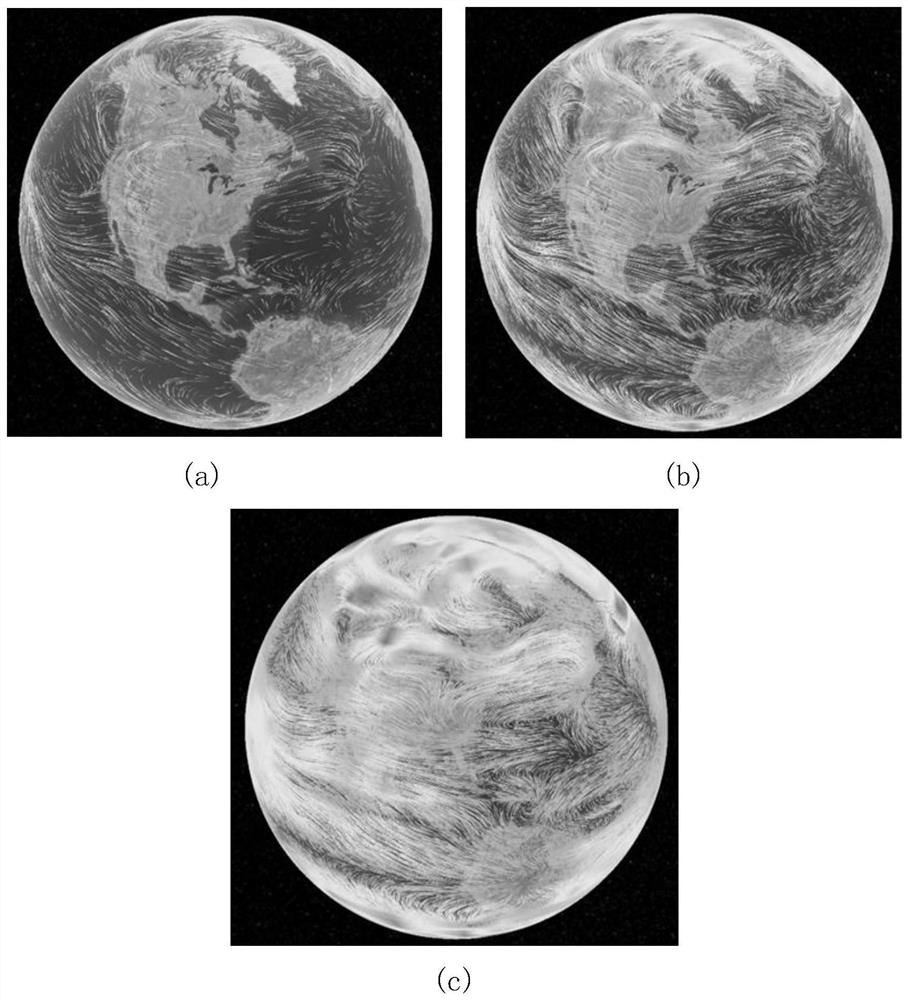

Near space atmospheric wind field real-time adaptive visualization method based on Web

PendingCN112634393ACharacterize local detail featuresRealistic and smooth dynamic visualizationTexturing/coloringGeometric image transformationComputational scienceImage resolution

The invention provides a near space atmospheric wind field real-time adaptive visualization method based on Web. The particle number and the distribution area are adaptively adjusted in real time according to the dynamic change of the vision field range, so that appropriate particle number and density can be obtained at different viewpoint heights and in different vision field ranges; and a streamline with proper density is generated based on a particle tracking method, so that the motion characteristics of the near-space atmospheric wind field of the region are expressed, the overall change trend of the atmospheric wind field can be completely expressed, and the local detail characteristics of the atmospheric wind field can be described more meticulously. And vivid, smooth and dynamic visualization of the atmospheric wind field under different resolutions is realized.

Owner:AEROSPACE INFORMATION RES INST CAS

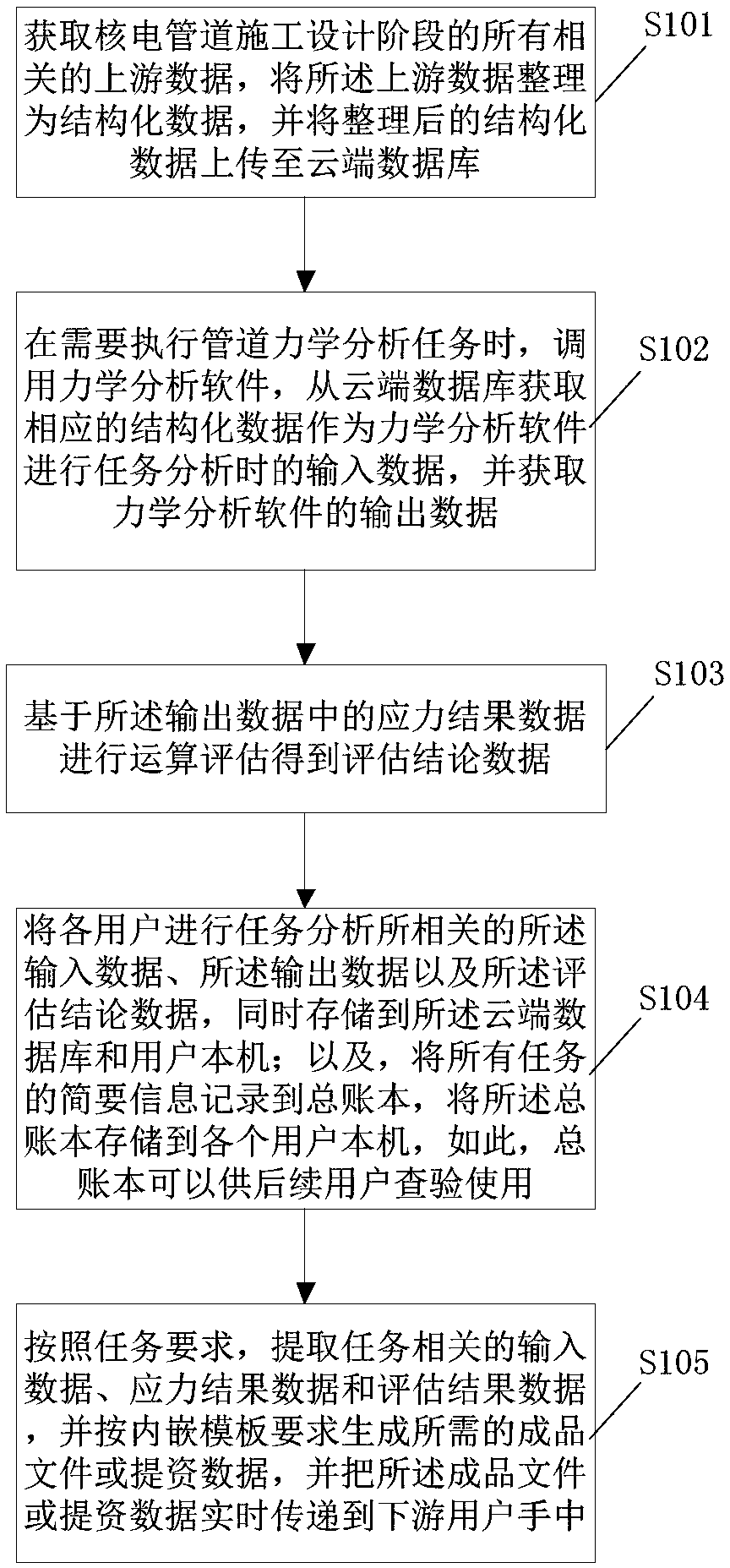

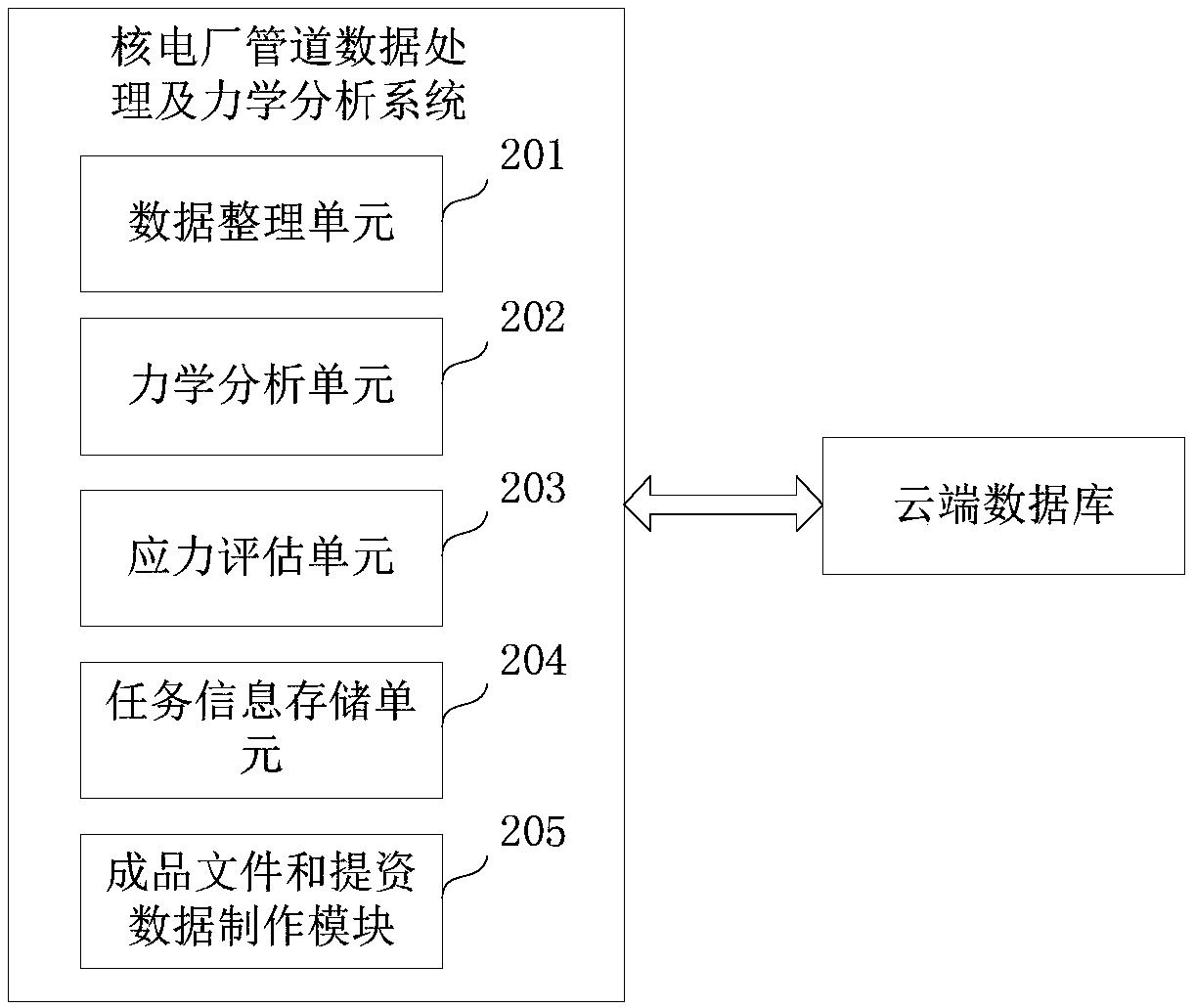

Nuclear power plant pipeline mechanics analysis method and system

ActiveCN109376393ARealize the whole process automationImprove transmission efficiencyDesign optimisation/simulationStructured data retrievalTask analysisNuclear power

The invention discloses a nuclear power plant pipeline mechanics analysis method and system. The method comprises the following steps: obtaining all relevant upstream data of the nuclear power pipeline construction design stage, arranging the upstream data into structured data and uploading the structured data to a cloud database; When the pipeline mechanics analysis task needs to be executed, themechanics analysis software is called to obtain the corresponding structured data from the cloud database as the input data of the mechanics analysis software, and the output data of the mechanics analysis software is also obtained. The evaluation result data is obtained by calculating and evaluating based on the stress result data in the output data. Thus realizing the whole process automation of the nuclear power pipeline mechanics analysis work, the method solves the problem of low efficiency of unstructured data transmission, realizes the transmission, collection and storage of full dataschema in the workflow, solves the tedious and time-consuming problem of manual data processing, and solves the problem that mechanical evaluation relies on manual accounting analysis, which consumesenormous manpower.

Owner:中广核工程有限公司 +2

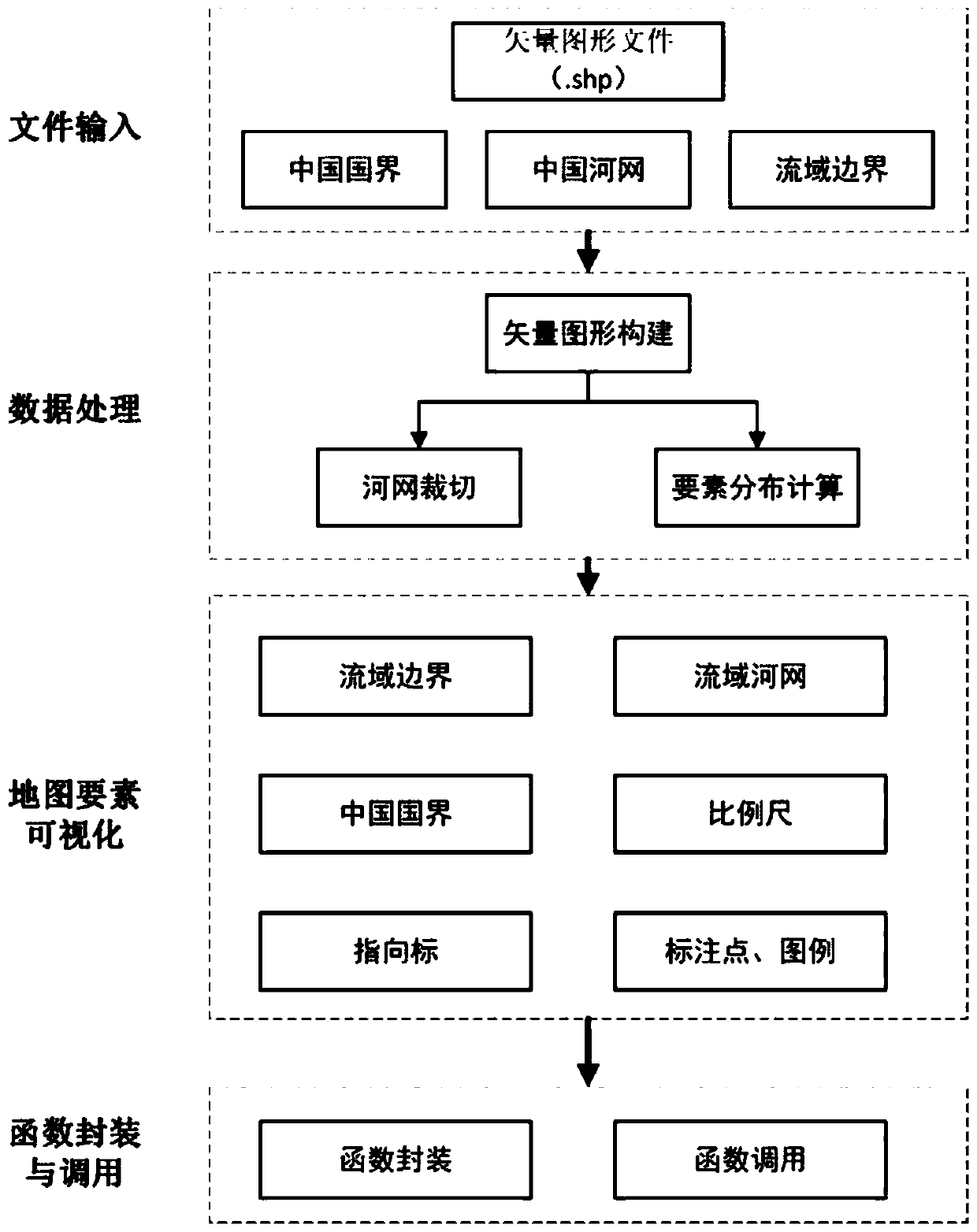

Drainage basin map making method for vector graphic file

ActiveCN111475592AAutomate processingRealize the whole process automationDrawing from basic elementsGeographical information databasesRiver networkComputer graphics (images)

The invention discloses a drainage basin map making method for a vector graphic file, which comprises the following steps of: reading region boundary data in a drainage basin map by taking a vector graphic file required for drawing the drainage basin map as input data; according to the obtained region boundary data, performing spatial analysis on the region boundary data so as to perform river network cutting and drainage basin map element distribution calculation; visualizing the drainage basin map elements, and storing the drawn drainage basin map to a specified path; and packaging the drawing process into class functions, and calling the class functions to draw a basin map. By designing the visualization class function for the vector graphic file, the needed vector graphic file is automatically processed, in the drawing process of the basin map, automatic calculation is conducted, element distribution positions are distributed, manual adjustment is not needed, and therefore full-process automation of basin map drawing is achieved.

Owner:SUN YAT SEN UNIV

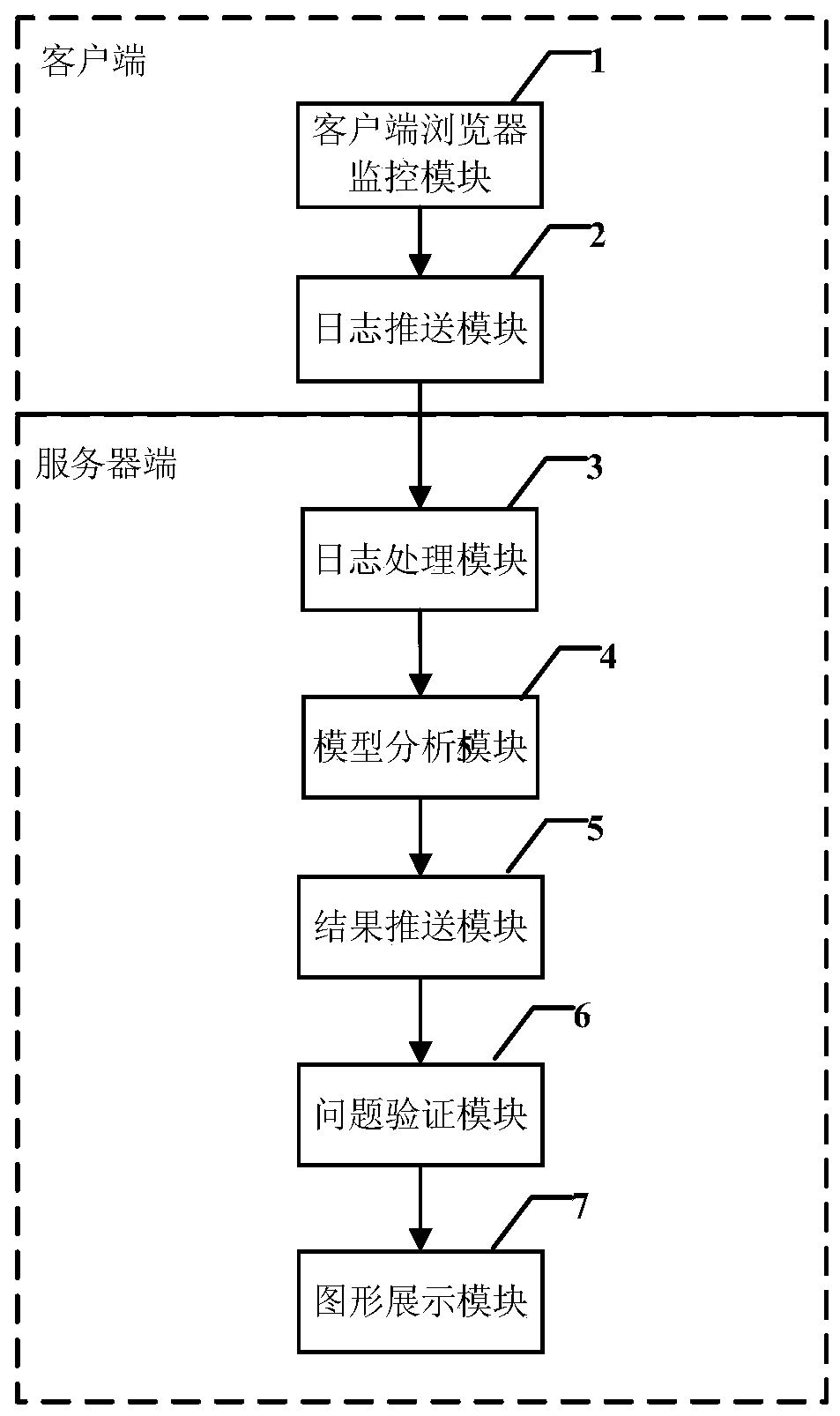

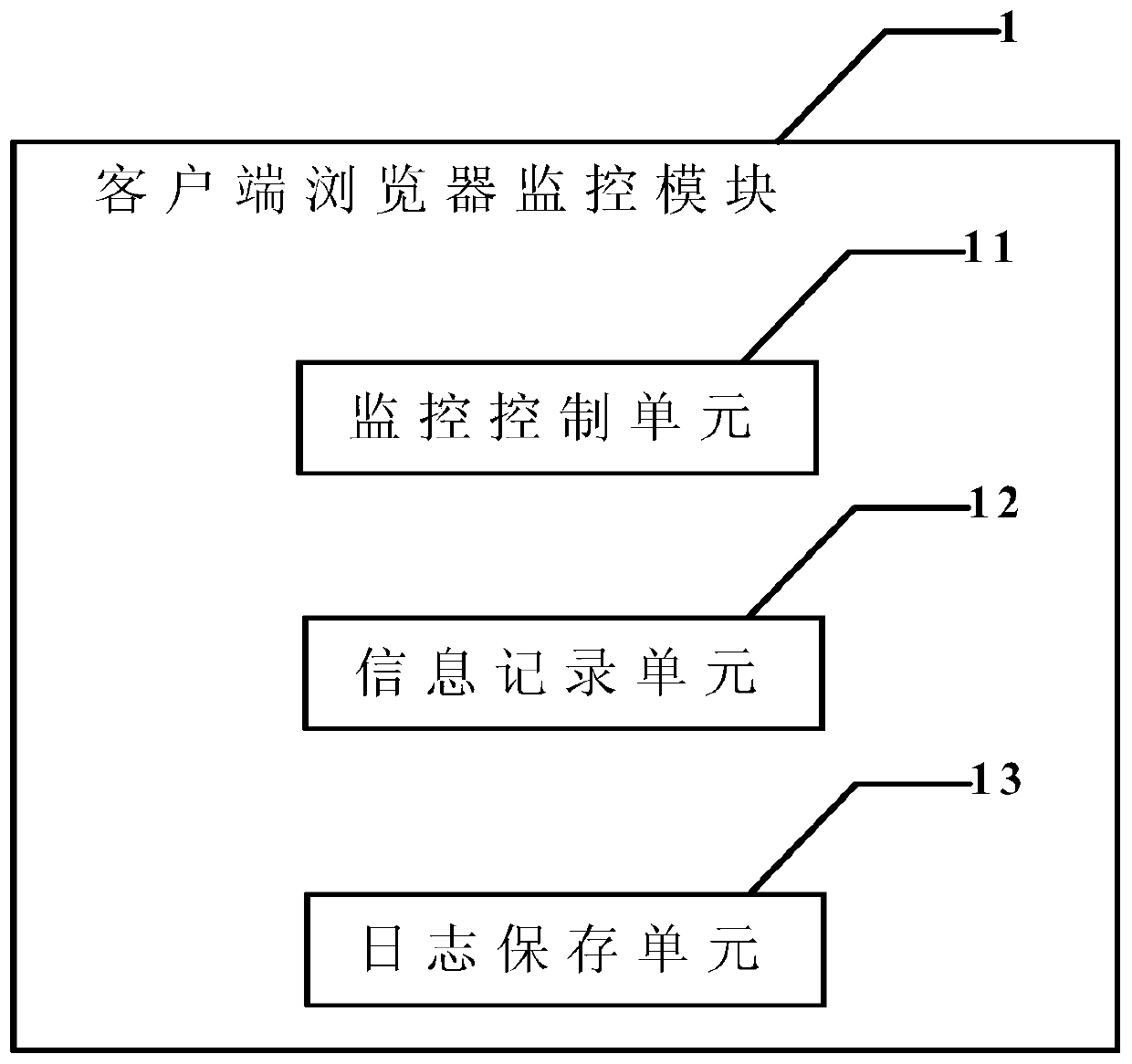

Client performance monitoring device and method based on information interaction

ActiveCN106407078BRealize the whole process automationReduce Performance Monitoring CostsWeb data indexingHardware monitoringModelling analysisResult list

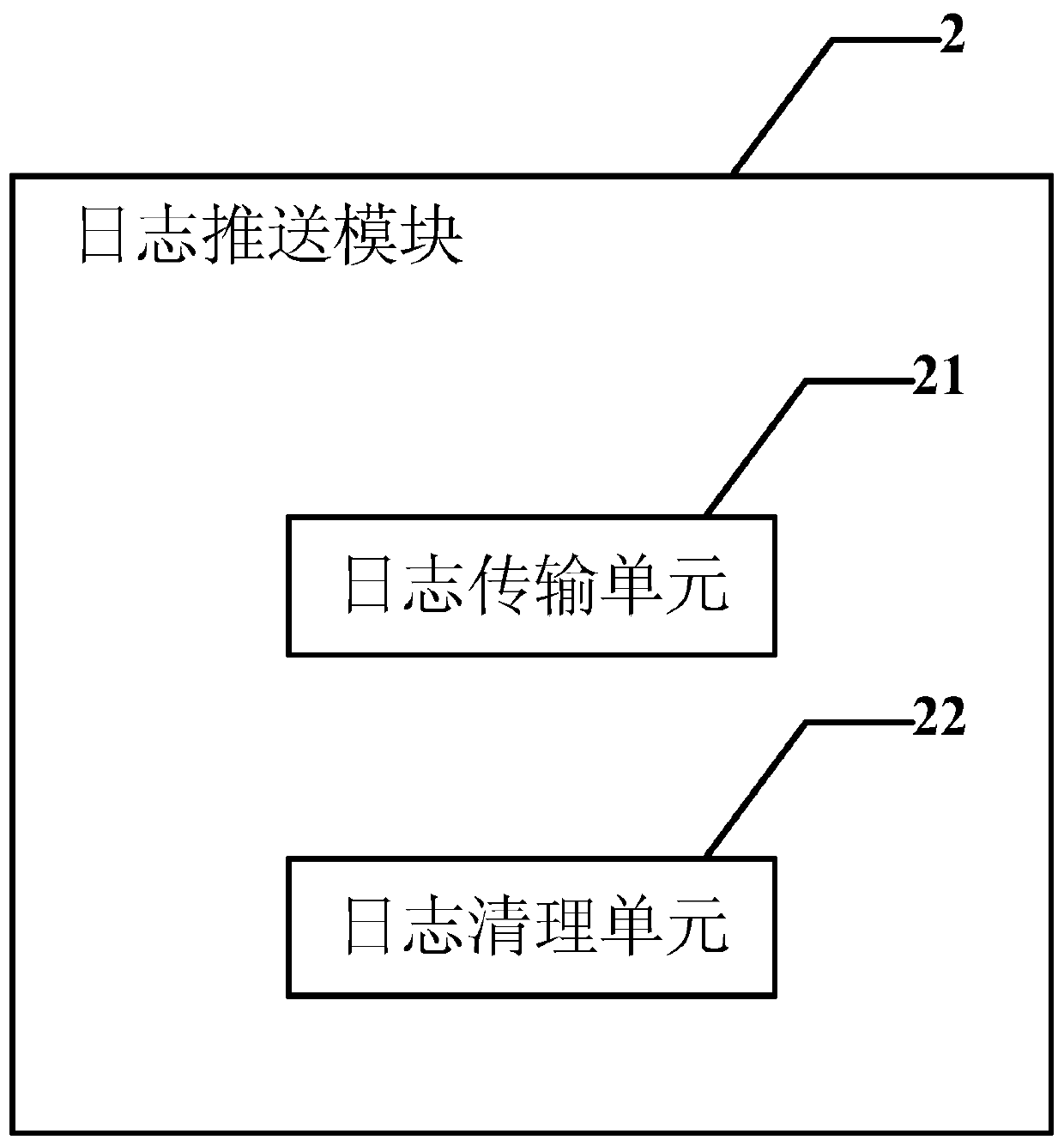

The invention provides an information interaction-based client performance monitoring device and method. The device specifically comprises a client browser monitoring module, a log push module, a log processing module, a model analyzing module and a result push module. The client browser module captures and stores performance logs concerning information interaction on a client browser; the log push module outputs performance logs; the log processing module reads and parses the performance logs and then stores the performance logs; the model analysis module analyzes the parsed performance logs via a preset model to obtain suspicious transaction information in the performance logs, establishes an analysis result list according to the suspicious transaction information and improves the rules and / or threshold values of the preset model by using the machine learning technology according to the analysis result list; the result push module determines suspicious transaction information of the client and test people corresponding to the suspicious transaction information according to the analysis result list of the client and sends the suspicious transaction information to the test people for modification.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Unmanned aerial vehicle automatic cruise method and system

ActiveCN113467519ALower application thresholdRealize the whole process automationPosition/course control in three dimensionsAutomotive engineeringReal-time computing

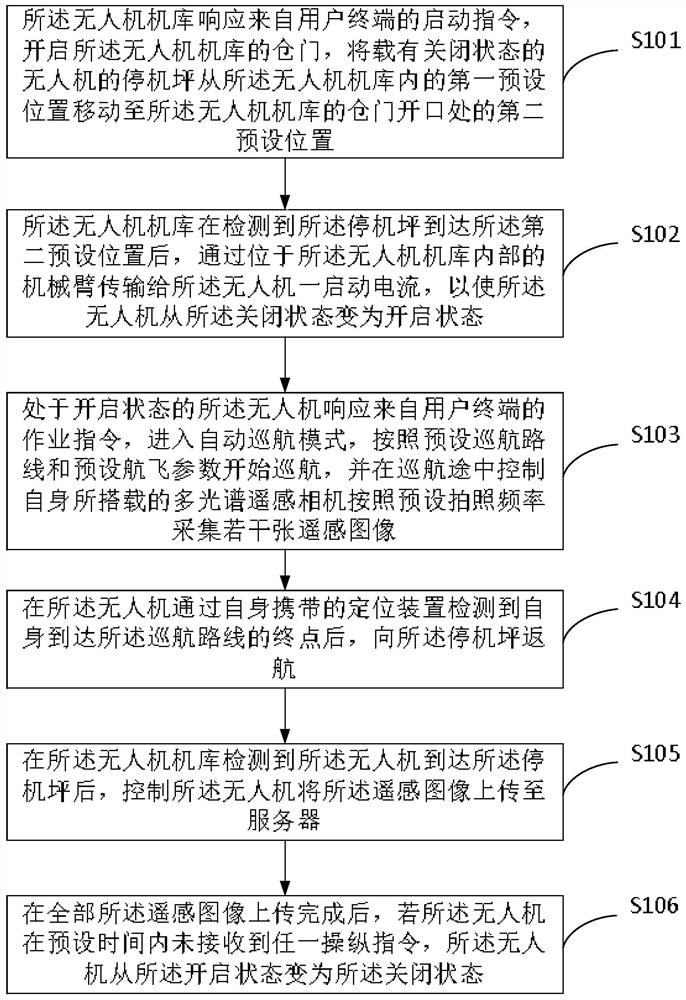

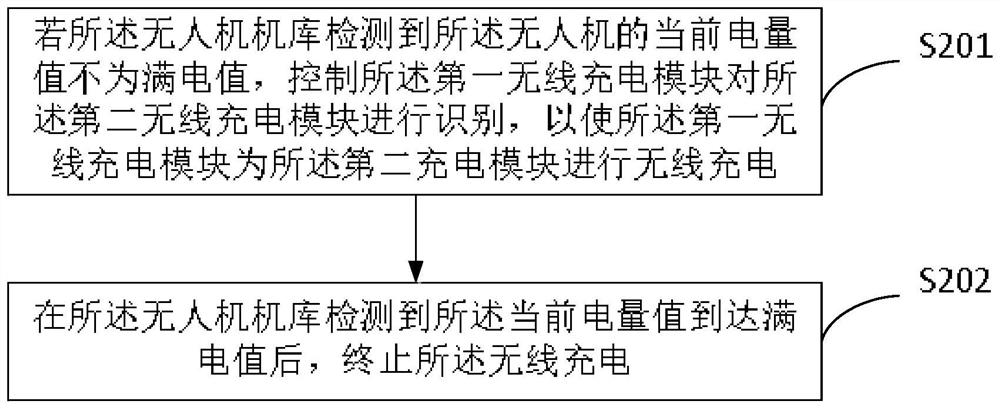

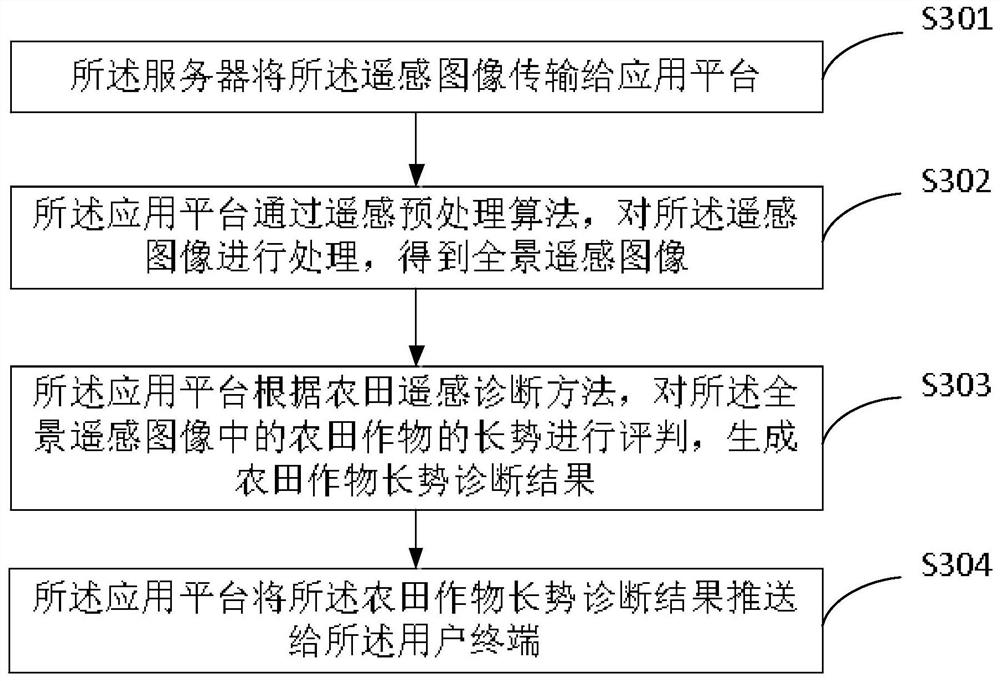

The invention provides an unmanned aerial vehicle automatic cruise method and system, the method is applied to the unmanned aerial vehicle automatic cruise system, the system comprises an unmanned aerial vehicle and an unmanned aerial vehicle hangar, and the method comprises the steps that the unmanned aerial vehicle hangar opens a bin door in response to an instruction of a user terminal; the parking apron carrying the unmanned aerial vehicle in the closed state is moved from a first preset position in the unmanned aerial vehicle hangar to a second preset position at a bin door opening of the unmanned aerial vehicle hangar; a starting current is transmitted to the unmanned aerial vehicle through an internal mechanical arm to enable the unmanned aerial vehicle to be in an open state; the unmanned aerial vehicle responds to an instruction of the user terminal to start cruising and collects a remote sensing image in the cruising process; the unmanned aerial vehicle returns to the parking apron after arriving at the end point of the cruise route; after the parking apron is reached, the remote sensing image is uploaded to a server; and after uploading of the remote sensing image is completed, if any operation instruction is not received within the preset time, the unmanned aerial vehicle is turned into a closed state. According to the invention, full-course automation of flight of the unmanned aerial vehicle can be realized, and the application threshold of remote sensing of the unmanned aerial vehicle is greatly reduced.

Owner:北京爱科农科技有限公司

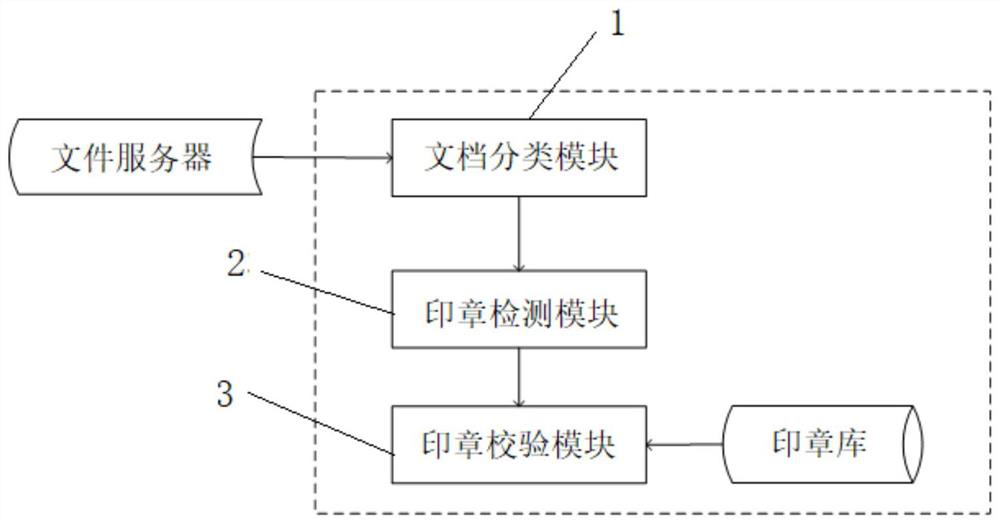

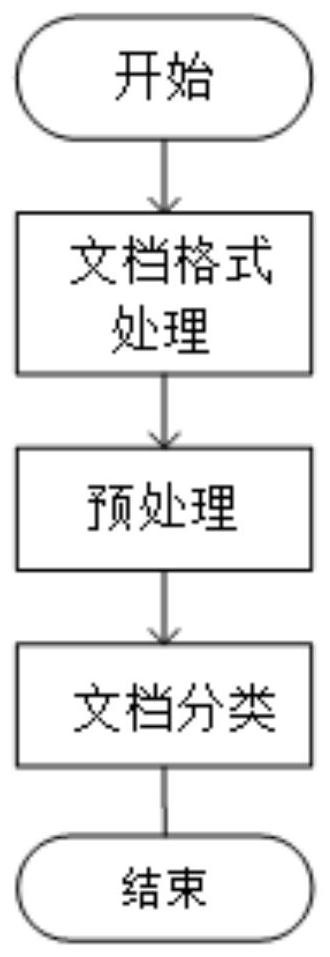

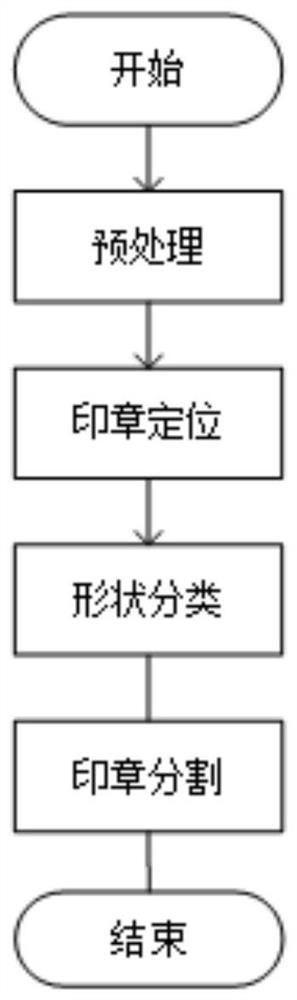

Intelligent seal checking method and system

PendingCN112529513ARealize the whole process automationAvoid human manipulationCharacter and pattern recognitionOffice automationFeature vectorAlgorithm

The invention provides an intelligent seal checking method and system. The system comprises a document classification module, a seal detection module and a seal checking module. The document classification module converts the target documents into pictures in a unified format, and then classifies the pictures after processing the pictures; the stamp detection module further processes the classified pictures, identifies stamps in the pictures, locates the positions of the stamps in the pictures, and divides the stamps in the pictures into a plurality of stamp pictures according to the positionsof the stamps; the seal verification module extracts feature vectors of the plurality of seal pictures, compares the feature vectors with feature vectors reserved in a seal library and then calculates a feature distance between the feature vectors; if the feature distance is smaller than a threshold value, a reserved seal ID is extracted; according to the invention, the seal in the document is subjected to operations of automatic detection and legality verification, so that the full-flow automatic processing of the paper document is realized, the mechanical manual operation is avoided, and the flow and efficiency of the application scenarios are optimized and perfected to the greatest extent.

Owner:深圳市赢时胜信息技术股份有限公司

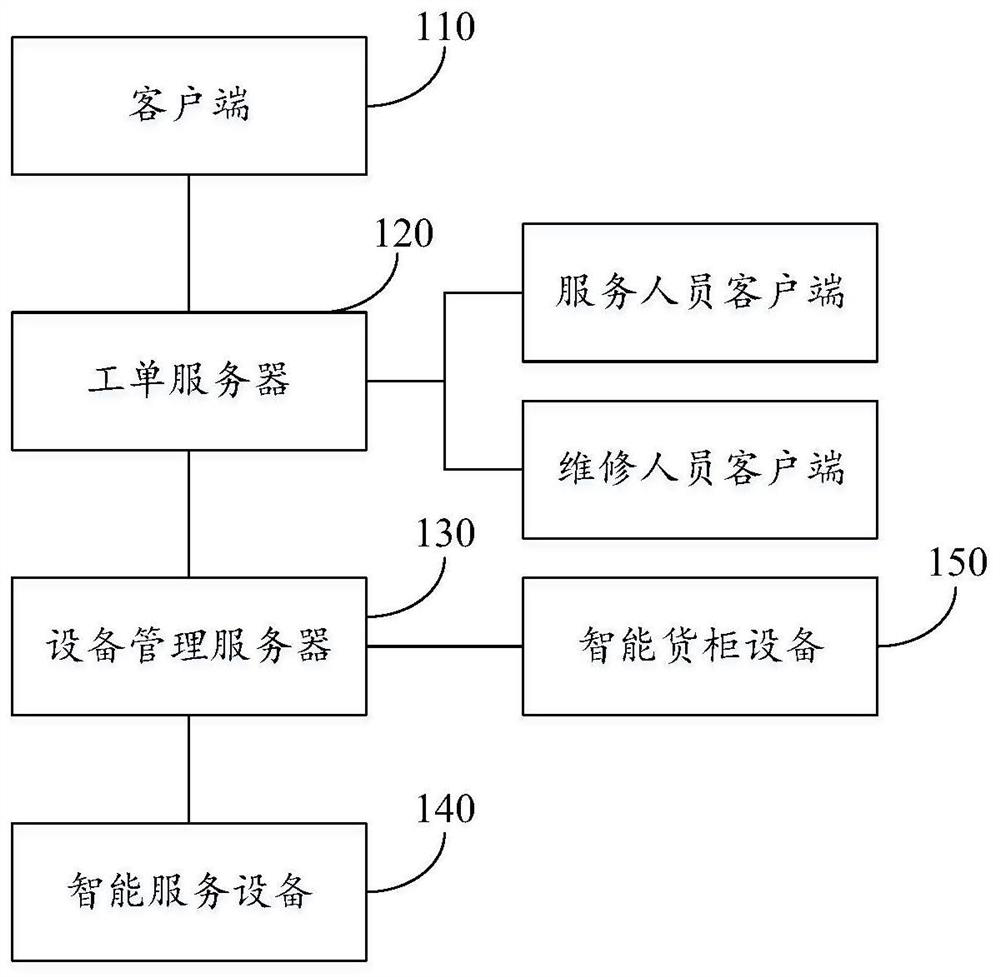

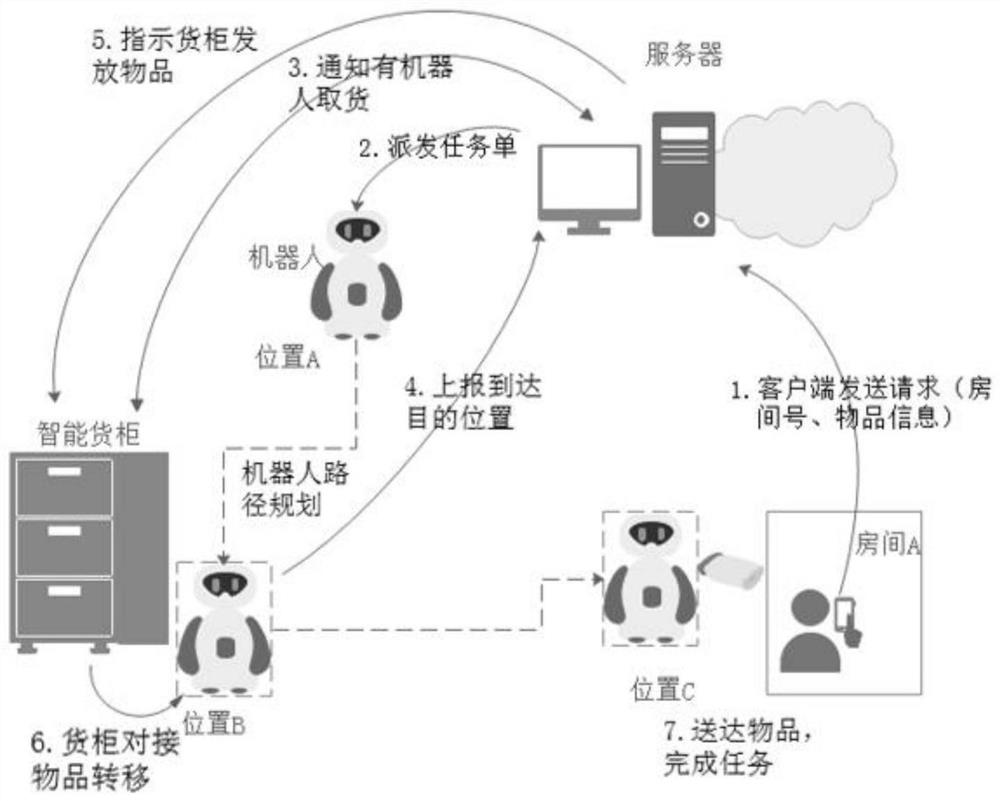

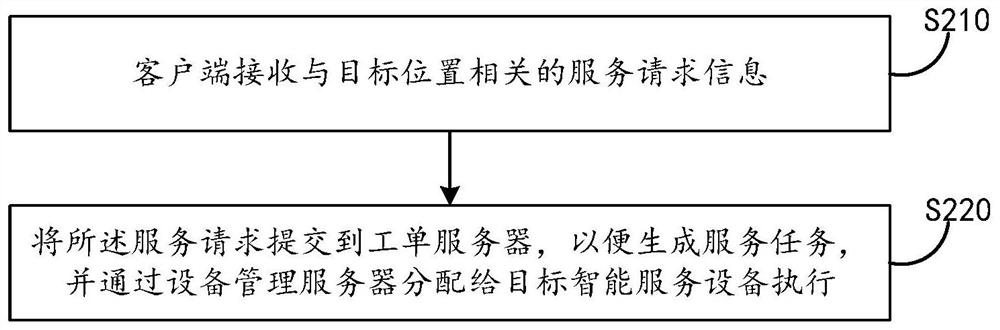

Service method, device and system

PendingCN112488882AFully automatedReduce manual interventionData processing applicationsElevatorsComputer networkEngineering

The embodiment of the invention discloses a service method, device and system, and the system comprises a client which is used for submitting service request information related to a target position in a service place; a work order server which is used for generating a service task according to the request information and sending task information to the equipment management server; an equipment management server which is used for determining target intelligent service equipment according to the task information and the information of the intelligent service equipment and sending the task information to the target intelligent service equipment; and the intelligent service equipment which is used for executing the task according to the received task information. According to the embodiment of the invention, the automation of the service process can be realized, and the manual intervention link is reduced.

Owner:ALIBABA GRP HLDG LTD

Filter tip rod feeding clamp

PendingCN114030883ARealize the whole process automationArticle unpackingConveyor partsClassical mechanicsCarton

The invention relates to a filter tip rod feeding clamp which comprises a frame, wherein two clamping plates are installed on the frame, the clamping plates are oppositely arranged in a left-right mode, and the clamping plates can move left and right in a reciprocating mode in the direction close to or away from each other; a material blocking plate which is installed on the frame and is located between the clamping plates; an edge opening suction cup which is installed on the frame, wherein the edge opening suction cup can move back and forth in the direction close to / away from the frame in a reciprocating mode; an edge pressing push rod which is mounted on the frame, wherein the edge pressing push rod can move back and forth in the oblique direction of the frame in the direction close to / away from the frame; and a feeding suction cup installed on the frame. A mechanical arm is matched with the clamp, manual operation can be completely replaced, grabbing, clamping and holding and side edge opening treatment of a carton cover with a filter tip rod and grabbing work of an empty carton are achieved, and therefore the full-process automation of a core process is achieved.

Owner:HUBEI CHINA TOBACCO IND

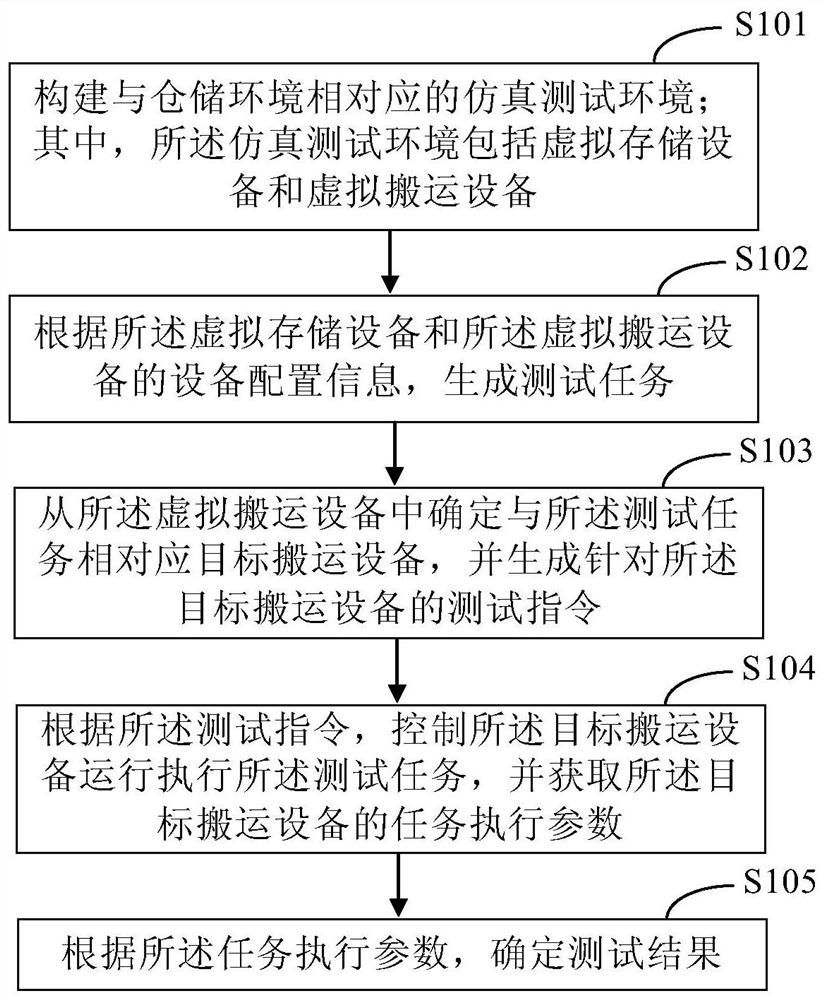

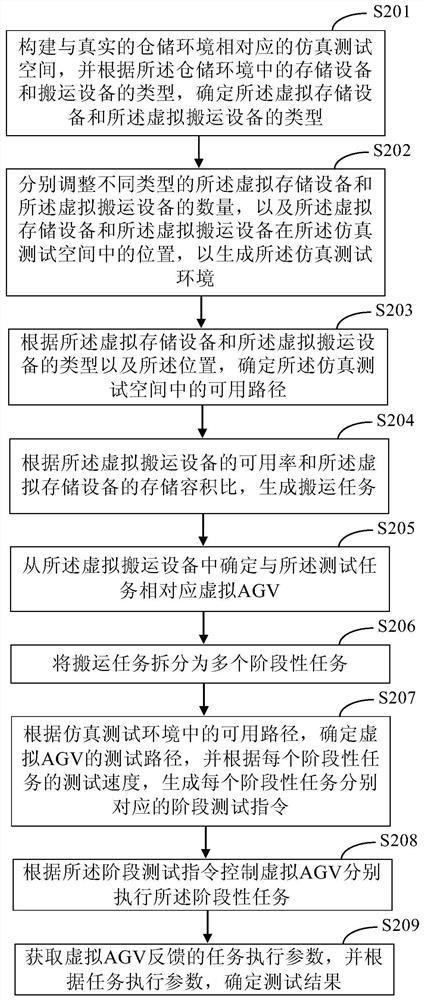

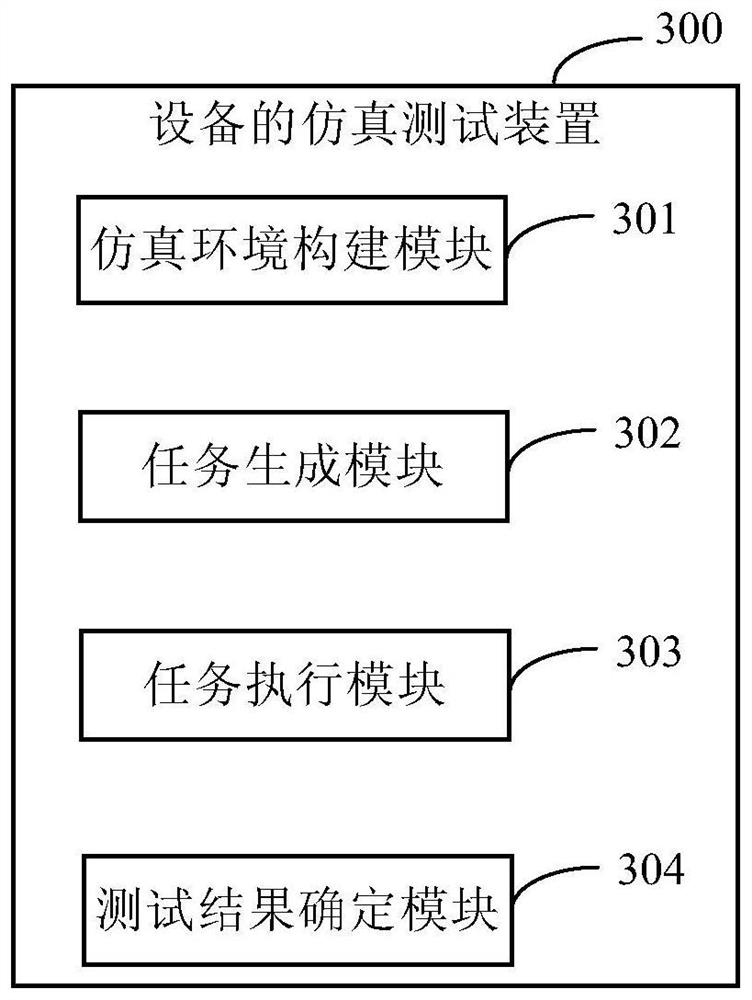

Simulation test method and device for equipment

PendingCN112486033ARealize the whole process automationReduce testing costsSimulator controlTest efficiencyLogistics management

The invention discloses a simulation test method and device for equipment, and relates to the technical field of warehouse logistics. A specific embodiment of the method comprises the following steps:constructing a simulation test environment corresponding to a storage environment, wherein the simulation test environment comprises virtual storage equipment and virtual carrying equipment; generating a test task according to the equipment configuration information of the virtual storage equipment and the virtual carrying equipment; determining target carrying equipment corresponding to the testtask from the virtual carrying equipment, and generating a test instruction for the target carrying equipment; according to the test instruction, controlling the target carrying equipment to executethe test task, and obtaining task execution parameters of the target carrying equipment; and determining a test result according to the task execution parameters. According to the embodiment, the testcost is reduced, the test period is shortened, and the test efficiency is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

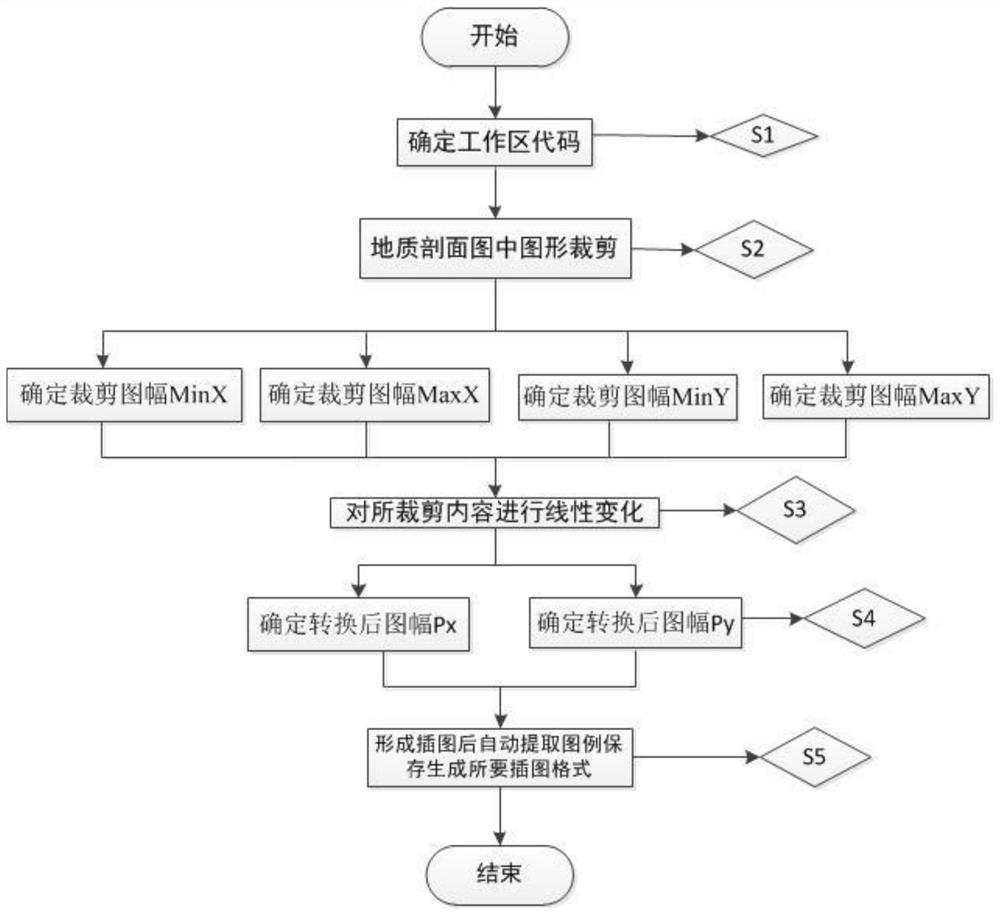

Sandstone type uranium deposit geological illustration mapping method

PendingCN114187386AImprove work efficiencyImprove mapping accuracyEditing/combining figures or textGeological sectionMining engineering

The invention belongs to the technical field of uranium mine digital exploration, and particularly relates to a sandstone type uranium mine geological illustration mapping method, which comprises the following steps of: 1, setting a ten-digit code of a working area; 2, on the geological profile map, rectangular sheet cutting is carried out; 3, linearly changing the rectangular cut content of the sheet in the geological profile map; and 4, carrying out automatic legend extraction on the cut sheet subjected to linear transformation by using digital uranium mine software. By utilizing the method, the automation and intelligentization of the whole process are realized, the working efficiency and the mapping precision are effectively improved, and a foundation is laid for newly calculating the resource reserves after the sample section of the resource reserve ore body engineering is changed.

Owner:核工业二一六大队

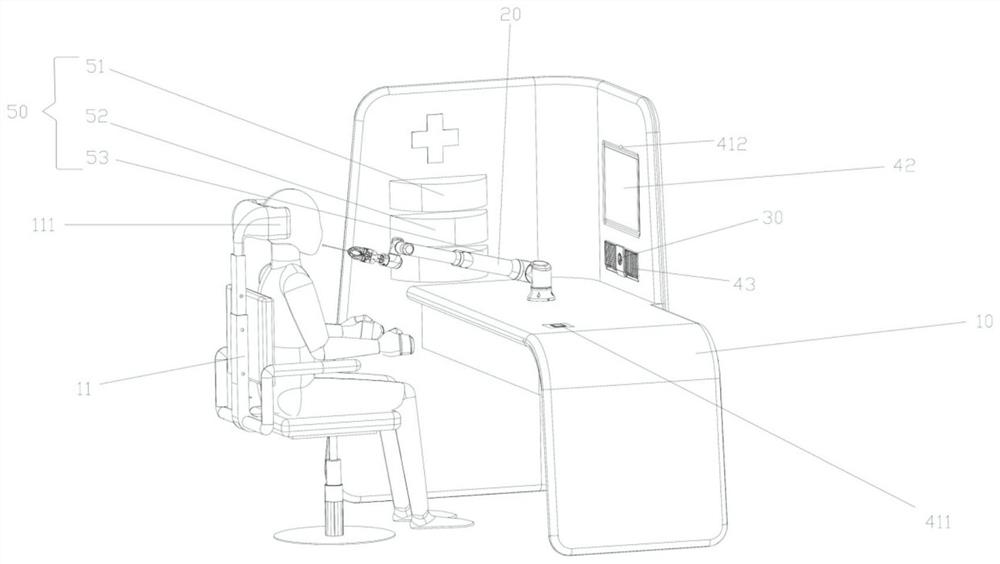

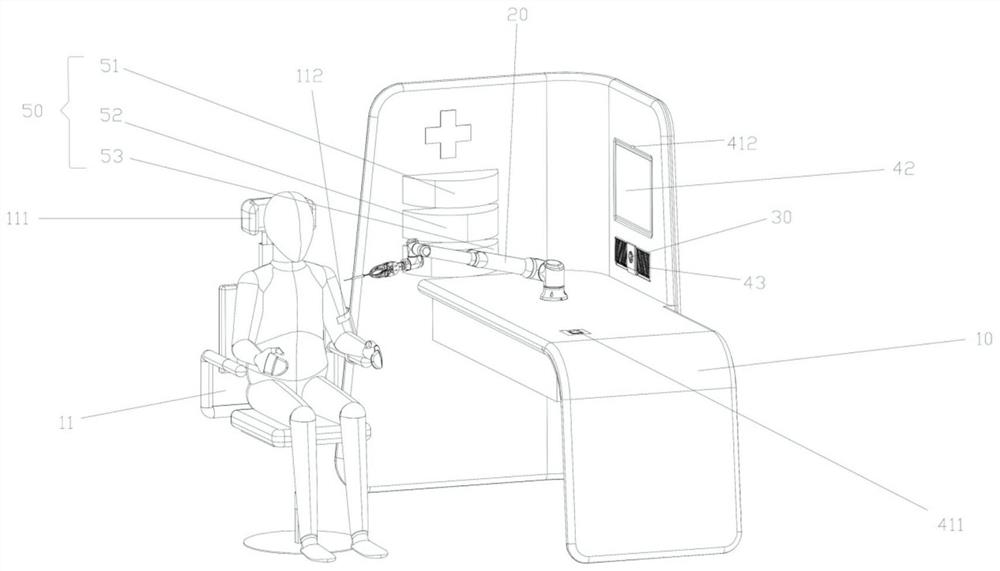

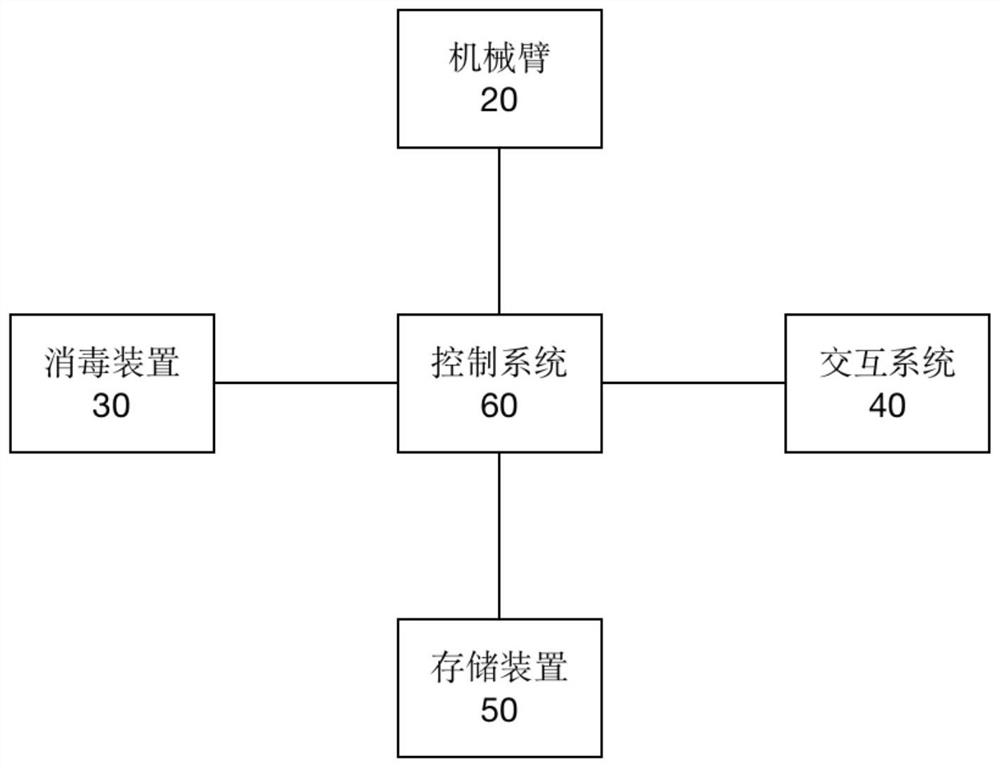

Nucleic acid collection and vaccination integrated device and method

PendingCN113425332AReduce the chance of infectionReduce workloadSurgical furnitureAutomatic syringesVaccinationControl system

The invention provides a nucleic acid collection and vaccination integrated device. Th integrated device comprises an operation table, a mechanical arm, a disinfection device, an interaction system, a storage device and a control system, the operation table comprises a seat, the seat comprises a head fixing device and an arm fixing device, the mechanical arm is installed on the operation table, and according to the control of the control system, nucleic acid collection and vaccination are carried out. The integrated device realizes full-process automatic nucleic acid collection and automatic vaccination, and reduces the probability of virus infection in the nucleic acid collection and vaccine injection process of medical personnel.

Owner:尹丰 +1

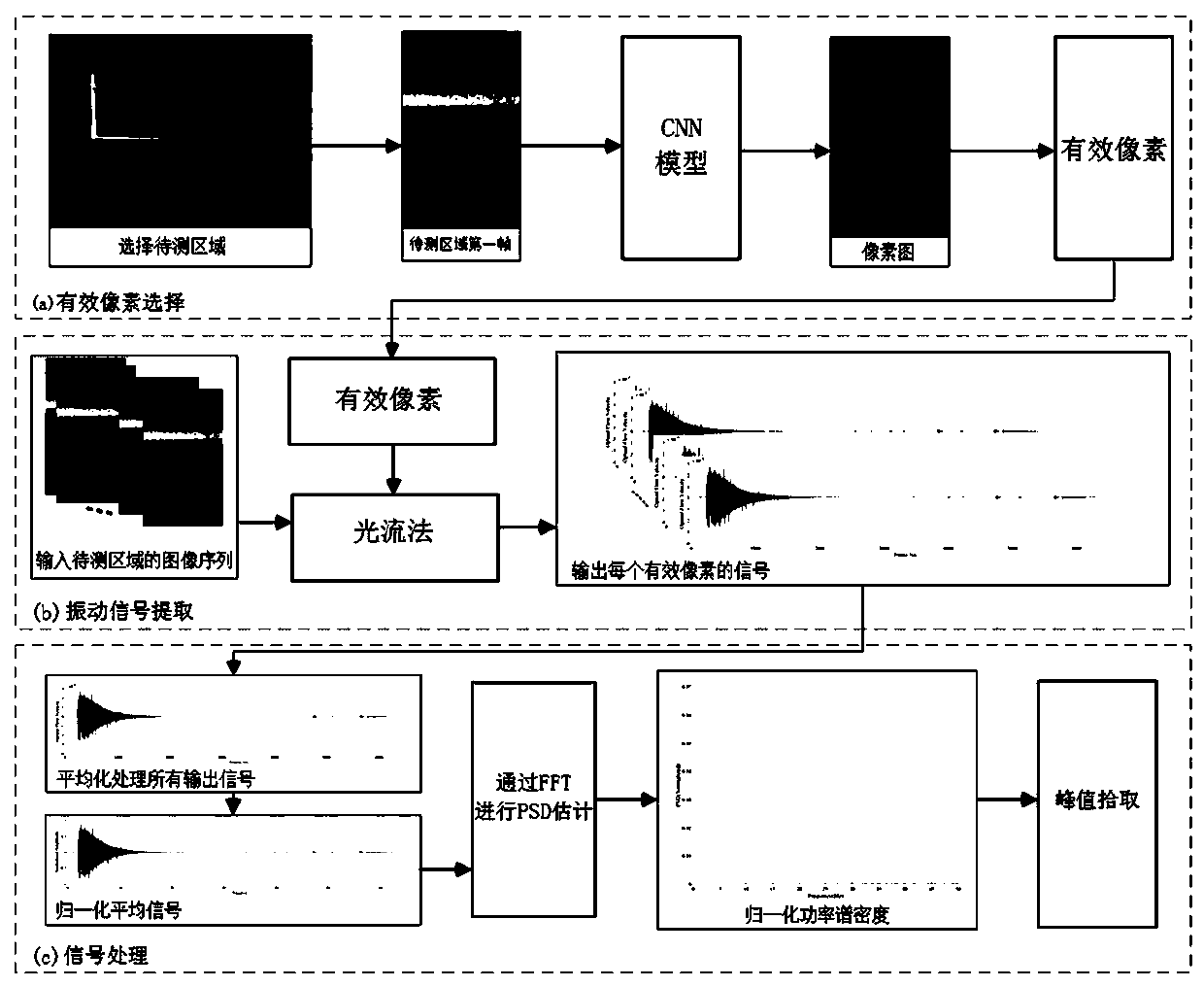

Non-contact vibration frequency measurement method based on deep learning and image processing

ActiveCN111275744ARealize the whole process automationAchieve targetless non-contact vibration frequency measurementImage enhancementImage analysisSpectral density estimationImaging processing

The invention relates to a non-contact vibration frequency measurement method based on deep learning and image processing. The method comprises the following steps: 1) selecting a to-be-measured areaof a measured object and extracting an image sequence of the to-be-measured area; 2) inputting a first frame of the image sequence into a deep convolutional neural network, and dividing all pixels inthe image into zero-value pixels and non-zero pixels; 3) selecting all non-zero pixels as effective pixels, and storing the coordinates of the non-zero pixels in a list for vibration signal extraction; 4) for each image in the image sequence, converting the image into a brightness signal by adopting an optical flow method, and then extracting a speed signal time history of each effective pixel; 5)averaging and normalizing the speed signal time history of all effective pixels; and 6) performing power spectral density estimation through Fourier transform to obtain power spectral density, and obtaining frequency composition through a peak value pickup method to obtain a non-contact vibration frequency measurement result. The method is beneficial to improving the efficiency and accuracy of non-contact vibration frequency measurement.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com